Top 9 Phone Cases Made In Usa List and Guide: How To Solve Scenar…

Introduction: Navigating the Global Market for phone cases made in usa

Navigating the global market for phone cases made in the USA presents a unique challenge for international B2B buyers. As demand for high-quality, durable, and environmentally friendly products rises, sourcing these phone cases can be daunting, especially when considering the nuances of quality, pricing, and supplier reliability. This comprehensive guide delves into various types of phone cases, including biodegradable options, premium leather, and handcrafted designs, ensuring that buyers can find products that align with their business needs and sustainability goals.

Throughout this guide, we will address essential aspects of the procurement process, including supplier vetting, cost analysis, and market trends specific to different regions such as Africa, South America, the Middle East, and Europe, including key markets like Germany and Nigeria. By offering insights into the manufacturing standards, environmental impacts, and customization possibilities, this resource empowers international B2B buyers to make informed purchasing decisions.

With a focus on the benefits of sourcing phone cases made in the USA—such as reduced carbon emissions, support for local economies, and superior quality—this guide is designed to enhance your sourcing strategy. Whether you are looking for bulk purchases or unique, personalized items for corporate gifts, understanding the landscape of American-made phone cases will provide the competitive edge necessary to thrive in today’s diverse marketplace.

Top 10 Phone Cases Made In Usa Manufacturers & Suppliers List

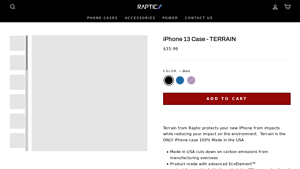

1. Raptic – Terrain iPhone 13 Case

Domain: rapticstrong.com

Registered: 2020 (5 years)

Introduction: Raptic Terrain iPhone 13 Case – Made in the USA, 100% biodegradable materials, 10 foot drop protection, lifetime warranty. Available colors: Black ($35.99), Blue ($35.99), Purple (Sold Out). Terrain protects your iPhone while reducing environmental impact, supporting local jobs, and eliminating carbon emissions from international transportation.

2. TORRO USA – Premium Leather Phone Cases

Domain: torrousa.com

Registered: 2019 (6 years)

Introduction: Phone Cases – Premium US Leather – TORRO USA

Available Models:

– Apple iPhone 17 Series

– iPhone 16 Pro Max

– iPhone 16 Pro

– iPhone 16 Plus

– iPhone 16

– iPhone 16e

– iPhone 15 Pro Max

– iPhone 15 Pro

– iPhone 15 Plus

– iPhone 15

– iPhone 14 Pro Max

– iPhone 14 Pro

– iPhone 14 Plus

– iPhone 14

– iPhone 13 Pro Max

– iPhone 13 Pro

– iPhone 13

– iPhone 13 Mini

– iPhone 12 Pro Max

– iPhone 12 Pro

– …

3. Carved – Live Edge Wood Phone Cases

Domain: carved.com

Registered: 1999 (26 years)

Introduction: Live edge wood phone cases, handcrafted from natural wood, unique designs, compatible with various phone models, offers protection and style, eco-friendly materials.

