Top 8 Golf Shoes Made In Usa List and Guide: How To Solve Scenari…

Introduction: Navigating the Global Market for golf shoes made in usa

In the competitive landscape of golf footwear, sourcing high-quality golf shoes made in the USA presents a unique challenge for international B2B buyers. As demand for premium, durable, and stylish golf shoes continues to rise, understanding the intricacies of the American market becomes crucial. This comprehensive guide equips buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Saudi Arabia—with essential insights into the various types of golf shoes available, their applications, and factors influencing pricing.

The guide delves into the distinct features of spiked versus spikeless shoes, highlighting performance benefits tailored to different playing conditions and preferences. It also emphasizes the importance of supplier vetting, providing a framework for assessing manufacturers based on quality, craftsmanship, and compliance with international standards. Additionally, the guide addresses cost considerations, enabling buyers to make informed financial decisions that align with their business objectives.

By navigating this guide, B2B buyers will gain a deeper understanding of the American golf shoe market, empowering them to make strategic purchasing decisions that not only enhance their product offerings but also meet the expectations of discerning customers. With the right knowledge and resources, your business can thrive in the growing global market for golf shoes made in the USA.

Top 10 Golf Shoes Made In Usa Manufacturers & Suppliers List

1. Athalonz – MANA Golf Shoes

Domain: athalonz.com

Registered: 2014 (11 years)

Introduction: Athalonz offers a range of golf shoes, including the MANA Golf Shoes and EnVe Golf Shoes, all handcrafted in the USA. Key features include: 1. MANA Golf Shoes – Price: $285 – Improved Optimal Athletic Positioning (OAP) for better performance – Made in USA – Waterproof Soft Italian Leather – Superior Grip & Glide 2.0 Traction – All-day comfort 2. EnVe Golf Shoes – Price: $175 – Over 9% more energy …

2. Straight Down – Cruise Sneaker

Domain: straightdown.com

Registered: 1997 (28 years)

Introduction: Men’s & Women’s Golf Shoes & Casual Shoes available at Straight Down. Key products include:

– Cruise Sneaker – White: $170.00

– Field V3 Shoe – Silver: $170.00

– Field V3 Shoe – New Indigo: $170.00

– Field V3 Shoe – Black: $170.00

– Court Shoe – White Deep Sea: $170.00

– Men Bella Perforated Derby Shoe – White: $200.00 (Best Seller)

– Women’s Boardwalk Sneaker – Verde: $170.00

– Bo…

3. ATHALONZ – Mana Mangrove Pro Golf Shoes

Domain: usalovelist.com

Registered: 2011 (14 years)

Introduction: 1. ATHALONZ – Mana Mangrove Pro golf shoes: Handcrafted in the USA.

2. COMMUNITYMade – Men’s Traction Golf shoe: Made in the USA.

4. Comunity Made – Men’s Traction LE Handcrafted Golf Shoes

Domain: comunitymade.com

Registered: 2016 (9 years)

Introduction: Men’s Traction LE Handcrafted Premium Golf Shoes, Regular price: $325.00. Available colors: Burgundy, Cenere Grey, Black. Sizes available: 7, 8, 8.5, 9, 9.5, 10, 10.5, 11, 11.5, 12, 13. Features include: handcrafted in L.A., made with premium Mastrotto® Italian leathers, OrthoLite® anti-microbial insole, lightweight cushioning with high elastic EVA midsole, Vibram® Rubber outsole for traction and …

5. Athalonz – Made in USA Promine

Domain: forums.golfwrx.com

Registered: 2005 (20 years)

Introduction: 1. **Brands Mentioned**: Athalonz, Allen Edmonds, Payntr Golf, New Balance.

2. **Manufacturing Locations**: Some shoes are made in the USA, specifically mentioned are Oregon (Payntr Golf) and Wisconsin (Allen Edmonds).

3. **Product Features**:

– Athalonz claims to have “made in USA” prominently displayed on their site.

– Allen Edmonds offers “hand crafted” shoes, although there are c…

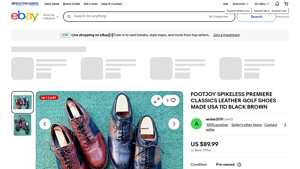

6. FootJoy – Spikeless Premiere Classics Golf Shoes

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: FOOTJOY SPIKELESS PREMIERE CLASSICS LEATHER GOLF SHOES, MADE IN USA, SIZE 11D, COLOR BLACK/BROWN, CONDITION: PRE-OWNED, PRICE: $89.99 OR BEST OFFER, ESTIMATED DELIVERY: THU, SEP 4 – THU, SEP 25, SHIPPING COST: $116.45, ITEM NUMBER: 226355538705.

7. TRUE linkswear – TRUE Lux² Player

Domain: truelinkswear.com

Registered: 2010 (15 years)

Introduction: TRUE linkswear offers comfortable golf footwear and apparel, including options for men and women. Key products include the TRUE Lux² Player with a spiked outsole designed for all weather conditions, available in five colors, and priced at $235. The brand also features a Mid-Summer Sale with discounts of up to 50% on select footwear and apparel.

