Top 8 Lorbec Metals Usa List and Guide: How To Solve Scenario 1: …

Introduction: Navigating the Global Market for lorbec metals usa

In the ever-evolving landscape of global trade, sourcing high-quality scrap metal, particularly from Lorbec Metals USA, presents both opportunities and challenges for international B2B buyers. Navigating the complexities of metal procurement requires a deep understanding of various scrap types, market conditions, and supplier capabilities. This guide is designed to equip buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Nigeria—with the knowledge necessary to make informed purchasing decisions.

This comprehensive resource delves into the intricacies of the scrap metal market, detailing the different types of ferrous and non-ferrous metals available for procurement, alongside their various applications across industries. We will also explore effective strategies for vetting suppliers, assessing cost structures, and optimizing logistics for international shipments. Buyers will gain insights into the recycling processes and sustainability practices that underpin Lorbec Metals USA’s operations, fostering a more responsible approach to sourcing.

By empowering B2B buyers with actionable insights and essential knowledge, this guide aims to streamline the purchasing process, reduce risks, and enhance the overall value derived from investments in scrap metal. Whether you’re looking to establish long-term supplier relationships or seeking to understand market trends, our guide serves as your essential tool for success in the global scrap metal market.

Top 10 Lorbec Metals Usa Manufacturers & Suppliers List

1. Lorbec Metals – Scrap & Recycling Services

2. Lorbec Metals USA – Scrap Metal Recycling

Domain: recycleinme.com

Registered: 2002 (23 years)

Introduction: Lorbec Metals USA Ltd specializes in recycling and trading of all grades of ferrous and non-ferrous scrap metal. They buy scrap metals including aluminum, copper, electronic scrap, steel, and miscellaneous metals. They provide safe and reliable transportation with their own fleet of trucks, which includes tractor trailers, roll off containers, and flatbed trailers. Additionally, they offer gaylord…

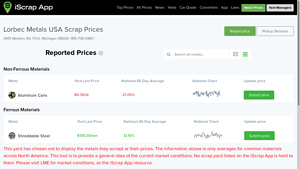

3. Lorbec Metals – Scrap Metal Price List

Domain: iscrapapp.com

Registered: 2010 (15 years)

Introduction: Lorbec Metals USA Scrap Metal Price List:

– Location: 3415 Western Rd, Flint, Michigan 48506

– Phone: 810-736-0961

**Non-Ferrous Materials:**

– Aluminum Cans: $0.39/lb (down 21.05%)

**Ferrous Materials:**

– Shreddable Steel: $135.00/ton (up 12.15%)

*Note: The yard has chosen not to display the metals they accept or their prices. The prices listed are averages for common materials across North …

4. Lorbec Metals – Recycling Facilities

Domain: bloomberg.com

Registered: 1993 (32 years)

Introduction: Lorbec Metals-USA Ltd operates recycling facilities.

5. Lorbec USA – Company Overview

6. Lorbec Metals USA Ltd. – Scrap Metal and Electronics Recycling

Domain: scrapmonster.com

Registered: 2009 (16 years)

Introduction: Lorbec Metals USA Ltd. accepts a variety of scrap materials including: Electronics (Laptops, Mobile phones, Modems/Routers, Servers), Metal (#2 Copper, #2 Insulated Wire, Aluminum Siding, Aluminum Wheels, Brass Radiators, Christmas Lights, Copper, Copper #1 Insulated Wire, Stainless Steel). They offer services for both non-ferrous and ferrous materials, providing immediate processing and payment. …

7. Lorbec USA – Business Services

8. ScrapRegister – Nickel & Copper Scrap Prices

Domain: scrapregister.com

Registered: 2012 (13 years)

Introduction: Nickel & Alloy Scrap Inconel 600: US$ 3.100, Nickel & Alloy Scrap Inconel 625: US$ 4.630, Nickel & Alloy Scrap Nickel 200: US$ 4.427, Copper Scrap #1 Ins Wire: US$ 1.530, Copper Scrap #2 Ins Wire: US$ 0.950

Understanding lorbec metals usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ferrous Scrap Metal | Comprises iron and steel; magnetic; commonly recycled in bulk. | Construction, manufacturing, automotive. | Pros: High availability, lower cost. Cons: Price volatility, limited to specific applications. |

| Non-Ferrous Scrap Metal | Includes aluminum, copper, brass; lighter and non-magnetic. | Electrical, plumbing, aerospace. | Pros: Higher value, diverse applications. Cons: Less abundant, requires careful sorting. |

| Electronic Scrap (E-Waste) | Consists of discarded electronic devices; contains valuable metals. | Recycling, refurbishing, resource recovery. | Pros: High recovery potential, environmental benefits. Cons: Requires specialized processing, potential regulatory challenges. |

| Processed Scrap Metal | Pre-processed for specific applications; includes baled and shredded materials. | Manufacturing, metal production. | Pros: Ready for immediate use, consistent quality. Cons: Higher processing costs, may lack some material variety. |

| Specialty Alloys | Custom blends for specific industrial applications; includes rare metals. | Aerospace, automotive, high-tech industries. | Pros: Tailored properties for specific needs, high demand. Cons: Higher cost, limited supply. |

What Are the Key Characteristics of Ferrous Scrap Metal?

