Top 8 Needles Usa List and Guide: How To Solve Scenario 1: Naviga…

Introduction: Navigating the Global Market for needles usa

As global B2B buyers increasingly seek reliable sources for essential products, navigating the complex landscape of the needles market in the USA presents unique challenges. Sourcing high-quality needles tailored to specific applications—whether for medical, industrial, or textile uses—demands a comprehensive understanding of the market dynamics, supplier capabilities, and cost considerations. This guide aims to equip international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, with the insights necessary to make informed purchasing decisions.

Throughout this guide, we will delve into various types of needles available in the USA, explore their diverse applications, and provide actionable strategies for vetting suppliers. Buyers will find detailed analyses on pricing structures, quality assurance processes, and logistical considerations that impact sourcing decisions. By highlighting key factors such as compliance with international standards and customer service offerings, this resource empowers B2B buyers to identify trustworthy suppliers that meet their specific needs.

With the right information at their fingertips, businesses can confidently engage with suppliers, ensuring they secure the best products at competitive prices while fostering lasting partnerships. This guide is your roadmap to successfully navigating the global market for needles in the USA, transforming challenges into opportunities for growth and innovation.

Top 10 Needles Usa Manufacturers & Suppliers List

1. Needles – Scenic Gateway City

2. Needles – Key Apparel Collection

Domain: nepenthesny.com

Registered: 2000 (25 years)

Introduction: Needles is a brand established in 1995, designed by NEPENTHES CEO Keizo Shimizu, with over 30 years of experience in global product introduction. The collection includes various apparel and accessories such as caps, jackets, pants, shirts, shorts, sweatshirts, and sunglasses. Key products include: 5 Panel Cap – Purple/Orange ($129), Track Jacket – Purple/Orange ($386), Track Pant – Purple/Orange (…

3. Road Trip USA – Needles, California Highlights

Domain: roadtripusa.com

Registered: 1997 (28 years)

Introduction: Needles, California, is a destination along Route 66 known for its neon signs, mom-and-pop motels, and Americana. It has a population of 4,982 and experiences summer temperatures between 100°F (38°C) and 120°F (49°C). Key attractions include the Wagon Wheel Restaurant (2420 Needles Hwy., 760/326-4305), which serves fresh food and all-you-can-eat fish ’n’ chips on Friday nights, and the El Garces H…

4. Custer Resorts – Scenic Drives

Domain: custerresorts.com

Registered: 1997 (28 years)

Introduction: Needles Highway is a 14-mile scenic drive through Custer State Park, featuring pine and spruce forests, meadows, and granite mountains. It is part of the Peter Norbeck National Scenic Byway and includes notable sights like Sylvan Lake and the Needle’s Eye rock formation. The highway is best enjoyed at a slower pace, with recommended travel speeds of 25 mph or slower, taking approximately 45 to 60 …

5. Britannica – Needles, California Overview

Domain: britannica.com

Registered: 1995 (30 years)

Introduction: Needles, California is a city located in San Bernardino County, southeastern California, situated on the Colorado River. Founded in 1883 as a way station for the Atlantic and Pacific Railroad, it was named after a group of needlelike peaks in Arizona. The city is known for extremely high temperatures, often exceeding 100 °F (38 °C), making it one of the hottest cities in the U.S. Key attractions i…

6. USA Needle Inc. – Precision Stainless Steel Medical Needles

Domain: usaneedle.com

Registered: 2009 (16 years)

Introduction: USA Needle Inc. specializes in the design and manufacturing of precision stainless steel medical and surgical needles, including conical, lancet, and multi-faceted needles. They offer wire services such as stainless steel wire straightening, cut-to-length services, forming, and bending. Their capabilities include custom equipment design and build, prototype needle development, process development,…

7. Needles – Track Pants

8. Acurea USA – Acupuncture Needles & Herbal Products

Domain: acureausa.com

Registered: 2013 (12 years)

Introduction: Acupuncture Needles: Spring Handle, Plastic Handle, Copper Handle, Detox, Korean Hand & Facial, Pipe Handle, Gold & Silver Plated, 7 Star & Plum Blossom Bleeding Needles. Herbal Products: Ayush Ayurvedic Herbs, BioHerboloQi, MYCONUTRI Mushroom Supplements, Pacific Herbs, Biocidin Botanicals, Essential oils, Qualiherb Single Herbs, Treasure of the East, Three Treasures Herbal Formulas, Three Treasu…

Understanding needles usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Sewing Needles | Varied sizes and types for different fabrics | Apparel manufacturing, textile production | Pros: Versatile; Cons: Can break easily. |

| Medical Needles | Sterile, precision-engineered for safety | Healthcare, pharmaceuticals | Pros: High safety standards; Cons: Costly. |

| Industrial Needles | Heavy-duty, designed for high-volume use | Manufacturing, automotive, upholstery | Pros: Durable; Cons: Requires specific machines. |

| Embroidery Needles | Specialized for embroidery threads | Custom apparel, promotional products | Pros: Enhances design quality; Cons: Limited use. |

| Knitting Needles | Available in various materials and sizes | Textile production, hobbyist markets | Pros: Wide variety; Cons: Skill-dependent. |

What Are the Key Characteristics of Sewing Needles for B2B Buyers?

