Top 8 East Coast Ports Of Usa List and Guide: How To Solve Scenar…

Introduction: Navigating the Global Market for east coast ports of usa

Navigating the complexities of international shipping can be a daunting challenge for businesses seeking to leverage the vast potential of East Coast ports in the USA. As global trade continues to expand, understanding how to effectively utilize these strategic gateways is critical for B2B buyers from regions like Africa, South America, the Middle East, and Europe. This guide offers a comprehensive overview of the East Coast ports, detailing their capabilities, types of cargo handled, and the unique advantages each port presents.

In this guide, we will explore various aspects of East Coast ports, including operational efficiencies, key supplier vetting processes, cost considerations, and logistics applications. Whether you are sourcing goods for manufacturing or seeking reliable shipping routes for exports, this resource equips you with the insights necessary to make informed purchasing decisions.

With detailed profiles of major ports such as New York, Savannah, and Charleston, along with practical advice on navigating regulatory requirements and optimizing supply chain processes, this guide empowers international buyers to capitalize on the growing opportunities within the US market. By understanding the nuances of each port and aligning them with your business needs, you can enhance your global trade strategies and drive sustainable growth.

Top 10 East Coast Ports Of Usa Manufacturers & Suppliers List

1. Cockett USA – Key Product Offerings

Domain: cockettgroup.com

Registered: 2001 (24 years)

Introduction: Cockett USA offers a range of products available at various ports on the East Coast of the USA. The key details include:

– Baltimore, MD: 4,000 L (barge supply, packed bulk, drum, pumping, ex-drum, tote, tank, tank truck)

– Boston, MA: 6,000 L (barge supply), 12,000 L (packed bulk)

– Bridgeport, CT: 19,000 L

– Charleston, SC: 10,000 L

– Ft Lauderdale (Port Everglades), FL: 6,000 L

– Hampton …

2. Marine Insight – Major U.S. East Coast Ports Overview

Domain: marineinsight.com

Registered: 2010 (15 years)

Introduction: The text provides detailed information about major U.S. East Coast ports, including the Port of New York and New Jersey, Port of Savannah, and Port of Virginia. Key details include cargo types handled, terminal capacities, annual cargo volumes, and recent infrastructure improvements. For example, the Port of New York and New Jersey handles approximately 85,510,000 tonnes of cargo and 7,250 vessels…

3. CruiseWise – East Coast Cruise Ports

Domain: cruisewise.cruisehelp.com

Registered: 1997 (28 years)

Introduction: East Coast Cruise Ports (US) include Baltimore, MD; Bayonne, NJ; Boston, MA; Charleston, SC; New York City (Brooklyn and Manhattan); Norfolk, VA; and San Juan, PR. CruiseWise offers great deals and the best prices on major cruise lines, exclusive bonus offers, and all qualifying cruise line offers, along with cruise line loyalty program benefits. Customers can book by calling 866-798-7447 or onlin…

4. iContainers – East Coast Freight Services

Domain: icontainers.com

Registered: 2003 (22 years)

Introduction: The text discusses the largest East Coast ports in the US, highlighting services such as Ocean Freight (FCL and LCL), Air Freight, International Moving, LTL Freight, Customs Clearance, and Delivery Solutions for US Imports. It mentions significant growth in East Coast ports, particularly Charleston and Jacksonville, with increases in containerized shipments from East Asia. The text emphasizes the …

5. Ship4WD – East Coast Container Ports Guide

Domain: ship4wd.com

Registered: 2020 (5 years)

Introduction: Top 6 East Coast Container Ports: A Business Guide

1. **Port of Miami (PortMiami)**

– Location: Biscayne Bay, Miami, Florida

– Size: 520 acres (approx. 2.1 million square meters)

– Depth: 50 feet (15.24 meters)

– TEUs handled (2022-2023): Nearly 1.1 million

– Economic impact: Generates over $61 billion for Miami-Dade County, supporting over 340,000 jobs.

2. **Port of Charleston**

…

6. Unicargo – Top 7 East Coast Container Ports

Domain: unicargo.com

Registered: 1997 (28 years)

Introduction: Top 7 East Coast Container Ports: A Business Guide. Key ports include: 1. Port of New York and New Jersey – Busiest port, handling 9.5 million TEUs in 2022, deep harbor (50 feet), extensive rail and highway networks. 2. Port of Savannah – Second-busiest, 5.9 million TEUs in 2022, largest single-terminal container facility, deepened harbor (47 feet), strong rail connectivity. 3. Port of Virginia (N…