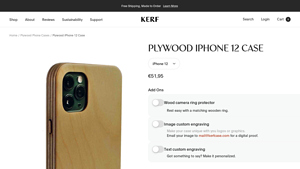

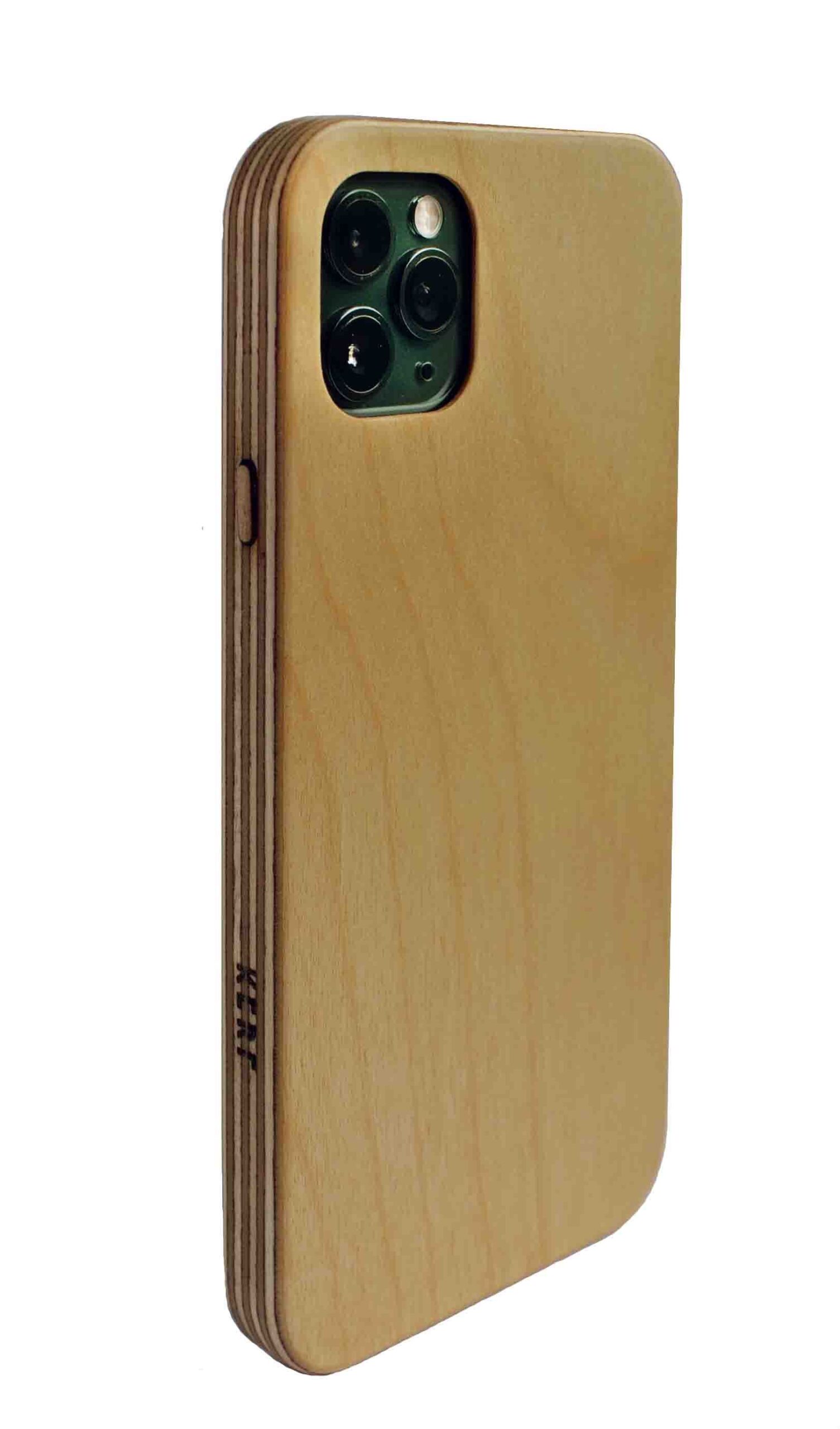

4. Kerfcase – Plywood iPhone 12 Case

Domain: kerfcase.com

Registered: 2013 (12 years)

Introduction: Product Name: Plywood iPhone 12 Case

Price: $60.00 (Maple), $70.00 (Cherry/Walnut), $90.00 (Teak)

Material: Plywood (available in Maple, Cherry, Walnut, Teak)

Handmade: Yes, made to order in the USA

Shipping: Free shipping in the US on orders over $60, ships worldwide

Delivery Time: 2-7 days for production, 2-4 days for shipping within the US

Warranty: Lifetime warranty for repairs and replacement…

5. Carved – Premium Wood and Resin Phone Cases

Domain: americangearguide.com

Registered: 2015 (10 years)

Introduction: Carved Phone Cases: Premium wood and resin cases for iPhone 15, Samsung S23, and Google Pixel 7. Unique designs, high reviews, available at Carved.com. WUDN Phone Cases: Wood inlay cases for iPhone 6 to 14 series and Samsung Galaxy, priced at $24. Magpul Cases: Thin, textured cases for iPhone X and Galaxy S9, known for good shock protection. ArmorSuit MilitaryShield Screen Protectors: Military-gra…

6. Carved – Handcrafted Phone Cases

Domain: usalovelist.com

Registered: 2011 (14 years)

Introduction: [{‘brand’: ‘Carved’, ‘location’: ‘Indiana’, ‘materials’: ‘real wood and resin’, ‘features’: ‘handcrafted, one-of-a-kind, fits specific phone models, MAG wireless chargers available’, ‘compatible_models’: ‘iPhone and Samsung Galaxy S series’}, {‘brand’: ‘Culley + Co.’, ‘location’: ‘East Coast’, ‘features’: ‘super strong, whimsical designs inspired by beach life’, ‘compatible_models’: ‘iPhone’}, {‘b…

7. Toast – Real Wooden Phone Covers

Domain: toastmade.com

Registered: 2011 (14 years)

Introduction: Real wooden phone covers by Toast are designed for various phone models including iPhone, Pixel, Samsung Galaxy, and more. They are made from furniture grade, real wood veneers that offer durability and a natural aesthetic. The covers are backed with premium adhesives for a secure fit and do not leave sticky residue upon removal. Options for laser-engraving and inlay are available for customizatio…

8. Casely – Phone Cases Collections

Domain: getcasely.com

Registered: 2016 (9 years)

Introduction: Phone Cases offered by Casely include a variety of styles and collections such as The Classic Collection, The Bold Collection, The Essential Collection, and The Magsafe® Collection. They provide options for different devices including iPhone, Samsung, and Google Pixel models. Key features include classic slim hard protective cases and bold dual-layer protection with a 3mm raised front lip. There a…

9. Rokform – Protective Cases & Accessories for iPhone and Galaxy

Domain: rokform.com

Registered: 2010 (15 years)

Introduction: Protective Cases & Accessories for Apple iPhone and Samsung. Free shipping on $45+ orders and free FedEx 2-Day on $79+ orders. 60-Day Money Back Guarantee. Product categories include: iPhone Cases (various models from iPhone 16 to iPhone 13 Mini), Galaxy Cases (various models from Galaxy S25 ULTRA to Galaxy S21 ULTRA), Google Pixel Cases, iPad Cases, and various mounts (car, motorcycle, bike, and …

Understanding phone cases made in usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Biodegradable Cases | Made from EcoElement™ materials; fully biodegradable packaging | Eco-conscious brands, sustainability-focused businesses | Pros: Environmentally friendly, supports local jobs. Cons: May have limited color options. |

| Premium Leather Cases | Crafted from high-quality USA cowhide; customizable options | High-end retailers, corporate gifts | Pros: Luxurious look, durable, customizable. Cons: Higher price point. |

| Wooden Cases | Handcrafted from live edge wood; unique designs | Artisanal shops, eco-friendly brands | Pros: Unique aesthetics, eco-friendly. Cons: Bulkier than plastic cases. |

| Rugged Cases | Military-grade drop protection; designed for extreme conditions | Construction, outdoor industries | Pros: Superior protection, durable. Cons: Can be heavy and bulky. |

| Slim Cases | Lightweight, minimalistic design; often compatible with wireless charging | Tech startups, everyday consumer brands | Pros: Sleek design, easy access to ports. Cons: Less protective than rugged variants. |

What Are Biodegradable Phone Cases Made in the USA?