8. G/FORE – Men’s Golf Shoes

Domain: gfore.com

Registered: 2009 (16 years)

Introduction: Men’s Golf Shoes – Features: Air circulation, Antimicrobial, Cooling effect, Tailored fit, Tour approved. Functionality, performance, and comfort are outstanding qualities in every pair. Available styles include MG4+ O2, G/18, Gallivan2r, Gallivanter, G.112 Golf, MG4+, MG4X2. Sizes range from 7 to 17, with options for regular and wide widths. Traction options include spiked and spikeless. Color op…

Understanding golf shoes made in usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Spiked Golf Shoes | Equipped with metal or plastic spikes for traction | Golf courses, tournaments | Pros: Superior grip; ideal for wet conditions. Cons: Can damage greens; less comfortable for walking. |

| Spikeless Golf Shoes | Flat soles with rubber traction patterns | Casual play, multi-sport use | Pros: Versatile; comfortable for walking. Cons: Less grip on wet surfaces; may compromise stability. |

| Athletic Golf Shoes | Designed with athletic performance in mind | Training, practice facilities | Pros: Enhanced comfort and support; suitable for high-performance athletes. Cons: May lack traditional golf aesthetics. |

| Classic Leather Golf Shoes | Traditional leather construction, stylish design | Upscale events, formal golf occasions | Pros: Timeless style; durable materials. Cons: Can be less breathable; may require breaking in. |

| Hybrid Golf Shoes | Combination of spiked and spikeless features | Versatile play, varying conditions | Pros: Adaptable to different terrains; good balance of comfort and grip. Cons: Can be heavier; may not excel in specific conditions. |

What Are Spiked Golf Shoes and Their B2B Relevance?

Spiked golf shoes are engineered for maximum traction, featuring cleats that dig into the turf, providing stability during swings. These shoes are particularly suitable for wet or uneven terrains, making them a preferred choice for golf courses and competitive tournaments. When purchasing spiked shoes, B2B buyers should consider the type of spikes (metal vs. plastic), as some courses have regulations against metal spikes. Understanding customer preferences for grip versus course conditions can aid in inventory decisions.

How Do Spikeless Golf Shoes Benefit Buyers?

Spikeless golf shoes offer a sleek design with rubber outsoles that feature various traction patterns. Their versatility allows golfers to transition seamlessly from the course to casual settings, making them ideal for B2B applications in retail environments that cater to diverse customer needs. Buyers should focus on comfort, breathability, and style when sourcing these shoes, as they appeal to a broader demographic, including younger golfers and those seeking multi-use footwear.

What Characteristics Define Athletic Golf Shoes?

Athletic golf shoes prioritize performance and comfort, incorporating advanced materials and technology to enhance support and reduce fatigue. These shoes are ideal for training facilities and practice ranges where golfers spend extended periods on their feet. B2B buyers should assess the fit, cushioning, and overall design to ensure they meet the demands of serious golfers. Highlighting these features in marketing can attract performance-driven customers.

Why Choose Classic Leather Golf Shoes?

Classic leather golf shoes combine style and functionality, making them suitable for upscale events and formal settings. Their durable construction appeals to buyers looking for long-lasting products that also convey a sense of tradition. However, B2B buyers should be aware of the need for proper care and maintenance, as leather can be less breathable. Offering a range of styles and sizes can cater to different customer preferences in this segment.

What Are the Advantages of Hybrid Golf Shoes?

Hybrid golf shoes merge the benefits of spiked and spikeless designs, offering versatility for various playing conditions. These shoes are particularly advantageous for B2B buyers targeting golfers who play in diverse environments. When considering hybrid options, it’s essential to evaluate the weight and materials, as these can affect performance and comfort. Marketing these shoes as adaptable can appeal to a wide range of customers, from casual players to serious competitors.

Key Industrial Applications of golf shoes made in usa

| Industry/Sector | Specific Application of golf shoes made in usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Golf Retail | Selling premium golf footwear to enthusiasts | Attracts high-end customers seeking quality and performance | Certifications of authenticity and craftsmanship |

| Sports Events & Tournaments | Providing footwear for players and staff | Ensures brand visibility and performance under competitive conditions | Bulk purchasing options and customization for branding |

| Corporate Golf Outings | Offering branded golf shoes as corporate gifts | Enhances client relationships and promotes brand loyalty | Customization options for branding and sizing flexibility |

| Golf Course Operations | Supplying staff with durable, comfortable footwear | Improves employee satisfaction and performance on the course | Quality assurance and after-sales support |

| Golf Training Facilities | Equipping trainers and students with performance shoes | Enhances training effectiveness and reduces injury risks | Sizing availability and specialized features for training needs |

How Are Golf Shoes Made in the USA Utilized in the Golf Retail Sector?

In the golf retail sector, premium golf shoes made in the USA are marketed to enthusiasts who prioritize quality and performance. These shoes often feature advanced technologies such as enhanced stability and optimal athletic positioning, making them appealing to serious golfers. Retailers can differentiate themselves in a competitive market by offering authentic American craftsmanship, which resonates well with customers looking for durability and style. For international buyers, ensuring that these shoes meet local standards and preferences is crucial, as is understanding the logistics of importing premium footwear.

What Role Do Golf Shoes Play in Sports Events and Tournaments?

