Top 8 List Of Manufacturing Companies In Usa List and Guide: How …

Introduction: Navigating the Global Market for list of manufacturing companies in usa

In today’s competitive global marketplace, sourcing reliable manufacturing companies in the USA can be a daunting challenge for international B2B buyers. With a myriad of options available, how can you ensure that your chosen supplier meets your quality, cost, and delivery requirements? This comprehensive guide is designed to equip you with the insights needed to navigate the complexities of the U.S. manufacturing landscape. It covers a diverse range of sectors, from textiles and consumer goods to advanced technology and pharmaceuticals, ensuring that you find the right partner for your specific needs.

Our guide delves into crucial aspects such as supplier vetting processes, cost structures, and applications of various products. By providing detailed profiles of reputable manufacturing companies, we empower you to make informed purchasing decisions that align with your business objectives. Whether you’re a buyer from Nigeria seeking durable textiles or a distributor from Europe looking for cutting-edge electronics, this resource serves as your one-stop solution.

Moreover, understanding the nuances of the U.S. manufacturing environment—including compliance with regulations and quality assurance practices—will enhance your confidence in forging partnerships across borders. With this guide, you’ll not only discover potential suppliers but also gain the knowledge necessary to establish successful, long-term business relationships. Embrace the opportunity to enhance your supply chain and drive your business forward in the global market.

Top 10 List Of Manufacturing Companies In Usa Manufacturers & Suppliers List

1. Boeing – Aerospace Vehicles; HP – Computer Products; Johnson & Johnson – Health & Beauty Products

Domain: indeed.com

Registered: 1998 (27 years)

Introduction: Boeing: Aerospace vehicles and equipment (airplanes, missiles, satellites); HP: Computer products (laptops, desktops, monitors, printers, tablets, accessories); Johnson & Johnson: Beauty, skincare, hygiene products (lotion, baby oil, mouthwash), vaccines, medical instruments (power tools, implants); Lancaster Colony: Bread rolls, bagels, condiments (mustard, vegetable dip, salad dressing); Lear Co…

2. AdvancedClient – Verified Manufacturing Data

Domain: advancedclient.io

Registered: 2023 (2 years)

Introduction: Top 1,000 verified manufacturing companies in the USA, sortable by industry, size, and location. Access to free company-level data that is updated regularly.

3. IQS Directory – OEM Manufacturing Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: OEM Manufacturers and OEM Manufacturing Companies across various categories including: 55 Gallon Drums, Automation Equipment, Automated Guided Vehicles, Air Pollution Control, Aluminum Extrusions, Balers, Blowers, Blow Molding, Boilers, Brushes, Cardboard Tubes, Carrying Cases, Ceramic Machining, Chillers, Clean Rooms, Conveyors, Corrugated Boxes, Crane Manufacturers, Deburring Equipment, Die Cast…

4. Companies Market Cap – Major Players

Domain: companiesmarketcap.com

Registered: 2020 (5 years)

Introduction: The text does not provide specific product details for the largest manufacturing companies. It primarily lists companies along with their market capitalization, stock prices, and country of origin.

5. Top Defense and Aerospace Brands – Key Players

6. Manufacturing USA – Collaborative Innovation

7. Lusha – Sales Intelligence Platform

Domain: lusha.com

Registered: 1999 (26 years)

Introduction: Lusha offers a sales intelligence platform designed to help businesses scale their sales efforts. Key features include:

– Contact & Company Search: Find ideal prospects from a database of manufacturing companies in the United States.

– Lead Streaming: AI recommendations for daily matched leads and auto-updating lists.

– Outreach Tools: Automate and personalize emails, and record/analyze sales m…

8. 99datacd – Manufacturing Companies List

Domain: 99datacd.com

Registered: 2011 (14 years)

Introduction: List of Manufacturing Companies in USA – 8939 Manufacturing Companies (All Types) Data – In Excel Format. Data Content: Company Name, Person Name, Mobile Number, Email Id, Website, City, State, Country, Business Category. Price: Rs. 2550/- Now Pay Only Rs. 1785/-. Updated 2025 with 75% to 85% Accuracy. Sources: Various B2B Portals, Industrial Directories, Exhibitions, MSME Members Data, Government…

Understanding list of manufacturing companies in usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Consumer Goods | Focus on mass production of everyday items | Retail, e-commerce, wholesale distribution | Pros: High availability; Cons: Competitive pricing |

| Industrial Equipment | Specialized machinery and tools for various industries | Manufacturing, construction, logistics | Pros: Tailored solutions; Cons: Higher investment costs |

| Electronics Manufacturing | Production of electronic components and devices | Technology, automotive, aerospace | Pros: Innovation-driven; Cons: Rapid obsolescence |

| Textiles and Apparel | Production of clothing and fabric goods | Fashion, home goods, industrial uniforms | Pros: Customization options; Cons: Labor-intensive |

| Pharmaceuticals | Development and production of medical drugs and devices | Healthcare, research institutions | Pros: High demand; Cons: Regulatory hurdles |

What are the Characteristics of Consumer Goods Manufacturing Companies?

Consumer goods manufacturing companies focus on producing everyday items such as food, beverages, household products, and personal care items. These companies often operate on a large scale, emphasizing mass production to meet consumer demand. B2B buyers in retail and e-commerce sectors typically engage with these manufacturers for their high availability and competitive pricing. However, buyers should be aware that the competitive landscape can lead to price wars, impacting margins.

How Do Industrial Equipment Manufacturers Cater to Businesses?

