Top 8 Mahr Federal Usa List and Guide: How To Solve Scenario 1: Q…

Introduction: Navigating the Global Market for mahr federal usa

In today’s fast-paced global marketplace, sourcing precise measurement solutions can be a daunting challenge for B2B buyers, particularly when considering the diverse offerings of Mahr Federal USA. As a leader in metrology and dimensional measurement, Mahr Federal provides a range of innovative tools and technologies that ensure high-quality manufacturing across various sectors, from automotive to aerospace. This guide serves as a comprehensive resource for international buyers from Africa, South America, the Middle East, and Europe, including countries like Vietnam and Saudi Arabia, to navigate the complexities of selecting the right metrology equipment.

Within this guide, you will discover an in-depth exploration of Mahr Federal’s extensive product offerings, including gaging instruments, metering systems, and calibration services. We will delve into their applications across industries, the nuances of supplier vetting, and considerations for cost-effectiveness. By equipping you with actionable insights and practical advice, this guide empowers you to make informed purchasing decisions that align with your specific operational needs. Whether you are looking to enhance production efficiency or ensure precision in measurement, understanding the capabilities of Mahr Federal USA will enable you to optimize your supply chain and elevate your manufacturing standards.

Top 10 Mahr Federal Usa Manufacturers & Suppliers List

1. Mahr Group – Innovative Metrology Solutions

Domain: mahr.com

Registered: 1997 (28 years)

Introduction: Mahr Group offers high-quality metrology for quality control in measuring rooms, production, incoming goods, and development. Their product range includes: 1. Metrology: Innovative measuring technology for length, diameter, surface, contour, form, position, gears, and shafts. 2. Metering Systems: Gear metering pumps, pumps for fiber production, and meter mix dispense machines for precise mixing an…

2. Mahrusa – Custom Meter Mix Dispense Solutions

Domain: mahrusa.com

Registered: 2010 (15 years)

Introduction: Industry Leading Custom Meter Mix Dispense Solutions, Precision Gear Pumps, Hazardous Area Solutions, Cannabis Processing & Dispensing, Mixing Heads (Static, Dynamic, Static/Dynamic), Mixer Tubes, Process Valves, Meter Mix Dispense Systems (Standard Machines, Custom Machines), Drum Pump Supply Systems, Solids Metering, Material Handling Equipment (Disc Feeders, Screw Feeders), Applications (Fillin…

3. Mahr Federal Inc. – Dimensional Measurement Solutions

Domain: toolandgagehouse.com

Registered: 1999 (26 years)

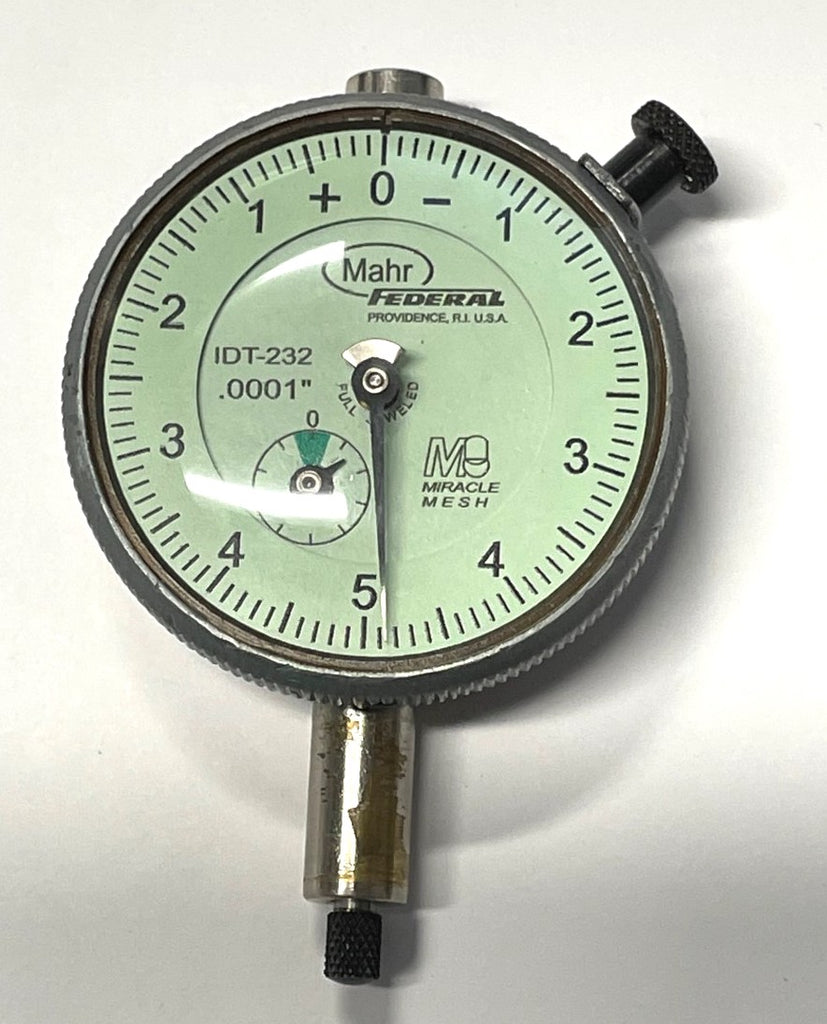

Introduction: Mahr Federal Inc. provides dimensional measurement solutions for precision manufacturers in various industries including automotive, defense, aerospace, and medical devices. They offer a range of gaging instruments such as dial indicators, hand-held indicator gages, digital readout air forks, high precision form or surface finish analysis instruments, and laboratory gages for calibrating gage bloc…

4. Mahr – High-Quality Metrology Products

Domain: metrology.mahr.com

Registered: 1997 (28 years)

Introduction: Mahr offers a wide range of high-quality metrology products for various applications, including: Handheld gages (calipers, micrometers, dial indicators), Length metrology & components (indication and evaluation instruments, probes, pneumatic length measuring instruments), Height measuring instruments (manual and motorized), Calibration & setting machines, Microscopes (measuring and 3D), Contour me…

5. Mahr Inc. – Precision Measurement Equipment

Domain: airframer.com

Registered: 2005 (20 years)

Introduction: Mahr Inc. specializes in inspection equipment and precision measurement equipment, including measurement impedance/resistance measuring equipment, optical measurement equipment, navigation aids (airborne), and distance measuring equipment.