Sports events and tournaments frequently require high-performance footwear for both players and staff. Golf shoes made in the USA provide the necessary traction and support to optimize performance under competitive conditions. By partnering with manufacturers of these shoes, event organizers can ensure that all participants are equipped with quality footwear, enhancing the overall experience. For international buyers, considering bulk purchasing options and potential customization for branding is essential to maximize visibility and create a cohesive event atmosphere.

How Can Corporate Golf Outings Benefit from Branded Golf Shoes?

Corporate golf outings can leverage the appeal of branded golf shoes made in the USA as high-value gifts for clients and employees. Offering these shoes can strengthen client relationships and promote brand loyalty, while also ensuring that recipients enjoy the comfort and performance of quality footwear on the course. When sourcing these shoes, businesses should focus on customization options that allow for their branding and consider the size range to accommodate all participants, particularly in diverse markets.

Why Are Golf Shoes Important for Golf Course Operations?

Golf courses can enhance staff performance and satisfaction by supplying employees with durable and comfortable golf shoes made in the USA. Such footwear not only improves mobility on the course but also reflects the professionalism of the establishment. For course operators, it’s vital to source shoes that guarantee quality and provide reliable after-sales support, ensuring that staff can rely on their gear throughout the season. International buyers should also consider local climate and course conditions when selecting appropriate footwear.

How Do Golf Training Facilities Utilize Golf Shoes Made in the USA?

Golf training facilities benefit from equipping trainers and students with high-performance golf shoes made in the USA, as these shoes enhance training effectiveness and reduce injury risks. The specialized design features of these shoes cater to the unique movements involved in golfing, making them a valuable asset for both learners and instructors. Buyers in this sector should pay attention to sizing availability and any specific features that may aid in training, ensuring that all participants are well-equipped for their development.

3 Common User Pain Points for ‘golf shoes made in usa’ & Their Solutions

Scenario 1: Sourcing Quality Golf Shoes for International Distribution

The Problem: B2B buyers in regions such as Africa, South America, and the Middle East often face challenges when sourcing high-quality golf shoes made in the USA. These buyers may encounter issues such as limited supplier options, high shipping costs, and concerns about product authenticity. Additionally, the varying standards of quality and craftsmanship can create uncertainty regarding whether the products will meet the expectations of local consumers. This can be especially frustrating when buyers have specific requirements for performance, comfort, and style that are critical for their market.

The Solution: To effectively source golf shoes made in the USA, buyers should leverage established connections with manufacturers known for their commitment to quality. Attending trade shows and industry events can facilitate direct communication with manufacturers, allowing buyers to assess product quality firsthand and negotiate better shipping terms. Furthermore, utilizing platforms that specialize in B2B transactions can help buyers identify reputable suppliers with transparent business practices. It’s also advisable to request samples before placing bulk orders to ensure that the shoes meet the desired standards of craftsmanship and performance.

Scenario 2: Meeting Diverse Consumer Preferences in Global Markets

The Problem: Golf shoes made in the USA often come with a distinct style and functionality that may not resonate with all international consumers. Buyers in diverse markets must navigate varying preferences, including color, design, and type (spiked vs. spikeless). This cultural disconnect can lead to excess inventory of products that do not sell, ultimately affecting profitability. Additionally, the need for customization or special features can complicate the buying process, especially when dealing with manufacturers that have rigid production lines.

The Solution: To address these consumer preference challenges, B2B buyers should conduct thorough market research before sourcing golf shoes. This includes analyzing local trends, customer feedback, and competitive offerings. Collaborating with manufacturers willing to accommodate customization requests—such as color variations or materials—can also provide a competitive edge. Establishing a feedback loop with local retailers can help in adjusting product offerings to better match consumer desires, ensuring that the inventory aligns with market demand.

Scenario 3: Ensuring Compliance with International Standards

The Problem: B2B buyers must navigate a complex landscape of regulations and standards when importing golf shoes made in the USA. Different countries have varying requirements regarding product safety, materials, and labeling, which can lead to complications during customs clearance. This regulatory burden not only increases operational costs but can also result in delayed shipments, unsatisfied customers, and potential legal repercussions.

The Solution: To mitigate these compliance challenges, B2B buyers should familiarize themselves with the specific import regulations of their target markets. Partnering with logistics companies that specialize in international trade can provide valuable insights into the necessary documentation and standards. Additionally, working with manufacturers that prioritize compliance and maintain certifications can streamline the process. Buyers should also consider investing in compliance training for their procurement teams to ensure that all aspects of the purchasing process adhere to international standards, ultimately reducing the risk of costly delays and penalties.

Strategic Material Selection Guide for golf shoes made in usa

When selecting materials for golf shoes made in the USA, several factors must be considered, including performance characteristics, durability, cost, and compliance with international standards. This guide examines four common materials used in the production of golf shoes, providing insights for international B2B buyers.

What Are the Key Properties of Leather in Golf Shoes?

Leather is a traditional material in golf shoe manufacturing, known for its durability and classic aesthetic. Key properties include excellent breathability, which helps regulate temperature during play, and natural resistance to wear and tear. However, leather can be sensitive to moisture and may require treatment to maintain its integrity.

Pros and Cons: Leather offers superior comfort and a premium feel, making it a popular choice among golfers. However, it can be more expensive than synthetic alternatives and may require more complex manufacturing processes, including tanning and finishing. Its susceptibility to water can limit its use in wet conditions unless treated.

