Top 8 Usa Manufacturing Companies List and Guide: How To Solve Sc…

Introduction: Navigating the Global Market for usa manufacturing companies

In today’s interconnected global economy, sourcing high-quality components from USA manufacturing companies presents both opportunities and challenges for international B2B buyers. Navigating the complexities of supply chains, varying compliance standards, and fluctuating costs can be daunting, especially for businesses in regions like Africa, South America, the Middle East, and Europe. This comprehensive guide addresses these challenges by providing an in-depth exploration of the diverse landscape of American manufacturing.

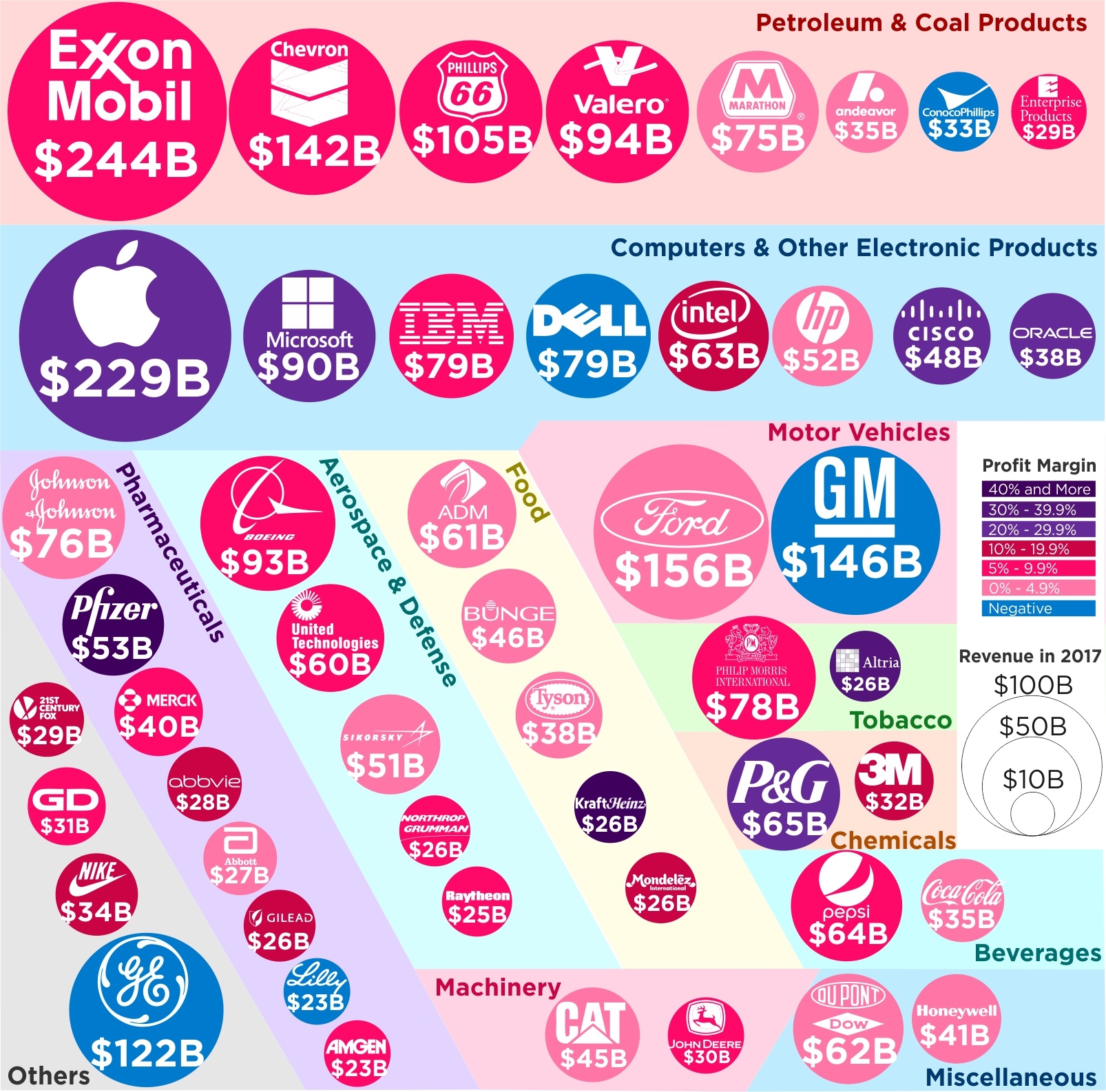

From automotive parts and aerospace technology to consumer goods and pharmaceuticals, the U.S. manufacturing sector is vast and varied. Our guide covers essential topics such as identifying reputable suppliers, understanding product applications, and evaluating cost structures. We delve into the nuances of supplier vetting processes, ensuring that you can confidently select partners who align with your quality and ethical standards.

By equipping international buyers with actionable insights and strategies, this guide empowers you to make informed purchasing decisions. With a focus on practical solutions tailored to your specific needs, we aim to facilitate successful partnerships that enhance your supply chain and drive business growth. Whether you are in Brazil seeking advanced machinery or in Germany looking for innovative electronics, this guide serves as your roadmap to navigating the global market for USA manufacturing companies.

Top 10 Usa Manufacturing Companies Manufacturers & Suppliers List

1. Manufacturing Companies – Key Players

2. Manufacturing USA – Advanced Manufacturing Solutions

Domain: manufacturingusa.com

Registered: 2002 (23 years)

Introduction: Manufacturing USA is a network of member institutes focused on advanced manufacturing, innovation, and workforce development. Key initiatives include collaboration with industry, academia, and government to address manufacturing challenges, support domestic supply chains, and cultivate a skilled workforce. Notable institutes within the network include MxD, ARM, America Makes, AIM Photonics, and Po…

3. Advanced Client – Verified Manufacturing Data

Domain: advancedclient.io

Registered: 2023 (2 years)

Introduction: Top 1,000 verified manufacturing companies in the USA, sortable by industry, size, and location. Access to free company-level data that is updated regularly.