Industrial equipment manufacturers create specialized machinery and tools essential for various industries, including construction, manufacturing, and logistics. These companies often provide tailored solutions designed to improve efficiency and productivity. B2B buyers in sectors requiring heavy machinery should consider the long-term investment potential and operational support offered. While these products can be costly, they often lead to significant cost savings through enhanced operational efficiencies.

What Distinguishes Electronics Manufacturing from Other Types?

Electronics manufacturing involves producing components and devices used in technology, automotive, and aerospace industries. This sector is characterized by rapid innovation and the constant need for updates to meet evolving technological standards. B2B buyers must consider the lifespan of electronic components, as rapid obsolescence can be a challenge. Engaging with reputable manufacturers ensures access to cutting-edge technology and reliable support.

Why Are Textiles and Apparel Manufacturers Important for B2B Buyers?

Textiles and apparel manufacturers produce clothing and fabric goods, catering to various markets, including fashion and industrial uniforms. These companies often offer customization options, allowing B2B buyers to create unique products tailored to their brand identity. While the labor-intensive nature of this industry can lead to higher costs, the ability to differentiate through unique designs can provide a competitive edge in crowded markets.

What Should B2B Buyers Know About Pharmaceuticals Manufacturing?

Pharmaceutical manufacturing focuses on developing and producing medical drugs and devices. This sector is highly regulated, requiring manufacturers to adhere to strict guidelines to ensure product safety and efficacy. B2B buyers, particularly in healthcare, must navigate these regulatory hurdles while seeking reliable suppliers. While the demand for pharmaceuticals remains high, buyers should be prepared for potential challenges related to compliance and quality assurance.

Key Industrial Applications of list of manufacturing companies in usa

| Industry/Sector | Specific Application of list of manufacturing companies in usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Textiles and Apparel | Sourcing of sustainable clothing and accessories | Access to high-quality, ethically produced goods enhances brand reputation and customer loyalty. | Certifications for sustainability, minimum order quantities, and lead times. |

| Consumer Electronics | Manufacturing of electronic components and devices | High-tech manufacturing capabilities ensure product reliability and innovation. | Compliance with international standards and testing certifications. |

| Food and Beverage | Production of packaging solutions for food products | Innovative packaging improves shelf life and brand visibility, catering to health-conscious consumers. | Material safety certifications and compatibility with local regulations. |

| Pharmaceuticals | Supply of medical devices and personal protective equipment | Ensures compliance with health regulations and enhances operational safety. | Regulatory compliance, quality assurance, and traceability requirements. |

| Automotive | Fabrication of automotive parts and components | High-quality components lead to improved vehicle performance and safety. | Supplier certifications, just-in-time delivery capabilities, and material specifications. |

How is the List of Manufacturing Companies in the USA Relevant to International B2B Buyers in Textiles and Apparel?

International B2B buyers from regions like Africa and South America are increasingly seeking sustainable clothing solutions. The list of manufacturing companies in the USA offers access to suppliers committed to ethical practices and high-quality production. This sector is particularly appealing due to the rising consumer demand for eco-friendly products. Buyers need to ensure that manufacturers have proper sustainability certifications and can meet minimum order quantities while adhering to expected lead times.

What Benefits Can Be Gained from Sourcing Consumer Electronics from the USA?

The USA is home to advanced manufacturing capabilities in the consumer electronics sector. International buyers can leverage this to obtain reliable electronic components and devices that meet high standards of quality and innovation. These products often come with compliance to international safety and performance standards, essential for maintaining market competitiveness. Buyers should prioritize sourcing manufacturers with a proven track record in compliance and testing certifications to mitigate risks associated with product failures.

How Does the Food and Beverage Sector Benefit from US Manufacturing?

In the food and beverage industry, sourcing from US manufacturers ensures access to innovative packaging solutions that enhance product visibility and shelf life. International buyers can benefit significantly from the expertise of these manufacturers in creating packaging that meets health-conscious consumer demands. It is crucial for buyers to verify that materials used in packaging comply with local food safety regulations and possess the necessary safety certifications to avoid regulatory hurdles.

Why is the Pharmaceutical Sector a Key Focus for Global Buyers?

For international B2B buyers in the pharmaceutical sector, the USA offers a robust supply chain for medical devices and personal protective equipment (PPE). This is vital for compliance with stringent health regulations. The list of manufacturing companies provides access to suppliers who prioritize quality assurance and traceability, ensuring that products meet international health standards. Buyers should focus on manufacturers that have a solid understanding of regulatory compliance and can provide comprehensive quality documentation.

What Advantages Does the Automotive Industry Gain from US Manufacturing?

The automotive industry benefits from the high-quality fabrication of parts and components available through US manufacturers. International buyers can enhance vehicle performance and safety by sourcing reliable components. It is essential for buyers to consider supplier certifications and the ability to deliver components just-in-time to align with production schedules. Understanding material specifications and performance standards is also critical for ensuring compatibility with local automotive regulations.

3 Common User Pain Points for ‘list of manufacturing companies in usa’ & Their Solutions

Scenario 1: Navigating the Complexity of Supplier Selection

The Problem: B2B buyers often face the daunting task of selecting the right manufacturing partner from a vast landscape of options in the U.S. This process can be overwhelming, especially for international buyers unfamiliar with the local market. Challenges include varying product quality, compliance with international standards, and differences in business practices. Buyers may struggle with inadequate information on company reputations, leading to potential losses from poor sourcing decisions.