Sewing needles come in various sizes and types, tailored for different fabrics and applications. They are essential in apparel manufacturing and textile production, where precision and fabric compatibility are critical. B2B buyers should consider the needle’s size, type, and the specific materials they will be working with. While sewing needles are versatile, they can break under high tension, making quality a vital purchasing consideration.

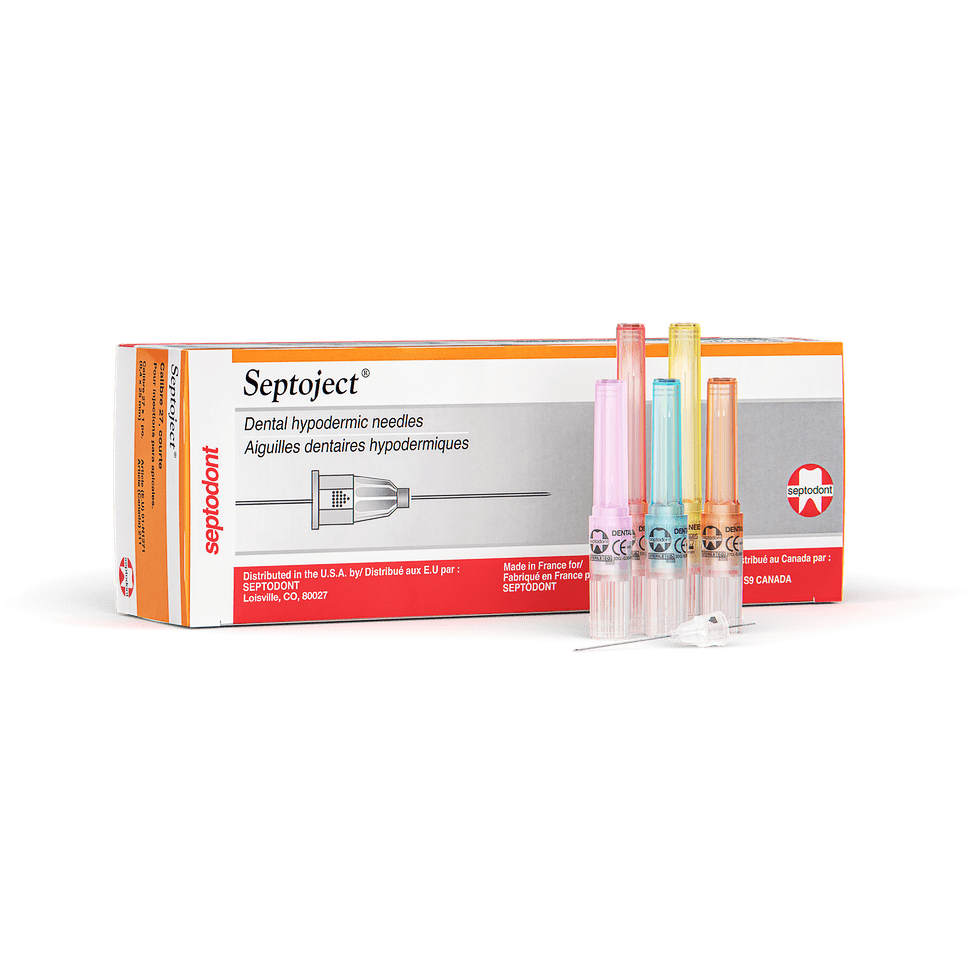

How Do Medical Needles Differ in Features and Applications?

Medical needles are engineered for precision and sterility, making them crucial in healthcare and pharmaceutical applications. These needles are designed to minimize discomfort and risk of infection, thus adhering to strict safety standards. B2B buyers in the medical field must prioritize quality and compliance with regulatory standards. Although medical needles are often more expensive, their reliability and safety make them indispensable in clinical settings.

What Should B2B Buyers Know About Industrial Needles?

Industrial needles are robust and designed for high-volume applications, often used in manufacturing, automotive, and upholstery sectors. These needles are built to withstand the rigors of heavy-duty use, ensuring efficiency in production environments. Buyers should be aware that industrial needles require specific sewing machines, which can limit compatibility. While they are durable, the investment in both needles and compatible machinery can be substantial.

Why Are Embroidery Needles Important for Custom Apparel?

Embroidery needles are specialized tools designed to work with embroidery threads, providing enhanced design quality in custom apparel and promotional products. Their unique features allow for smooth stitching without damaging the fabric. B2B buyers should consider the type of embroidery being produced and the compatibility of needles with their machines. While they enhance design quality, their use is limited to specific applications, necessitating careful planning for procurement.

What Factors Should Influence the Selection of Knitting Needles?

Knitting needles come in various materials and sizes, catering to diverse textile production needs and hobbyist markets. They are essential for creating knitted fabrics, with options ranging from bamboo to metal, each offering different benefits. B2B buyers should consider the type of yarn and the skill level of the end-users when selecting knitting needles. While they provide a wide variety of options, the effectiveness of knitting needles can vary based on user expertise, impacting overall productivity.