4. TradingView – Market Analysis Tools

Domain: tradingview.com

Registered: 2010 (15 years)

Introduction: US companies engaged in producer manufacturing sector include Caterpillar, Inc., GE Vernova Inc., Applied Materials, Inc., Eaton Corporation, PLC, Deere & Company, Lam Research Corporation, Trane Technologies plc, 3M Company, Illinois Tool Works Inc., Johnson Controls International plc, Carrier Global Corporation, PACCAR Inc., Cummins Inc., AMETEK, Inc., Rockwell Automation, Inc., Ingersoll Rand I…

5. Infocleanse – Top U.S. Manufacturing Companies

6. Takeda Healthtech – Biotech Software Solutions

Domain: builtin.com

Registered: 1999 (26 years)

Introduction: Takeda Healthtech: Software, Analytics, Biotech, Pharmaceutical, Manufacturing; Mondelēz International: Big Data, Food, Hardware, Machine Learning, Retail, Automation, Manufacturing; General Motors: Automotive, Big Data, Information Technology, Robotics, Software, Transportation, Manufacturing; Magna International: Automotive, Hardware, Robotics, Software, Transportation, Manufacturing; Munchkin, …

7. Airstream – Travel Trailers; Burt’s Bees – Personal Care; California House – Custom Furniture; Gorilla Glue – Adhesives; Heritage Bicy

Domain: uschamber.com

Registered: 1996 (29 years)

Introduction: Airstream: Travel trailers and recreational vehicles; Burt’s Bees: Lip balm, makeup, face cream, body lotion, toothpaste; California House: Custom-made high-end furniture including pool tables, shuffleboard tables, home bars; Gorilla Glue: Adhesives, tapes, sealants; Heritage Bicycles: Made-in-the-USA bicycles and coffee; L.L.Bean: Duck boots, shoes, tote bags, pillows, rugs, furniture; Lodge Manu…

8. Manufacturing Giants – Key Players in Industry

Understanding usa manufacturing companies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aerospace Manufacturing | Focus on aircraft and spacecraft; high precision | Defense contracts, commercial aviation | Pros: High quality, innovation; Cons: Long lead times, high costs. |

| Consumer Electronics | Mass production of devices; rapid technological change | Retail distribution, OEM partnerships | Pros: Wide variety, scalability; Cons: Price volatility, quick obsolescence. |

| Food and Beverage Processing | Compliance with health regulations; diverse products | Grocery suppliers, food service | Pros: Essential goods, steady demand; Cons: Regulatory challenges, perishability. |

| Automotive Manufacturing | Production of vehicles and parts; complex supply chains | OEM partnerships, aftermarket sales | Pros: High demand, technological advancements; Cons: Market fluctuations, high capital investment. |

| Pharmaceutical Manufacturing | Strict regulatory compliance; R&D-driven | Healthcare providers, wholesalers | Pros: High margins, consistent demand; Cons: Lengthy approval processes, high R&D costs. |

What Are the Key Characteristics of Aerospace Manufacturing Companies?

Aerospace manufacturing is characterized by its focus on producing aircraft, spacecraft, and related equipment. Companies in this sector prioritize precision engineering and adhere to stringent safety regulations. B2B buyers in industries such as defense and commercial aviation often seek partnerships with aerospace manufacturers for high-quality components and systems. When considering a supplier, buyers should evaluate the manufacturer’s certifications, technological capabilities, and historical performance on contracts to ensure reliability and compliance.

How Do Consumer Electronics Manufacturers Operate?

Consumer electronics manufacturers are defined by their ability to produce a wide range of devices, from smartphones to home appliances. This sector is marked by rapid innovation and high competition, requiring manufacturers to frequently update their products. B2B buyers, particularly retailers and OEMs, benefit from the scalability and diversity of offerings. However, they must be aware of the potential for price volatility due to market trends and the fast-paced nature of technology, which can render products obsolete quickly.

What Makes Food and Beverage Processing Companies Unique?

Food and beverage processing companies are essential for transforming raw agricultural products into consumable goods. They operate under strict health and safety regulations, which can vary by region. B2B buyers in grocery supply and food services rely on these manufacturers for consistent, quality products. When engaging with suppliers, buyers should consider the manufacturer’s compliance with food safety standards, production capacity, and the diversity of their product range, as these factors can significantly impact supply chain stability.

What Should Buyers Know About Automotive Manufacturing?

Automotive manufacturing involves the production of vehicles and their components, characterized by complex supply chains and a focus on innovation. This sector supports both original equipment manufacturers (OEMs) and the aftermarket. B2B buyers must consider the manufacturer’s ability to adapt to market changes, technological advancements, and compliance with environmental regulations. While the automotive sector often presents high demand, buyers should also be cautious of market fluctuations and the capital investment required for long-term partnerships.

Why Are Pharmaceutical Manufacturing Companies Critical?

Pharmaceutical manufacturing companies specialize in producing medications and health-related products, operating under rigorous regulatory frameworks. This sector is heavily research and development-driven, often leading to high profit margins for successful products. B2B buyers, including healthcare providers and wholesalers, should prioritize manufacturers with a strong track record in compliance and product efficacy. Buyers must also consider the lengthy approval processes and substantial R&D investments that can affect product availability and pricing.