Biodegradable phone cases, such as those made from EcoElement™ materials, are designed to minimize environmental impact. These cases decompose in landfill and ocean settings, making them ideal for eco-conscious businesses. B2B buyers should consider the growing demand for sustainable products, as these cases not only reduce carbon emissions but also resonate with environmentally aware consumers. However, limited color options may restrict branding opportunities.

Why Choose Premium Leather Phone Cases for Your B2B Needs?

Premium leather phone cases, crafted from high-quality USA cowhide, offer a luxurious aesthetic and durability. They are suitable for high-end retailers and corporate gifting, allowing for personalization that enhances brand identity. While the price point is higher, the investment can yield significant returns in customer loyalty and brand prestige. Businesses should weigh the appeal of luxury against their target market’s budget.

What Makes Wooden Phone Cases Unique for B2B Purchases?

Wooden phone cases, handcrafted from live edge wood, provide a unique selling proposition with their artisanal quality. They are particularly appealing to eco-friendly brands and artisanal shops that prioritize sustainability and individuality. B2B buyers should consider the niche market that values handcrafted products; however, the bulkier design may not suit all consumers.

How Do Rugged Phone Cases Benefit Businesses in Demanding Industries?

Rugged phone cases are engineered for extreme conditions, featuring military-grade drop protection. They are ideal for businesses in construction or outdoor activities, where device durability is paramount. While these cases offer superior protection, their weight and bulkiness may deter consumers looking for sleek designs. B2B buyers should assess their target audience’s needs for protection versus aesthetics.

What Advantages Do Slim Phone Cases Offer for Everyday Use?

Slim phone cases focus on minimalism and lightweight design, often allowing for wireless charging compatibility. They appeal to tech startups and everyday consumer brands that prioritize style and functionality. While they provide less protection than rugged cases, their sleek design and easy access to ports make them attractive to a broad audience. B2B buyers should evaluate the balance between protection and aesthetics in their product offerings.

Key Industrial Applications of phone cases made in usa

| Industry/Sector | Specific Application of Phone Cases Made in USA | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Protective cases for mobile devices | Enhanced device longevity and reduced replacement costs | Quality assurance, local manufacturing standards |

| Corporate Gifting | Custom-branded leather phone cases | Improved brand visibility and customer loyalty | Personalization options, minimum order quantities |

| Eco-Friendly Products | Biodegradable phone cases for sustainability | Aligns with corporate sustainability goals | Material certifications, biodegradability standards |

| Retail | High-end phone cases for luxury markets | Attracts premium customers and increases sales | Design uniqueness, compatibility with various devices |

| Electronics Repair | Durable cases for refurbished devices | Increases trust and customer satisfaction | Warranty offerings, testing standards for durability |

How Are Phone Cases Made in the USA Used in Telecommunications?

In the telecommunications industry, phone cases made in the USA are primarily used to protect mobile devices from damage, extending their lifespan. This is crucial for businesses that rely on mobile technology for communication. These cases often meet stringent local manufacturing standards, which can be a decisive factor for international buyers seeking quality assurance. By sourcing domestically, businesses can also reduce lead times and ensure timely delivery, which is vital for maintaining operational efficiency.

What Role Do Custom-Branded Phone Cases Play in Corporate Gifting?

Custom-branded leather phone cases made in the USA serve as unique corporate gifts that enhance brand visibility. Companies can personalize these cases to reflect their brand identity, thus fostering customer loyalty and strengthening business relationships. For international buyers, it’s essential to consider minimum order quantities and customization timelines to ensure that the gifts align with marketing campaigns or special events. The high-quality materials also convey a sense of professionalism and attention to detail.

How Do Eco-Friendly Phone Cases Benefit Businesses?

Businesses committed to sustainability can benefit from sourcing biodegradable phone cases made in the USA. These products not only align with environmental goals but also appeal to eco-conscious consumers and partners. International buyers, especially from regions with strict environmental regulations, should prioritize certifications that validate the biodegradability and sustainability of materials used. This can enhance the brand’s reputation and attract a broader customer base interested in eco-friendly products.

What Advantages Do High-End Phone Cases Offer Retailers?

Retailers targeting luxury markets can leverage high-end phone cases made in the USA to attract discerning customers. These cases often feature unique designs and premium materials that set them apart in a crowded marketplace. For B2B buyers, it’s crucial to evaluate the uniqueness of designs and compatibility with various devices to ensure product offerings meet consumer demands. Additionally, understanding market trends can help retailers stock cases that resonate with their target audience.

How Can Durable Phone Cases Enhance Electronics Repair Services?

In the electronics repair sector, durable phone cases made in the USA can significantly enhance the trustworthiness of refurbished devices. By providing high-quality protective cases, repair businesses can assure customers of the longevity and reliability of their devices. International buyers should focus on warranty offerings and testing standards for durability, as these factors can influence customer satisfaction and repeat business. A well-protected device not only reduces return rates but also elevates the overall service experience.

3 Common User Pain Points for ‘phone cases made in usa’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in Sourcing Phone Cases

The Problem: B2B buyers often face significant challenges when sourcing phone cases made in the USA, particularly regarding quality assurance. When purchasing in bulk, especially for international markets, buyers may encounter inconsistencies in product quality, which can lead to customer dissatisfaction and potential returns. Buyers from regions like Africa and South America may also be concerned about whether the cases will meet local standards and preferences, adding another layer of complexity to their procurement process.

The Solution: To overcome quality assurance challenges, B2B buyers should establish a robust vetting process for manufacturers. This includes requesting samples before placing large orders to evaluate the quality firsthand. It’s crucial to inquire about the manufacturer’s certifications, such as ISO 9001, which indicates a commitment to quality management. Additionally, buyers should consider partnering with manufacturers who offer comprehensive warranties and guarantees on their products, such as lifetime warranties, which indicate confidence in product durability. Engaging in direct communication with the manufacturers can also clarify any concerns regarding product specifications and local compliance.