Ferrous scrap metal is primarily composed of iron and steel, making it magnetic and easily recyclable. It is often available in large quantities, making it cost-effective for various industries, particularly construction and manufacturing. B2B buyers should consider the fluctuating market prices and the specific applications for which ferrous scrap is suitable, as its properties can limit its use in certain high-performance environments.

How Does Non-Ferrous Scrap Metal Differ from Ferrous?

Non-ferrous scrap metal encompasses materials such as aluminum, copper, and brass, which do not contain iron and are non-magnetic. This type of scrap is typically lighter and commands a higher market value due to its diverse applications in electrical systems, plumbing, and aerospace industries. Buyers must be aware of the sorting process required for non-ferrous metals, as they often need to be separated from ferrous materials to maximize value and efficiency in recycling.

Why Is Electronic Scrap (E-Waste) Important in Today’s Market?

Electronic scrap, or e-waste, consists of discarded electronic devices that contain valuable metals like gold, silver, and copper. This type of scrap is increasingly significant due to the growing volume of electronic waste generated globally. B2B buyers focusing on sustainability can benefit from investing in e-waste recycling, but they should also consider the regulatory challenges and specialized processing needed to recover materials effectively.

What Are the Advantages of Processed Scrap Metal for Buyers?

Processed scrap metal refers to materials that have been pre-processed for specific applications, including baled or shredded forms. This type of scrap provides consistent quality and is ready for immediate use in manufacturing and metal production. While processed scrap can be more expensive due to the additional processing, it offers efficiency and reliability, making it a favorable option for businesses with immediate production needs.

How Can Specialty Alloys Meet Specific Industrial Needs?

Specialty alloys are custom blends of metals designed to meet specific industrial requirements, often used in high-tech industries like aerospace and automotive. These alloys can provide tailored properties, such as enhanced strength or corrosion resistance. However, buyers should be prepared for higher costs and potentially limited availability, making careful sourcing and partnerships with reliable suppliers essential for success in this market segment.

Key Industrial Applications of lorbec metals usa

| Industry/Sector | Specific Application of lorbec metals usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Recycling of scrap metals for production processes | Reduces raw material costs and waste management | Ensure compliance with local regulations and quality standards. |

| Construction | Supply of recycled steel for structural projects | Enhances sustainability and reduces carbon footprint | Verify material specifications and sourcing logistics. |

| Electronics | Processing of electronic scrap for valuable metals | Provides a sustainable source of precious metals | Consider e-waste regulations and safe disposal practices. |

| Automotive | Recycling of ferrous and non-ferrous metals from vehicles | Supports circular economy initiatives | Assess logistics for large-scale scrap collection and transportation. |

| Energy Sector | Reclamation of metals from old infrastructure | Facilitates resource recovery and sustainability | Evaluate the quality and consistency of scrap materials. |

How is Lorbec Metals USA Used in Manufacturing?

In the manufacturing sector, Lorbec Metals USA plays a critical role in recycling scrap metals, which are essential for various production processes. By sourcing recycled metals, manufacturers can significantly reduce raw material costs while promoting waste management practices. This is particularly valuable for international buyers who are looking to meet sustainability goals and comply with environmental regulations. Buyers should ensure that the metals sourced meet local and international quality standards to avoid production disruptions.

What are the Applications in Construction?

In the construction industry, Lorbec Metals USA supplies recycled steel that is utilized in various structural projects. This not only enhances sustainability but also helps in reducing the carbon footprint associated with traditional steel production. For businesses in regions such as Africa and South America, where construction growth is rapid, sourcing recycled steel can also lead to cost savings. Key considerations for buyers include verifying material specifications and ensuring timely sourcing logistics to meet project deadlines.

How Does Lorbec Metals USA Support Electronics Recycling?

Lorbec Metals USA specializes in processing electronic scrap to extract valuable metals, including copper and aluminum. This application is increasingly relevant as electronic waste continues to rise globally. For international buyers, particularly in the Middle East, there are significant opportunities to source sustainable materials that contribute to circular economy initiatives. Buyers should be aware of e-waste regulations in their countries and prioritize suppliers who adhere to safe disposal practices.

What is the Role in the Automotive Industry?

In the automotive sector, Lorbec Metals USA recycles ferrous and non-ferrous metals sourced from end-of-life vehicles. This process supports circular economy initiatives and helps automotive companies reduce their environmental impact. For businesses in Europe, where strict environmental regulations are in place, sourcing recycled metals can enhance compliance and corporate responsibility. Buyers must assess the logistics involved in large-scale scrap collection and transportation to ensure efficiency.

How is Lorbec Metals USA Relevant in the Energy Sector?

The energy sector benefits from Lorbec Metals USA’s capabilities in reclaiming metals from old infrastructure, which is vital for resource recovery. This application is particularly important as countries seek to upgrade their energy systems while minimizing waste. For buyers in regions like Saudi Arabia and Nigeria, understanding the quality and consistency of scrap materials is crucial for successful projects. Evaluating sourcing practices and ensuring compliance with industry standards can significantly enhance operational efficiency.