Impact on Application: Leather is compatible with various weather conditions, but its performance may diminish in extreme moisture without proper treatment. For international buyers, understanding local climate conditions is crucial to selecting the right leather type.

How Does Synthetic Material Compare for Golf Shoes?

Synthetic materials, such as polyurethane (PU) and thermoplastic polyurethane (TPU), are increasingly popular in golf shoe production due to their lightweight nature and water resistance. These materials often feature enhanced durability and flexibility, making them suitable for various playing conditions.

Pros and Cons: Synthetic materials are generally more affordable and easier to manufacture than leather, allowing for quicker production times. However, they may not provide the same level of breathability, which can lead to discomfort during prolonged use. Additionally, while they are resistant to moisture, they may not offer the same aesthetic appeal as leather.

Impact on Application: Synthetic materials are highly compatible with wet conditions, making them ideal for regions with high rainfall. B2B buyers from areas like Nigeria or Saudi Arabia should consider the moisture levels in their markets when selecting synthetic options.

What Role Does EVA Foam Play in Golf Shoe Comfort?

EVA (Ethylene Vinyl Acetate) foam is commonly used in the midsoles of golf shoes, providing cushioning and shock absorption. This material is lightweight and offers excellent energy return, enhancing performance during play.

Pros and Cons: The primary advantage of EVA foam is its comfort and shock-absorbing properties, which can reduce fatigue during long rounds. However, it may not be as durable as other materials and can degrade over time, particularly under extreme conditions.

Impact on Application: EVA foam is suitable for various climates, but its longevity can be affected by heat and humidity. Buyers from hot regions should inquire about the specific formulations used to ensure durability.

How Do Rubber Outsoles Enhance Traction in Golf Shoes?

Rubber is a common choice for outsoles in golf shoes, providing excellent traction and stability on the course. Key properties include resistance to abrasion and a high coefficient of friction, which enhances grip during swings.

Pros and Cons: Rubber outsoles are durable and provide reliable traction, making them suitable for various playing surfaces. However, they can add weight to the shoe, which may affect overall comfort. Additionally, rubber can be more expensive than other outsole materials.

Impact on Application: International buyers should consider the types of courses prevalent in their regions, as different surfaces may require specific rubber compounds for optimal performance. Compliance with local standards for rubber materials can also affect procurement.

Summary Table of Material Selection for Golf Shoes Made in USA

| Material | Typical Use Case for golf shoes made in usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Premium golf shoes | Excellent breathability and comfort | Sensitive to moisture, high cost | High |

| Synthetic | Versatile, all-weather golf shoes | Lightweight and water-resistant | Less breathable, lower aesthetic | Medium |

| EVA Foam | Cushioning midsoles | Superior shock absorption | Less durable, can degrade over time | Medium |

| Rubber | Outsoles for traction | Excellent grip and durability | Can add weight, higher cost | Medium to High |

This strategic material selection guide provides valuable insights for international B2B buyers looking to source high-quality golf shoes made in the USA. Understanding the properties, advantages, and limitations of each material will help in making informed procurement decisions tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for golf shoes made in usa

What Are the Key Stages in the Manufacturing Process of Golf Shoes Made in the USA?

The manufacturing of golf shoes in the USA involves several critical stages that ensure high quality and performance. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality materials, such as leather, synthetic fabrics, and rubber. Each material is assessed for durability, comfort, and performance characteristics. Suppliers often provide certifications for their materials, ensuring they meet industry standards. This stage may also involve cutting the materials to the required specifications using precision tools and techniques.

-

Forming: During the forming stage, the cut materials are shaped into the various components of the golf shoe. Techniques such as molding and stitching are commonly used. For instance, the upper part of the shoe may be molded to create an ergonomic fit that enhances comfort and performance. Advanced technologies like 3D printing may also be employed to create custom-fit components, allowing for greater personalization.

-

Assembly: The assembly process brings together all the components of the shoe. This includes attaching the upper to the sole, which is critical for ensuring stability and traction. Skilled craftsmen often perform this step to maintain a high standard of quality. Automated systems might be used for specific tasks, but manual oversight is essential to ensure that each pair meets the brand’s quality expectations.

-

Finishing: The final stage involves quality checks and finishing touches. This may include polishing, adding branding elements, and preparing the shoes for packaging. A meticulous inspection is conducted to ensure that each shoe is free from defects and meets design specifications. This stage is crucial as it directly impacts the product’s aesthetic and functional quality.

How Is Quality Assurance Implemented in Golf Shoe Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of golf shoes, ensuring that products meet or exceed industry standards. Various international and industry-specific standards apply, including ISO 9001, which outlines quality management system requirements.

-

International Standards Compliance: Adherence to ISO 9001 ensures that manufacturers maintain a consistent quality management system. This involves regular audits and documentation of processes, allowing for continuous improvement. Additionally, certifications such as CE mark and API (American Petroleum Institute) standards may apply, depending on the materials and technologies used in the shoe manufacturing process.

-

Quality Control Checkpoints: Effective QA includes multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified quality standards before production begins.

– In-Process Quality Control (IPQC): During manufacturing, various checks are conducted to monitor processes and identify any deviations from established standards. This may involve visual inspections and measurements.