Scenario 2: Addressing Environmental Sustainability Concerns in Phone Case Production

The Problem: International buyers are increasingly focused on sustainability and environmental responsibility. Sourcing phone cases made in the USA presents a unique challenge in ensuring that the products are not only high-quality but also environmentally friendly. Buyers may struggle with identifying which manufacturers utilize sustainable practices, such as biodegradable materials, and those that do not contribute to carbon emissions.

The Solution: To address environmental concerns, B2B buyers should prioritize manufacturers that offer eco-friendly products. For instance, sourcing phone cases made from biodegradable materials or those that adhere to sustainable production practices can significantly reduce environmental impact. Buyers can utilize certifications such as Green Seal or EcoLabel to identify products that meet specific environmental standards. Additionally, forming partnerships with manufacturers who are transparent about their supply chain practices can enhance credibility and trust. Engaging in discussions about sustainability initiatives can also help buyers align their sourcing strategies with their corporate social responsibility goals.

Scenario 3: Understanding Shipping Logistics and Cost Implications

The Problem: B2B buyers often face logistical challenges when sourcing phone cases made in the USA, particularly concerning shipping costs and delivery timelines. For international buyers, shipping can become a major expense, and delays can disrupt inventory management and customer fulfillment. This is especially critical for businesses operating in fast-paced markets where timely product availability is crucial.

The Solution: To effectively manage shipping logistics, B2B buyers should conduct thorough research on various shipping options and their associated costs. It is advisable to work closely with logistics partners who have experience in international shipping and can provide competitive rates. Buyers should also consider manufacturers who offer fast shipping options and can accommodate varying order sizes without significant cost increases. Implementing a just-in-time inventory strategy can help mitigate excess inventory costs, allowing businesses to maintain a lean operation while ensuring that products are available when needed. Additionally, leveraging technology to track shipments can help anticipate delays and improve communication with customers regarding delivery timelines.

Strategic Material Selection Guide for phone cases made in usa

What Are the Key Materials for Phone Cases Made in the USA?

When selecting materials for phone cases manufactured in the USA, it is essential to consider various factors that affect performance, durability, and compliance with international standards. Below are analyses of four common materials used in the production of phone cases, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Polycarbonate Perform as a Material for Phone Cases?

Polycarbonate is a popular choice for phone cases due to its high impact resistance and lightweight nature. It can withstand significant temperature variations and has a high melting point, making it suitable for various environments. Polycarbonate is also resistant to UV radiation, which helps maintain the aesthetic quality of the case over time.

Pros: Polycarbonate offers excellent durability and is relatively inexpensive to manufacture. Its clarity allows for stylish designs, and it can be easily molded into intricate shapes.

Cons: While it is robust, polycarbonate can scratch more easily than other materials like TPU. Additionally, its production process can be more complex, which might lead to increased manufacturing costs.

Impact on Application: Polycarbonate is compatible with wireless charging and can be treated to enhance its scratch resistance. However, its susceptibility to scratches may affect the long-term appearance of the product.

Considerations for International Buyers: Buyers from regions such as Africa and South America should be aware of ASTM standards for impact resistance. Compliance with these standards can enhance marketability in regions that prioritize product safety and quality.

What Are the Advantages of Thermoplastic Polyurethane (TPU)?

Thermoplastic Polyurethane (TPU) is another widely used material for phone cases, known for its flexibility and resilience. TPU can endure high levels of stress and is resistant to oils and grease, making it suitable for everyday use.

Pros: TPU cases are highly durable and provide excellent shock absorption, which is critical for protecting devices. They can also be produced in a variety of colors and finishes, appealing to diverse consumer preferences.

Cons: TPU can be more expensive than polycarbonate and may not offer the same level of rigidity. Additionally, the manufacturing process can be less efficient, potentially leading to longer lead times.

Impact on Application: TPU is compatible with wireless charging and does not interfere with phone signal reception. However, its flexibility may not provide the same level of protection as more rigid materials in extreme conditions.

Considerations for International Buyers: Buyers in Europe, particularly Germany, may seek compliance with DIN standards for material safety. Ensuring that TPU meets these standards can facilitate entry into these markets.

How Does Leather Stand Out in Phone Case Production?

Leather, particularly high-quality USA cowhide, is often used for premium phone cases. It offers a unique aesthetic appeal and a tactile experience that synthetic materials cannot match.

Pros: Leather is durable and ages well, developing a unique patina over time. It can also provide a luxurious look and feel, which can be a significant selling point in high-end markets.

Cons: Leather is more expensive than synthetic materials and requires more care to maintain its appearance. Additionally, it may not provide the same level of impact protection as plastic materials.

Impact on Application: Leather cases often come with additional features such as card slots and stands, enhancing their functionality. However, they may not be suitable for users who prioritize rugged protection.

Considerations for International Buyers: Buyers from the Middle East and Africa may need to consider local preferences for leather products, including ethical sourcing and sustainability. Compliance with local regulations regarding animal products is also essential.

What Role Does Wood Play in Phone Case Manufacturing?

Wooden phone cases, such as those crafted from live edge wood, offer a distinctive and eco-friendly option. They are often handcrafted, adding a unique touch to each case.

Pros: Wooden cases are biodegradable and can appeal to environmentally conscious consumers. They provide a unique aesthetic that differentiates products in a crowded market.

Cons: Wood is less durable than synthetic materials and may not provide the same level of shock protection. Additionally, the manufacturing process can be labor-intensive, leading to higher costs.

Impact on Application: Wooden cases may not be compatible with wireless charging due to their thickness and material properties. However, they can be customized with engravings, appealing to niche markets.

Considerations for International Buyers: Buyers should be aware of regulations regarding the sourcing of wood materials, particularly in regions with strict environmental laws. Compliance with international standards for sustainable forestry can enhance brand reputation.