3 Common User Pain Points for ‘lorbec metals usa’ & Their Solutions

Scenario 1: Navigating Unpredictable Scrap Prices

The Problem: International B2B buyers often face the challenge of fluctuating scrap metal prices, which can complicate budgeting and financial planning. For instance, a manufacturing company in Nigeria may source aluminum from Lorbec Metals USA but finds that the prices vary significantly week-to-week due to market dynamics. This unpredictability can lead to purchasing decisions that either overspend or miss out on favorable pricing, creating strain on financial resources.

The Solution: To mitigate the impact of price fluctuations, buyers should establish a proactive pricing strategy with Lorbec Metals USA. This can involve regularly monitoring market trends through platforms like the iScrap App, which provides current pricing information. Additionally, buyers can negotiate long-term contracts that lock in prices for a specified duration, providing stability in budgeting. Engaging directly with Lorbec’s sales team for insights into upcoming trends and market conditions can also aid in making informed purchasing decisions, ensuring that companies can adapt quickly to price changes.

Scenario 2: Ensuring Quality and Compliance with Scrap Metal

The Problem: B2B buyers, particularly in industries that require specific quality standards, often struggle with the assurance that the scrap metal they receive meets regulatory and quality requirements. A buyer in the Middle East purchasing non-ferrous metals may worry about compliance with local environmental regulations, fearing that subpar materials could lead to costly fines or reputational damage.

The Solution: To address quality concerns, buyers should request comprehensive documentation from Lorbec Metals USA regarding the sourcing and processing of scrap materials. This includes certifications related to quality and environmental compliance. Establishing a quality assurance protocol, such as routine inspections or third-party audits of the scrap materials, can also provide peace of mind. Buyers should actively communicate their specific quality requirements and ensure that Lorbec’s offerings align with their industry standards, fostering a relationship based on transparency and trust.

Scenario 3: Managing Logistics for Scrap Metal Transportation

The Problem: Logistics can be a significant pain point for B2B buyers dealing with scrap metal, especially when transportation delays or damage occur. For example, a construction firm in South America might encounter issues with timely delivery of recycled steel from Lorbec Metals USA, impacting project timelines and increasing costs due to delays.

The Solution: To enhance logistical efficiency, buyers should take advantage of Lorbec Metals USA’s transportation capabilities, which include their fleet of trucks designed for safe and reliable delivery. Engaging in thorough planning by coordinating delivery schedules well in advance can help mitigate delays. Buyers should also communicate their specific logistics needs, such as preferred delivery times and special handling instructions. Utilizing tracking systems to monitor shipments in real-time can further improve transparency and allow for quick adjustments if any issues arise during transport. Establishing a clear communication line with Lorbec’s logistics team will ensure that both parties are aligned and can respond swiftly to any challenges.

Strategic Material Selection Guide for lorbec metals usa

What Are the Key Properties of Aluminum in Scrap Metal Recycling?

Aluminum is one of the most commonly recycled materials at Lorbec Metals USA. It boasts excellent corrosion resistance, lightweight characteristics, and a high strength-to-weight ratio, making it suitable for various applications, including automotive and aerospace components. Aluminum can withstand temperatures up to 660°C (1220°F) without losing its structural integrity, which is crucial for industries requiring high-performance materials.

Pros & Cons of Aluminum

The primary advantages of aluminum include its recyclability, which significantly reduces energy consumption compared to primary production, and its durability, which extends the lifespan of end products. However, the manufacturing complexity can be a drawback, as aluminum requires specialized processes for recycling and fabrication. Additionally, while aluminum is relatively cost-effective, fluctuations in global market prices can impact its overall expense.

Impact on Application

In applications where weight savings are critical, such as in the automotive sector, aluminum’s properties make it an ideal choice. Its compatibility with various media, including water and some chemicals, further enhances its appeal. However, specific alloys may be less suitable for certain environments, necessitating careful selection based on application needs.

Considerations for International Buyers

International buyers from regions like Africa and the Middle East should be aware of compliance standards such as ASTM and ISO certifications when sourcing aluminum. Understanding local regulations regarding recycling practices and material specifications is essential to ensure smooth transactions.

What Are the Key Properties of Copper in Scrap Metal Recycling?

Copper is another vital material processed at Lorbec Metals USA, known for its excellent electrical conductivity and thermal properties. It is highly resistant to corrosion, particularly in marine environments, making it a preferred choice for electrical wiring and plumbing applications.

Pros & Cons of Copper

The advantages of copper include its high durability and resistance to wear, which make it suitable for long-lasting applications. However, the cost of copper can be a significant disadvantage, as it is generally more expensive than other metals, which may deter some buyers. Additionally, the recycling process for copper can be more complex due to the need for separation from other materials.

Impact on Application

Copper’s compatibility with various media, including water and oil, makes it ideal for plumbing and electrical applications. Its thermal conductivity is particularly beneficial in heat exchangers and electrical components, where efficient heat transfer is crucial.

Considerations for International Buyers

For international buyers, especially from South America and Europe, understanding the specific grades of copper and their compliance with local standards is critical. Buyers should also consider the implications of tariffs and trade regulations that may affect pricing and availability.

What Are the Key Properties of Steel in Scrap Metal Recycling?

Steel is a fundamental material at Lorbec Metals USA, known for its strength and versatility. It can withstand high pressures and temperatures, making it suitable for construction and manufacturing applications. Steel’s corrosion resistance can be enhanced through galvanization or alloying.