The Solution: To effectively navigate the supplier selection process, B2B buyers should leverage comprehensive databases and directories that list manufacturing companies in the U.S. Resources such as Dun & Bradstreet provide detailed insights, including financial performance, industry classifications, and contact information. Buyers should prioritize companies with a solid track record of reliability and quality, as evidenced by customer reviews and industry certifications. Additionally, engaging in virtual trade shows or industry webinars can offer firsthand insights into suppliers’ capabilities. Establishing clear criteria for evaluating potential partners—such as production capacity, quality control measures, and compliance with international regulations—will streamline the selection process, ensuring that buyers choose manufacturers that align with their needs.

Scenario 2: Overcoming Communication Barriers in International Transactions

The Problem: International B2B buyers often encounter communication barriers when engaging with U.S. manufacturing companies. Differences in time zones, language, and cultural business practices can lead to misunderstandings and delays in the procurement process. These challenges can hinder the timely delivery of products and affect overall project timelines, leading to frustration and potential financial losses.

The Solution: To mitigate communication challenges, B2B buyers should adopt a multi-faceted approach. First, establishing a primary point of contact within the manufacturing company is crucial. This person should be fluent in both English and the buyer’s language, if possible. Utilizing technology can also enhance communication; platforms like Slack or Microsoft Teams facilitate real-time discussions and file sharing. Furthermore, investing in a translation service can help bridge any language gaps, ensuring that important documents and specifications are accurately conveyed. Setting clear expectations for communication frequency and preferred methods can also help maintain alignment throughout the sourcing process.

Scenario 3: Ensuring Compliance with Regulatory Standards

The Problem: B2B buyers sourcing products from U.S. manufacturing companies must navigate a complex landscape of regulatory standards and compliance requirements. This is particularly challenging for international buyers who may not be fully aware of U.S. regulations related to product safety, environmental impact, and labor practices. Failing to ensure compliance can lead to costly fines, product recalls, and damage to brand reputation.

The Solution: To ensure compliance with regulatory standards, B2B buyers should conduct thorough due diligence on potential manufacturing partners. This includes reviewing certifications such as ISO, FDA approvals, or any industry-specific standards relevant to the products being sourced. Buyers should also inquire about the manufacturer’s quality assurance processes and their adherence to labor laws and environmental regulations. Collaborating with a local legal advisor or compliance consultant can provide additional assurance that all necessary regulations are being met. Additionally, establishing a robust quality control plan that includes regular audits and inspections can help mitigate compliance risks, ensuring that products meet both U.S. and international standards before they reach the market.

Strategic Material Selection Guide for list of manufacturing companies in usa

When selecting materials for manufacturing in the USA, international B2B buyers must consider various factors that impact product performance, cost, and compliance with industry standards. This guide analyzes four common materials used by manufacturing companies in the USA, providing insights into their properties, advantages, disadvantages, and specific considerations for international buyers.

What Are the Key Properties of Steel in Manufacturing?

Steel is widely recognized for its strength and versatility, making it a preferred choice in various manufacturing applications. Key properties of steel include high tensile strength, excellent durability, and good corrosion resistance when treated. It can withstand significant temperature and pressure variations, making it suitable for heavy-duty applications, such as automotive and construction.

Pros and Cons of Using Steel

The primary advantage of steel is its durability, which translates to a longer lifespan for products. However, it can be relatively expensive compared to other materials, and the manufacturing processes can be complex, involving welding and machining. Additionally, while steel is suitable for many applications, its weight can be a disadvantage in industries where lightweight materials are preferred.

Impact on Application

Steel’s compatibility with various media, including oils and chemicals, makes it ideal for industrial applications. However, buyers must consider the specific grade of steel to ensure it meets the necessary performance standards for their intended use.

How Does Aluminum Compare as a Manufacturing Material?

Aluminum is another popular material in manufacturing, known for its lightweight and corrosion-resistant properties. It has a lower density than steel, which makes it easier to handle and transport. Key properties include excellent thermal and electrical conductivity, making it suitable for applications in the electronics and aerospace sectors.

Pros and Cons of Using Aluminum

The lightweight nature of aluminum is a significant advantage, particularly in industries focused on reducing weight for efficiency. However, aluminum can be more expensive than steel, and its lower tensile strength may limit its use in heavy-duty applications. Additionally, manufacturing processes like extrusion can be complex, requiring specialized equipment.

Impact on Application

Aluminum’s corrosion resistance is particularly beneficial in marine and outdoor applications. Buyers should ensure compliance with relevant standards, such as ASTM, to guarantee product quality and performance.

What Are the Benefits of Using Plastics in Manufacturing?

Plastics are highly versatile materials used across various industries, from consumer goods to automotive components. Key properties include lightweight, flexibility, and resistance to corrosion and chemicals. Plastics can be molded into complex shapes, making them suitable for intricate designs.

Pros and Cons of Using Plastics

The primary advantage of plastics is their cost-effectiveness and ease of manufacturing. However, they may not offer the same level of durability as metals, leading to potential issues in high-stress applications. Additionally, some plastics can degrade under UV exposure, which may limit their use in outdoor applications.

Impact on Application

Plastics are compatible with a wide range of media, making them suitable for various applications. However, international buyers should be aware of the specific types of plastics and their compliance with safety standards.

Why Choose Composites for Advanced Manufacturing Applications?

Composites, made from two or more constituent materials, offer unique properties that can be tailored for specific applications. They often combine the strength of metals with the lightweight nature of plastics. Key properties include high strength-to-weight ratios and excellent fatigue resistance.

Pros and Cons of Using Composites

The main advantage of composites is their ability to be engineered for specific performance characteristics, making them ideal for advanced applications in aerospace and automotive industries. However, they can be more expensive to manufacture and require specialized knowledge for processing. Additionally, the recycling of composites can pose challenges.