– Final Quality Control (FQC): Once the shoes are assembled, a final inspection is performed to ensure that each pair meets quality and performance specifications before packaging. -

Common Testing Methods: Various testing methods are employed to evaluate the durability, comfort, and performance of golf shoes. These may include:

– Static and Dynamic Load Testing: Assessing how the shoes perform under different weights and movements.

– Water Resistance Testing: Ensuring that the materials used can withstand moisture, which is essential for outdoor sports.

– Traction Testing: Evaluating the grip of the sole on various surfaces to ensure safety and performance.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital for ensuring product reliability and safety.

-

Supplier Audits: Conducting on-site audits of manufacturing facilities allows buyers to assess compliance with quality standards. During these audits, buyers can evaluate the manufacturing processes, materials used, and the overall production environment.

-

Quality Control Reports: Requesting detailed QC reports can provide insights into the supplier’s quality management practices. These reports should include data on testing results, inspection outcomes, and any corrective actions taken for non-conformities.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent entities conduct thorough evaluations of the manufacturing processes and final products, offering unbiased assessments that can help buyers make informed decisions.

-

Certifications and Documentation: Buyers should look for suppliers that possess relevant certifications and maintain thorough documentation of their quality control processes. This includes maintaining records of compliance with international standards and any industry-specific certifications.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating quality control nuances can be complex for B2B buyers from different regions. Understanding local regulations, market expectations, and cultural differences in quality perception is crucial.

-

Understanding Local Regulations: Different regions may have unique regulations governing product safety and quality standards. For instance, buyers from the European Union may need to ensure compliance with CE marking requirements, while those in the Middle East might focus on standards set by local authorities.

-

Cultural Expectations: Buyers should recognize that perceptions of quality can vary between cultures. For example, in some regions, aesthetic appeal may be prioritized, while in others, durability and performance might be the primary focus. This understanding can help buyers communicate their quality expectations more effectively.

-

Supply Chain Transparency: Building a transparent supply chain is essential for maintaining quality. Buyers should seek suppliers that provide clear visibility into their sourcing, manufacturing, and quality assurance processes. This transparency fosters trust and ensures that quality standards are consistently met.

By focusing on these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing golf shoes made in the USA, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘golf shoes made in usa’

Introduction

Sourcing high-quality golf shoes made in the USA can be a strategic move for international buyers seeking durable, stylish, and performance-oriented footwear. This guide offers a step-by-step checklist to streamline your procurement process, ensuring that you find suppliers who meet your specific needs while adhering to the highest standards of craftsmanship.

Step 1: Define Your Technical Specifications

Before diving into the market, outline your specific requirements for golf shoes. Consider factors such as materials (leather, synthetic), shoe types (spiked vs. spikeless), and performance features (waterproofing, breathability). Establishing clear specifications helps in narrowing down potential suppliers and ensures that you receive products that meet your expectations.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify manufacturers and brands specializing in American-made golf shoes. Use industry directories, trade shows, and online platforms to compile a list of potential suppliers. Look for companies with a strong reputation and positive reviews, particularly those that highlight their commitment to quality and American craftsmanship.

Step 3: Verify Supplier Certifications

It’s crucial to ensure that the suppliers you consider have the necessary certifications for manufacturing and quality assurance. Check for certifications that demonstrate compliance with industry standards, such as ISO certifications or membership in reputable trade associations. This step is vital for minimizing risk and ensuring that the products you source are reliable and safe.

Step 4: Request Samples for Evaluation

Once you’ve shortlisted potential suppliers, request samples of their golf shoes for evaluation. Testing the shoes for comfort, fit, durability, and overall quality can provide invaluable insights into their craftsmanship. Pay attention to the details such as stitching, material finish, and performance features to gauge whether they meet your specifications.

Step 5: Evaluate Pricing and Payment Terms

Analyze the pricing structures of your shortlisted suppliers while considering the total cost of ownership. Look for transparency in pricing and be aware of additional costs such as shipping, taxes, and potential tariffs. Establish clear payment terms, including deposits and payment schedules, to ensure a smooth transaction process.

Step 6: Assess Production Capacity and Lead Times

Understanding the production capacity and lead times of your suppliers is essential for planning your inventory and meeting customer demand. Inquire about their manufacturing capabilities, including the number of units they can produce within your required timeframe. This step ensures that you can align your sourcing strategy with your business needs.

Step 7: Establish Communication and Support Channels

Effective communication is key to a successful partnership. Ensure that your chosen supplier is responsive and willing to address any queries or concerns. Establish clear channels for ongoing support, including contact persons and timelines for feedback, to facilitate a collaborative relationship that can adapt to any future needs.

By following this checklist, B2B buyers can effectively navigate the sourcing landscape for golf shoes made in the USA, ensuring a successful procurement process that meets their business objectives.

Comprehensive Cost and Pricing Analysis for golf shoes made in usa Sourcing

What Are the Key Cost Components for Sourcing Golf Shoes Made in the USA?

When sourcing golf shoes manufactured in the USA, understanding the cost structure is vital for B2B buyers. The primary cost components include:

-

Materials: High-quality materials are essential for performance and durability. Expect to pay a premium for materials sourced domestically, such as leather, synthetic fabrics, and specialized outsoles. Sustainable materials may also incur higher costs but can enhance brand value.