Pros & Cons of Steel

The primary advantage of steel is its durability and strength, which make it ideal for structural applications. However, the weight of steel can be a disadvantage in applications where lightweight materials are preferred. Additionally, the cost of steel can vary based on market conditions, impacting overall project budgets.

Impact on Application

Steel’s compatibility with various construction materials and its ability to be recycled multiple times without loss of quality make it a preferred choice in the construction industry. Its performance in high-stress applications further solidifies its position as a go-to material.

Considerations for International Buyers

International buyers, particularly from Europe and Africa, should be aware of compliance with standards such as DIN and ASTM when sourcing steel. Understanding local market conditions and pricing trends is also essential for making informed purchasing decisions.

What Are the Key Properties of Electronic Scrap in Recycling?

Electronic scrap, or e-scrap, is an increasingly important material at Lorbec Metals USA. It consists of discarded electrical devices and components, which contain valuable metals like gold, silver, and copper. E-scrap recycling helps recover these metals while minimizing environmental impact.

Pros & Cons of Electronic Scrap

The primary advantage of e-scrap is its potential for recovering high-value materials, which can offset recycling costs. However, the complexity of processing e-scrap, including the need for specialized equipment and handling, can pose challenges. Additionally, regulatory compliance regarding hazardous materials can complicate the recycling process.

Impact on Application

E-scrap is particularly relevant in industries focused on sustainability and resource recovery. The ability to reclaim precious metals makes e-scrap an attractive option for manufacturers looking to reduce raw material costs.

Considerations for International Buyers

Buyers from regions such as the Middle East and South America should be aware of international regulations regarding e-scrap recycling. Compliance with environmental standards and proper handling procedures is crucial to ensure successful transactions.

| Material | Typical Use Case for lorbec metals usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive parts, aerospace components | Excellent corrosion resistance | Manufacturing complexity | Medium |

| Copper | Electrical wiring, plumbing | High electrical conductivity | Higher cost compared to alternatives | High |

| Steel | Construction, manufacturing | High strength and durability | Heavier than other materials | Medium |

| Electronic Scrap | Resource recovery, precious metal reclamation | High-value metal recovery | Complex processing requirements | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for lorbec metals usa

What Are the Main Stages of Manufacturing at Lorbec Metals USA?

Lorbec Metals USA operates as Flint, Michigan’s largest scrap yard, focusing on recycling and trading ferrous and non-ferrous scrap metals. The manufacturing process for Lorbec involves several key stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage is crucial for ensuring that all scrap metals are properly sorted and cleaned. The company employs advanced sorting techniques, including magnet separation for ferrous materials and air classification for lighter materials. This meticulous preparation helps in maximizing the quality of the end product, ensuring that impurities are removed before further processing.

-

Forming: In this phase, the prepared materials are shaped and resized according to specific customer requirements. Techniques such as shredding, shearing, and baling are commonly used. Shredders break down larger metal pieces into manageable sizes, while balers compact the materials into bales for easier transport and handling. This process not only enhances the efficiency of shipping but also optimizes storage space.

-

Assembly: Although Lorbec primarily focuses on recycling, assembly plays a role in creating composite materials or preparing materials for shipment. The company can combine different grades of metals to meet client specifications, ensuring that the final product aligns with the quality standards expected in the global market.

-

Finishing: The finishing stage involves final quality checks and surface treatments to enhance the durability and marketability of the recycled metals. This may include cleaning, coating, or further processing to achieve the desired finish. By focusing on this stage, Lorbec ensures that its products are not only functional but also appealing to international buyers.

How Does Quality Assurance Work at Lorbec Metals USA?

Quality assurance (QA) is an integral part of Lorbec Metals USA’s operations, ensuring that all products meet stringent international standards and customer expectations. The company adheres to several relevant quality standards, including ISO 9001, which provides a framework for consistent quality management.

What International Standards Does Lorbec Metals USA Follow?

-

ISO 9001: This globally recognized standard focuses on quality management systems and is crucial for organizations aiming to improve customer satisfaction and operational efficiency. Lorbec’s commitment to ISO 9001 demonstrates its dedication to maintaining high-quality processes and continuously improving its manufacturing practices.

-

CE Marking: For products intended for the European market, CE marking is essential. It indicates compliance with EU safety, health, and environmental protection standards, which is particularly important for international B2B buyers from Europe.

-

API Standards: For clients in industries such as oil and gas, adhering to American Petroleum Institute (API) standards ensures that the materials meet specific safety and quality requirements, reinforcing Lorbec’s reputation as a reliable supplier.

What Are the Key Quality Control Checkpoints?

Quality Control (QC) at Lorbec Metals USA encompasses various checkpoints throughout the manufacturing process, ensuring that products consistently meet quality standards:

-

Incoming Quality Control (IQC): Upon receiving scrap materials, Lorbec conducts thorough inspections to verify that they meet specified requirements. This includes checking for contamination and ensuring the proper grades of metals are received.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks are performed to monitor the quality of the materials being processed. This can involve testing the integrity of bales or assessing the effectiveness of shredding operations.