Key Industrial Applications of needles usa

| Industry/Sector | Specific Application of needles usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Surgical and medical needles | Precision in procedures, improved patient outcomes | Compliance with international medical standards, quality certifications, and reliable supply chains |

| Textile Manufacturing | Needles for sewing and embroidery machines | Enhanced production efficiency, reduced downtime | Compatibility with existing machinery, bulk purchasing options, and material quality |

| Automotive | Needles for fuel injection systems | Improved performance and efficiency of engines | Specifications for needle dimensions and materials, supplier reliability, and lead times |

| Agriculture | Needles for agricultural machinery | Increased efficiency in planting and harvesting | Durability against environmental factors, adaptability to various machinery, and availability of spare parts |

| Electronics | Needles for circuit board assembly | Enhanced precision in component placement | Precision engineering capabilities, adherence to industry standards, and responsiveness to demand fluctuations |

How Are Surgical and Medical Needles Used in Healthcare?

In the healthcare sector, surgical and medical needles are crucial for various procedures, including injections, suturing, and blood sampling. They ensure precision, which is vital for patient safety and effective treatment. International buyers, particularly from Africa and the Middle East, must prioritize suppliers who comply with stringent medical regulations and quality certifications to ensure patient safety. Additionally, reliable supply chains are essential to meet the often urgent demands of healthcare facilities.

What Role Do Needles Play in Textile Manufacturing?

In textile manufacturing, needles are integral to sewing and embroidery machines, directly impacting production efficiency. High-quality needles reduce the frequency of machine jams and fabric damage, leading to less downtime and lower operational costs. Buyers from South America and Europe should consider the compatibility of needles with their existing machinery, the availability of bulk purchasing options, and the quality of materials used to ensure longevity and performance.

How Are Needles Utilized in Automotive Applications?

In the automotive industry, needles are employed in fuel injection systems to optimize engine performance and efficiency. Their precision is critical in ensuring that fuel is delivered accurately, which can enhance fuel economy and reduce emissions. B2B buyers must focus on suppliers that provide needles with specific dimensions and materials suited for their vehicle models, as well as those that demonstrate reliability in their supply capabilities to avoid production delays.

What Is the Importance of Needles in Agriculture?

Agricultural machinery uses needles for various functions, including planting and harvesting. These needles help improve the efficiency of operations, enabling farmers to increase yield and reduce labor costs. For buyers in Africa and South America, sourcing durable needles that can withstand harsh environmental conditions is crucial. Additionally, compatibility with various types of agricultural equipment and the availability of spare parts can significantly impact operational efficiency.

How Are Needles Applied in Electronics Manufacturing?

In electronics, needles are essential for circuit board assembly, where they are used to place components with high precision. This application is vital for the performance and reliability of electronic devices. International buyers must ensure that their suppliers adhere to industry standards for precision engineering and can respond quickly to fluctuations in demand. This responsiveness is vital in the fast-paced electronics market, where time-to-market can significantly affect competitiveness.

3 Common User Pain Points for ‘needles usa’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance for Imports

The Problem: B2B buyers importing needles from the USA often face challenges with regulatory compliance, particularly when entering markets in regions like Africa and South America. Different countries have varying standards for medical devices and products, which can lead to confusion and potential delays. Non-compliance can result in hefty fines, shipment rejections, and a damaged reputation, making it crucial for businesses to understand the specific regulations governing needles in their target markets.

The Solution: To overcome these compliance hurdles, buyers should first conduct comprehensive research on the regulatory requirements of their destination markets. Engaging with local legal consultants or regulatory affairs experts can provide invaluable insights into necessary certifications and documentation. Buyers should also establish clear communication with suppliers in the USA to ensure that products meet the required standards and that all necessary certifications (like FDA approval or ISO certifications) are provided. Utilizing a reliable logistics partner familiar with customs regulations can help streamline the import process, ensuring that shipments are compliant and delivered on time.

Scenario 2: Ensuring Quality Control in Manufacturing

The Problem: Quality control is a significant concern for B2B buyers sourcing needles from manufacturers in the USA. Variability in product quality can lead to product recalls, customer dissatisfaction, and increased operational costs. Buyers might struggle with ensuring that the needles they procure consistently meet the necessary quality and safety standards, which is critical in sectors such as healthcare.

The Solution: To ensure high-quality products, buyers should implement a robust quality assurance strategy. This involves setting specific quality criteria before placing orders and conducting regular audits of manufacturers. Buyers can request samples and conduct their own testing to verify that products meet their specifications. Additionally, establishing a quality management system (QMS) can aid in monitoring product quality throughout the manufacturing process. Collaborating with manufacturers who have established quality certifications (such as ISO 13485 for medical devices) can further guarantee adherence to stringent quality standards.

Scenario 3: Managing Supply Chain Disruptions

The Problem: B2B buyers often encounter supply chain disruptions, particularly for products like needles that are essential in medical and industrial applications. Factors such as natural disasters, geopolitical issues, and global pandemics can affect the availability of raw materials or manufacturing capabilities, leading to delays and increased costs. This unpredictability can severely impact businesses that rely on timely deliveries to meet customer demands.

The Solution: To mitigate the risks associated with supply chain disruptions, buyers should diversify their supplier base. Establishing relationships with multiple manufacturers in different geographical locations can reduce dependency on a single source and enhance supply chain resilience. Additionally, implementing a just-in-time (JIT) inventory strategy can help maintain optimal stock levels without overcommitting resources. Buyers should also invest in supply chain visibility tools that allow for real-time tracking of orders and inventory levels, enabling proactive responses to potential disruptions. Regular communication with suppliers and staying updated on global supply chain trends will allow buyers to anticipate challenges and adjust their strategies accordingly.