Impact on Application

Composites are suitable for applications requiring high performance under extreme conditions. International buyers must consider compliance with standards such as ASTM and JIS to ensure product quality.

Summary Table of Material Selection for Manufacturing Companies in the USA

| Material | Typical Use Case for list of manufacturing companies in usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive parts, construction materials | High durability and strength | Heavier weight, complex manufacturing | High |

| Aluminum | Aerospace components, electronics | Lightweight and corrosion-resistant | Higher cost, lower tensile strength | Medium |

| Plastics | Consumer goods, packaging | Cost-effective and versatile | Less durable, potential UV degradation | Low |

| Composites | Aerospace, high-performance automotive parts | Tailored performance characteristics | Higher manufacturing cost, recycling challenges | High |

This analysis provides valuable insights for international B2B buyers considering material selection for manufacturing in the USA. Understanding the properties, advantages, and limitations of each material will aid in making informed decisions that align with specific application requirements and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for list of manufacturing companies in usa

What Are the Key Stages in Manufacturing Processes for Companies in the USA?

Manufacturing processes in the USA typically involve several critical stages, each designed to ensure efficiency and quality. Understanding these stages can help international B2B buyers assess potential suppliers more effectively.

Material Preparation: How Are Raw Materials Processed?

Material preparation is the first stage in the manufacturing process, where raw materials are sourced, inspected, and prepared for production. This involves:

- Sourcing: Suppliers often engage with certified vendors to ensure high-quality raw materials that meet industry specifications.

- Inspection: Incoming materials undergo rigorous quality checks, including visual inspections and material property testing to ensure they meet defined standards.

- Preparation: Raw materials are cut, shaped, or processed to fit the requirements of the subsequent manufacturing stages. Techniques such as machining, milling, and chemical treatment are commonly employed.

For B2B buyers, it’s crucial to verify that suppliers maintain robust sourcing and inspection processes to guarantee the quality of the final products.

Forming: What Techniques Are Used to Shape Products?

The forming stage involves transforming raw materials into their desired shapes and forms. Techniques vary based on the material and product type:

- Casting: Molten metal is poured into molds to create specific shapes, commonly used in heavy manufacturing.

- Molding: Similar to casting but often involves plastics, where heated material is shaped in molds.

- Machining: Subtractive processes like turning and milling remove material from a solid block to achieve precise dimensions.

Buyers should inquire about the specific techniques employed by manufacturers, as these directly affect product quality and production efficiency.

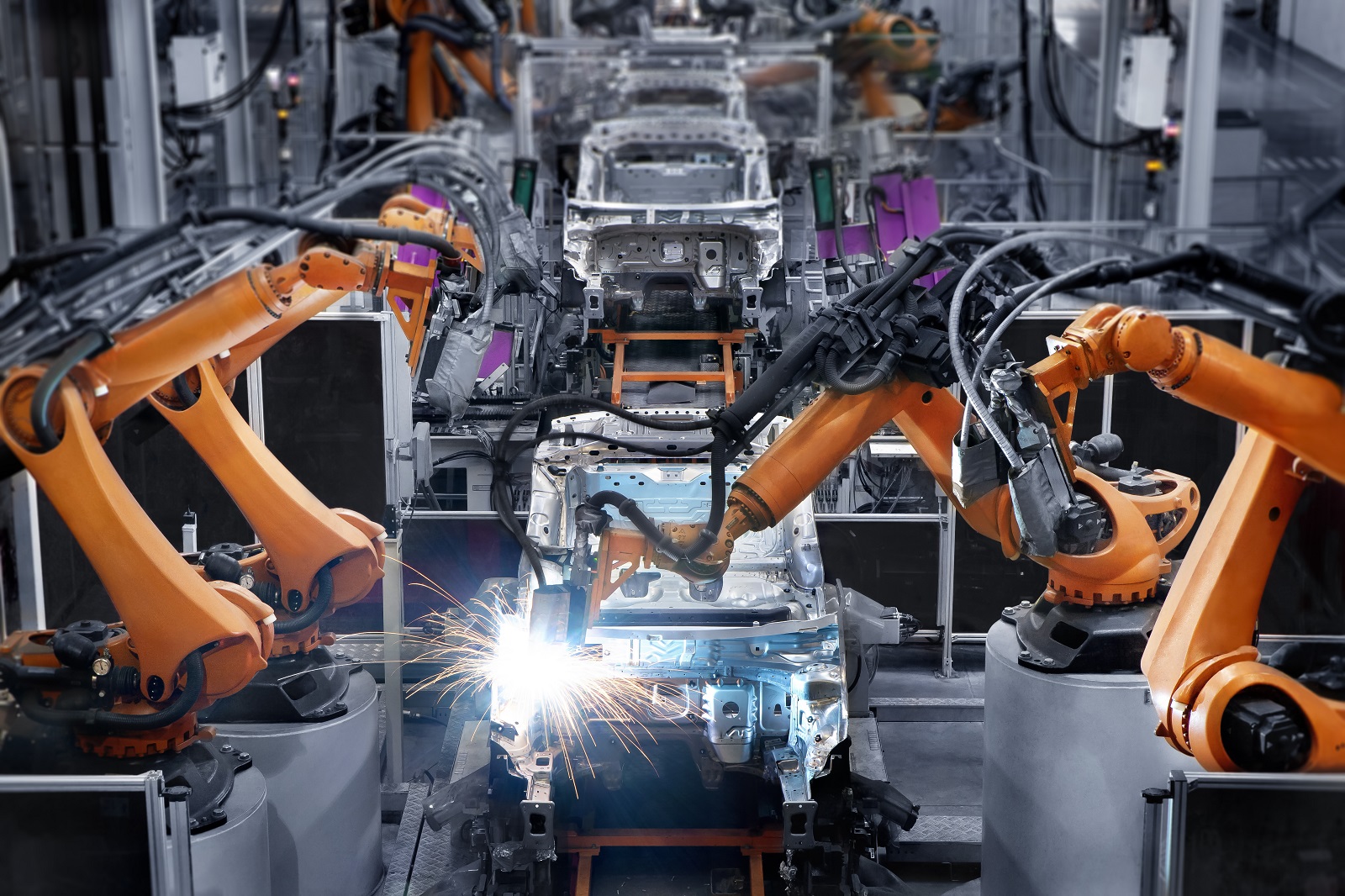

Assembly: How Are Components Integrated?