Key Industrial Applications of usa manufacturing companies

| Industry/Sector | Specific Application of USA Manufacturing Companies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Production of aircraft and defense systems | Access to advanced technology and skilled labor | Compliance with international safety standards and regulations |

| Automotive | Manufacturing of automotive parts and systems | Enhanced quality control and innovation | Supplier reliability and adherence to just-in-time delivery |

| Pharmaceuticals | Production of medical devices and pharmaceuticals | High standards of quality and safety | Regulatory compliance and certifications for international markets |

| Consumer Electronics | Manufacturing of electronic devices and accessories | Cutting-edge technology and competitive pricing | Intellectual property protection and supply chain transparency |

| Food and Beverage | Production of packaged food products | Assurance of quality and safety in food processing | Certifications for food safety and traceability in sourcing |

How Are USA Manufacturing Companies Applied in the Aerospace Sector?

In the aerospace industry, USA manufacturing companies play a pivotal role in the production of aircraft and defense systems. They leverage advanced technologies and specialized labor to create components that meet rigorous safety and performance standards. For international buyers, especially from Africa and the Middle East, understanding compliance with international aviation regulations is crucial. Companies looking to source aerospace parts must ensure that suppliers are certified to meet standards such as AS9100, which governs quality management systems in aerospace.

What Role Do USA Manufacturing Companies Play in Automotive Manufacturing?

The automotive sector benefits significantly from USA manufacturing companies that produce high-quality parts and systems, including engines, transmissions, and electronic components. These manufacturers are known for their rigorous quality control processes and innovative practices, ensuring that products meet global standards. For international buyers, particularly from Europe and South America, it is essential to evaluate the reliability of suppliers and their ability to deliver just-in-time. This minimizes inventory costs and enhances production efficiency.

How Are USA Manufacturing Companies Impacting the Pharmaceutical Industry?

In pharmaceuticals, USA manufacturing companies are critical for producing medical devices and drugs, adhering to strict quality and safety standards. These manufacturers often utilize advanced technologies to ensure the efficacy and safety of their products. For international B2B buyers, particularly in regions like Brazil and Africa, sourcing from US manufacturers means ensuring compliance with FDA regulations and obtaining necessary certifications. This can enhance marketability and trust in the products being sold.

What Innovations Are USA Manufacturing Companies Bringing to Consumer Electronics?

The consumer electronics industry benefits from the innovation and technological advancements provided by USA manufacturing companies. They produce a wide range of electronic devices, from smartphones to smart home gadgets, ensuring that they meet consumer demands for quality and performance. For international buyers, especially those in Europe, it is vital to assess the protection of intellectual property and the transparency of the supply chain. This helps mitigate risks associated with counterfeit products and ensures a reliable sourcing strategy.

How Do USA Manufacturing Companies Ensure Quality in Food and Beverage Production?

In the food and beverage sector, USA manufacturing companies are responsible for producing packaged food products that meet stringent safety and quality standards. These companies implement rigorous quality control measures to ensure that food processing adheres to safety protocols. For international buyers, understanding certifications such as HACCP (Hazard Analysis Critical Control Point) is essential when sourcing food products. This not only guarantees safety but also enhances traceability in the supply chain, which is increasingly important in global trade.

3 Common User Pain Points for ‘usa manufacturing companies’ & Their Solutions

Scenario 1: Difficulty in Navigating Compliance Standards

The Problem: B2B buyers from international markets often face significant challenges when dealing with USA manufacturing companies due to complex compliance and regulatory standards. For instance, a Brazilian firm looking to import medical devices may struggle to understand the FDA regulations governing the production and sale of such products in the U.S. This lack of clarity can lead to delays, increased costs, and even the risk of non-compliance, which can hinder market entry and damage business relationships.

The Solution: To navigate these compliance challenges, international buyers should engage directly with U.S. manufacturing partners early in the procurement process. Start by conducting thorough research on relevant regulations applicable to your specific industry. Utilize resources like the FDA’s website, or consult with regulatory experts familiar with both U.S. and your local compliance standards. Additionally, establish a communication line with your U.S. manufacturing partner to clarify any uncertainties regarding compliance documentation and quality assurance processes. Consider forming a joint compliance team that includes members from both companies to streamline compliance checks and ensure adherence to standards.

Scenario 2: Supply Chain Disruptions and Delays

The Problem: Many international buyers experience unpredictable supply chain disruptions when sourcing from U.S. manufacturers. A Middle Eastern company may place an order for specialty machinery only to face unforeseen delays due to transportation issues, customs clearance, or raw material shortages. These disruptions can result in costly project delays and impact the buyer’s ability to meet their own customer deadlines.

The Solution: To mitigate supply chain risks, B2B buyers should implement a proactive supply chain management strategy. Begin by diversifying your supplier base to include multiple U.S. manufacturers for critical components. This can help to ensure that if one supplier encounters issues, others can step in to fulfill your needs. Additionally, establish clear communication protocols regarding order statuses and potential delays. Leverage technology platforms that provide real-time tracking of shipments and inventory levels to better anticipate disruptions. Lastly, consider building a buffer stock for essential items to cushion against unforeseen delays.

Scenario 3: Quality Control Concerns in Product Specifications

The Problem: Quality assurance is a paramount concern for international buyers when sourcing products from U.S. manufacturers. For example, a South American electronics company may specify a particular material for a component but finds that the final product does not meet their quality expectations. This misalignment can lead to product failures, customer dissatisfaction, and a tarnished reputation in the market.

The Solution: To ensure quality control, B2B buyers should develop a comprehensive specification document that outlines every requirement in detail, including materials, dimensions, tolerances, and testing protocols. This document should be shared and reviewed collaboratively with the U.S. manufacturer to ensure mutual understanding. Additionally, consider implementing a phased approach to production, where prototypes are created and tested before full-scale manufacturing begins. Establish regular quality audits and check-ins throughout the production process to monitor adherence to specifications. Finally, seek third-party quality assurance services that can provide an unbiased assessment of product quality before shipment, thus minimizing the risk of receiving subpar goods.

Strategic Material Selection Guide for usa manufacturing companies

What Are the Key Properties of Common Materials Used in USA Manufacturing?