Strategic Material Selection Guide for needles usa

When selecting materials for needles used in various applications, it is essential to consider their properties, advantages, disadvantages, and the specific needs of international B2B buyers. Below is an analysis of four common materials utilized in the manufacturing of needles in the USA.

What are the Key Properties of Stainless Steel Needles?

Stainless Steel is a widely used material for needles due to its excellent mechanical properties and corrosion resistance. It typically features a temperature rating that can withstand high heat, making it suitable for various applications, including medical and industrial uses. The most common grades, such as 304 and 316, offer good tensile strength and resistance to oxidation.

Pros: Stainless steel needles are durable, resistant to rust, and can be sterilized, making them ideal for medical applications. They also have a relatively low manufacturing complexity.

Cons: The cost of stainless steel can be higher compared to other materials, and while it is resistant to corrosion, it is not entirely immune, particularly in harsh chemical environments.

Impact on Application: Stainless steel needles are compatible with a wide range of media, including biological fluids and various chemicals, enhancing their versatility.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with international standards such as ASTM and ISO for medical devices. Knowledge of local regulations regarding material safety is crucial.

How Does Aluminum Compare as a Needle Material?

Aluminum is another material used for specific needle applications, particularly in less demanding environments. It is lightweight and offers good corrosion resistance, especially when anodized.

Pros: The lightweight nature of aluminum needles can reduce fatigue during extended use, making them suitable for applications requiring precision and control. They are also generally more affordable than stainless steel.

Cons: Aluminum is less durable than stainless steel and may not withstand high temperatures or pressures. Its mechanical properties can degrade under certain conditions, limiting its use in critical applications.

Impact on Application: Aluminum needles are best suited for applications where weight is a priority, but they may not be ideal for high-pressure or high-temperature environments.

Considerations for International Buyers: Buyers should be aware of the specific alloy grades used and their compliance with standards like JIS or DIN, particularly in the Middle East and Europe, where material specifications can vary significantly.

What are the Benefits of Using Plastic Needles?

Plastic needles are increasingly popular in applications such as medical devices and consumer products. They are typically made from polymers like polypropylene or polyethylene, which can be engineered for specific properties.

Pros: Plastic needles are lightweight, cost-effective, and can be produced in large quantities with relative ease. They are also resistant to corrosion and can be designed to be single-use, promoting hygiene.

Cons: The mechanical strength of plastic needles is generally lower than that of metal needles, and they may not be suitable for high-pressure applications. Their temperature resistance is also limited compared to metals.

Impact on Application: Plastic needles are ideal for applications where sterility and single-use are paramount, such as in medical settings for injections or sampling.

Considerations for International Buyers: Compliance with medical device regulations in different regions, such as the FDA in the USA or CE marking in Europe, is essential for plastic needle manufacturers targeting international markets.

Why Choose Titanium Needles for Specialized Applications?

Titanium is a premium material used for specialized needle applications, particularly in the medical field. It offers exceptional strength-to-weight ratio and corrosion resistance.

Pros: Titanium needles are biocompatible, making them suitable for surgical applications. They are also lightweight and have a high resistance to corrosion, even in saline environments.

Cons: The primary drawback of titanium is its cost, which is significantly higher than that of stainless steel or plastic. Additionally, manufacturing titanium needles can be more complex due to the material’s properties.

Impact on Application: Titanium needles are particularly advantageous in applications involving sensitive biological environments, where corrosion and biocompatibility are critical.

Considerations for International Buyers: Buyers should ensure compliance with international medical device standards and consider the higher costs associated with titanium when budgeting for projects.

Summary Table

| Material | Typical Use Case for needles usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Medical and industrial applications | Excellent durability and corrosion resistance | Higher cost compared to other materials | High |

| Aluminum | Precision applications requiring lightweight | Lightweight and cost-effective | Less durable under high pressure | Medium |

| Plastic | Single-use medical devices | Cost-effective and hygienic | Lower mechanical strength | Low |

| Titanium | Surgical applications | Biocompatibility and corrosion resistance | High cost and complex manufacturing | High |

This guide provides a comprehensive overview of material selection for needles in the USA, tailored to the needs of international B2B buyers. Understanding these materials’ properties and considerations can help in making informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for needles usa

What Are the Key Stages in the Manufacturing Process of Needles in the USA?

The manufacturing of needles in the USA involves several critical stages that ensure the final product meets stringent quality and performance standards. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation: The manufacturing process begins with the selection of high-grade materials, often stainless steel or other alloys known for their durability and resistance to corrosion. The raw materials are cut and shaped into appropriate sizes, often using precision cutting tools to ensure accuracy. This stage is crucial as the quality of the raw materials directly impacts the performance of the needles.

Forming: Once prepared, the materials undergo a forming process, which typically involves techniques such as forging or cold drawing. Forging enhances the mechanical properties of the metal, while cold drawing helps in achieving the desired dimensions and surface finish. Advanced machinery is employed to ensure uniformity and precision during this stage.

Assembly: After forming, the individual components of the needles are assembled. This may include attaching the needle body to the eye or other components, depending on the type of needle being manufactured. Automated assembly lines are commonly used to enhance efficiency, but manual assembly may also be employed for specialized or intricate designs.

Finishing: The final stage involves finishing processes such as polishing, coating, and sterilization. Polishing ensures a smooth surface, reducing friction during use, while coatings may be applied to enhance durability or specific functionalities (e.g., anti-corrosive properties). Sterilization is particularly important for medical needles, ensuring they are safe for use in clinical environments.