6. Mahr – Precision Measuring Tools

Domain: penntoolco.com

Registered: 1997 (28 years)

Introduction: Mahr is a multinational, medium-sized, family business, founded in 1861 in Esslingen, Germany. It is one of the oldest metrology companies in Europe and has been a leader in precision measuring tools in the U.S. since its arrival in 1970. Mahr offers an extensive range of metrology tools including Air Gaging, Digimar, Height Measuring Instruments, Gages, Gage Blocks, MarCal Calipers, MarTest Dial …

7. Mahr Federal – Dimensional Measurement Tools

8. Mahr Inc. – Dimensional Measurement Solutions

Understanding mahr federal usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dimensional Measurement Tools | High precision instruments for measuring dimensions | Automotive, aerospace, medical devices | Pros: Accurate, reliable, industry-standard. Cons: May require specialized training. |

| Meter Mix Dispense Systems | Customizable systems for precise liquid and paste dispensing | Manufacturing, food processing, pharmaceuticals | Pros: Tailored solutions, high efficiency. Cons: Initial setup costs can be high. |

| Rotary Stroke Bearings | Durable bearings providing precise rotary and linear motion | Robotics, automation, machinery | Pros: Long service life, versatile. Cons: Limited to specific application types. |

| Calibration Services | Comprehensive calibration for measurement instruments | Quality assurance, compliance industries | Pros: Ensures accuracy, ISO-certified. Cons: Ongoing costs for regular calibration. |

| Custom Gaging Solutions | Tailored gages for specific measurement needs | Job shops, manufacturing sectors | Pros: Meets unique requirements, improves efficiency. Cons: Longer lead times for custom orders. |

What Are the Key Characteristics of Dimensional Measurement Tools from Mahr Federal?

Dimensional measurement tools from Mahr Federal are designed for high precision and reliability, catering to industries such as automotive, aerospace, and medical devices. These tools include a wide range of products, such as dial indicators and digital readout systems, that provide accurate measurements essential for quality control. When considering these tools, buyers should evaluate their specific measurement needs, the required accuracy levels, and whether staff will need training to use these sophisticated instruments effectively.

How Do Meter Mix Dispense Systems Enhance Manufacturing Processes?

Mahr’s meter mix dispense systems are engineered for high precision in dispensing liquids and pastes, making them ideal for diverse applications in manufacturing, food processing, and pharmaceuticals. These systems are customizable, allowing businesses to adapt them to specific production needs, which enhances efficiency and reduces waste. Buyers should consider their production volume, the complexity of the materials being dispensed, and the potential for future scalability when investing in these systems.

What Advantages Do Rotary Stroke Bearings Offer in Automation?

Mahr’s rotary stroke bearings provide targeted and repeatable movements, making them essential components in robotics, automation, and machinery applications. Their durability and precision enable manufacturers to achieve high performance and reliability in their operations. When purchasing these bearings, businesses should assess their application requirements, the expected load conditions, and compatibility with existing systems to ensure optimal performance.

Why Are Calibration Services Critical for Quality Assurance?

Calibration services offered by Mahr Federal are vital for maintaining the accuracy of measurement instruments across various industries, particularly in quality assurance and compliance sectors. With ISO certifications, these services ensure that instruments meet stringent industry standards. Buyers must consider the frequency of required calibrations, the specific instruments needing service, and the associated costs to maintain compliance and operational integrity.

How Do Custom Gaging Solutions Address Unique Measurement Needs?

Mahr Federal specializes in custom gaging solutions that cater to specific measurement requirements in job shops and manufacturing sectors. These tailored gages improve measuring efficiency and ensure that unique production specifications are met. When exploring custom gaging options, buyers should evaluate their measurement challenges, the potential impact on production efficiency, and the lead time for custom solutions to align with their operational timelines.

Key Industrial Applications of mahr federal usa

| Industry/Sector | Specific Application of Mahr Federal USA | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Dimensional measurement solutions for engine parts | Ensures precision in manufacturing, reducing defects and costs | Need for ISO-certified equipment and calibration services |

| Aerospace | High-precision gaging for component manufacturing | Enhances safety and compliance with stringent regulatory standards | Requirements for traceability and compliance with aerospace standards |

| Medical Devices | Calibration of medical device manufacturing tools | Guarantees accuracy and reliability, crucial for patient safety | Need for validated calibration processes and certification |

| Industrial Machinery | Measurement solutions for machinery components | Increases operational efficiency and reduces downtime | Consideration of ruggedness and adaptability to extreme conditions |

| Plastics and Composites | Meter mix dispense technology for material processing | Improves consistency in product quality and reduces waste | Importance of customization for specific material properties |

How is Mahr Federal USA Applied in the Automotive Sector?