-

Final Quality Control (FQC): Before products are shipped to clients, a final inspection ensures that all items meet the necessary specifications and quality standards. This may include dimensional checks, weight verification, and visual inspections.

What Common Testing Methods Are Employed?

Lorbec Metals USA employs various testing methods to ensure the quality of its products:

-

Chemical Analysis: This method determines the composition of metals, ensuring that they meet client specifications. Techniques such as X-ray fluorescence (XRF) are commonly used for accurate analysis.

-

Physical Testing: This includes tests for tensile strength, ductility, and hardness, which are essential for understanding the material properties and suitability for specific applications.

-

Environmental Testing: Given the focus on sustainability, Lorbec conducts tests to ensure that its processes and products adhere to environmental regulations, minimizing their ecological footprint.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, can take several steps to verify the quality control measures of suppliers like Lorbec Metals USA:

-

Audits: Conducting on-site audits can provide insights into the manufacturing processes and quality control measures in place. This firsthand evaluation helps buyers assess compliance with industry standards.

-

Quality Reports: Requesting detailed quality reports and certifications can offer transparency regarding the supplier’s adherence to relevant standards. This information can be crucial in decision-making.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality assurance processes. This is particularly important for international transactions where trust may be a concern.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must consider various nuances when engaging with suppliers like Lorbec Metals USA:

-

Cultural Differences: Understanding the cultural context can help in navigating communication and negotiation processes. Building relationships based on trust and mutual understanding is vital.

-

Regulatory Compliance: Different regions have specific regulations regarding scrap metal trading and recycling. Buyers must be aware of these regulations to ensure compliance and avoid potential legal issues.

-

Logistics and Transportation: Quality assurance doesn’t end with manufacturing; the logistics of transporting materials can impact product quality. Ensuring that the supplier has reliable transportation options is crucial.

By taking these factors into account, B2B buyers can enhance their procurement strategies and ensure they partner with suppliers that prioritize quality and sustainability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lorbec metals usa’

Introduction

This practical sourcing guide serves as a comprehensive checklist for international B2B buyers interested in procuring scrap metal from Lorbec Metals USA. By following these steps, you can ensure a smooth procurement process, mitigate risks, and establish a successful partnership with one of the leading scrap metal recycling companies in the United States.

Step 1: Identify Your Scrap Metal Needs

Understanding your specific scrap metal requirements is essential before reaching out to suppliers. Determine the types and grades of metal you need, such as aluminum, copper, or steel. This clarity will help you communicate effectively and ensure that you receive the appropriate materials for your projects.

Step 2: Research Lorbec Metals USA’s Offerings

Take time to review the services and types of scrap metals offered by Lorbec Metals USA. Their expertise spans both ferrous and non-ferrous metals, along with various processing capabilities like baling and resource reclaiming. Familiarizing yourself with their capabilities will help you match your needs with their services, streamlining your procurement process.

Step 3: Verify Logistics and Transportation Options

Logistics play a crucial role in the procurement of scrap metal. Lorbec Metals USA operates its own fleet, providing reliable transportation solutions. Assess their logistics capabilities, including truck types and delivery schedules, to ensure they can accommodate your shipping requirements effectively.

- Consider:

- The availability of roll-off containers and flatbed trailers.

- Pickup services and whether they can cater to your location in Africa, South America, the Middle East, or Europe.

Step 4: Evaluate Pricing Structures

Understanding the pricing models and current market conditions is vital for effective budgeting. Regularly check Lorbec Metals USA’s pricing for various scrap metals and compare these with industry standards. Be mindful of fluctuations in scrap metal prices, as they can significantly impact your total procurement costs.

Step 5: Request Samples or Visits

Whenever possible, request samples or arrange a visit to Lorbec Metals USA’s facility. This firsthand experience allows you to assess their operational standards and the quality of their scrap metals. Engaging directly with their team can also facilitate discussions on your specific needs and potential custom solutions.

Step 6: Review Compliance and Certifications

Ensure that Lorbec Metals USA meets all necessary regulatory compliance and industry certifications. This step is crucial for establishing a trustworthy partnership and ensuring that the materials you procure meet international standards.

- Focus on:

- Environmental certifications related to recycling practices.

- Compliance with local and international trade regulations.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful procurement relationship. Establish clear lines of communication with your contact at Lorbec Metals USA, and set expectations regarding response times and information sharing. Consistent communication can help address any issues promptly and foster a collaborative working relationship.

By following this step-by-step checklist, you can confidently navigate the sourcing process with Lorbec Metals USA, ensuring a reliable supply of quality scrap metal for your business needs.

Comprehensive Cost and Pricing Analysis for lorbec metals usa Sourcing

What Are the Key Cost Components in Sourcing from Lorbec Metals USA?

When considering sourcing from Lorbec Metals USA, it’s crucial to understand the various cost components that influence pricing. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of raw materials, such as ferrous and non-ferrous metals, significantly impacts pricing. Lorbec Metals specializes in diverse scrap metals, including aluminum, copper, and steel. Prices fluctuate based on market demand, availability, and quality of the metals being sourced.

-

Labor: Labor costs encompass wages, benefits, and training for staff involved in processing and recycling operations. Skilled labor may demand higher wages, particularly in regions with competitive labor markets.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Efficient operations can reduce overhead costs, thus allowing Lorbec Metals to offer more competitive pricing.