How Is Quality Assurance Implemented in Needle Manufacturing?

Quality assurance (QA) is a critical component of the needle manufacturing process, ensuring that products meet international and industry-specific standards. The implementation of QA includes adherence to standards such as ISO 9001, which outlines requirements for a quality management system, as well as industry-specific certifications like CE and API for medical devices.

International Standards: ISO 9001 is widely recognized and establishes a framework for consistent quality management practices. Compliance with this standard ensures that manufacturers follow best practices in production, leading to improved customer satisfaction and reduced waste.

Industry-Specific Standards: For medical needles, compliance with CE (Conformité Européenne) standards is essential for selling products in Europe, while API (American Petroleum Institute) standards are relevant for needles used in oil and gas applications. These certifications not only enhance product credibility but also assure buyers of the product’s safety and efficacy.

What Are the Key Quality Control Checkpoints in Needle Manufacturing?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process to ensure that the final products meet established standards. Common QC checkpoints include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival. This includes checking for material specifications, dimensions, and any signs of damage. Only materials that meet the required standards are approved for use in production.

In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are conducted to monitor the quality of the production. This includes dimensional checks and performance testing of the products at various stages. Any deviations from the standards are addressed immediately to prevent defective products from progressing further in the manufacturing line.

Final Quality Control (FQC): Once the needles are fully manufactured, a comprehensive inspection is performed. This includes visual inspections, functional tests, and, for medical needles, sterility testing. Only products that pass these stringent checks are packaged and shipped.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to mitigate risks and ensure product reliability. Here are some effective strategies to achieve this.

Conducting Audits: Buyers can perform on-site audits of the manufacturing facilities to assess compliance with quality standards. This provides firsthand insight into the manufacturing processes and the supplier’s commitment to quality.

Requesting Quality Reports: Suppliers should provide detailed quality assurance documentation, including inspection reports, certification of compliance with international standards, and records of past quality control audits. This documentation can help buyers understand the supplier’s quality management practices.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspections can be scheduled at various stages of production to ensure compliance with agreed standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must be aware of specific nuances related to quality control and certification when sourcing needles from the USA.

Understanding Regional Regulations: Different countries have varying regulations concerning medical devices and industrial needles. Buyers should familiarize themselves with the certification requirements in their respective regions to ensure compliance.

Language and Documentation Barriers: Language differences can pose challenges in understanding quality documentation. It is advisable for buyers to seek suppliers who can provide documentation in a language they are comfortable with, ensuring clarity in communication.

Cultural Considerations: Cultural differences can influence business practices and expectations regarding quality. Building strong relationships with suppliers through open communication can help bridge these gaps and foster a collaborative approach to quality assurance.

In conclusion, understanding the manufacturing processes and quality assurance practices for needles in the USA is vital for international B2B buyers. By focusing on key manufacturing stages, rigorous quality control checkpoints, and effective verification strategies, buyers can ensure they partner with reliable suppliers who meet their quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘needles usa’

To assist international B2B buyers in sourcing ‘needles usa’, this practical sourcing guide provides a step-by-step checklist designed to streamline the procurement process. Whether you’re from Africa, South America, the Middle East, or Europe, these actionable insights will help you make informed decisions when selecting suppliers and products.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the specifications of the needles you require. This includes the type, size, material, and any specific features needed for your industry. Defining these criteria helps narrow down suppliers who can meet your exact needs, reducing time spent on unsuitable options.

- Considerations:

- Types of needles (e.g., sewing, medical, industrial).

- Material requirements (e.g., stainless steel, plastic).

- Compliance with industry standards (ISO, ASTM).

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers in the needles industry. Utilize online directories, trade shows, and industry publications to compile a list of companies. This initial research phase is crucial to understanding the market landscape and the options available.

- Tools to Use:

- Industry-specific trade directories (e.g., ThomasNet, Alibaba).

- Networking platforms (e.g., LinkedIn) to connect with industry professionals.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications and compliance with relevant standards. This step is essential to ensure that the products meet safety and quality requirements, which is particularly important in sectors like healthcare and manufacturing.

- What to Check:

- ISO certifications that indicate quality management.

- Compliance with local regulations and international standards.

Step 4: Request Samples for Testing

Once you have narrowed down your list of suppliers, request samples of the needles for quality assessment. Testing samples will provide firsthand experience regarding the product’s performance and suitability for your applications.

- Testing Criteria:

- Durability and strength.

- Precision and ease of use.

- Compatibility with your existing equipment or processes.

Step 5: Analyze Pricing and Terms of Sale

Compare pricing structures and terms of sale from different suppliers. Understanding the total cost of procurement, including shipping and potential duties, is vital for budgeting and ensuring that you receive the best value for your investment.

- Factors to Consider:

- Bulk purchasing discounts.

- Payment terms and conditions.

- Return policies and warranty offers.

Step 6: Conduct Supplier Background Checks

Before finalizing your supplier choice, perform background checks to assess their reputation and reliability. Contact previous customers for feedback and review any available case studies or testimonials. This diligence helps mitigate risks associated with supplier selection.

- Key Questions to Ask:

- What has been the supplier’s experience in your industry?

- Are there any known issues with product quality or delivery timelines?