-

Labor: Labor costs in the USA are typically higher than in many other countries. Skilled craftsmen involved in the production of golf shoes contribute to the overall labor cost, which can account for a significant portion of the total manufacturing expense.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance associated with the production facilities. USA-based manufacturers often face higher overhead costs due to regulations and standards.

-

Tooling: Initial setup costs for molds and machinery can be substantial, especially for custom designs. This is a one-time expense but should be factored into the pricing model for bulk orders.

-

Quality Control (QC): Rigorous QC processes are crucial in maintaining the quality of golf shoes. These processes add to the overall cost but are essential for ensuring that the shoes meet performance standards and buyer specifications.

-

Logistics: Shipping costs can vary widely based on the distance to the buyer’s location, shipping method, and Incoterms. For international buyers, customs duties and tariffs may also apply.

-

Margin: Manufacturers typically build a profit margin into the pricing of their products, which can vary based on the brand’s positioning and market strategy.

What Influences the Pricing of Golf Shoes Made in the USA?

Several factors can influence the pricing of golf shoes, particularly for international B2B buyers:

-

Volume/MOQ: Larger orders often qualify for bulk pricing discounts. Understanding the minimum order quantities (MOQs) set by suppliers can help negotiate better rates.

-

Specifications and Customization: Customized designs or specific performance features (like spiked versus spikeless soles) can significantly affect the price. Be prepared for additional costs associated with bespoke requests.

-

Materials and Quality Certifications: Shoes made with premium materials or those that meet specific quality certifications may come at a higher price. Certifications can also be a selling point in certain markets.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established brands may charge more due to perceived quality, while emerging manufacturers might offer competitive rates to gain market entry.

-

Incoterms: The terms of trade (e.g., FOB, CIF) can impact the overall cost for the buyer. Understanding these terms is crucial for calculating the total landed cost.

What Are the Best Negotiation Tips for International B2B Buyers of Golf Shoes?

-

Research and Benchmarking: Before entering negotiations, research prevailing market prices for similar products. This knowledge can provide leverage in discussions with suppliers.

-

Focus on Total Cost of Ownership (TCO): Rather than just the initial purchase price, consider the TCO, which includes shipping, tariffs, and potential warranty or return costs. A higher initial cost may lead to lower long-term expenses if the product is more durable.

-

Leverage Long-term Relationships: Building a strong relationship with suppliers can lead to better terms and pricing over time. Consider discussing future orders or collaborations to secure favorable pricing.

-

Be Flexible with Specifications: If cost is a significant concern, being open to alternatives in materials or designs can lead to cost savings.

-

Negotiate Payment Terms: Flexible payment options can improve cash flow and reduce financial strain, making it easier to commit to larger orders.

Conclusion

Understanding the comprehensive cost structure and pricing dynamics of golf shoes made in the USA is essential for international B2B buyers. By considering the cost components, pricing influencers, and effective negotiation strategies, buyers can make informed decisions that align with their business needs and budget constraints. Always remember to factor in the potential long-term benefits of investing in high-quality products, which can enhance brand reputation and customer satisfaction.

Alternatives Analysis: Comparing golf shoes made in usa With Other Solutions

Introduction to Alternative Solutions for Golf Footwear

When considering golf shoes, particularly those made in the USA, international B2B buyers should explore various alternatives that cater to different preferences and needs. While American-made golf shoes are often celebrated for their craftsmanship and performance, several other viable options can deliver similar benefits. This analysis compares golf shoes made in the USA against spiked shoes from established global brands and spikeless golf shoes that prioritize comfort and versatility.

Comparison Table

| Comparison Aspect | Golf Shoes Made In USA | Spiked Shoes from Global Brands | Spikeless Golf Shoes |

|---|---|---|---|

| Performance | High traction, stability, and comfort | Excellent grip in wet conditions | Moderate traction, good for dry turf |

| Cost | Premium pricing, typically $150-$300 | Ranges from $100-$250 | Mid-range pricing, typically $80-$200 |

| Ease of Implementation | Readily available through select retailers | Widely available online and in stores | Easily available, often in sporting goods stores |

| Maintenance | Requires regular cleaning and care | Moderate care needed | Low maintenance, easy to clean |

| Best Use Case | Ideal for competitive play | Suitable for various weather conditions | Great for casual play or walking |

Detailed Breakdown of Alternatives

Spiked Shoes from Global Brands

Spiked shoes, commonly produced by well-known brands like Adidas and Nike, offer exceptional grip and stability, particularly on wet or slippery courses. These shoes often feature advanced technology in their design, such as lightweight materials and enhanced cushioning. However, they may not provide the same level of comfort as their American-made counterparts, and they can sometimes lack the durability expected from premium footwear. Furthermore, their reliance on spikes can lead to issues on hard surfaces, making them less versatile for off-course activities.

Spikeless Golf Shoes

Spikeless golf shoes have gained popularity due to their comfort and versatility. Brands like Skechers and Ecco produce models that can be worn on and off the golf course without compromising style. These shoes typically feature rubber outsoles that provide adequate traction while allowing for a more casual look. The primary drawback is that they may not perform as well in wet conditions compared to spiked shoes, which can limit their effectiveness in certain environments. However, they are often more affordable and require less maintenance, making them appealing for casual golfers.