-

Tooling: For specific processing needs, the cost of tooling can vary. If custom machinery is required for unique specifications, this will add to the overall cost.

-

Quality Control (QC): Ensuring that materials meet industry standards involves additional costs. Certifications may be necessary for international buyers, influencing the final pricing structure.

-

Logistics: Transportation costs depend on the distance from the supplier to the buyer, mode of transport, and the volume of materials being shipped. Lorbec Metals operates its own fleet, which can optimize logistics costs but may vary based on shipping routes and fuel prices.

-

Margin: The profit margin is influenced by all the above costs. Understanding Lorbec’s pricing strategy can help buyers gauge how much flexibility exists for negotiation.

How Do Price Influencers Impact Sourcing Decisions for International Buyers?

Several factors affect the pricing and sourcing dynamics for international buyers, especially those from Africa, South America, the Middle East, and Europe.

-

Volume/MOQ: Larger orders often lead to reduced prices per unit due to economies of scale. Understanding the minimum order quantity (MOQ) is vital for negotiating better rates.

-

Specifications/Customization: Custom orders may incur additional costs. Clear communication of specifications is essential to avoid unexpected expenses.

-

Materials and Quality: The quality of the scrap materials influences pricing significantly. Buyers should ensure that they understand the quality standards and certifications required for their specific markets.

-

Supplier Factors: Factors such as supplier reliability, reputation, and service quality can impact pricing. A trustworthy supplier may offer more favorable terms, including better pricing or payment options.

-

Incoterms: Familiarity with Incoterms is crucial for international transactions. These terms dictate who is responsible for shipping, insurance, and tariffs, which can significantly affect the overall cost.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing?

International buyers should adopt strategic approaches to optimize costs when sourcing from Lorbec Metals USA.

-

Negotiate Terms: Engage in open discussions regarding pricing, payment terms, and delivery schedules. A well-prepared negotiation strategy can yield better deals.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also additional costs such as logistics, tariffs, and potential waste disposal. A lower upfront cost may result in higher overall expenses.

-

Monitor Market Prices: Stay informed about scrap metal pricing trends. Tools like the iScrap App can provide insights into current market conditions, helping buyers make informed decisions.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing and service. Regular communication can also facilitate smoother transactions.

-

Understand Pricing Nuances: Be aware of seasonal variations in pricing and market conditions that could impact costs. Timing your purchases strategically can result in significant savings.

Disclaimer

The prices and information provided are indicative and subject to change based on market conditions and supplier discretion. Always confirm current pricing and terms directly with Lorbec Metals USA prior to making sourcing decisions.

Alternatives Analysis: Comparing lorbec metals usa With Other Solutions

Understanding Alternatives in Scrap Metal Recycling Solutions

When considering solutions for scrap metal recycling, B2B buyers often seek alternatives that match their operational needs, budget constraints, and environmental goals. This analysis focuses on comparing Lorbec Metals USA, a leading scrap metal recycling provider, with other viable options in the market. The goal is to help international buyers make informed decisions that align with their specific requirements.

| Comparison Aspect | Lorbec Metals USA | Alternative 1: Local Scrap Yards | Alternative 2: Online Metal Marketplaces |

|---|---|---|---|

| Performance | Specializes in ferrous and non-ferrous metals with efficient processing capabilities. | Varies by location and may not offer specialized services. | Broad range of metals but depends on seller reliability. |

| Cost | Competitive pricing based on local market conditions. | Typically lower costs but fluctuates with demand and supply. | Variable pricing; often higher due to platform fees. |

| Ease of Implementation | Established transport logistics and customer service. | May require additional coordination for pickups. | User-friendly platforms but requires self-management for logistics. |

| Maintenance | Regular maintenance of equipment ensures consistent service. | Dependent on yard management; quality may vary. | Minimal maintenance as it’s a digital platform. |

| Best Use Case | Ideal for businesses needing reliable recycling services with transport options. | Suitable for local businesses seeking cost-effective solutions. | Best for those with specific metal needs and who can manage logistics. |

Alternative 1: Local Scrap Yards

Local scrap yards provide a more community-focused approach to recycling. They often cater to businesses within a specific geographical area and may offer lower costs due to reduced transportation needs. However, the performance and service quality can vary significantly from one yard to another. Buyers might face challenges in terms of consistency and specialization in the types of metals processed, which can impact the overall recycling experience.

Alternative 2: Online Metal Marketplaces

Online metal marketplaces have emerged as a popular alternative for scrap metal transactions, allowing buyers and sellers to connect digitally. These platforms can provide a wide range of metal options and prices based on current market trends. However, they require buyers to manage their logistics and transport, which can complicate the recycling process. Moreover, the reliability of sellers can vary, leading to potential risks in quality and service delivery.

Making the Right Choice for Your Scrap Metal Needs

Selecting the right solution for scrap metal recycling hinges on your specific business needs and operational capabilities. Lorbec Metals USA stands out for its comprehensive services and strong customer support, making it ideal for businesses that prioritize reliability and efficiency. On the other hand, local scrap yards may offer cost-effective options, while online marketplaces can provide flexibility and a wider selection. Ultimately, B2B buyers should evaluate their volume of scrap, preferred service level, and logistical capabilities to determine the best fit for their recycling requirements.