Step 7: Establish Clear Communication Channels

Effective communication is crucial throughout the sourcing process. Ensure that you establish clear lines of communication with your chosen supplier to facilitate smooth transactions and address any concerns that may arise during the procurement process.

- Best Practices:

- Set up regular check-ins or updates.

- Utilize project management tools to track progress and resolve issues promptly.

By following these steps, international B2B buyers can effectively navigate the sourcing process for needles in the USA, ensuring that they make informed, strategic purchasing decisions.

Comprehensive Cost and Pricing Analysis for needles usa Sourcing

What Are the Key Cost Components for Sourcing Needles in the USA?

When sourcing needles in the USA, understanding the cost structure is crucial for B2B buyers. The primary components include:

-

Materials: The quality and type of materials used in needle production significantly affect costs. High-quality stainless steel or specialty alloys may increase the price but provide better durability and performance.

-

Labor: Labor costs can vary depending on the region and the skill level required for production. In the USA, labor costs are generally higher than in many developing countries, which can impact pricing.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient operations can help mitigate these costs, making it essential for buyers to evaluate suppliers’ operational efficiencies.

-

Tooling: Initial tooling costs can be significant, particularly for custom needle designs. These costs are typically amortized over the production volume, making them a vital consideration for larger orders.

-

Quality Control (QC): Ensuring that needles meet industry standards and certifications involves additional costs. Implementing rigorous QC processes can enhance product reliability but may increase overall costs.

-

Logistics: Shipping and handling costs vary based on destination, volume, and selected Incoterms. Buyers should consider these factors when calculating total costs.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary widely based on market demand and competition.

How Do Price Influencers Impact Needle Sourcing Costs?

Several factors influence pricing in the needle market:

-

Volume/MOQ: Minimum order quantities (MOQs) can lead to bulk discounts. Suppliers often provide better pricing for larger orders, making it essential for buyers to assess their needs accurately.

-

Specifications and Customization: Custom designs or specific specifications can significantly increase costs. Buyers should weigh the need for customization against the potential price increase.

-

Materials: As mentioned, the choice of materials directly affects the price. Buyers should request detailed material specifications to ensure they receive the best value.

-

Quality and Certifications: Needles that meet higher quality standards or certifications (e.g., ISO, CE) typically command higher prices. However, these certifications can also enhance product reliability and safety.

-

Supplier Factors: The supplier’s reputation, production capacity, and geographic location can influence pricing. Established suppliers with robust quality assurance processes may charge a premium.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) affects shipping responsibilities and costs. Buyers should clarify these terms to avoid unexpected expenses.

What Tips Can Help Buyers Negotiate Better Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost management are key:

-

Negotiate Terms: Engage in open discussions regarding pricing, MOQ, and payment terms. Suppliers may be flexible on these terms to secure a deal.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the upfront price. Consider factors like durability, warranty, and maintenance costs.

-

Understand Pricing Nuances: Be aware that pricing may vary based on regional market conditions. Conduct market research to identify competitive pricing and leverage this information during negotiations.

-

Build Long-Term Relationships: Developing strong relationships with suppliers can lead to better pricing, more favorable terms, and priority during production schedules.

-

Request Detailed Quotes: Always ask for itemized quotes that break down costs. This transparency can reveal areas for negotiation and help in comparing multiple suppliers.

Disclaimer on Pricing

The prices of needles sourced from the USA can vary widely based on numerous factors. It is advisable for buyers to obtain multiple quotes and conduct thorough due diligence to ensure they are getting competitive pricing that meets their specific needs.

Alternatives Analysis: Comparing needles usa With Other Solutions

Introduction to Alternatives in the B2B Needle Solutions Market

In the competitive landscape of B2B needle solutions, it’s essential to evaluate various options to determine the best fit for specific business needs. Different technologies and methods can achieve similar objectives, but their performance, cost, and ease of implementation can vary significantly. This section provides a comparative analysis of ‘Needles USA’ against other viable alternatives, allowing international buyers to make informed decisions.

Comparison Table

| Comparison Aspect | Needles USA | Alternative 1: Medical-Grade Needles | Alternative 2: Biodegradable Needles |

|---|---|---|---|

| Performance | High precision for various applications | Reliable performance in clinical settings | Moderate performance, suitable for specific uses |

| Cost | Mid-range pricing | Generally higher due to quality standards | Competitive pricing, often lower than traditional needles |

| Ease of Implementation | User-friendly, widely available | Requires training for optimal use | Simple to use, but limited availability in some regions |

| Maintenance | Minimal; designed for durability | Regular maintenance needed | Limited lifespan, needs frequent replacement |

| Best Use Case | Versatile for different industries | Ideal for healthcare and surgical applications | Suitable for environmentally conscious businesses |

Detailed Breakdown of Alternatives

Alternative 1: Medical-Grade Needles

Medical-grade needles are designed for precise applications in healthcare settings. They offer reliable performance, particularly in clinical environments where safety and accuracy are paramount. However, they typically come at a higher price point due to stringent quality standards and regulatory compliance. Additionally, the implementation of medical-grade needles may require specialized training for personnel, which can increase operational costs. While they excel in performance, their higher maintenance needs and costs can be a disadvantage for businesses with tighter budgets.