Assembly is a critical phase where individual components are put together to form the final product. This stage can include:

- Manual Assembly: Skilled workers assemble products using tools and equipment, ideal for complex or custom products.

- Automated Assembly: Robotics and automated systems are increasingly used for high-volume production, ensuring consistency and reducing labor costs.

For international buyers, understanding the assembly process can provide insights into lead times and the potential for customization.

Finishing: What Are the Common Techniques for Final Touches?

Finishing processes enhance the appearance and functionality of products. Common techniques include:

- Surface Treatment: Processes such as painting, anodizing, or galvanizing are used to improve aesthetics and protect against corrosion.

- Quality Polishing: Final polishing ensures that products meet visual and tactile quality standards.

It’s essential for buyers to know the finishing techniques used, as they can impact product longevity and performance.

What Quality Assurance Standards Should B2B Buyers Look for?

Quality assurance (QA) is vital in the manufacturing process, ensuring that products meet specific standards before reaching the market. For international B2B buyers, understanding these standards is essential.

What Are the Relevant International Quality Standards?

ISO 9001 is a widely recognized international standard for quality management systems. Compliance indicates that a manufacturer has effective processes in place to meet customer requirements and enhance satisfaction. Other industry-specific standards include:

- CE Marking: Relevant for products sold in Europe, indicating compliance with safety, health, and environmental protection standards.

- API Standards: Critical for manufacturers in the oil and gas industry, ensuring products meet safety and performance benchmarks.

Buyers should request certification documents to verify compliance with these standards, which can significantly influence purchasing decisions.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated into the manufacturing process to catch defects early. Common checkpoints include:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival.

- In-Process Quality Control (IPQC): Monitors production processes to identify and rectify issues in real time.

- Final Quality Control (FQC): Conducts comprehensive testing of finished products before shipping.

These checkpoints help maintain product integrity and reduce the likelihood of defects reaching the customer.

What Testing Methods Are Commonly Used in Manufacturing?

Testing methods are essential to validate product quality and performance. Common techniques include:

- Destructive Testing: Involves testing samples until failure to understand material limits.

- Non-Destructive Testing (NDT): Methods like ultrasonic testing and X-ray inspection assess material integrity without causing damage.

- Performance Testing: Evaluates how products perform under specified conditions, often critical for safety and compliance.

B2B buyers should inquire about the testing methods employed by manufacturers to ensure reliability and safety.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is vital for international buyers. Here are effective strategies:

- Audits: Conducting on-site audits allows buyers to assess manufacturing processes, facilities, and QC measures directly.

- Quality Reports: Requesting detailed QC reports provides insights into the supplier’s adherence to standards and procedures.

- Third-Party Inspections: Engaging independent inspection agencies can offer unbiased evaluations of product quality and compliance.

Understanding these verification methods can help buyers mitigate risks associated with international sourcing.

What Are the Nuances in Quality Control for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Cultural Differences: Understanding regional manufacturing practices and quality expectations can facilitate better communication with suppliers.

- Regulatory Compliance: Different countries may have varying regulations regarding product safety and quality, making it essential to ensure suppliers meet local requirements.

- Supply Chain Challenges: Global logistics can introduce risks related to product quality during transit. Buyers should discuss packaging and shipping standards with suppliers.

By considering these factors, international B2B buyers can make more informed decisions when selecting manufacturing partners in the USA.

In summary, a comprehensive understanding of the manufacturing processes and quality assurance measures in US manufacturing companies is crucial for international B2B buyers. By focusing on these critical areas, buyers can better evaluate potential suppliers and ensure that they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘list of manufacturing companies in usa’

Introduction

Sourcing manufacturing companies in the USA can be a complex task, especially for international buyers looking to establish strong supply chains. This guide provides a practical checklist to help you navigate the process effectively, ensuring you find reliable partners that meet your specific needs.

Step 1: Identify Your Specific Requirements

Before diving into the search, clearly define what you need from a manufacturing partner. Consider the type of product, volume requirements, and any specific materials or technologies needed. Establishing these criteria upfront will streamline the selection process and help you focus on companies that can meet your needs.

Step 2: Research Potential Suppliers

Start by compiling a list of manufacturing companies using directories, trade associations, and industry reports. Resources like the Made in America Directory and Dun & Bradstreet can provide comprehensive listings. Pay attention to the companies’ specializations and geographic locations to ensure they align with your sourcing strategy.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers have the necessary certifications relevant to your industry, such as ISO, FDA, or CE marks. These certifications demonstrate a commitment to quality and compliance with industry standards. Look for certifications that specifically relate to your product type to ensure they meet your quality expectations.

Step 4: Assess Financial Stability

Understanding a supplier’s financial health is crucial for long-term partnerships. Request financial statements or reports to assess their revenue trends and overall stability. A financially sound company is more likely to fulfill orders consistently and invest in quality improvements.