Essential Technical Properties and Trade Terminology for lorbec metals usa

What Are the Key Technical Properties of Scrap Metal at Lorbec Metals USA?

Understanding the technical properties of scrap metal is essential for B2B buyers, particularly those involved in manufacturing and recycling. Here are some critical specifications that define the quality and usability of materials processed at Lorbec Metals USA:

1. Material Grade

Material grades refer to the classification of metals based on their composition and properties. At Lorbec Metals USA, ferrous and non-ferrous metals are categorized into various grades. For instance, aluminum may be sorted into 6061 and 6063 grades based on its alloying elements. Knowing the grade is vital for buyers to ensure they are acquiring materials that meet their specific application requirements, particularly in industries like automotive or construction.

2. Tolerance

Tolerance is the allowable deviation from a standard dimension or property. In the context of scrap metal, this can pertain to the size, thickness, or purity of the metal. Tolerances are crucial in B2B transactions because they affect the compatibility of materials with existing manufacturing processes. Buyers need to ensure that the scrap metal they purchase can be integrated seamlessly into their production lines.

3. Purity Level

Purity level indicates the percentage of the primary metal in a scrap material. For example, copper scrap can range from 85% to 99% purity. Higher purity levels often command better prices and are preferred for applications requiring superior electrical conductivity or corrosion resistance. Buyers should be aware of purity levels to make informed purchasing decisions that align with their quality standards.

4. Yield Strength

Yield strength is a measure of the stress at which a material begins to deform plastically. Understanding the yield strength of metals sourced from Lorbec Metals USA can help buyers determine their suitability for structural applications. This property is particularly important for construction firms or manufacturers of heavy machinery where material integrity is critical.

What Are Common Trade Terms Used in Scrap Metal Transactions?

Familiarity with industry jargon is essential for effective communication in the B2B space. Below are some common trade terms relevant to transactions with Lorbec Metals USA:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of scrap metal, OEMs often rely on high-quality recycled metals to create components. Understanding this term helps buyers identify potential partnerships and sourcing opportunities.

2. MOQ (Minimum Order Quantity)

MOQ signifies the smallest quantity of a product that a supplier is willing to sell. For scrap metal, MOQs can vary based on the type and grade of metal. Knowing the MOQ is crucial for buyers to plan their procurement effectively, ensuring they meet their production needs without incurring excess costs.

3. RFQ (Request for Quotation)

An RFQ is a formal document issued by a buyer to solicit price quotes from suppliers. This process is common in the scrap metal industry, where pricing can fluctuate based on market conditions. Understanding how to draft an RFQ can help buyers secure favorable pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the costs and risks at various points in the shipping process. For international buyers, familiarity with Incoterms is critical to avoid misunderstandings and ensure smooth transactions.

5. Scrap Market Dynamics

This term encompasses the various factors influencing scrap metal prices, including supply and demand, geopolitical events, and economic conditions. Understanding market dynamics is essential for buyers to time their purchases effectively and negotiate better deals.

By grasping these technical properties and trade terms, international B2B buyers can enhance their negotiation capabilities, ensure compliance with industry standards, and optimize their supply chain operations when working with Lorbec Metals USA.

Navigating Market Dynamics and Sourcing Trends in the lorbec metals usa Sector

What Are the Current Market Dynamics and Key Trends in the Lorbec Metals USA Sector?

The global scrap metal market is experiencing significant transformations driven by various factors, including increased demand for recycled materials, fluctuating commodity prices, and evolving regulatory frameworks. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for strategic sourcing. The rise of digital platforms and technologies is streamlining the sourcing process, enabling buyers to access real-time pricing information and better negotiate terms. Innovations in logistics and transportation, such as integrated supply chain solutions, are also enhancing efficiency, allowing for the timely movement of materials across borders.

Sustainability is becoming a key driver in the industry. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to recycling and responsible sourcing practices. This trend is particularly relevant for markets in Europe and North America, where regulatory pressures are intensifying. The demand for high-quality non-ferrous and ferrous scrap metals, such as aluminum and copper, continues to rise, fueled by their applications in various industries, including automotive and construction. As global supply chains adapt to these shifts, buyers must remain vigilant about market fluctuations and emerging trends to secure favorable sourcing agreements.

How Is Sustainability Influencing Ethical Sourcing Practices in the Lorbec Metals USA Sector?

The environmental impact of scrap metal sourcing and recycling cannot be overstated. As concerns about climate change and resource depletion grow, businesses are increasingly held accountable for their supply chain practices. For B2B buyers, partnering with suppliers like Lorbec Metals USA, which emphasizes sustainable recycling processes, can enhance their corporate social responsibility (CSR) initiatives. Ethical sourcing involves ensuring that materials are procured in a manner that minimizes environmental harm and supports fair labor practices.

Lorbec Metals USA is committed to reducing waste and promoting a greener planet through its recycling operations. By investing in advanced processing technologies and efficient logistics, the company is able to reclaim valuable resources while minimizing the carbon footprint associated with metal production. Additionally, buyers should look for suppliers with recognized certifications, such as ISO 14001, which indicates a commitment to environmental management systems. By prioritizing partners that align with their sustainability goals, international buyers can strengthen their market position and appeal to environmentally conscious consumers.