Alternative 2: Biodegradable Needles

Biodegradable needles are an innovative solution aimed at reducing environmental impact. They are often made from sustainable materials and are designed to decompose after disposal, making them an attractive option for environmentally conscious businesses. While their pricing is competitive, their performance is moderate and may not be suitable for all applications. Moreover, the limited availability in certain markets can hinder their implementation. These needles offer a compelling alternative for businesses looking to enhance their sustainability practices, but they may not meet the stringent performance standards required in critical applications.

Conclusion: Choosing the Right Needle Solution for Your Business

When selecting a needle solution, B2B buyers must consider their specific needs, including performance requirements, budget constraints, and sustainability goals. ‘Needles USA’ offers a versatile option that balances quality and affordability, making it suitable for a range of industries. In contrast, medical-grade needles provide superior performance for healthcare applications but come at a higher cost, while biodegradable needles cater to environmentally conscious businesses with moderate performance and competitive pricing. Ultimately, the decision should align with the organization’s objectives, ensuring that the chosen solution effectively meets operational demands while supporting broader business goals.

Essential Technical Properties and Trade Terminology for needles usa

What Are the Key Technical Properties of Needles in the USA Market?

Understanding the essential technical properties of needles is crucial for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. Here are some key specifications to consider:

1. Material Grade

The material used in needle manufacturing significantly impacts performance and durability. Common materials include stainless steel, carbon steel, and specialized alloys. For example, stainless steel needles are resistant to rust and corrosion, making them ideal for medical applications. Selecting the right material grade ensures that the needles meet the specific demands of their intended use, whether in textiles or medical fields.

2. Tolerance

Tolerance refers to the permissible limits of variation in a needle’s dimensions. In precision applications, such as surgical needles, tight tolerances (measured in micrometers) are critical for ensuring proper function and safety. B2B buyers must consider tolerance specifications to maintain quality control and compliance with industry standards.

3. Needle Size and Gauge

Needle size is often indicated by its gauge, with higher numbers representing thinner needles. For instance, a 20-gauge needle is thicker than a 25-gauge needle. The size impacts the application; for example, larger needles are used for thicker materials, while finer needles are suited for delicate fabrics or tasks. Understanding gauge specifications helps buyers choose the right needle for their specific needs.

4. Point Style

The point style of a needle determines its application. Common types include round, sharp, and wedge points. Each type is designed for specific materials and tasks; for example, sharp points penetrate fabrics easily, while wedge points are ideal for thicker materials. Buyers should be familiar with point styles to ensure compatibility with their production processes.

5. Coating

Needles may come with various coatings to enhance performance, such as silicone or Teflon. These coatings can reduce friction, improve glide through materials, and prevent sticking. When sourcing needles, understanding the benefits of different coatings can lead to improved efficiency and product quality.

What Are the Common Trade Terms Used in the Needles Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B environment. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are marketed under another company’s brand. In the needles industry, buyers may work with OEMs to source specialized needles tailored to their specifications, allowing them to maintain brand integrity while ensuring high-quality components.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory effectively and ensure cost-efficiency. In the needles market, MOQs can vary significantly depending on the manufacturer and product type.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For B2B buyers in the needles market, issuing an RFQ allows for comparative analysis of costs and terms, ensuring that they obtain the best possible deal.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B transactions involving needles, as they clarify who is responsible for shipping, insurance, and tariffs, thereby minimizing potential disputes.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. In the needles industry, understanding lead times is essential for effective supply chain management. Buyers should factor in lead times when planning production schedules to avoid disruptions.

By grasping these technical properties and trade terms, B2B buyers can navigate the needles market more effectively, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the needles usa Sector

What Are the Key Trends Influencing the Needles USA Market?

The needles market in the USA is shaped by various global drivers and emerging trends that present significant opportunities for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe. A primary driver is the increasing demand for specialized medical and industrial needles, attributed to advancements in healthcare technologies and the growing prevalence of chronic diseases. This trend is further fueled by the rise in minimally invasive procedures, which require precision needles for effective outcomes.

Emerging B2B technology trends, such as the integration of digital supply chain management and automation, are transforming the sourcing landscape. Companies are increasingly adopting data analytics and IoT solutions to enhance inventory management, streamline operations, and reduce lead times. Additionally, the shift towards e-commerce platforms is enabling international buyers to access a broader range of needle products with improved transparency regarding pricing and delivery options.

Market dynamics also reflect a shift towards customization, with manufacturers offering tailored solutions to meet specific client needs. This trend is particularly relevant for businesses in sectors such as textiles, medical supplies, and manufacturing, where precision and quality are paramount. As a result, international buyers must remain agile, leveraging these trends to identify reputable suppliers and forge strategic partnerships that align with their sourcing requirements.

How Is Sustainability and Ethical Sourcing Addressed in the Needles USA Sector?

Sustainability and ethical sourcing are increasingly critical considerations for B2B buyers in the needles sector. The environmental impact of manufacturing processes, particularly in terms of waste generation and resource depletion, has prompted many companies to adopt sustainable practices. These practices include using eco-friendly materials, optimizing production processes to minimize energy consumption, and implementing waste recycling initiatives.

Ethical supply chains are essential for ensuring product quality and safety, especially in the medical and industrial sectors. Buyers are encouraged to prioritize suppliers that adhere to stringent ethical standards, such as fair labor practices and responsible sourcing of raw materials. Certifications like ISO 14001 for environmental management and Oeko-Tex for textile safety are becoming vital indicators of a supplier’s commitment to sustainability.