Step 5: Conduct On-Site Visits or Virtual Tours

Whenever possible, arrange for on-site visits to potential suppliers’ facilities. If travel is not feasible, request virtual tours to gain insights into their operations. Observing their manufacturing processes, quality control measures, and working conditions will provide a clearer picture of their capabilities and reliability.

Step 6: Request Samples and Test Quality

Before finalizing any agreements, request product samples to evaluate the quality firsthand. Testing samples against your specifications will help identify any potential issues before placing large orders. Ensure that the samples represent the final product you intend to source.

Step 7: Establish Clear Communication Channels

Effective communication is vital for a successful partnership. Discuss preferred methods of communication, frequency of updates, and key contacts on both sides. Establishing clear channels will help prevent misunderstandings and ensure that both parties are aligned throughout the sourcing process.

By following this checklist, you can navigate the landscape of manufacturing companies in the USA with confidence, ensuring that you select partners who can meet your business’s unique needs.

Comprehensive Cost and Pricing Analysis for list of manufacturing companies in usa Sourcing

What Are the Key Cost Components in Manufacturing Sourcing from U.S. Companies?

When evaluating manufacturing companies in the USA, understanding the cost structure is crucial for international buyers. The primary components that contribute to the overall cost include:

-

Materials: The type and quality of raw materials significantly impact pricing. Sourcing from reputable suppliers ensures quality but may raise costs.

-

Labor: Labor costs in the U.S. can be higher than in many other regions due to minimum wage laws and benefits. This is especially relevant for labor-intensive industries.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses. Companies may pass these costs onto buyers, so it’s essential to inquire about overhead allocations.

-

Tooling: The cost of molds and machinery can vary widely based on the complexity of the product. Custom tooling can lead to higher initial costs but may yield better quality and efficiency.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability but can add to manufacturing costs. Buyers should consider the long-term savings from fewer defects.

-

Logistics: Shipping costs can fluctuate based on fuel prices, carrier rates, and distance. For international buyers, understanding Incoterms is vital for predicting total logistics costs.

-

Margin: Manufacturers typically add a profit margin that reflects their operational risks and market conditions. This can vary significantly between industries.

How Do Price Influencers Affect Manufacturing Costs?

Several factors can influence pricing when sourcing from U.S. manufacturers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts, while smaller orders may incur higher per-unit costs. Understanding MOQ policies is crucial for budget management.

-

Specifications and Customization: Customized products may require additional design and tooling costs. Clear communication regarding specifications can help mitigate unexpected expenses.

-

Materials and Quality Certifications: The choice of materials (e.g., eco-friendly, high-performance) can impact both cost and compliance with international standards. Certifications may also add to the cost but can enhance marketability.

-

Supplier Factors: The reputation and reliability of the supplier play a significant role in pricing. Established companies may offer higher prices due to their perceived reliability and quality assurance processes.

-

Incoterms: Understanding the terms of shipment (e.g., FOB, CIF) can help buyers manage shipping costs and responsibilities effectively.

What Are the Best Negotiation Strategies for International Buyers?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation is key to achieving favorable pricing:

-

Leverage Total Cost of Ownership (TCO): Consider not just the purchase price but all costs associated with ownership, including shipping, customs duties, and potential after-sale service. This holistic view can inform negotiations.

-

Build Relationships: Establishing a rapport with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable conditions.

-

Be Clear on Expectations: Clearly communicate your requirements and expectations upfront to avoid misunderstandings that could lead to increased costs later.

-

Research and Benchmarking: Conduct market research to understand the going rates for similar products. This knowledge can empower you during negotiations.

-

Timing: Being strategic about when to place orders can also influence pricing. Off-peak seasons may offer better rates due to reduced demand.

What Should International Buyers Keep in Mind Regarding Pricing Nuances?

International buyers should be aware of certain pricing nuances when sourcing from U.S. manufacturers:

-

Currency Fluctuations: Exchange rates can affect pricing significantly. Consider hedging strategies to mitigate risks associated with currency fluctuations.

-

Tariffs and Trade Policies: Be informed about any tariffs that may apply to imported goods. Changes in trade policy can impact overall costs.

-

Shipping and Customs: Factor in potential delays and additional costs associated with international shipping and customs clearance.

Disclaimer on Indicative Prices

Prices provided by manufacturers may vary based on the specific requirements and market conditions. It is advisable to request detailed quotes tailored to your unique sourcing needs to ensure accurate budgeting.

Alternatives Analysis: Comparing list of manufacturing companies in usa With Other Solutions

Exploring Alternatives to the List of Manufacturing Companies in the USA

In today’s globalized market, buyers have numerous options to source manufacturing capabilities, including traditional lists of companies, online platforms, and manufacturing networks. Understanding these alternatives helps B2B buyers make informed decisions that align with their operational needs and strategic goals.

| Comparison Aspect | List Of Manufacturing Companies In USA | Online Manufacturing Platforms | Local Manufacturing Networks |

|---|---|---|---|

| Performance | Reliable, established companies | Varies based on platform | High quality, local expertise |

| Cost | Potentially higher due to local labor | Competitive pricing | Can vary, often higher than mass production |

| Ease of Implementation | Requires research and vetting | User-friendly interfaces | May require local outreach |

| Maintenance | Generally stable | Ongoing tech support | Community-driven support |

| Best Use Case | Large scale orders and complex needs | Quick, smaller orders | Custom, local projects |

What are the Advantages and Disadvantages of Online Manufacturing Platforms?