In the landscape of USA manufacturing, material selection is critical for product performance and durability. Understanding the properties, advantages, and limitations of commonly used materials can guide international B2B buyers in making informed decisions.

How Do Metals Perform in Manufacturing Applications?

Key Properties: Metals such as steel and aluminum boast high strength-to-weight ratios, excellent thermal and electrical conductivity, and good corrosion resistance when treated. For instance, stainless steel can withstand high temperatures and pressures, making it suitable for various applications from automotive to aerospace.

Pros & Cons: The durability of metals is a significant advantage, allowing for long-lasting products. However, the cost of raw metals can be high, and the manufacturing processes often require specialized equipment, increasing complexity. For example, while aluminum is lightweight and resistant to corrosion, it may not be suitable for high-stress applications compared to steel.

Impact on Application: Metals are compatible with various media, including water, oil, and gases, but specific grades must be selected based on the intended use. For example, food-grade stainless steel is essential in the food processing industry to prevent contamination.

Considerations for International Buyers: Compliance with international standards such as ASTM (American Society for Testing and Materials) or DIN (Deutsches Institut für Normung) is crucial. Buyers from regions like Europe may prefer materials that meet these standards to ensure quality and reliability.

What Role Do Plastics Play in Manufacturing?

Key Properties: Plastics, including polycarbonate and nylon, are lightweight, resistant to corrosion, and can be molded into complex shapes. They often have lower thermal and electrical conductivity compared to metals, which can be a disadvantage in certain applications.

Pros & Cons: The primary advantage of plastics is their versatility and lower cost, making them suitable for mass production. However, their durability can be a concern, particularly in high-temperature or high-stress environments where they may deform or break.

Impact on Application: Plastics are often used in consumer goods, automotive parts, and electronic housings. However, compatibility with specific chemicals must be considered, as some plastics can degrade when exposed to solvents or oils.

Considerations for International Buyers: International buyers should be aware of the varying regulations regarding plastic materials, particularly in Europe, where restrictions on certain types of plastics (like BPA) may apply. Familiarity with compliance standards such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is essential.

How Do Composites Enhance Manufacturing Capabilities?

Key Properties: Composite materials, such as carbon fiber and fiberglass, offer exceptional strength-to-weight ratios and improved fatigue resistance. They are often designed to withstand extreme environments, including high temperatures and corrosive conditions.

Pros & Cons: The main advantage of composites is their lightweight nature, which significantly enhances fuel efficiency in automotive and aerospace applications. However, they can be more expensive to produce and require specialized manufacturing techniques, which can complicate the supply chain.

Impact on Application: Composites are particularly effective in applications requiring high strength with minimal weight, such as in aerospace components. However, their compatibility with various media must be assessed, especially when used in chemical processing industries.

Considerations for International Buyers: Buyers should consider the certifications required for composite materials, especially in industries like aerospace and automotive. Familiarity with international standards such as AS9100 for aerospace quality management can be beneficial.

What Are the Benefits of Ceramics in Manufacturing?

Key Properties: Ceramics, including alumina and zirconia, are known for their hardness, wear resistance, and thermal stability. They can withstand high temperatures and are often used in applications where metals may fail.

Pros & Cons: The durability and resistance to wear make ceramics ideal for cutting tools and high-temperature applications. However, they are brittle and can fracture under stress, which limits their use in structural applications.

Impact on Application: Ceramics are commonly used in electronics, aerospace, and medical devices due to their insulating properties and biocompatibility. Their chemical resistance makes them suitable for harsh environments.

Considerations for International Buyers: Compliance with standards such as ISO 9001 for quality management systems is essential for ceramics used in medical or aerospace applications. Understanding the specific requirements for importing ceramics into different regions can help streamline procurement.

Summary Table of Material Selection

| Material | Typical Use Case for USA Manufacturing Companies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Metals | Automotive and aerospace components | High strength and durability | High cost and manufacturing complexity | High |

| Plastics | Consumer goods and electronic housings | Versatile and cost-effective | Less durable in high-stress environments | Medium |

| Composites | Aerospace and automotive lightweight parts | Exceptional strength-to-weight ratio | Expensive and complex to manufacture | High |

| Ceramics | Electronics and medical devices | Excellent thermal stability | Brittle and prone to fracture | Medium |

This analysis provides a comprehensive overview of material selection considerations for international B2B buyers looking to engage with USA manufacturing companies. Understanding these factors will enable buyers to make informed decisions that align with their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for usa manufacturing companies

What Are the Typical Manufacturing Processes Used by USA Manufacturing Companies?

USA manufacturing companies employ a variety of processes that can be broadly categorized into several key stages: material preparation, forming, assembly, and finishing. Understanding these stages can help international B2B buyers gauge the efficiency and quality of their potential suppliers.

Material Preparation: How Do Manufacturers Ensure Quality Raw Materials?

The first stage involves sourcing and preparing raw materials. Manufacturers often establish relationships with reputable suppliers to ensure the quality and consistency of materials. Techniques such as material inspection, sampling, and testing are commonly employed to validate the specifications of incoming materials. This can include checking for chemical composition, physical properties, and mechanical performance. For B2B buyers, it is crucial to verify that suppliers adhere to industry standards for material sourcing, particularly for specialized applications in sectors like aerospace or pharmaceuticals.

Forming: What Techniques Are Commonly Used in Manufacturing?

Once materials are prepared, they undergo forming processes that shape them into usable components. Common techniques include casting, machining, molding, and additive manufacturing (3D printing). Each technique has its advantages and is selected based on factors such as material properties, production volume, and design complexity. For instance, casting is often used for complex shapes, while machining is preferred for high precision. B2B buyers should inquire about the forming methods utilized by suppliers, as this can directly affect the quality and performance of the final product.

Assembly: How Do Manufacturers Ensure Accurate Assembly of Components?