In the automotive industry, Mahr Federal USA provides advanced dimensional measurement solutions for critical engine components. These solutions help manufacturers maintain tight tolerances, which is essential for the performance and longevity of engine parts. By utilizing Mahr’s precision gaging instruments, automotive manufacturers can significantly reduce defects, which in turn lowers production costs. International buyers should consider the need for ISO-certified equipment and reliable calibration services to ensure compliance with global quality standards.

What Role Does Mahr Federal USA Play in Aerospace Manufacturing?

Mahr Federal USA’s high-precision gaging instruments are vital for the aerospace sector, where safety and regulatory compliance are paramount. These tools ensure that components meet strict specifications, helping manufacturers avoid costly recalls and ensuring passenger safety. The precision offered by Mahr’s products contributes to the overall reliability of aerospace systems. Buyers in this sector must focus on traceability and adherence to aerospace industry standards when sourcing equipment.

Why is Mahr Federal USA Important for Medical Device Manufacturing?

In the medical device sector, Mahr Federal USA specializes in calibrating manufacturing tools to ensure they meet stringent accuracy requirements. This is crucial, as even minor deviations can lead to significant safety issues for patients. Mahr’s calibration services help manufacturers ensure that their devices perform reliably and comply with health regulations. Buyers should prioritize validated calibration processes and seek certified services to maintain compliance and quality assurance.

How Does Mahr Federal USA Enhance Industrial Machinery Efficiency?

Mahr Federal USA offers comprehensive measurement solutions for industrial machinery, focusing on enhancing operational efficiency. By implementing their precision instruments, manufacturers can monitor and control production variables effectively, leading to reduced downtime and increased productivity. For international buyers, sourcing considerations should include the ruggedness of the equipment and its adaptability to various environmental conditions typical in industrial settings.

What Benefits Does Mahr Federal USA Provide in Plastics and Composites Processing?

In the plastics and composites industry, Mahr Federal USA’s meter mix dispense technology is crucial for ensuring the accuracy and consistency of material processing. This technology helps manufacturers optimize their production processes, leading to less waste and higher quality products. Buyers should consider the customization options available to meet specific material properties and processing needs, ensuring that the solutions fit seamlessly into their production lines.

3 Common User Pain Points for ‘mahr federal usa’ & Their Solutions

Scenario 1: Quality Assurance Challenges in Precision Manufacturing

The Problem: In the competitive world of precision manufacturing, maintaining consistent quality assurance is crucial. B2B buyers often struggle with variations in the manufacturing process, leading to defects that can halt production and result in costly reworks. For instance, a manufacturer in the aerospace sector might experience discrepancies in component dimensions due to inadequate measurement tools. Such issues not only affect product quality but also customer satisfaction and contractual obligations.

The Solution: To address these quality assurance challenges, B2B buyers should consider investing in Mahr Federal’s dimensional measurement solutions. Start by conducting a thorough assessment of your current measurement practices and identify any gaps in precision. Mahr Federal offers a wide range of gaging instruments, including high-precision form and surface finish analysis tools, which can help detect and quantify variations early in the production process. Implementing regular calibration and maintenance of these instruments, ideally through Mahr’s factory repair services, will ensure that your measurements remain accurate. Additionally, utilizing Mahr’s applications engineers for training on best practices can enhance your team’s ability to use these tools effectively, leading to improved quality control and reduced waste.

Scenario 2: Difficulty in Customizing Metering Solutions

The Problem: Many international B2B buyers face challenges when trying to customize metering solutions for specific production needs. For instance, a company in South America may require a unique meter mix dispense solution for a new product line that involves viscous materials. Off-the-shelf solutions often fall short, leading to inefficiencies and increased production costs.

The Solution: To effectively customize metering solutions, B2B buyers should leverage Mahr Federal’s expertise in precision engineering. Begin by engaging with Mahr’s process engineers early in the design phase of your production line. They can provide insights into the specific requirements of your application, such as viscosity, flow rates, and environmental conditions. Mahr’s Metering Systems division specializes in creating tailored solutions that meet diverse production needs, so don’t hesitate to discuss your unique challenges. Collaborating closely with Mahr will ensure that you receive a custom metering solution that not only enhances efficiency but also aligns with your production goals. Furthermore, consider incorporating their preventative maintenance services to maximize the longevity and reliability of your metering equipment.

Scenario 3: Ensuring Compliance with International Standards

The Problem: B2B buyers operating in global markets often find themselves navigating a complex landscape of compliance and regulatory standards. For example, a manufacturer in the Middle East may need to ensure that their measurement systems comply with ISO standards, which can be challenging without the right expertise and tools. Non-compliance can lead to significant fines and loss of business opportunities.

The Solution: To ensure compliance with international standards, B2B buyers should partner with Mahr Federal, which is well-versed in ISO-9001 and ISO-17025 certifications. Start by reviewing your current measurement systems and compare them against the necessary compliance benchmarks. Mahr Federal’s metrology laboratory is equipped to provide calibration services that adhere to these standards, thus guaranteeing that your measurement processes are reliable and accurate. Additionally, Mahr offers training programs to educate your staff on compliance requirements and best practices in measurement. By proactively addressing compliance issues with Mahr’s support, you can mitigate risks, enhance your brand’s reputation, and open doors to new international business opportunities.

Strategic Material Selection Guide for mahr federal usa

What Are the Key Materials Used in Mahr Federal USA Products?

Mahr Federal USA employs a variety of materials in its manufacturing processes, each chosen for specific applications and performance characteristics. Understanding these materials is crucial for international B2B buyers looking to make informed purchasing decisions.

How Does Stainless Steel Benefit Mahr Federal USA’s Products?