Online manufacturing platforms, such as Alibaba or ThomasNet, provide a flexible and scalable solution for sourcing manufacturing services. These platforms connect buyers with a wide range of manufacturers, often at competitive prices. The primary advantage is the ease of use; buyers can quickly compare multiple manufacturers and their offerings. However, the quality of products can vary significantly, and it may be challenging to ascertain the reliability of suppliers without thorough vetting. Additionally, these platforms are better suited for smaller orders, as the larger-scale needs may not be adequately addressed.

How Do Local Manufacturing Networks Offer Unique Benefits?

Local manufacturing networks, often formed by clusters of companies, provide a unique approach to sourcing manufacturing. These networks capitalize on regional expertise, allowing buyers to engage with manufacturers that have specific knowledge of local markets and compliance requirements. The primary advantage of local networks is the ability to support custom projects that require close collaboration and flexibility. However, costs can be higher than those associated with mass production, and the process may involve more time-consuming outreach to identify the right partners.

Conclusion: How Can B2B Buyers Make the Right Choice for Their Manufacturing Needs?

Choosing the right manufacturing solution depends on a buyer’s specific needs, project scale, and budget constraints. For large-scale projects requiring reliability and proven performance, a list of manufacturing companies in the USA may be the best fit. Conversely, for smaller orders or projects needing quick turnaround, online manufacturing platforms provide a convenient alternative. Local manufacturing networks are ideal for custom projects that benefit from regional expertise and collaboration. By assessing these options against their operational goals, B2B buyers can make strategic decisions that drive efficiency and success in their supply chains.

Essential Technical Properties and Trade Terminology for list of manufacturing companies in usa

What Are Key Technical Properties in Manufacturing?

Understanding the technical properties of products is crucial for international B2B buyers, particularly when sourcing from manufacturing companies in the USA. Here are some essential specifications that influence product quality and compatibility:

1. Material Grade

Material grade refers to the quality and type of material used in manufacturing products, which can significantly affect durability and performance. For instance, stainless steel may be preferred for its corrosion resistance in industries like food processing. Buyers should ensure that the material grade meets their specific requirements for applications, as it directly impacts the product’s longevity and safety.

2. Tolerance

Tolerance indicates the allowable deviation from a specified dimension or measurement. In manufacturing, tight tolerances are critical for parts that must fit together perfectly, such as in machinery or automotive components. Understanding tolerances helps buyers assess the precision of the manufacturing process and its suitability for their projects, which can reduce assembly issues and product failures.

3. Surface Finish

Surface finish refers to the texture and quality of a product’s surface. It can range from rough to smooth and can affect both aesthetics and functionality, such as in electronic components where surface conductivity is key. Buyers should consider the required surface finish for their applications to ensure proper performance and compliance with industry standards.

4. Load Capacity

Load capacity denotes the maximum load that a component or product can safely support. This is particularly important in sectors like construction or transportation. Buyers need to evaluate the load capacities of products to ensure they meet safety standards and operational requirements, preventing failures and accidents.

5. Chemical Resistance

Chemical resistance indicates how well a material can withstand exposure to various chemicals without degrading. This property is particularly vital for products used in industries such as pharmaceuticals or food processing, where contamination can have serious consequences. Buyers should inquire about chemical resistance to ensure product reliability in specific environments.

What Trade Terms Should International Buyers Know?

Familiarity with trade terminology is essential for smooth transactions and effective communication with manufacturing companies. Here are several key terms that buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. This term is significant for buyers looking for customized solutions or specific components that integrate into their products. Working with OEMs can enhance product differentiation and quality control.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to ensure they can meet purchase requirements without overcommitting financially. Buyers should negotiate MOQs that align with their production needs to optimize inventory management.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. This process is vital for comparing costs and ensuring competitive pricing. An effective RFQ should clearly outline product specifications, quantities, and delivery timelines to facilitate accurate responses from manufacturers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps buyers manage logistics and shipping costs, ensuring clarity on who bears the risk and responsibility during transit.

5. Lead Time

Lead time is the amount of time taken from the initiation of an order until its completion. This term is critical for buyers planning production schedules and inventory levels. Recognizing lead times allows buyers to make informed decisions about when to place orders to avoid delays in their operations.

By grasping these essential technical properties and trade terminologies, international B2B buyers can navigate the complexities of sourcing from manufacturing companies in the USA more effectively. This knowledge fosters better decision-making and strengthens supplier relationships, ultimately leading to successful business outcomes.

Navigating Market Dynamics and Sourcing Trends in the list of manufacturing companies in usa Sector

What Are the Current Market Dynamics and Key Trends in the Manufacturing Sector in the USA?

The manufacturing sector in the USA is witnessing transformative changes driven by globalization, technological advancements, and shifting consumer preferences. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly attracted to U.S. manufacturers for their innovation, quality, and reliability. Key trends include the rise of Industry 4.0 technologies such as automation, IoT, and AI, which enhance operational efficiency and product quality. As these technologies become more prevalent, they offer buyers improved transparency and real-time data, enabling more informed sourcing decisions.

Additionally, there is a growing emphasis on local sourcing as companies aim to mitigate supply chain disruptions experienced during the COVID-19 pandemic. This trend is particularly significant for international buyers, as it allows for reduced shipping times and costs while supporting U.S. job growth. Furthermore, sustainability is becoming a crucial factor in the decision-making process, with buyers increasingly favoring manufacturers that prioritize eco-friendly practices and materials. The increasing regulatory focus on sustainability, alongside consumer demand for ethical products, is shaping sourcing strategies and pushing companies to adopt more sustainable practices.

How Are Sustainability and Ethical Sourcing Influencing B2B Relationships in Manufacturing?