Moreover, the demand for ‘green’ certifications and materials is rising, with many international buyers seeking suppliers that utilize biodegradable or recyclable materials in their needle production. This trend not only aligns with global sustainability goals but also appeals to increasingly conscious consumers who prefer eco-friendly products. By focusing on sustainability and ethical sourcing, B2B buyers can enhance their brand reputation while contributing positively to the environment.

What Is the Historical Context of the Needles USA Market?

The needles market in the USA has evolved significantly since its inception in the late 19th century. With the establishment of the railroad system and the subsequent growth of various industries, the demand for different types of needles, including those used in sewing, medical applications, and industrial purposes, began to rise. This growth was particularly influenced by the expansion of textile manufacturing and advancements in medical technologies.

Over the decades, the industry has adapted to changing consumer needs and technological advancements, leading to the development of specialized needles designed for specific applications. The introduction of automation in manufacturing processes has further streamlined production, enhancing efficiency and quality. Today, the needles market continues to innovate, driven by the need for precision and reliability in various sectors, including healthcare, textiles, and manufacturing. This historical context underscores the importance of understanding market dynamics for B2B buyers looking to navigate the current landscape effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of needles usa

-

How do I ensure the quality of needles sourced from the USA?

To ensure the quality of needles, it is crucial to conduct thorough supplier vetting. Request certifications like ISO or FDA approval, which indicate compliance with safety and quality standards. Consider asking for product samples to test for durability and performance before placing a large order. Additionally, establishing a quality assurance process, including regular audits of the supplier’s facilities and production methods, can help maintain consistent quality in your purchases. -

What are the common payment terms for B2B transactions in the needle industry?

Payment terms can vary widely among suppliers, but common practices include Net 30, Net 60, or payment upon delivery. It’s advisable to negotiate terms that align with your cash flow needs. Some suppliers may require a deposit upfront, especially for custom orders, while others may offer letters of credit for larger transactions. Always ensure that payment methods are secure, and consider using escrow services for high-value transactions to mitigate risk. -

What is the minimum order quantity (MOQ) for needles from US suppliers?

Minimum order quantities (MOQs) can differ based on the supplier and the type of needles. Typically, MOQs range from 100 to 1,000 units, depending on the product specifications and the supplier’s production capabilities. For customized products, MOQs may be higher due to setup costs. Always confirm MOQs before initiating negotiations, and consider discussing flexibility on order sizes, especially if you’re a new buyer. -

How can I customize needles for my specific needs?

Many US suppliers offer customization options for needles, including variations in size, material, and packaging. To initiate the customization process, provide detailed specifications and any relevant drawings or samples. It’s essential to communicate your needs clearly and establish timelines for production. Additionally, inquire about any associated costs and minimum order requirements for customized products to ensure they fit within your budget. -

What logistics considerations should I be aware of when importing needles from the USA?

When importing needles, consider factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with the regulations specific to medical or industrial needles. Ensure all documentation, such as commercial invoices and packing lists, is accurate to avoid delays. Understanding the customs duties and taxes applicable to your shipment can also help you budget effectively and avoid unexpected costs. -

What regulatory compliance should I be aware of when sourcing needles?

Sourcing needles from the USA requires adherence to various regulatory standards depending on your country of import. Familiarize yourself with the regulations set by your local health authorities, which may include certifications like CE marking in Europe or compliance with the FDA in the USA. It’s advisable to work closely with suppliers who can provide documentation proving that their products meet your regulatory requirements. -

How do I build a strong relationship with needle suppliers in the USA?

Building a strong relationship with suppliers involves consistent communication, transparency, and mutual trust. Start by clearly outlining your expectations and requirements from the beginning. Regularly check in with suppliers to discuss order progress, feedback, and potential improvements. Establishing a partnership mentality, where both parties benefit from the relationship, can lead to better pricing, priority service, and enhanced product quality over time. -

What are the common challenges when sourcing needles from the USA, and how can I overcome them?

Common challenges include high shipping costs, regulatory compliance issues, and potential delays in production. To overcome these challenges, consider consolidating orders to reduce shipping expenses and working with suppliers who have experience in international trade. Establishing clear timelines and maintaining open lines of communication can help mitigate delays. Additionally, staying informed about regulatory changes in both the USA and your own country can prevent compliance issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for needles usa

What Are the Key Takeaways for B2B Buyers in Needles, USA?

In conclusion, strategic sourcing in Needles, California, presents a unique opportunity for international B2B buyers. The city’s strategic location at the crossroads of major transportation routes, including Interstate 40 and the Burlington Northern Santa Fe Railroad, enhances its accessibility and logistics capabilities. This connectivity allows for efficient supply chain management, making it an attractive hub for sourcing high-quality goods at competitive prices.

Moreover, the supportive business environment, characterized by a rich history and a commitment to growth, fosters partnerships that can lead to mutually beneficial outcomes. International buyers, particularly from Africa, South America, the Middle East, and Europe, can leverage these advantages to establish reliable supply chains and tap into the diverse market offerings available in Needles.

How Can International Buyers Capitalize on Opportunities in Needles?

As we look to the future, it is essential for B2B buyers to engage actively with local suppliers and explore the unique products that emerge from this region. By fostering relationships with businesses in Needles, international buyers can not only secure their supply chains but also benefit from the innovative spirit that defines this vibrant community. We encourage you to consider Needles, USA, as a strategic sourcing destination that promises growth and success for your business ventures.