Stainless steel is a primary material used in many of Mahr Federal’s gaging instruments. Its key properties include excellent corrosion resistance, high strength, and the ability to withstand extreme temperatures and pressures. This makes stainless steel particularly suitable for applications in harsh environments, such as automotive and aerospace industries.

Pros: Stainless steel is durable and can withstand wear and tear, making it ideal for long-term use. It also has a relatively low maintenance requirement.

Cons: The main drawbacks are its higher cost compared to other metals and the complexity involved in machining, which can lead to longer lead times.

Impact on Application: Stainless steel is compatible with a wide range of media, including oils, fuels, and water, making it versatile for various measurement applications.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider compliance with international standards such as ASTM and ISO, which are often required for quality assurance in manufacturing.

What Role Does Aluminum Play in Mahr Federal USA’s Offerings?

Aluminum is another material frequently utilized in Mahr Federal’s products, particularly for components that require lightweight properties without sacrificing strength. It has a favorable strength-to-weight ratio and excellent corrosion resistance.

Pros: Aluminum is cost-effective and easier to machine than stainless steel, reducing manufacturing complexity and time.

Cons: While it is durable, aluminum is less robust than stainless steel and can be prone to deformation under heavy loads.

Impact on Application: Aluminum is suitable for applications where weight is a critical factor, such as in portable measuring devices.

Considerations for International Buyers: Compliance with regional standards is vital, especially in Europe, where regulations may dictate specific material properties for safety and performance.

How Do Plastics Enhance Mahr Federal USA’s Product Range?

Plastics, particularly high-performance polymers, are used in various gaging instruments and components. These materials offer excellent chemical resistance and can be engineered to meet specific performance criteria.

Pros: Plastics are lightweight, cost-effective, and can be molded into complex shapes, allowing for innovative designs.

Cons: They may not withstand high temperatures or mechanical stresses as well as metals, which can limit their application scope.

Impact on Application: Plastics are ideal for applications involving corrosive chemicals or where weight savings are essential.

Considerations for International Buyers: Buyers should ensure that the selected plastic materials comply with local regulations regarding chemical resistance and safety standards.

What Advantages Does Composite Material Offer for Mahr Federal USA?

Composite materials are increasingly being used in advanced applications due to their unique properties. They combine the benefits of different materials, such as strength and lightweight characteristics.

Pros: Composites offer exceptional strength-to-weight ratios and can be tailored for specific applications, enhancing performance.

Cons: They can be more expensive and complex to manufacture, which may increase lead times.

Impact on Application: Composites are particularly advantageous in applications requiring high strength and low weight, such as aerospace components.

Considerations for International Buyers: It’s essential to verify that composite materials meet relevant international standards, such as those set by ASTM or JIS.

Summary Table of Material Selections

| Material | Typical Use Case for Mahr Federal USA | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Gaging instruments for automotive and aerospace | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Aluminum | Lightweight components in portable measuring devices | Cost-effective and easy to machine | Less robust under heavy loads | Medium |

| Plastics | Gaging instruments exposed to corrosive chemicals | Lightweight and moldable | Limited high-temperature resistance | Low |

| Composites | Advanced applications in aerospace | Exceptional strength-to-weight ratio | Higher cost and manufacturing complexity | High |

This strategic material selection guide serves as a foundational resource for international B2B buyers, helping them navigate the complexities of material choices in Mahr Federal USA’s product offerings.

In-depth Look: Manufacturing Processes and Quality Assurance for mahr federal usa

What Are the Key Stages in the Manufacturing Process at Mahr Federal USA?

Mahr Federal USA employs a comprehensive manufacturing process designed to produce high-quality metrology instruments and equipment. The main stages of this process include material preparation, forming, assembly, and finishing, each critical to ensuring precision and performance.

How Is Material Prepared for Manufacturing?

Material preparation involves selecting high-grade materials that meet specific standards for durability and precision. Mahr Federal emphasizes the use of high-quality metals and composites, which are rigorously tested for their mechanical properties before being approved for production. This step includes cutting, shaping, and treating materials to ensure they are suitable for subsequent manufacturing processes.

What Forming Techniques Are Utilized?

Once the materials are prepared, the forming stage commences. Mahr Federal employs various techniques, such as CNC machining and precision casting, to create components with high dimensional accuracy. CNC (Computer Numerical Control) technology allows for complex shapes and intricate designs, enabling the production of components that meet exact specifications. Forming techniques are chosen based on the part’s complexity, volume requirements, and material properties.

How Is the Assembly Process Conducted?

The assembly process at Mahr Federal is meticulously organized to ensure that each component fits together seamlessly. Skilled technicians use specialized tools and fixtures to assemble products, often under strict tolerances. This stage may also involve integrating electronic components and software for automated measuring systems, ensuring that the end product meets operational requirements.

What Finishing Techniques Are Applied?

Finishing techniques play a crucial role in enhancing the product’s performance and aesthetic appeal. Mahr Federal employs processes such as surface treatment, coating, and polishing to improve wear resistance and reduce friction. Quality control is embedded in this stage, with inspections conducted to verify that surface finishes meet the required specifications.

What Quality Assurance Standards Does Mahr Federal USA Adhere To?

Quality assurance is integral to Mahr Federal’s manufacturing philosophy. The company adheres to internationally recognized standards such as ISO 9001 and industry-specific certifications, including CE and API. These standards ensure that products not only meet customer expectations but also comply with legal and regulatory requirements.

How Are Quality Control Checkpoints Established?

Mahr Federal implements a rigorous quality control process that includes several checkpoints throughout the manufacturing stages:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components before they enter the production line. Materials that do not meet specified criteria are rejected.