The assembly stage involves putting together various components to create the final product. This can be done manually or through automated processes, depending on the scale of production. Quality assurance during assembly is critical; manufacturers often implement strategies such as standardized work instructions, assembly jigs, and automated vision systems to ensure accuracy. B2B buyers should look for suppliers that employ lean manufacturing principles to minimize waste and enhance efficiency in the assembly process.

Finishing: What Techniques Are Used to Enhance Product Quality?

The finishing stage involves processes that improve the surface quality and performance of the product. Techniques such as coating, polishing, and heat treatment are commonly employed to enhance durability, corrosion resistance, and aesthetics. The choice of finishing technique can be influenced by the product’s intended use and the environmental conditions it will face. Buyers should request information about the finishing processes used by their suppliers to ensure that they meet the specific requirements of their applications.

How Is Quality Assurance Managed in USA Manufacturing Companies?

Quality assurance (QA) is integral to the manufacturing process, ensuring that products meet predefined standards and specifications. USA manufacturers often adhere to both international and industry-specific standards to maintain a high level of quality.

What International Standards Are Commonly Followed?

One of the most widely recognized international standards is ISO 9001, which provides a framework for quality management systems. This standard emphasizes a process-based approach and customer satisfaction, making it a valuable benchmark for B2B buyers. Other industry-specific standards may include CE marking for products sold in the European Economic Area, API standards for oil and gas equipment, and AS9100 for aerospace products. Buyers should verify that their suppliers have the necessary certifications relevant to their industry.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves systematic monitoring of various stages of the manufacturing process. Typical QC checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring of production processes to identify defects or deviations in real-time.

- Final Quality Control (FQC): Comprehensive testing and inspection of finished products before shipment.

B2B buyers should inquire about the QC protocols of potential suppliers and whether they conduct regular audits and inspections to maintain compliance with quality standards.

What Testing Methods Are Commonly Used in Quality Assurance?

Manufacturers employ various testing methods to validate product quality. These can include mechanical testing (tensile, compression), chemical analysis, dimensional inspection, and performance testing under simulated conditions. Non-destructive testing (NDT) techniques, such as ultrasonic and radiographic testing, are also prevalent, especially in industries where safety is paramount. Buyers should request details about the testing methods used and the frequency of such tests to ensure reliability.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must adopt a proactive approach to verify the quality control practices of their suppliers. Here are several strategies:

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality assurance processes. Buyers can develop an audit checklist based on relevant standards and specific requirements. During the audit, buyers should evaluate the manufacturing environment, review documentation, and observe QC practices in action.

How Can Buyers Access QC Reports and Documentation?

Requesting access to quality control reports and documentation can provide insights into a supplier’s adherence to quality standards. This may include inspection reports, test results, and records of corrective actions taken in response to identified defects. Buyers should seek transparency in these documents to ensure that suppliers are maintaining high quality.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can add an extra layer of assurance for B2B buyers. Independent inspectors can provide unbiased evaluations of manufacturing processes and product quality. This is particularly important for international transactions, where buyers may not have direct oversight of production. Third-party inspections can help identify potential issues before products are shipped, reducing the risk of receiving substandard goods.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate specific challenges related to quality control and certification. Understanding local regulations, import/export requirements, and compliance with international standards is essential. Buyers should also be aware of the cultural differences that may affect manufacturing practices and quality assurance. Establishing clear communication and expectations from the outset can help mitigate misunderstandings and ensure a smoother procurement process.

In conclusion, a thorough understanding of manufacturing processes and quality assurance protocols can significantly enhance the decision-making capabilities of international B2B buyers. By focusing on these critical aspects, buyers can forge stronger partnerships with USA manufacturing companies and ensure the quality and reliability of their products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘usa manufacturing companies’

Introduction

This guide provides a comprehensive checklist for B2B buyers looking to source products from USA manufacturing companies. Understanding the nuances of the U.S. manufacturing landscape can help international buyers make informed decisions that align with their business needs and quality standards.

Step 1: Define Your Product Requirements

Establishing clear product specifications is the foundation of successful sourcing. Determine the technical specifications, quality standards, and any regulatory compliance required for your products. This clarity will not only guide your search for manufacturers but also help ensure that the final product meets your expectations.

Step 2: Research Potential Suppliers

Begin by compiling a list of potential manufacturing companies in the U.S. Utilize resources such as industry directories, trade shows, and business networks. Look for companies that specialize in your specific product category and have a proven track record of reliability and quality.

- Utilize Online Platforms: Websites like the Made in America Directory can help you identify manufacturers that produce goods domestically.

- Leverage Industry Associations: Joining industry-specific organizations can provide insights into reputable suppliers.

Step 3: Evaluate Supplier Capabilities

Before committing, it’s crucial to assess the capabilities of potential suppliers. Request detailed company profiles, including their production capacity, technology used, and quality control processes.

- Look for Certifications: Ensure that the manufacturers hold relevant certifications (e.g., ISO 9001) that reflect their commitment to quality and safety.

- Examine Past Projects: Reviewing case studies or testimonials from previous clients can offer insights into their reliability and performance.

Step 4: Verify Compliance and Certifications

In an increasingly regulated market, compliance with local and international standards is paramount. Confirm that the manufacturers adhere to relevant regulations and standards, such as safety certifications and environmental compliance.

- Request Documentation: Ask for copies of compliance certificates and any third-party audits.

- Investigate Their Supply Chain: Understanding where and how they source raw materials can reveal potential risks in quality and compliance.

Step 5: Conduct Site Visits or Virtual Tours

Whenever possible, visit the manufacturing facilities to gain firsthand knowledge of their operations. If a physical visit isn’t feasible, request a virtual tour to observe the production processes and working conditions.

- Assess the Environment: Pay attention to cleanliness, organization, and safety protocols.