Summary Table of Material Selection for Phone Cases Made in the USA

| Material | Typical Use Case for Phone Cases Made in USA | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | General-purpose protective cases | High impact resistance | Susceptible to scratching | Medium |

| Thermoplastic Polyurethane (TPU) | Flexible and shock-absorbing cases | Excellent shock absorption | More expensive than polycarbonate | Medium to High |

| Leather | Premium and luxury cases | Unique aesthetic and durability | Higher cost and maintenance required | High |

| Wood | Eco-friendly and handcrafted cases | Biodegradable and unique aesthetics | Less durable and higher manufacturing costs | Medium to High |

This guide serves as a strategic resource for international B2B buyers looking to understand the material landscape for phone cases made in the USA, ensuring informed decisions that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for phone cases made in usa

What Are the Key Stages in the Manufacturing Process of Phone Cases Made in the USA?

The manufacturing of phone cases in the USA involves several critical stages that ensure high-quality products tailored to the needs of consumers and businesses alike. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Phone Case Manufacturing?

The first step in the manufacturing process is material preparation. Different materials are used based on the type of phone case being produced. For instance, biodegradable cases often utilize advanced EcoElement™ materials, while leather cases may use premium cowhide sourced from local suppliers. Each material is selected for its durability, aesthetic appeal, and performance characteristics.

Before manufacturing begins, materials undergo strict quality checks to ensure they meet specific standards. This includes assessing the tensile strength, flexibility, and resistance to environmental factors. Additionally, manufacturers often engage in sustainable practices, reducing waste and minimizing the carbon footprint associated with material sourcing.

What Techniques Are Used to Form Phone Cases?

Forming is the next crucial stage in the manufacturing process. This involves shaping the prepared materials into the desired form of the phone case. Techniques vary depending on the material used:

-

Injection Molding: Commonly used for plastic cases, this technique involves injecting molten material into a mold to create the case shape. It allows for precise dimensions and the incorporation of intricate designs.

-

Laser Cutting: Employed for wood and leather cases, laser cutting provides high precision and clean edges. It can also be used for engraving logos or other designs.

-

Handcrafting: For premium products like leather cases, handcrafting is often utilized to ensure quality and attention to detail. This technique allows for customization, which is appealing to B2B buyers seeking unique offerings for their clients.

How Are Phone Cases Assembled and Finished?

Following the forming process, assembly takes place. This stage involves putting together different components of the phone case, such as attaching buttons, adding internal padding, or incorporating additional features like magnetic closures for wallet cases.

The finishing process encompasses surface treatments that enhance durability and aesthetics. This may include coating for scratch resistance, dyeing for color uniformity, and polishing for a refined look. Quality control checkpoints during this stage are essential to ensure that the final product meets the required specifications.

What Quality Assurance Measures Are Taken in Phone Case Manufacturing?

Quality assurance (QA) is a vital aspect of phone case manufacturing, ensuring that products meet international standards and customer expectations.

Which International Standards Govern Phone Case Quality?

Manufacturers often adhere to various international quality standards, such as ISO 9001, which focuses on effective quality management systems. Compliance with these standards demonstrates a commitment to quality and consistency in manufacturing processes.

In addition to ISO standards, specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply, depending on the materials used and the intended market. These certifications ensure that products are safe and meet regulatory requirements, which is particularly important for B2B buyers operating in highly regulated markets.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control is implemented at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production line. Any substandard materials are rejected to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is performed to identify any deviations from quality standards. This includes checking dimensions, material integrity, and overall assembly quality.

-

Final Quality Control (FQC): Once the product is assembled, a comprehensive inspection is conducted. This includes functionality tests, visual inspections, and adherence to safety standards. Products that do not pass this stage are either reworked or discarded.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, especially those from diverse international markets, should take several steps to ensure that their suppliers maintain robust quality control practices:

-

Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards. Audits can be conducted by the buying company or through third-party organizations.

-

Request Quality Reports: Suppliers should provide detailed reports on their quality control processes, including data from IQC, IPQC, and FQC stages. This transparency helps build trust and ensures accountability.

-

Engage Third-Party Inspectors: Utilizing independent inspection services can further assure buyers of the quality of products before they are shipped. These inspectors can conduct thorough evaluations based on the buyer’s specific requirements and international standards.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding quality control nuances is essential. Different regions may have varying quality expectations and regulatory requirements.

-

Cultural Considerations: Buyers should be aware of cultural differences that may influence quality perceptions. For instance, the emphasis on sustainability may be more pronounced in European markets, while durability may be prioritized in other regions.

-

Compliance with Local Regulations: It’s crucial for B2B buyers to understand and communicate local regulations that their suppliers must comply with. This ensures that the products not only meet quality standards but are also compliant with regional laws.

-

Building Long-term Relationships: Establishing long-term partnerships with suppliers can lead to improved quality assurance practices. Regular communication and collaboration on quality expectations can enhance product consistency and reliability.

In summary, the manufacturing processes and quality assurance measures for phone cases made in the USA are designed to meet high standards and cater to the diverse needs of international B2B buyers. By understanding these processes and implementing effective verification strategies, buyers can ensure they procure high-quality products that align with their market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘phone cases made in usa’

In today’s competitive market, sourcing high-quality phone cases made in the USA can provide significant advantages, such as improved supply chain reliability and enhanced brand reputation. This guide will equip international B2B buyers with a practical checklist to streamline the procurement process.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for the phone cases you intend to procure. Consider factors such as materials (e.g., biodegradable options, leather), compatibility with various phone models, and design aesthetics. Clearly defined specifications will help you communicate your needs effectively to potential suppliers.