-

In-Process Quality Control (IPQC): During the manufacturing process, inspections are conducted to monitor critical parameters and dimensions. This ensures that any deviations from specifications are identified and corrected promptly.

-

Final Quality Control (FQC): At the end of the production line, finished products undergo thorough testing and inspection. This stage verifies that all specifications are met before the products are shipped to customers.

What Testing Methods Are Commonly Used?

To ensure the highest quality, Mahr Federal employs various testing methods tailored to the specific applications of its products. Common testing techniques include:

- Dimensional Measurement: Utilizing advanced metrology equipment to verify the accuracy of dimensions and tolerances.

- Functional Testing: Assessing the performance of products under simulated operational conditions to ensure reliability and efficiency.

- Environmental Testing: Subjecting products to extreme conditions (temperature, humidity, etc.) to evaluate their durability and performance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential. Here are some actionable steps buyers can take:

-

Conduct Audits: Regular audits of manufacturing facilities can provide insights into the supplier’s quality management systems and adherence to international standards.

-

Request Quality Reports: Suppliers should be able to provide detailed reports outlining their quality control processes, including metrics on defect rates, inspection results, and corrective actions taken.

-

Engage Third-Party Inspectors: Utilizing independent inspection services can offer an objective assessment of the supplier’s manufacturing and quality control practices.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers must be aware of specific nuances related to quality control and certification when engaging with suppliers like Mahr Federal. Understanding local regulations and compliance requirements is vital. For instance:

-

Regional Standards: Different regions may have varying standards and certifications. Buyers should confirm that the supplier’s products meet the necessary certifications for their specific market.

-

Documentation: Proper documentation of quality control practices and certifications is crucial for customs clearance and compliance with local regulations.

-

Communication: Establishing clear communication channels with suppliers regarding quality expectations and regulatory requirements can facilitate smoother transactions and reduce misunderstandings.

Conclusion

Mahr Federal USA’s commitment to high-quality manufacturing processes and stringent quality assurance measures positions it as a reliable partner for B2B buyers across diverse industries. By understanding the manufacturing stages and quality control protocols, international buyers can make informed decisions and establish long-term partnerships that enhance their operational efficiency and product quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mahr federal usa’

In today’s competitive manufacturing landscape, sourcing high-quality measurement solutions from Mahr Federal USA is essential for ensuring precision and efficiency in production processes. This guide provides a practical checklist to assist international B2B buyers in navigating the procurement of Mahr Federal products effectively.

Step 1: Define Your Technical Specifications

Start by outlining the specific measurement needs of your manufacturing process. Clearly defined technical specifications ensure that the products you procure meet your operational requirements. Consider factors such as measurement range, accuracy, and environmental conditions where the equipment will be used.

- Measurement Type: Identify whether you need dimensional gaging instruments, calibration solutions, or specialized gages for unique applications.

- Industry Standards: Reference relevant industry standards that your products must comply with, ensuring they align with your quality assurance protocols.

Step 2: Research Product Offerings

Investigate the full range of products available from Mahr Federal USA. Understanding the variety of solutions, such as precision gages, calibration instruments, and metrology systems, will help you select the best fit for your needs.

- Product Catalog: Review the online catalog or request a brochure to gain insights into the latest technologies and innovations.

- Application Suitability: Assess which products are designed for your specific industry, be it automotive, aerospace, or medical devices.

Step 3: Evaluate Potential Suppliers

Before finalizing any purchase, it’s critical to evaluate potential suppliers. Request detailed information about Mahr Federal USA’s operational history, customer service reputation, and technical support capabilities.

- Company Profile: Look for case studies or testimonials from similar businesses that have successfully implemented Mahr’s solutions.

- Support Services: Inquire about available training, maintenance services, and calibration support to ensure you receive comprehensive assistance post-purchase.

Step 4: Verify Supplier Certifications

Ensure that Mahr Federal USA meets relevant certifications and quality standards. This step is crucial for guaranteeing that the products comply with international measurement standards.

- ISO Certifications: Confirm their ISO-9001 and ISO-17025 certifications, which indicate adherence to quality management and calibration standards.

- NIST Compliance: Check for compliance with U.S. National Institute of Standards and Technology (NIST) protocols to ensure measurement accuracy.

Step 5: Request Samples or Demonstrations

If feasible, request samples or demonstrations of the equipment before making a bulk purchase. This hands-on experience can provide invaluable insights into product performance and usability.

- Testing Conditions: Ensure that the testing conditions closely match your operational environment for accurate evaluation.

- Technical Feedback: Engage your technical team during the demonstration to gather their feedback on usability and integration into existing processes.

Step 6: Negotiate Terms and Conditions

Once you’ve selected the appropriate products and evaluated the supplier, negotiate terms of purchase. This step can significantly impact your overall project costs and delivery timelines.

- Pricing Structure: Discuss pricing, bulk discounts, and potential payment terms to align with your budget.

- Delivery and Support: Confirm lead times for delivery and post-sale support to avoid disruptions in your production schedule.

Step 7: Place Your Order and Monitor Delivery

After finalizing the terms, place your order and closely monitor the delivery process. Maintain communication with Mahr Federal USA to ensure timely shipping and address any issues that may arise.

- Tracking Information: Request tracking information to stay updated on the shipment status.

- Quality Check on Arrival: Upon receipt, conduct a thorough inspection of the products to verify they meet the specified quality standards.

By following this checklist, international B2B buyers can streamline the sourcing process for Mahr Federal USA products, ensuring they invest in high-quality measurement solutions that enhance their manufacturing capabilities.