- Meet the Team: Engaging with key personnel can provide insight into their expertise and commitment to quality.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, enter negotiations regarding pricing, delivery timelines, and payment terms. Clear communication during this phase can prevent misunderstandings later on.

- Discuss Minimum Order Quantities (MOQs): Understanding MOQs can help you manage inventory and cash flow effectively.

- Include Quality Assurance Clauses: Ensure that there are clear terms regarding quality checks and what happens in case of defects.

Step 7: Establish a Communication Plan

Effective communication is vital for maintaining a successful supplier relationship. Set up a plan for regular updates and feedback, ensuring both parties are aligned throughout the production process.

- Use Technology: Implement project management tools or communication platforms to streamline interactions.

- Schedule Regular Check-Ins: Frequent updates can help address any issues promptly and foster a collaborative partnership.

By following these steps, international B2B buyers can successfully navigate the complexities of sourcing from U.S. manufacturing companies, ensuring that they select reliable partners that meet their specific needs.

Comprehensive Cost and Pricing Analysis for usa manufacturing companies Sourcing

What Are the Key Cost Components in Sourcing from USA Manufacturing Companies?

When engaging with manufacturing companies in the USA, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials can significantly impact pricing. USA manufacturers often use high-quality materials, which can raise costs. Buyers should inquire about alternative materials that may reduce expenses without compromising quality.

-

Labor: Labor costs in the USA are generally higher than in many other countries, influenced by minimum wage laws and benefits. Understanding the labor component is essential, especially when assessing the overall cost of production.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses. Overhead can vary widely depending on the location and operational efficiency of the manufacturer.

-

Tooling: Initial tooling costs can be substantial, particularly for custom parts. Buyers should factor in these costs when considering the total price and potential long-term savings from bulk orders.

-

Quality Control (QC): Ensuring product quality is paramount, particularly for international shipments. QC processes add to the cost but are essential for maintaining standards and compliance with international regulations.

-

Logistics: Shipping costs are a significant factor, especially for international orders. These costs can fluctuate based on fuel prices and shipping routes.

-

Margin: Manufacturers typically add a profit margin to their costs. Understanding the margin can help buyers evaluate the fairness of pricing.

What Influences Pricing for USA Manufacturing Companies?

Several factors can influence pricing beyond the basic cost components:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced prices per unit. Buyers should negotiate MOQs to optimize their costs.

-

Specifications and Customization: Custom products usually come with higher costs due to unique tooling and production processes. Buyers should assess whether customization is necessary or if standard products could suffice.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ISO, ASTM) can increase costs but may be essential for specific industries. Buyers should weigh the importance of these factors against cost.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may command higher prices due to their track record of quality and service.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can affect overall costs, including who bears the risk and responsibility for shipping. Understanding these terms is vital for budgeting.

How Can International B2B Buyers Negotiate Better Prices?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation is key to optimizing costs:

-

Leverage Total Cost of Ownership (TCO): Buyers should consider not just the purchase price but also the long-term costs associated with maintenance, shipping, and potential tariffs. A thorough TCO analysis can provide insights into the true cost of a supplier.

-

Negotiate Terms: Engage in discussions around payment terms, lead times, and delivery schedules. Flexibility in these areas can often lead to cost savings.

-

Research Market Prices: Understanding the market landscape helps buyers gauge whether the prices offered are competitive. This knowledge empowers them during negotiations.

-

Establish Relationships: Building strong relationships with suppliers can lead to better pricing and terms over time. Loyal customers may benefit from discounts or preferential treatment.

What Should Buyers Keep in Mind About Pricing Nuances?

International buyers should be aware of several pricing nuances:

-

Currency Fluctuations: Exchange rate volatility can significantly impact costs. Buyers should consider hedging strategies if they are making large purchases.

-

Import Tariffs and Duties: Understanding the tariffs applicable to imported goods from the USA is crucial for accurate budgeting. Buyers should research these costs to avoid unexpected expenses.

-

Regulatory Compliance: Certain industries may have strict compliance requirements that can affect costs. Buyers should ensure they understand these regulations to avoid potential fines or additional costs.

Disclaimer: Prices can vary widely based on numerous factors, and the information provided is indicative. Buyers should conduct thorough due diligence and obtain specific quotes tailored to their needs before making purchasing decisions.

Alternatives Analysis: Comparing usa manufacturing companies With Other Solutions

Exploring Alternatives to USA Manufacturing Companies

When considering manufacturing solutions, international B2B buyers have several options. While USA manufacturing companies offer robust production capabilities, there are viable alternatives that can meet specific needs depending on performance, cost, and other factors. This analysis compares USA manufacturing companies with two alternative solutions: overseas manufacturing and additive manufacturing (3D printing).

| Comparison Aspect | USA Manufacturing Companies | Overseas Manufacturing | Additive Manufacturing (3D Printing) |

|---|---|---|---|

| Performance | High-quality standards and compliance with regulations. | Varies by region; often lower quality control. | Excellent for prototyping; quality improves with advancements. |

| Cost | Generally higher due to labor and operational costs. | Lower costs due to cheaper labor and materials. | Can be cost-effective for small runs but expensive for mass production. |

| Ease of Implementation | Established supply chains and logistics. | Complex logistics; potential tariffs and import issues. | Requires specialized knowledge and equipment; can be time-consuming. |

| Maintenance | Established maintenance protocols and support. | Maintenance can be challenging due to distance and time zones. | Minimal maintenance; however, requires continuous software updates. |

| Best Use Case | High-quality, regulated products for domestic markets. | Cost-sensitive products for mass markets. | Custom parts, prototypes, and low-volume production. |

What Are the Pros and Cons of Overseas Manufacturing?