Step 2: Identify Target Suppliers

Research and compile a list of manufacturers specializing in phone cases made in the USA. Utilize industry directories, trade shows, and online platforms to find reputable suppliers. Pay attention to their production capabilities, product range, and customer reviews to ensure they align with your sourcing goals.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify that potential suppliers hold relevant certifications. Look for compliance with industry standards, such as ISO certifications or environmental sustainability certifications. This step is crucial in ensuring that the products meet quality benchmarks and adhere to ethical manufacturing practices.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted suppliers, request product samples to assess quality firsthand. Evaluate the craftsmanship, durability, and overall design of the phone cases. This step will help you determine if the supplier can meet your quality expectations before placing a bulk order.

Step 5: Inquire About Production Capacity and Lead Times

Discuss production capabilities and lead times with the suppliers. Understanding their capacity to handle your order volume and their timelines will help you plan your inventory and avoid potential disruptions. Ensure they can accommodate your specific requirements, especially during peak seasons.

Step 6: Negotiate Pricing and Payment Terms

Engage in discussions about pricing, including bulk order discounts, payment terms, and delivery costs. Transparency in pricing is essential to avoid unexpected expenses later. Clarify the payment structure, whether upfront, upon delivery, or through net terms, to establish a mutually beneficial agreement.

Step 7: Establish a Communication Plan

Finally, set up a clear communication plan to facilitate ongoing dialogue with your chosen supplier. Regular updates on production status, shipping schedules, and any potential issues will foster a collaborative relationship. Effective communication is key to a successful sourcing partnership.

By following these steps, B2B buyers can confidently navigate the procurement process for phone cases made in the USA, ensuring quality products that meet their business needs while supporting local manufacturing.

Comprehensive Cost and Pricing Analysis for phone cases made in usa Sourcing

What Are the Key Cost Components in Sourcing Phone Cases Made in the USA?

When sourcing phone cases manufactured in the USA, understanding the cost structure is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The selection of materials significantly impacts the overall cost. Premium options such as biodegradable plastics or high-quality leather, as seen in products from Raptic and TORRO USA, will naturally command higher prices compared to standard materials. Sustainable and eco-friendly materials are increasingly favored, appealing to environmentally conscious consumers.

-

Labor: Labor costs in the USA are generally higher than in many developing regions. However, this often correlates with superior craftsmanship, quality control, and compliance with local labor laws. Investing in skilled labor can enhance product quality, thereby justifying the cost.

-

Manufacturing Overhead: This encompasses utilities, rent, and equipment costs associated with production facilities. USA-based manufacturers may incur higher overhead due to stringent regulations and higher operational costs, which can be reflected in the pricing.

-

Tooling: The cost of tooling for custom designs can be significant, particularly for unique or specialized phone cases. Customization often requires investment in molds and machinery, which can affect the initial order cost and should be factored into the total project budget.

-

Quality Control: Implementing robust QC processes is essential to ensure product consistency and compliance with international standards. This adds to the overall cost but can prevent costly returns and maintain brand reputation.

-

Logistics: Shipping costs can vary based on distance and shipping methods. For international buyers, understanding Incoterms (International Commercial Terms) is crucial, as they define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs.

-

Margin: The profit margin for manufacturers typically ranges between 20% to 50%, influenced by the brand’s positioning, product uniqueness, and market demand.

How Do Price Influencers Affect the Cost of Phone Cases?

Several factors influence the pricing structure for phone cases made in the USA:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly impact pricing. Larger orders often qualify for bulk discounts, reducing the per-unit cost. Buyers should consider their projected sales volume when negotiating prices.

-

Specifications and Customization: Tailored designs or features (e.g., personalized engravings or specific material types) can increase costs. Buyers should balance the desire for unique offerings with budget constraints.

-

Quality and Certifications: Products that meet specific quality certifications (like military-grade standards) may be priced higher. Buyers should assess whether these certifications align with their market requirements.

-

Supplier Factors: The reliability, reputation, and manufacturing practices of the supplier can also affect pricing. Establishing a long-term relationship with a reputable supplier may lead to better pricing and terms over time.

What Negotiation Strategies Can B2B Buyers Use to Optimize Costs?

International buyers from regions like Africa, South America, the Middle East, and Europe should adopt several strategies to enhance cost-efficiency:

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but all associated costs, including shipping, duties, and potential returns. A lower upfront cost may lead to higher TCO if quality issues arise.

-

Leverage Competition: Solicit quotes from multiple suppliers to create a competitive environment, which can facilitate better pricing and terms.

-

Negotiate Payment Terms: Discuss flexible payment options, such as installment payments or longer payment windows, which can improve cash flow and reduce financial pressure.

-

Build Relationships: Establishing a strong rapport with suppliers can lead to more favorable terms, including discounts for repeat orders or referrals.

Conclusion: What Should Buyers Keep in Mind When Sourcing Phone Cases from the USA?

While sourcing phone cases made in the USA can be more costly compared to overseas options, the benefits of quality, compliance, and sustainability often justify the investment. International buyers must consider various cost components, pricing influencers, and negotiation strategies to ensure they make informed purchasing decisions. Always seek clarity on costs and terms to avoid surprises, and remember that a thorough understanding of the total cost of ownership will lead to more strategic sourcing decisions.

Alternatives Analysis: Comparing phone cases made in usa With Other Solutions

When evaluating options for phone protection, it’s essential to consider various alternatives to phone cases made in the USA. This analysis compares domestically produced phone cases against other popular solutions, highlighting their unique features, advantages, and potential drawbacks.