Comprehensive Cost and Pricing Analysis for mahr federal usa Sourcing

What Are the Key Cost Components in Mahr Federal USA Sourcing?

When sourcing products from Mahr Federal, it’s essential to understand the various cost components that contribute to the overall pricing structure. The primary cost components include:

-

Materials: The quality and type of materials used significantly impact pricing. Mahr Federal utilizes high-grade materials for their precision instruments, which can elevate costs but ensure durability and reliability.

-

Labor: Skilled labor is necessary for the production of sophisticated metrology and dispensing systems. Labor costs in the USA may be higher compared to other regions, reflecting the expertise required to produce high-precision tools.

-

Manufacturing Overhead: This encompasses costs related to utilities, equipment maintenance, and facility operations. Mahr Federal’s commitment to quality assurance adds to these overheads, as they invest in advanced manufacturing technologies and stringent quality control processes.

-

Tooling: Custom tooling may be necessary for specific applications, contributing to initial setup costs. This factor can vary significantly based on the complexity of the required tools.

-

Quality Control (QC): Mahr Federal maintains rigorous quality control measures, with their calibration systems certified to ISO-9001 and ISO-17025. This investment in QC ensures high standards but can also increase product prices.

-

Logistics: Shipping and handling costs can fluctuate based on destination and volume. Consideration of logistics is crucial for international buyers who may face additional tariffs and customs fees.

-

Margin: Mahr Federal’s pricing structure includes a margin that reflects their brand reputation and quality. This margin is influenced by their commitment to innovation and customer service.

How Do Volume and Customization Influence Pricing?

Pricing can be significantly affected by the volume of orders and customization requirements. Mahr Federal often provides discounts for larger volumes or minimum order quantities (MOQs), making it more cost-effective for businesses that can place bulk orders. Customization adds complexity and cost, as specialized designs or materials may require additional engineering and production time.

What Role Do Quality and Certifications Play in Pricing?

Quality certifications and standards play a crucial role in establishing trust and reliability in the products offered by Mahr Federal. Their adherence to rigorous quality standards justifies premium pricing, particularly for international buyers who may require assurance of compliance with local regulations. Buyers should consider the long-term benefits of investing in high-quality, certified products that can reduce operational risks and enhance overall efficiency.

How Can International Buyers Negotiate for Better Pricing?

For international buyers, effective negotiation strategies can yield better pricing outcomes. Here are some tips:

-

Understand Total Cost of Ownership (TCO): Evaluate not just the initial purchase price, but also maintenance, logistics, and potential downtime costs. A higher upfront cost may result in lower TCO if the equipment is more reliable.

-

Leverage Market Insights: Buyers from Africa, South America, the Middle East, and Europe should research market trends and competitor pricing. This information can strengthen negotiation positions.

-

Consider Incoterms: Familiarize yourself with Incoterms to clarify shipping responsibilities and costs. Choosing the right Incoterm can significantly affect total expenses.

-

Build Relationships: Establishing a long-term relationship with Mahr Federal can lead to better pricing and support. Loyal customers often receive preferential treatment regarding pricing and service.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers should be aware of fluctuations in currency exchange rates, which can impact pricing. Additionally, consider the potential for tariffs and import duties that may apply when bringing products into their home countries. Understanding these factors can help in making more informed purchasing decisions.

Conclusion

While Mahr Federal products may come with a premium price tag, the value derived from their quality, precision, and reliability is often worth the investment. By understanding the cost structure and leveraging strategic negotiation techniques, international buyers can make informed purchasing decisions that align with their business needs. Always approach pricing discussions with a focus on the long-term benefits and the total cost of ownership to maximize value.

Alternatives Analysis: Comparing mahr federal usa With Other Solutions

Understanding Alternative Solutions to Mahr Federal USA

When evaluating measurement and metrology solutions, it’s crucial for international B2B buyers to consider various alternatives to ensure they select the right technology for their needs. Mahr Federal USA, with its longstanding reputation for precision and innovation, is a prominent player in the market. However, alternatives may offer different features, pricing, and capabilities that could better align with specific operational requirements.

Comparison Table

| Comparison Aspect | Mahr Federal USA | Mitutoyo | Renishaw |

|---|---|---|---|

| Performance | High precision with ISO-certified standards | Excellent accuracy and wide product range | Superior accuracy with advanced technology |

| Cost | Moderate to high, reflective of quality | Competitive pricing with varied options | Higher price point due to advanced tech |

| Ease of Implementation | User-friendly with extensive support | Easy integration into existing systems | May require specialized training |

| Maintenance | Robust support with calibration services | Regular maintenance required | Requires specialized skills for upkeep |

| Best Use Case | Precision manufacturing in various industries | General-purpose metrology across sectors | High-tech applications like aerospace |

Detailed Breakdown of Alternatives

Mitutoyo

Mitutoyo is renowned for its comprehensive range of measurement tools that cater to different industries, from automotive to electronics. The brand offers competitive pricing while maintaining a high level of accuracy. Its tools are designed for easy integration into existing systems, making them a practical choice for many manufacturers. However, while the performance is commendable, regular maintenance is necessary to uphold accuracy, which could lead to increased long-term costs.

Renishaw

Renishaw specializes in advanced metrology systems, particularly for high-tech applications like aerospace and medical devices. Their products are known for superior accuracy and innovative technology, such as laser measurement systems and probe technology. However, these advantages come at a premium price, which may not be feasible for all businesses. Additionally, Renishaw’s equipment often requires specialized training for effective implementation and maintenance, which could be a barrier for companies with limited resources.