Sustainability and ethical sourcing have emerged as critical considerations for B2B buyers in the U.S. manufacturing sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt greener practices. Manufacturers are increasingly investing in sustainable materials and technologies to minimize waste and carbon footprints. Certifications such as ISO 14001 for environmental management and LEED for building sustainability are becoming essential credentials for companies aiming to attract environmentally conscious buyers.

For international B2B buyers, understanding a manufacturer’s commitment to ethical sourcing is vital. This includes ensuring that suppliers adhere to fair labor practices, responsible sourcing of raw materials, and transparency throughout the supply chain. Buyers are encouraged to look for manufacturers that provide detailed sustainability reports and certifications, as these indicators reflect a company’s commitment to ethical practices. By prioritizing these factors, buyers can not only align with their corporate social responsibility goals but also enhance their brand reputation in increasingly eco-aware markets.

How Has the U.S. Manufacturing Sector Evolved Over Time?

The evolution of the U.S. manufacturing sector has been marked by significant technological and economic shifts. Historically dominated by labor-intensive processes, the industry has progressively embraced mechanization and automation since the Industrial Revolution. The introduction of assembly lines and mass production techniques in the early 20th century revolutionized manufacturing efficiency and output.

In recent decades, the focus has shifted towards high-tech manufacturing and advanced materials, aligning with global trends in digital transformation. The rise of globalization has also played a pivotal role, leading to increased competition and the need for U.S. manufacturers to innovate continually. As international markets expand, U.S. manufacturers are now more inclined to adapt their strategies to meet diverse global demands while maintaining high standards of quality and sustainability. This evolution continues to present opportunities for international B2B buyers seeking reliable partners in the U.S. manufacturing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of list of manufacturing companies in usa

-

How do I identify reliable manufacturing companies in the USA?

To identify reliable manufacturing companies in the USA, start by utilizing directories such as Dun & Bradstreet or the Made in America Directory. Look for companies with positive reviews, industry certifications, and a solid history of performance. Networking through industry associations and trade shows can also provide valuable insights. Additionally, consider reaching out to current or past clients for testimonials to gauge their reliability and quality of service. -

What is the best way to vet a manufacturing supplier in the USA?

The best way to vet a manufacturing supplier is to conduct thorough research. This includes checking their financial stability, industry reputation, and compliance with relevant regulations. Request samples of their products to assess quality and consistency. Arrange site visits to evaluate their facilities and processes. Finally, ensure they have robust quality assurance protocols in place to maintain product standards. -

What are the typical minimum order quantities (MOQs) for manufacturing in the USA?

Minimum order quantities (MOQs) can vary significantly based on the type of product and manufacturer. Generally, MOQs can range from as low as 100 units for small batch manufacturers to several thousand for larger companies. When negotiating MOQs, consider discussing your specific needs and potential for future orders, as some suppliers may be flexible with minimums for long-term partnerships. -

How can I ensure product customization when working with US manufacturers?

To ensure product customization, clearly communicate your specifications and requirements during the initial discussions. Provide detailed design documents and prototypes if possible. Establish a collaborative relationship with the manufacturer, encouraging them to offer suggestions based on their expertise. Regularly review prototypes and samples throughout the production process to ensure that the final product aligns with your expectations. -

What payment terms should I expect when sourcing from US manufacturers?

Payment terms can vary by manufacturer but typically include options like net 30, net 60, or upfront deposits. It’s common for manufacturers to request a deposit of 30% to 50% before production begins, with the balance due upon completion or delivery. Always clarify payment terms in the contract and consider using secure payment methods to mitigate risks associated with international transactions. -

What quality assurance practices should I look for in a US manufacturer?

Look for manufacturers that implement robust quality assurance (QA) practices, such as ISO certifications or Six Sigma methodologies. Ask about their QA processes, including inspections, testing protocols, and how they handle defects or issues. A reliable manufacturer will have documentation of their QA procedures and be willing to provide reports on product testing and compliance with industry standards. -

How do logistics and shipping work when sourcing from US manufacturers?

Logistics and shipping arrangements can vary depending on the manufacturer and your location. Most US manufacturers can assist with logistics, including coordinating shipping and handling. Discuss shipping options, lead times, and costs upfront. It’s also advisable to consider using a freight forwarder who can handle customs clearance and ensure timely delivery of your goods to your destination. -

What challenges should I anticipate when importing products from the USA?

When importing products from the USA, anticipate challenges such as customs regulations, tariffs, and potential delays in shipping. Familiarize yourself with the import laws in your country to avoid compliance issues. Additionally, fluctuating exchange rates can impact costs, so consider locking in rates if possible. Building strong relationships with your suppliers and freight forwarders can help navigate these challenges effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for list of manufacturing companies in usa

In the ever-evolving landscape of global manufacturing, strategic sourcing from U.S. companies presents a unique opportunity for international B2B buyers. The diverse range of products, from textiles to technology, underscores the value of American craftsmanship and innovation. Companies like 3M and 1888 Mills not only exemplify quality but also highlight the trend toward sustainability and local production, which resonate strongly with conscientious consumers worldwide.

For buyers in Africa, South America, the Middle East, and Europe, engaging with U.S. manufacturers means accessing reliable supply chains and superior products that meet international standards. The emphasis on ethical sourcing and manufacturing practices enhances brand reputation and customer loyalty, particularly in markets increasingly focused on sustainability.

As you consider your sourcing strategies, remember that building partnerships with U.S. manufacturers can yield long-term benefits, including competitive pricing, product exclusivity, and enhanced market positioning. The future is bright for those who embrace these opportunities, as the demand for quality, American-made products continues to grow. Explore the possibilities today and leverage the strength of U.S. manufacturing to elevate your business.