Overseas manufacturing often appeals to businesses looking to reduce costs significantly. Countries like China, India, and Vietnam offer lower labor costs, which can lead to a more affordable production model. However, this approach comes with challenges such as quality control issues, longer lead times, and potential communication barriers due to time zone differences. Additionally, fluctuating tariffs and trade regulations can complicate the logistics of importing goods, leading to unexpected costs.

How Does Additive Manufacturing Compare?

Additive manufacturing, commonly known as 3D printing, presents an innovative alternative for producing custom parts and prototypes. This technology allows for the creation of complex designs that would be difficult or impossible to achieve with traditional manufacturing methods. While it can be cost-effective for small production runs, the costs can escalate significantly for larger volumes. Additionally, the need for specialized equipment and expertise can be a barrier for some businesses. Despite these challenges, the flexibility and speed of additive manufacturing make it an attractive option for industries needing rapid prototyping and customized solutions.

How Can B2B Buyers Choose the Right Solution?

Selecting the right manufacturing solution hinges on understanding specific business needs, including budget constraints, desired quality, and production volume. USA manufacturing companies are ideal for those prioritizing quality, compliance, and proximity, especially for regulated industries. Conversely, businesses focused on cost savings may lean towards overseas manufacturing, while those needing rapid prototyping or customization might find additive manufacturing to be the best fit. Ultimately, a thorough assessment of these alternatives will empower B2B buyers to make informed decisions that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for usa manufacturing companies

What Are the Essential Technical Properties Relevant to USA Manufacturing Companies?

Understanding the critical technical properties in the manufacturing sector is vital for international buyers. These specifications not only ensure product quality but also influence cost and delivery timelines. Here are some key properties to consider:

1. Material Grade

Material grade refers to the specific classification of materials based on their properties, such as strength, corrosion resistance, and thermal stability. In the manufacturing industry, selecting the right material grade is crucial for ensuring that the final product meets performance standards and complies with regulatory requirements. For instance, aerospace components require high-grade materials to withstand extreme conditions, while consumer goods may utilize more cost-effective options.

2. Tolerance

Tolerance defines the acceptable limits of variation in a physical dimension. It is essential in manufacturing to ensure that parts fit together correctly and function as intended. Tight tolerances may lead to higher manufacturing costs but are necessary for precision-engineered products, such as medical devices or automotive components. Understanding tolerance levels helps buyers assess quality control and manufacturing capabilities.

3. Surface Finish

Surface finish pertains to the texture and smoothness of a material’s surface, which can impact both aesthetics and functionality. Different applications may require varying finishes, from rough for better adhesion to smooth for easy cleaning. Buyers should specify surface finish requirements to ensure the final product meets both performance and design expectations.

4. Strength-to-Weight Ratio

This property measures the strength of a material relative to its weight and is especially important in industries like aerospace and automotive. A high strength-to-weight ratio allows for lighter components that maintain structural integrity, which can improve fuel efficiency and overall performance. International buyers should inquire about this ratio when evaluating materials for specific applications.

5. Yield Strength

Yield strength indicates the maximum stress a material can withstand without permanent deformation. This property is crucial for ensuring that parts can endure operational stresses without failing. Understanding yield strength helps buyers select materials that can handle specific loads, reducing the risk of product failure in the field.

What Are Common Trade Terms Used in USA Manufacturing?

Familiarizing oneself with industry jargon can significantly enhance communication and negotiation processes between international buyers and USA manufacturing companies. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships is vital, as it affects product availability, quality assurance, and warranty considerations.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For international buyers, knowing the MOQ can impact purchasing decisions and inventory management. Negotiating MOQs can lead to better pricing or more favorable terms.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products or services. This process allows buyers to compare costs and capabilities across multiple vendors, facilitating informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping and freight. Understanding these terms helps buyers clarify shipping costs, risk transfer, and delivery obligations, which can prevent misunderstandings during international transactions.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to the delivery of the product. Knowing lead times is essential for planning and inventory management, especially for international buyers who may face longer shipping durations.

By grasping these essential properties and trade terms, international B2B buyers can navigate the complexities of the USA manufacturing landscape more effectively, leading to better purchasing decisions and successful partnerships.

Navigating Market Dynamics and Sourcing Trends in the usa manufacturing companies Sector

What Are the Current Market Dynamics and Key Trends in the USA Manufacturing Sector?

The USA manufacturing sector is currently shaped by several global drivers, including technological advancements, geopolitical shifts, and evolving consumer preferences. One of the most significant trends is the accelerated adoption of Industry 4.0 technologies, such as IoT, AI, and automation. These innovations not only enhance production efficiency but also improve supply chain visibility, making it easier for international buyers to track orders and manage inventories. Additionally, the COVID-19 pandemic has prompted manufacturers to rethink their supply chain strategies, focusing more on resilience and flexibility. This shift is particularly relevant for B2B buyers from regions like Africa, South America, the Middle East, and Europe, where sourcing from the USA offers a balance of quality and reliability.

Emerging sourcing trends include a growing preference for nearshoring and reshoring. As international buyers seek to mitigate risks associated with global supply chains, they are increasingly looking to establish partnerships with US manufacturers that can deliver timely and cost-effective solutions. Furthermore, the emphasis on digital platforms for procurement processes is rising. E-commerce solutions tailored for B2B transactions are becoming vital for international buyers, allowing them to access a wide range of products and services efficiently.

How Are Sustainability and Ethical Sourcing Influencing B2B Relationships in Manufacturing?

Sustainability and ethical sourcing are now critical components of B2B relationships within the USA manufacturing sector. Environmental impact considerations are driving companies to adopt sustainable practices, from sourcing raw materials to production methods. Many manufacturers are investing in renewable energy sources and implementing waste reduction strategies, which not only help minimize their carbon footprint but also appeal to environmentally conscious buyers.