Conclusion: How to Choose the Right Measurement Solution

Selecting the right measurement solution requires a thorough understanding of your specific operational needs and constraints. B2B buyers should consider factors such as the precision required, budget limitations, ease of implementation, and the level of ongoing support necessary. While Mahr Federal USA offers a strong combination of performance and support, alternatives like Mitutoyo and Renishaw may provide unique advantages depending on the application. Conducting a detailed analysis of these factors will empower buyers to make informed decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for mahr federal usa

What Are the Key Technical Properties of Mahr Federal USA Products?

Understanding the technical specifications of Mahr Federal USA’s products is crucial for B2B buyers, especially in industries that demand precision and reliability. Here are some essential technical properties:

-

Material Grade

Mahr products are typically constructed from high-grade materials such as hardened steel and other alloys. The choice of material directly affects durability, wear resistance, and overall performance in demanding applications. For buyers, selecting equipment with the appropriate material grade ensures longevity and reduces replacement costs. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. Mahr Federal USA emphasizes tight tolerances (often in the microns) for their metrology tools and pumps. This is vital for industries like aerospace and automotive, where even minute discrepancies can lead to significant operational issues. Buyers must prioritize products with appropriate tolerances to meet their quality assurance standards. -

Accuracy

Accuracy measures how close a measurement is to the true value. Mahr’s products are designed to deliver exceptional accuracy, which is critical for ensuring the integrity of manufacturing processes. In sectors such as medical devices and defense, where precision is non-negotiable, buyers should look for equipment that guarantees high accuracy levels to maintain compliance and performance. -

Service Life

The expected service life of Mahr products, often spanning several decades with minimal maintenance, is a key selling point. This longevity is particularly important for B2B buyers who want to minimize downtime and avoid frequent replacements. Understanding the service life can help in budgeting and forecasting operational costs. -

Calibration Certification

Mahr Federal’s calibration services are certified to ISO-9001 and ISO-17025 standards. This ensures that their measurement tools provide reliable and repeatable results. For B2B buyers, this certification is essential for compliance with industry regulations and quality assurance protocols, ensuring that their products meet the necessary standards.

What Are Common Trade Terms Relevant to Mahr Federal USA?

Familiarity with industry terminology can streamline communication and negotiations between buyers and suppliers. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Mahr Federal USA often supplies OEMs with precision measurement tools. Understanding this term helps buyers identify potential partnerships and sourcing strategies. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units that a supplier is willing to sell. Mahr Federal USA may have MOQs for certain specialized equipment. Buyers should be aware of these quantities to ensure they meet order requirements and avoid excess inventory. -

RFQ (Request for Quotation)

An RFQ is a standard business process wherein a buyer requests pricing and terms from suppliers for specified products or services. For Mahr Federal USA, submitting an RFQ can initiate a dialogue regarding custom solutions or bulk purchases, helping buyers secure favorable terms. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including delivery, risk, and costs. Mahr Federal USA’s international clients must understand these terms to negotiate shipping and logistics effectively. -

Lead Time

Lead time is the period between the initiation of an order and its delivery. For Mahr Federal USA, understanding lead times is crucial for buyers who depend on timely delivery for their production schedules. This helps in planning inventory and managing supply chain logistics. -

Calibration

Calibration refers to the process of adjusting and verifying the accuracy of measurement instruments. Mahr Federal USA provides calibration services that ensure their equipment meets industry standards. Buyers should prioritize calibration capabilities to maintain operational accuracy and compliance.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing products from Mahr Federal USA, ensuring that they select equipment that meets their specific requirements and industry standards.

Navigating Market Dynamics and Sourcing Trends in the mahr federal usa Sector

What Are the Current Market Dynamics and Key Trends in the Mahr Federal USA Sector?

The Mahr Federal USA sector is experiencing significant transformations driven by advancements in technology, globalization, and evolving customer expectations. As precision manufacturing becomes increasingly critical across industries—ranging from aerospace to automotive—international buyers are seeking reliable suppliers that can provide high-quality measurement solutions. The rise of Industry 4.0 and smart manufacturing technologies is also reshaping sourcing strategies, with a focus on automated and integrated systems that enhance efficiency and accuracy.

Emerging trends include the growing demand for custom solutions that cater to specific production needs, particularly in markets such as Africa, South America, the Middle East, and Europe. Buyers are prioritizing suppliers like Mahr that can offer tailored metering systems and gaging products, ensuring that they meet the unique requirements of their operations. Additionally, there is a notable shift towards digital solutions that facilitate remote monitoring and maintenance, further enhancing operational efficiency.

Another key trend is the increased emphasis on quality assurance and compliance. As international regulations become more stringent, B2B buyers are looking for partners with robust certifications and proven track records in quality control, such as ISO-9001 and ISO-17025. This focus on compliance not only ensures product reliability but also builds trust between manufacturers and their clients.

How Important Is Sustainability and Ethical Sourcing in the Mahr Federal USA Sector?

Sustainability and ethical sourcing are gaining traction in the Mahr Federal USA sector, as both consumers and businesses recognize the environmental impact of manufacturing processes. Buyers are increasingly aware of the carbon footprint associated with their supply chains and are actively seeking partners that prioritize sustainability. This shift not only influences purchasing decisions but also shapes brand reputation in competitive markets.

Mahr Federal is committed to sustainable practices, employing environmentally friendly materials and processes in its manufacturing. The company’s focus on durability and longevity in its metering systems and gaging products reduces waste and promotes resource efficiency. Furthermore, obtaining ‘green’ certifications and utilizing eco-friendly materials can serve as a competitive advantage, attracting environmentally conscious B2B buyers.