Conclusion: Choosing the Right Golf Footwear for Your Needs

When deciding on golf footwear, B2B buyers should consider the specific needs of their clientele and the environments in which the shoes will be used. Golf shoes made in the USA offer premium quality and performance, making them suitable for serious golfers seeking durability and stability. In contrast, spiked shoes from global brands provide excellent grip for varied weather conditions, while spikeless options cater to those prioritizing comfort and casual wear. Ultimately, understanding the target market and their preferences will guide buyers in selecting the most appropriate footwear solution for their business needs.

Essential Technical Properties and Trade Terminology for golf shoes made in usa

What Are the Key Technical Properties of Golf Shoes Made in the USA?

Understanding the technical properties of golf shoes is crucial for B2B buyers looking to source high-quality products. Here are some essential specifications to consider:

1. Material Grade

The material grade of golf shoes often refers to the quality and type of materials used in construction, such as leather, synthetic fabrics, or rubber. High-grade materials enhance durability, comfort, and performance, particularly under varying weather conditions. For instance, premium leather provides breathability and longevity, making it suitable for prolonged use on the golf course. Sourcing shoes made with high-grade materials can significantly reduce returns and increase customer satisfaction.

2. Comfort Features

Comfort features include cushioning, arch support, and ergonomic design, which are critical for golfers who spend hours on the course. Advanced cushioning technologies, like EVA (Ethylene Vinyl Acetate) or proprietary insoles, can alleviate foot fatigue. B2B buyers should prioritize shoes that offer superior comfort features as they directly impact performance and player satisfaction, ultimately influencing repeat purchases.

3. Traction and Stability

The traction system of golf shoes is essential for maintaining grip during swings and navigating various terrains. Many shoes incorporate spiked or spikeless designs with specialized outsoles that offer stability without sacrificing comfort. B2B buyers should assess traction capabilities, especially in regions with wet or uneven surfaces, to ensure that their products meet the performance expectations of their customers.

4. Weight and Flexibility

The weight of golf shoes affects a player’s mobility and stamina. Lightweight designs enhance performance by allowing for easier movement, while flexibility promotes a natural range of motion. When sourcing golf shoes, buyers should consider these factors, as they play a vital role in the overall user experience.

5. Water Resistance

Water-resistant materials and treatments are vital for golf shoes, especially in regions prone to rain or dew. Shoes that incorporate waterproof membranes or water-repellent treatments help keep feet dry and comfortable. B2B buyers should look for products that emphasize water resistance, as they can appeal to golfers who play in diverse weather conditions.

What Are the Common Trade Terms Used in Sourcing Golf Shoes Made in the USA?

Familiarity with industry terminology can streamline negotiations and enhance communication with suppliers. Here are some key terms relevant to sourcing golf shoes:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are marketed by another company. In the context of golf shoes, an OEM may manufacture shoes for a brand that sells them under its label. Understanding OEM relationships can help B2B buyers evaluate product quality and brand reputation.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to produce or sell. This term is crucial for buyers as it affects inventory management and cost-efficiency. Knowing the MOQ can help businesses plan their purchases according to demand while avoiding excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products or services. For golf shoes, submitting an RFQ allows buyers to compare offers from multiple manufacturers, ensuring competitive pricing and favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers engaged in global sourcing, as they clarify the risk and cost responsibilities associated with shipping golf shoes.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. For golf shoes, understanding lead times is crucial for inventory planning and meeting market demands. Buyers should negotiate lead times with suppliers to ensure timely delivery, especially during peak seasons.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing golf shoes made in the USA, ensuring they meet both quality and performance standards.

Navigating Market Dynamics and Sourcing Trends in the golf shoes made in usa Sector

What Are the Key Market Drivers for Golf Shoes Made in the USA?

The global golf shoe market has seen a resurgence, driven by a growing interest in golf across various demographics, particularly in emerging markets in Africa, South America, the Middle East, and Europe. As the sport gains popularity, the demand for high-quality, performance-oriented footwear has increased. International B2B buyers are increasingly looking for products that combine functionality with style, emphasizing the importance of comfort, traction, and stability during play. The trend toward customization and personalized footwear is also gaining traction, with brands offering bespoke options to cater to diverse consumer preferences.

Technological advancements in materials and manufacturing processes are shaping the future of golf shoes. Innovations such as breathable fabrics, lightweight construction, and advanced cushioning systems are becoming standard features. Moreover, the rise of e-commerce platforms is transforming how international buyers source products, allowing them to easily compare offerings and access a broader range of golf shoes made in the USA.

How Are Sustainability and Ethical Sourcing Influencing the Golf Shoe Market?

Sustainability is increasingly becoming a priority for B2B buyers in the golf shoe sector. With growing awareness about environmental issues, manufacturers are adopting eco-friendly practices in their production processes. This includes using sustainable materials, such as recycled plastics and organic textiles, which significantly reduce the environmental impact of manufacturing golf shoes.

Ethical sourcing practices are also gaining importance. Buyers are scrutinizing supply chains to ensure that their products are made under fair labor conditions. Certifications such as Fair Trade and Global Organic Textile Standard (GOTS) are becoming critical for brands aiming to enhance their credibility and appeal to socially conscious consumers. By focusing on sustainability and ethical sourcing, businesses not only comply with regulatory requirements but also meet the expectations of a growing segment of environmentally aware customers, thus enhancing their marketability.