For international B2B buyers, the importance of ethical supply chains cannot be overstated. Companies are increasingly looking for partners that adhere to fair labor practices and demonstrate corporate social responsibility. Certifications such as ISO 14001 (Environmental Management) and Fair Trade certifications are becoming essential benchmarks for evaluating potential suppliers. Buyers from regions like Europe, which often have stringent sustainability standards, can leverage these certifications to ensure compliance and foster trustworthy relationships with US manufacturers.

Additionally, the use of ‘green’ materials, such as recycled plastics and sustainably sourced timber, is gaining traction. Buyers can benefit from engaging with manufacturers that prioritize these materials, as they often lead to reduced environmental impacts and enhanced brand reputation.

What Is the Historical Context of Manufacturing in the USA Relevant to B2B Buyers?

The evolution of the USA manufacturing sector has been marked by significant shifts that are pertinent for B2B buyers. Historically, the Industrial Revolution laid the groundwork for mass production techniques that transformed the manufacturing landscape. Over the decades, the sector has adapted to technological advancements, moving from traditional manufacturing methods to more sophisticated, technology-driven processes.

The late 20th century saw the globalization of supply chains, enabling US manufacturers to source materials and labor from around the world. However, recent geopolitical tensions and supply chain disruptions have prompted a reevaluation of these strategies, leading to a resurgence in domestic manufacturing. This evolution is particularly relevant for international buyers seeking reliable partners, as it highlights the USA’s commitment to quality and innovation in the face of global challenges.

As the sector continues to evolve, understanding its historical context allows B2B buyers to make informed decisions when sourcing products and establishing partnerships with US manufacturers.

Frequently Asked Questions (FAQs) for B2B Buyers of usa manufacturing companies

-

How do I find reliable USA manufacturing companies for my business needs?

To find trustworthy USA manufacturing companies, start by leveraging online directories like ThomasNet or the Made in America Directory. Attend industry trade shows and exhibitions to network directly with manufacturers. Additionally, consider reaching out to local chambers of commerce or trade associations, which often have resources and recommendations for reputable manufacturers. Always check reviews, ratings, and case studies to assess the credibility and track record of potential suppliers. -

What are the typical minimum order quantities (MOQs) for USA manufacturers?

Minimum order quantities (MOQs) can vary significantly based on the type of product and manufacturer. Generally, MOQs range from a few hundred to several thousand units. Smaller companies might have lower MOQs, while larger manufacturers may require higher quantities to justify production costs. It’s essential to discuss your specific needs with the manufacturer to see if they can accommodate lower MOQs, especially for custom or specialty products. -

What payment terms should I expect when dealing with USA manufacturers?

Payment terms can differ widely among manufacturers. Common arrangements include a 30% deposit upon order confirmation, with the remaining balance due before shipment. Some manufacturers may offer net payment terms (e.g., net 30 or net 60 days) for established relationships. Always clarify payment terms upfront to avoid misunderstandings and ensure that they align with your financial planning. -

How can I ensure quality assurance (QA) when sourcing from USA manufacturers?

To ensure quality assurance, establish clear specifications and standards before production begins. Request samples and conduct thorough inspections at various stages of the manufacturing process. It’s also advisable to include quality assurance clauses in your contract, allowing for penalties or returns if products do not meet agreed-upon standards. Regular communication and visits to the production site, if feasible, can further enhance quality control. -

What should I consider regarding logistics when sourcing from USA manufacturers?

Logistics is a crucial aspect of sourcing from USA manufacturers. Consider shipping costs, delivery times, and customs regulations that may apply to your country. Work with manufacturers who have reliable logistics partners or can facilitate transportation. Be clear about your timeline and delivery needs, and factor in any potential delays due to international shipping or customs clearance processes. -

How do I vet potential suppliers in the USA?

Vetting potential suppliers involves conducting thorough due diligence. Start with online research, including reviews and ratings on platforms like Trustpilot or Google. Request references from previous clients and follow up with them to gauge their experiences. Additionally, consider visiting the supplier’s facility or conducting a video call to assess their operations and capabilities. Certifications such as ISO can also indicate a commitment to quality and reliability. -

Can USA manufacturers customize products for my specific needs?

Many USA manufacturers offer customization options to meet specific business requirements. This can include alterations to design, materials, and packaging. It’s essential to communicate your needs clearly and discuss any limitations or additional costs associated with customization. Some manufacturers may have minimums for custom orders, so ensure you understand their capabilities before proceeding. -

What are the key benefits of sourcing from USA manufacturing companies?

Sourcing from USA manufacturing companies provides several advantages, including shorter lead times, higher quality standards, and better communication due to time zone alignment. Additionally, manufacturers often comply with strict regulations and safety standards, ensuring product reliability. Supporting local businesses can also enhance your brand image and appeal to consumers who prioritize ethical sourcing and sustainability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for usa manufacturing companies

The manufacturing landscape in the United States presents immense opportunities for international B2B buyers, particularly in sectors like aerospace, technology, and consumer goods. Strategic sourcing is essential for optimizing supply chains, reducing costs, and ensuring product quality. By engaging with U.S. manufacturers, businesses can leverage advanced technologies, skilled labor, and robust production capabilities that adhere to high standards.

For buyers from Africa, South America, the Middle East, and Europe, establishing partnerships with American manufacturers can facilitate access to innovative products and reliable services, enhancing competitiveness in local markets. The emphasis on sustainability and ethical sourcing within U.S. manufacturing also aligns with the growing global demand for responsible business practices.

Looking ahead, the U.S. manufacturing sector is poised for growth, particularly with advancements in automation and digitalization. International buyers are encouraged to explore these partnerships, tapping into the unique value propositions offered by U.S. companies. As the global market evolves, the strategic sourcing of American-made products can be a pivotal factor in achieving long-term success and sustainability. Embrace this opportunity to connect with U.S. manufacturers and elevate your business strategy.