Ethical supply chains are equally important, as transparency and fair labor practices become essential criteria for sourcing decisions. Companies are expected to demonstrate their commitment to ethical sourcing, ensuring that their products are manufactured responsibly. This trend is particularly significant for international buyers from regions such as Africa and South America, where ethical considerations can influence market access and partnerships.

What Is the Brief Evolution and History of Mahr Federal USA Relevant to B2B Buyers?

Established over 85 years ago in Providence, Rhode Island, Mahr Federal has evolved from a small company into a recognized leader in precision measurement solutions. Its deep expertise in dimensional measurement has positioned it as a trusted partner for industries such as automotive, aerospace, and medical devices. The company’s extensive history reflects a commitment to innovation and quality, as evidenced by its development of advanced gaging instruments and calibration services.

Mahr Federal’s legacy of excellence and reliability has established a strong foundation for its operations. As the market continues to evolve, the company remains focused on adapting to the changing needs of international B2B buyers, ensuring that it delivers cutting-edge solutions that meet the demands of a dynamic manufacturing landscape. This history of innovation and customer-centricity makes Mahr Federal an attractive choice for businesses seeking high-quality measurement solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of mahr federal usa

-

How do I solve quality assurance issues in my manufacturing process?

Quality assurance in manufacturing can be enhanced by integrating Mahr Federal’s advanced dimensional measurement solutions. Their products, including precision gages and calibration systems, are designed to monitor and control variations effectively. By utilizing Mahr’s expertise and products, you can establish a robust quality assurance protocol that ensures compliance with international standards and improves product reliability. Regular calibration and maintenance services offered by Mahr also help sustain measurement accuracy over time. -

What is the best metrology solution for my specific industry needs?

Mahr Federal offers a diverse range of metrology solutions tailored for various industries, including automotive, aerospace, and medical devices. To determine the best solution for your needs, consider your specific application requirements, such as the type of measurements, accuracy levels, and environmental conditions. Mahr’s team of applications engineers can provide customized recommendations and support to help you select the most effective metrology tools for your manufacturing processes. -

How can I customize Mahr products to fit my unique production requirements?

Mahr Federal excels in providing customized solutions to meet unique production needs. Their process engineers collaborate closely with clients to design tailor-made gaging and measurement systems that align with specific operational requirements. Whether you need specialized gages or unique calibration processes, Mahr’s commitment to customer satisfaction ensures that you receive the right solution that optimizes your manufacturing efficiency. -

What are the minimum order quantities (MOQ) for Mahr products?

Minimum order quantities (MOQ) for Mahr products can vary based on the specific product line and customization requirements. Generally, Mahr aims to accommodate the needs of their clients, including smaller businesses. It is advisable to reach out to Mahr’s sales team directly to discuss your order needs and any potential MOQs that may apply to your specific situation. -

What payment terms does Mahr Federal offer for international buyers?

Mahr Federal provides flexible payment terms to accommodate international buyers. Typically, payment options include bank transfers, letters of credit, and other secure methods that ensure both parties’ financial safety. Specific terms may vary based on the order size, buyer’s credit history, and the region. It’s best to discuss payment options directly with your Mahr sales representative to find the most suitable arrangement. -

How does Mahr ensure the quality of its products during international shipping?

Mahr Federal prioritizes the quality of its products throughout the shipping process. They utilize robust packaging solutions designed to protect sensitive instruments from damage during transit. Additionally, Mahr maintains strict quality control protocols, ensuring that all products undergo thorough inspection and calibration before shipping. By implementing these practices, Mahr guarantees that you receive high-quality, reliable products regardless of your location. -

What support does Mahr provide for product maintenance and servicing?

Mahr Federal offers comprehensive maintenance and servicing support to ensure your equipment remains operational and efficient. Their services include on-site training, preventative maintenance programs, and factory repair services. By partnering with Mahr, you gain access to their skilled technicians who can assist with troubleshooting and provide technical support, helping to minimize downtime and optimize your manufacturing processes. -

How can I vet Mahr Federal as a reliable supplier for my business?

Vetting Mahr Federal as a supplier involves researching their reputation, industry experience, and product offerings. With over 85 years in the metrology industry, Mahr has established itself as a trusted name in precision measurement solutions. Additionally, reviewing customer testimonials, case studies, and certifications such as ISO-9001 and ISO-17025 can provide insight into their quality standards. Engaging directly with Mahr’s sales and support teams can further clarify their capabilities and commitment to customer satisfaction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for mahr federal usa

Mahr Federal USA stands out as a formidable player in the field of precision measurement and metrology solutions, offering a comprehensive range of products tailored to meet the diverse needs of global industries. With over 160 years of experience, Mahr’s commitment to innovation and quality assurance translates into significant value for international B2B buyers. By leveraging Mahr’s expertise, companies can enhance their manufacturing processes, ensuring accuracy and efficiency that are critical in today’s competitive market.

Strategic sourcing from Mahr not only provides access to cutting-edge technology but also fosters long-term partnerships that can drive operational excellence. The ability to customize solutions, coupled with superior service and support, positions Mahr as a reliable ally for businesses across Africa, South America, the Middle East, and Europe.

As industries evolve, Mahr Federal USA remains dedicated to advancing precision engineering. International buyers are encouraged to explore how Mahr’s innovative solutions can integrate into their operations, enhancing productivity and quality. Embrace the opportunity to collaborate with a leader in metrology and secure a competitive edge in your market. Reach out today to discover how Mahr can transform your manufacturing processes for a more efficient and profitable future.