Comparison Table

| Comparison Aspect | Phone Cases Made in USA | Alternative 1: Imported Phone Cases | Alternative 2: Custom 3D Printed Cases |

|---|---|---|---|

| Performance | High durability; often military-grade | Varies widely; may lack robust protection | Customizable for specific needs but may not match durability of traditional cases |

| Cost | Generally higher due to local manufacturing | Typically lower due to mass production | Moderate; costs can vary based on design complexity |

| Ease of Implementation | Readily available through US retailers | Widely available online and in stores | Requires access to 3D printing technology and design expertise |

| Maintenance | Low; usually requires occasional cleaning | Low; minimal upkeep needed | Moderate; may need occasional repairs or replacements |

| Best Use Case | Ideal for environmentally-conscious consumers | Suitable for budget-conscious buyers | Best for niche markets or personalized solutions |

Detailed Breakdown of Alternatives

Alternative 1: Imported Phone Cases

Imported phone cases are often mass-produced in countries with lower labor costs, resulting in a lower price point for consumers. While they can provide a wide variety of styles and designs, the performance can be inconsistent. Many imported cases lack the robust protection seen in high-quality USA-made options, which can lead to increased risk of damage to devices. Additionally, the environmental impact of long-distance shipping and the use of non-biodegradable materials can be a concern for eco-conscious buyers.

Alternative 2: Custom 3D Printed Cases

3D printed phone cases offer a unique solution for those seeking customization and specific design features. Buyers can choose materials, colors, and designs that fit their personal style or brand identity. However, while 3D printing allows for creativity, the durability and protective capabilities of these cases can vary significantly based on the material used and the printing process. Moreover, they may require additional maintenance and repair, making them less convenient for everyday use.

Conclusion

Choosing the right phone case solution depends on the specific needs and priorities of the B2B buyer. For businesses focused on sustainability and quality, USA-made cases offer excellent performance and support local economies. However, those with budget constraints or a need for unique designs may find value in imported or custom 3D printed options. Understanding the trade-offs in performance, cost, and maintenance will aid in making an informed decision that aligns with your organizational goals and values.

Essential Technical Properties and Trade Terminology for phone cases made in usa

What Are the Key Technical Properties of Phone Cases Made in the USA?

When sourcing phone cases manufactured in the USA, understanding their technical properties is crucial for B2B buyers. Here are some essential specifications to consider:

-

Material Composition

The materials used in phone cases greatly influence durability, aesthetics, and environmental impact. Common materials include thermoplastic polyurethane (TPU), polycarbonate, and eco-friendly options like biodegradable plastics. For instance, TPU offers excellent shock absorption and flexibility, while polycarbonate is known for its toughness and resistance to impact. Choosing the right material ensures that the product meets quality standards and consumer expectations. -

Drop Protection Rating

This specification indicates how well a phone case can withstand falls and impacts. Many manufacturers adhere to military-grade standards, such as MIL-STD-810G, which involves rigorous testing for durability. A case with a high drop protection rating (e.g., 10-foot drop tested) is essential for B2B buyers targeting markets that prioritize device longevity and protection. -

Biodegradability

With increasing environmental concerns, the biodegradability of phone cases is becoming a significant selling point. Cases made with materials like EcoElement™ can biodegrade within a year in landfill conditions, making them appealing to eco-conscious consumers. This property not only reduces environmental impact but can also enhance brand reputation in sustainability-focused markets. -

Compatibility and Fit

Phone cases must be designed for specific models to ensure proper fit and functionality. Compatibility with features such as wireless charging and MagSafe technology is essential. Buyers should look for precise cutouts that allow access to buttons and ports without compromising protection, ensuring that the case meets user needs. -

Weight and Dimensions

The weight and dimensions of a phone case affect usability and consumer preference. Lightweight materials enhance portability, while slim designs appeal to users who prefer minimal bulk. Understanding these specifications helps buyers select products that align with market trends toward sleek, functional designs. -

Warranty and Quality Assurance

A lifetime warranty or a robust quality assurance program is indicative of a manufacturer’s confidence in their product. This assurance can be a decisive factor for B2B buyers, as it reflects product reliability and can influence purchasing decisions.

What Are Common Trade Terms Related to Phone Cases Made in the USA?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are key trade terms to familiarize yourself with:

-

OEM (Original Equipment Manufacturer)

An OEM produces components or products that are used in another company’s end product. In the context of phone cases, an OEM may manufacture cases that are branded by another company, allowing businesses to expand their product lines without investing in production. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest order quantity a supplier is willing to accept. Understanding MOQs is vital for B2B buyers to manage inventory levels and cash flow effectively. Suppliers in the phone case industry may set MOQs based on production costs and material availability. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. It’s a crucial step in the procurement process, enabling buyers to compare costs and negotiate terms before making a purchase decision. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers in shipping and delivery. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk transfer, and liability, ensuring smoother transactions. -

Lead Time

Lead time is the period between placing an order and receiving the goods. In the phone case industry, lead times can vary based on production schedules, material availability, and shipping logistics. Knowing lead times helps buyers plan inventory and meet market demands effectively. -

Customization Options

Many manufacturers offer customization for phone cases, such as personalized designs or unique features. Understanding customization options allows B2B buyers to differentiate their offerings in competitive markets and cater to specific consumer preferences.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing phone cases made in the USA, ultimately driving successful business outcomes.

Navigating Market Dynamics and Sourcing Trends in the phone cases made in usa Sector

What Are the Key Market Dynamics and Trends Influencing Phone Cases Made in the USA?

The phone cases market, particularly those manufactured in the USA, is experiencing notable growth driven by several global factors. Increasing smartphone penetration across Africa, South America, the Middle East, and Europe has created a burgeoning demand for protective accessories. Additionally, a rising preference for locally sourced products is influencing international B2B buyers to consider US-made phone cases. Factors such as quality assurance, advanced manufacturing technologies, and compliance with stringent safety regulations further enhance the appeal of American-made products.

Emerging trends in technology and sourcing are also shaping the market landscape. The integration of smart materials and features, such as wireless charging compatibility and military-grade protection, caters to the evolving needs of consumers. Moreover, the growing emphasis on customization and personalization allows B2B buyers to offer unique products that meet specific customer preferences. Digital transformation in manufacturing processes, including the use of AI and automation, is streamlining production, ensuring faster turnaround times, and enhancing product quality.