What Is the Historical Context of Golf Shoes Made in the USA?

The evolution of golf shoes in the USA dates back to the early 20th century when the sport began to gain popularity. Early designs were primarily leather-based, aimed at providing the necessary support and traction for golfers. Over the decades, technological advancements have transformed these shoes into specialized footwear that combines performance with style.

The introduction of spiked shoes in the 1920s marked a significant milestone, providing golfers with enhanced grip on various terrains. As the sport evolved, so did the designs, leading to the emergence of spikeless options that cater to the modern golfer’s lifestyle. Today, golf shoes made in the USA are recognized for their superior craftsmanship and innovation, serving not just as functional sportswear but also as fashion statements on and off the course. This rich history reinforces the value of American-made products in the global market, appealing to buyers seeking quality and tradition.

Frequently Asked Questions (FAQs) for B2B Buyers of golf shoes made in usa

-

How can I ensure the quality of golf shoes made in the USA?

To guarantee the quality of golf shoes made in the USA, request detailed specifications and quality assurance (QA) certifications from suppliers. Look for manufacturers that follow strict quality control processes and use premium materials. It’s beneficial to ask for samples before committing to larger orders, as this allows you to assess craftsmanship and performance. Additionally, researching the manufacturer’s reputation and customer reviews can provide insights into their reliability and product quality. -

What are the benefits of sourcing golf shoes made in the USA?

Sourcing golf shoes made in the USA offers several advantages, including superior craftsmanship, shorter lead times, and the ability to customize products to meet specific needs. American-made products often adhere to higher environmental and labor standards, which can enhance your brand’s image. Additionally, supporting local manufacturing can be a compelling selling point to customers who value domestic products, especially in markets sensitive to international trade issues. -

What is the typical minimum order quantity (MOQ) for golf shoes made in the USA?

The MOQ for golf shoes made in the USA can vary significantly between manufacturers, typically ranging from 50 to 500 pairs. Factors influencing MOQ include the complexity of the design, materials used, and production capabilities of the supplier. It’s essential to communicate your needs clearly and negotiate the MOQ based on your business model, especially if you’re testing new markets or launching a new product line. -

What customization options are available for golf shoes made in the USA?

Many manufacturers of golf shoes made in the USA offer various customization options, including color, material, sizing, and branding features such as logos or specific designs. Discuss your requirements with potential suppliers to understand their capabilities and any additional costs associated with customization. Customization can help differentiate your product in the marketplace and meet specific customer preferences. -

What payment terms should I expect when sourcing golf shoes from the USA?

Payment terms can vary widely among suppliers but typically include options such as 30% upfront deposit and 70% upon delivery, or net 30/60 days after receipt of goods. It’s crucial to clarify payment terms upfront to avoid misunderstandings. Consider negotiating terms that align with your cash flow and risk management strategies, especially if you’re ordering in bulk or establishing a long-term partnership. -

How can I vet suppliers of golf shoes made in the USA?

To effectively vet suppliers, start by checking their business credentials, production capabilities, and client testimonials. Request references from other B2B clients to assess reliability and product quality. Visiting the supplier’s facility, if possible, can provide firsthand insight into their manufacturing processes. Additionally, ensure they comply with all relevant labor and environmental regulations to mitigate risks associated with unethical practices. -

What logistics considerations should I keep in mind when importing golf shoes from the USA?

When importing golf shoes, consider shipping costs, customs duties, and delivery times, which can significantly impact your overall budget and timeline. Work with a freight forwarder experienced in handling footwear to navigate international shipping regulations and optimize logistics. Understanding the logistics process, including documentation and compliance requirements, will help ensure a smooth import experience and minimize delays. -

What are the current trends in golf shoe design and technology?

Current trends in golf shoe design focus on comfort, performance, and sustainability. Innovations include lightweight materials, enhanced traction systems, and customizable features for improved fit and support. Many brands are also integrating eco-friendly materials and manufacturing processes to appeal to environmentally conscious consumers. Staying informed about these trends can help you select products that resonate with your target market and enhance your competitive edge.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for golf shoes made in usa

In conclusion, strategic sourcing of golf shoes made in the USA presents a unique opportunity for international B2B buyers seeking quality, craftsmanship, and performance. The emphasis on American manufacturing not only ensures high standards of production but also aligns with growing consumer demand for locally-sourced products. As highlighted, brands like Athalonz and New Balance exemplify innovation in design and technology, providing golfers with footwear that enhances both comfort and stability.

For buyers in Africa, South America, the Middle East, and Europe, investing in American-made golf shoes can significantly elevate your product offerings. These shoes cater to a diverse market, appealing to golfers who prioritize performance and durability. Moreover, the rising trend towards sustainability and ethical sourcing further amplifies the value of American craftsmanship in your inventory.

Looking ahead, now is the time to forge partnerships with manufacturers that embody these values. By incorporating golf shoes made in the USA into your portfolio, you not only meet the expectations of discerning consumers but also position your business as a leader in quality and innovation within the global golf market. Embrace this opportunity to differentiate your offerings and drive growth.