What Is the Historical Context of Lorbec Metals USA in the Scrap Metal Industry?

Lorbec Metals USA has established itself as a leader in the scrap metal recycling sector, particularly in Flint, Michigan. With a history rooted in innovation and a commitment to quality service, the company has adapted to the evolving needs of its clients over the years. Initially focused on local scrap processing, Lorbec Metals has expanded its operations to cater to a broader international market, reflecting the growing demand for recycled materials globally.

As the largest scrap yard in Flint, Lorbec Metals USA has consistently enhanced its capabilities, including the processing of diverse grades of ferrous and non-ferrous metals. The company’s commitment to customer service and environmental sustainability has positioned it as a trusted partner for B2B buyers, ensuring that they receive not only competitive pricing but also reliable and responsible sourcing options. This historical context is essential for buyers looking to establish long-term relationships with a supplier that values both quality and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of lorbec metals usa

-

How do I ensure quality when sourcing scrap metals from Lorbec Metals USA?

To guarantee quality when sourcing scrap metals from Lorbec Metals USA, request certifications and documentation that verify the material’s specifications and grades. Additionally, inquire about their quality assurance processes, including inspections and testing methods. Establish a clear communication channel with their team to discuss your specific quality requirements. You might also consider visiting their facility or asking for samples before making larger purchases to ensure they meet your standards. -

What are the payment terms for international buyers when dealing with Lorbec Metals USA?

Lorbec Metals USA typically offers flexible payment terms for international buyers, which can vary based on the order size and frequency. Common payment methods include wire transfers and letters of credit. It’s advisable to discuss and negotiate payment terms upfront to ensure mutual understanding. Inquire about any upfront deposits that may be required for large orders and clarify the timeline for payment processing to avoid delays in shipment. -

What is the minimum order quantity (MOQ) for scrap metals from Lorbec Metals USA?

The minimum order quantity (MOQ) for scrap metals from Lorbec Metals USA may depend on the type of metal and the specifics of your order. Generally, they are open to accommodating varying order sizes, but larger quantities can often yield better pricing. It’s recommended to contact their sales team to discuss your specific needs and to negotiate terms that work for both parties. -

How does Lorbec Metals USA handle logistics and shipping for international orders?

Lorbec Metals USA manages logistics and shipping through their own fleet of trucks, ensuring reliable transportation. For international orders, they collaborate with freight forwarders to navigate customs and shipping regulations effectively. Discuss your delivery requirements with their team to determine the best shipping methods and timelines. Ensure you understand the associated costs and responsibilities for customs clearance to avoid unexpected delays. -

What types of scrap metals does Lorbec Metals USA accept for recycling?

Lorbec Metals USA specializes in a wide range of ferrous and non-ferrous scrap metals, including aluminum, copper, steel, and electronic scrap. They pride themselves on their capability to process various grades of scrap, ensuring that all materials are handled with care. If you have specific metals in mind, reach out to their team to confirm acceptance and any special processing requirements. -

How can I verify the credentials and reliability of Lorbec Metals USA as a supplier?

To verify the credentials and reliability of Lorbec Metals USA, start by checking their business registration and any relevant certifications in the recycling industry. Look for reviews and testimonials from other B2B clients, and consider reaching out to industry associations for insights. Additionally, request references from previous international buyers to gauge their experiences, especially regarding service quality and compliance with international trading standards. -

What customization options are available for scrap metal processing?

Lorbec Metals USA offers various customization options for scrap metal processing, including specific sorting, bailing, and packaging requirements. Discuss your unique needs with their team to see how they can accommodate your requests. Customization may also extend to transportation logistics, where you can specify the type of containers or delivery methods that best suit your operational needs. -

How does Lorbec Metals USA contribute to sustainable recycling practices?

Lorbec Metals USA is committed to sustainable recycling practices, focusing on reducing waste and minimizing environmental impact. They implement efficient processing techniques and resource reclaiming methods to ensure that scrap metals are recycled effectively. By partnering with them, you not only support your business needs but also contribute to a greener planet. Inquire about their sustainability initiatives for more insights into their practices and potential collaborations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for lorbec metals usa

In today’s competitive global market, strategic sourcing is essential for international B2B buyers seeking reliable partners in the recycling and scrap metal industry. Lorbec Metals USA stands out as Flint, Michigan’s largest scrap yard, specializing in both ferrous and non-ferrous metals. Their commitment to customer service, combined with a comprehensive range of capabilities—from processing to resource reclaiming—positions them as a leader in sustainable practices.

For buyers from Africa, South America, the Middle East, and Europe, establishing a partnership with Lorbec Metals USA can facilitate access to high-quality scrap metal at competitive prices. Their operational excellence, characterized by a dedicated fleet for transportation and flexible service offerings, ensures that clients’ needs are met efficiently and effectively.

Looking ahead, the demand for recycled materials will only increase as industries prioritize sustainability. By choosing Lorbec Metals USA as a sourcing partner, businesses can not only enhance their supply chain resilience but also contribute to a greener future. We encourage international buyers to connect with Lorbec Metals USA to explore how they can benefit from strategic sourcing and become part of the global recycling movement.