How Is Sustainability and Ethical Sourcing Shaping the Phone Cases Market?

Sustainability and ethical sourcing are critical factors for B2B buyers in the phone case sector. The environmental impact of manufacturing practices has become a significant concern, leading companies to adopt eco-friendly materials and production methods. For example, products like the Raptic Terrain phone case are made from biodegradable materials, significantly reducing carbon footprints. This not only helps mitigate climate change but also resonates with consumers increasingly interested in sustainability.

Additionally, ethical supply chains are vital for fostering trust and credibility among international buyers. Certifications related to sustainable practices, such as ‘Made in USA’ labels and eco-certifications, provide assurance of compliance with environmental standards. B2B buyers are encouraged to prioritize suppliers who demonstrate commitment to sustainable practices, as this can enhance their brand reputation and appeal to eco-conscious consumers.

What Is the Historical Context of Phone Case Manufacturing in the USA?

The evolution of phone case manufacturing in the USA reflects broader technological advancements and consumer trends. Initially, phone cases were primarily utilitarian, focusing solely on protection. However, as smartphones became integral to everyday life, the demand for stylish and functional designs surged. This shift prompted manufacturers to innovate, integrating materials like leather and wood into their offerings, while also emphasizing personalization options.

Over the years, the rise of global competition has pressured US manufacturers to differentiate themselves through quality and sustainability. The current trend towards local sourcing has revitalized interest in American-made products, providing opportunities for B2B buyers to forge partnerships with manufacturers committed to ethical practices. This historical context underscores the importance of innovation and sustainability as key drivers of success in the phone case market.

Frequently Asked Questions (FAQs) for B2B Buyers of phone cases made in usa

-

How do I choose the right supplier for phone cases made in the USA?

When selecting a supplier for phone cases made in the USA, prioritize those with a proven track record in quality and reliability. Request samples to assess product quality and durability, and inquire about their manufacturing processes to ensure compliance with your standards. Additionally, check for certifications and customer testimonials. Establish clear communication channels and consider visiting the facility if possible, as this can provide valuable insights into their operations and quality control measures. -

What customization options are available for USA-made phone cases?

Many USA-based manufacturers offer extensive customization options, including color, material, logo branding, and design features. Minimum order quantities (MOQs) for customization can vary by supplier, so it’s important to discuss your specific needs early on. Some suppliers may also provide personalized packaging solutions to enhance your brand’s visibility. Be sure to ask about the timeline for custom orders to align with your product launch schedule. -

What are the typical payment terms for purchasing phone cases in bulk?

Payment terms can vary widely among suppliers, but common practices include a deposit upfront (typically 30-50%) with the balance due upon delivery or before shipping. Some suppliers may also offer net payment terms (e.g., Net 30, Net 60) for established buyers. Discussing payment terms upfront is essential to avoid misunderstandings. Always ensure that payment methods are secure and that there are protections in place for international transactions. -

How do I ensure quality assurance when sourcing phone cases from the USA?

To ensure quality assurance, request detailed information about the supplier’s quality control processes. This may include inspections at various production stages and testing for durability and material safety. Some suppliers may offer certifications, such as ISO 9001, which indicates adherence to quality management standards. Establishing a clear communication plan for addressing quality issues and setting expectations for defect rates can also help maintain product quality. -

What are the shipping options for importing phone cases from the USA?

Shipping options for importing phone cases from the USA can include air freight, sea freight, or express courier services. The choice of shipping method will depend on factors such as order size, budget, and urgency. Discuss logistics with your supplier to understand their shipping practices and any associated costs. Be mindful of customs regulations in your country to avoid delays and additional fees upon arrival. -

What is the impact of sourcing USA-made phone cases on my supply chain?

Sourcing phone cases made in the USA can positively impact your supply chain by reducing lead times and minimizing carbon emissions associated with international shipping. Local production often allows for greater flexibility in order quantities and customization, facilitating quicker adjustments to market demands. Additionally, supporting local manufacturers can enhance your brand’s image, appealing to environmentally conscious consumers. -

Are there any import duties or taxes when sourcing phone cases from the USA?

Yes, importing phone cases from the USA may incur various import duties and taxes, which vary by country and product classification. It’s important to research your country’s customs regulations to understand the applicable rates and ensure compliance. You can also consult with a customs broker to facilitate the import process and provide guidance on documentation and potential costs associated with your order. -

What are the advantages of sourcing biodegradable phone cases made in the USA?

Sourcing biodegradable phone cases made in the USA offers several advantages, particularly for eco-conscious businesses. These products typically have a lower environmental impact due to reduced carbon emissions from local manufacturing and shipping. Additionally, they can enhance your brand’s sustainability profile, attracting environmentally aware consumers. As regulations around plastic waste tighten globally, offering biodegradable options can also position your business as a leader in responsible sourcing.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for phone cases made in usa

In conclusion, the strategic sourcing of phone cases manufactured in the USA offers significant advantages for international B2B buyers. By prioritizing American-made products, companies can reduce their carbon footprint, ensure higher quality standards, and support local economies. The diverse range of materials—from biodegradable options to premium leather—caters to various market segments, appealing to environmentally conscious consumers and those seeking luxury products alike.

Moreover, as global supply chains become increasingly complex, sourcing domestically mitigates risks associated with international shipping and tariffs, ensuring a more reliable and timely delivery of goods. This is particularly vital for businesses in regions like Africa, South America, the Middle East, and Europe, where maintaining customer satisfaction through timely product availability is crucial.

Looking forward, the trend towards sustainability and local manufacturing is expected to grow. International buyers are encouraged to engage with American suppliers to leverage these benefits, build lasting partnerships, and meet the evolving demands of their customers. Embrace this opportunity to enhance your product offerings with high-quality, responsibly sourced phone cases that resonate with today’s eco-conscious consumers.