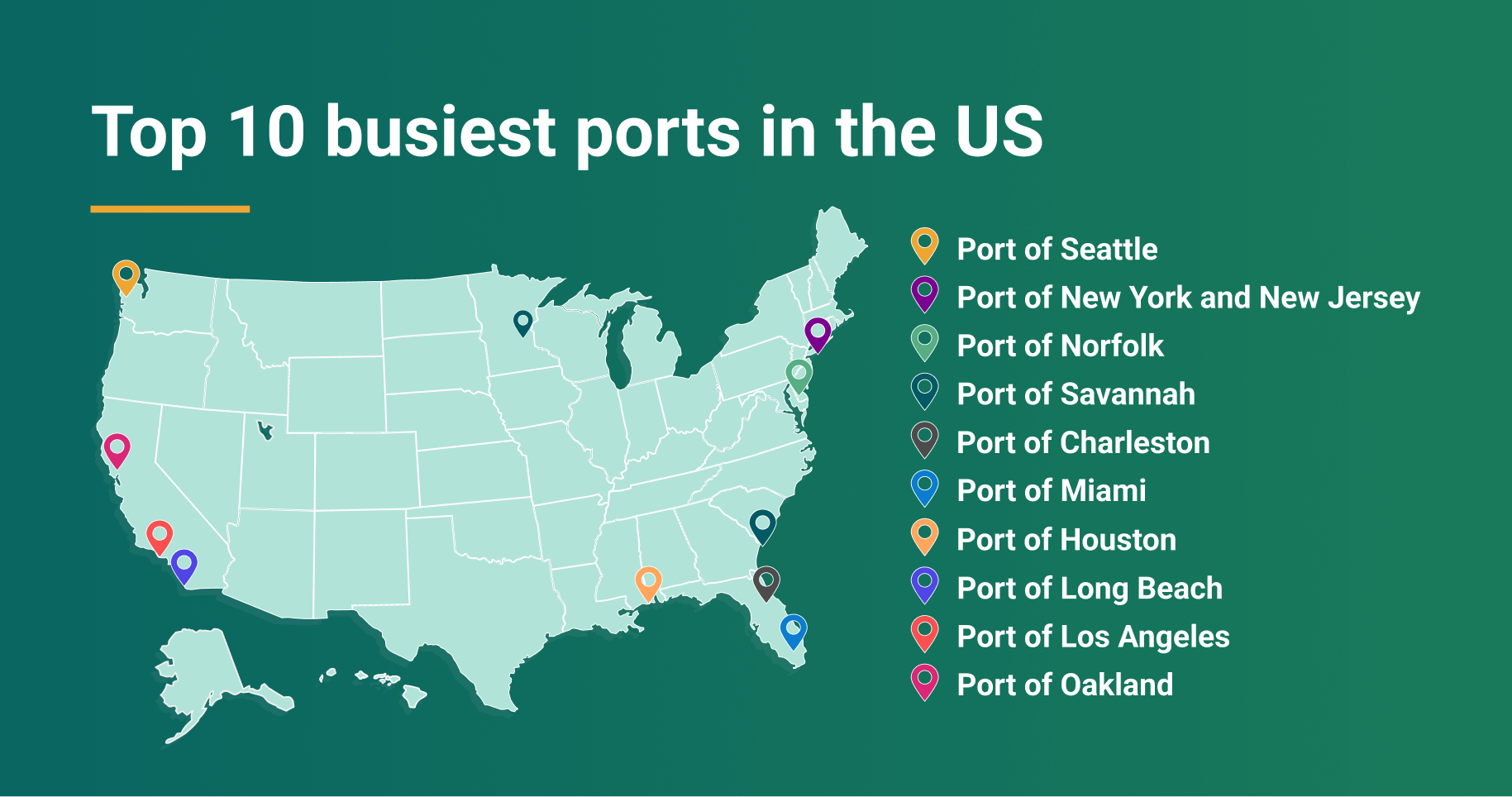

7. Pangea Network – Top US Ports by TEUs in 2025

Domain: pangea-network.com

Registered: 2010 (15 years)

Introduction: Top 10 Busiest and Biggest Ports in the USA in 2025 based on TEUs handled in 2022: 1. Port of Los Angeles, California – 9,911,159 TEUs; 2. Port of Long Beach, California – 9,133,657 TEUs; 3. Port of New York and New Jersey – 9,493,664 TEUs; 4. Port of Savannah, Georgia – 5,892,131 TEUs; 5. Port of Seattle and Tacoma, Washington – 3,384,018 TEUs; 6. Port of Houston, Texas – 3,974,901 TEUs; 7. Port …

8. Searates – Comprehensive U.S. Port Services

Domain: searates.com

Registered: 2005 (20 years)

Introduction: United States Ports – List of Ports in United States. Services include FCL shipping, LCL shipping, bulk & break bulk, dangerous cargoes, insurance, inspection services, abandoned cargoes, pharmaceutical & healthcare logistics, certification, project cargo, customs clearance, survey services, reefer cargoes, and warehousing. Tools available: real-time freight calculator, container tracking, air tra…

Understanding east coast ports of usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Container Ports | Specialized terminals for containerized cargo; high throughput. | Import/export of manufactured goods, electronics, consumer products. | Pros: Efficient handling, quick turnaround. Cons: Higher congestion during peak seasons. |

| Bulk Ports | Facilities for handling bulk commodities (liquid and dry). | Import/export of raw materials like grains, coal, and chemicals. | Pros: Cost-effective for large volumes. Cons: Limited flexibility for smaller shipments. |

| RORO (Roll-on/Roll-off) Ports | Designed for vehicles; direct access for wheeled cargo. | Import/export of automobiles, trucks, and heavy machinery. | Pros: Fast loading/unloading; reduced damage risk. Cons: Limited to wheeled cargo only. |

| Breakbulk Ports | Handle cargo that is not containerized; diverse cargo types. | Import/export of machinery, large equipment, and project cargo. | Pros: Flexibility for oversized items. Cons: Slower handling compared to container ports. |

| Cruise Ports | Primarily for passenger vessels; may also handle cargo. | Tourism and cruise-related goods and services. | Pros: Boosts local economy; diverse services. Cons: Seasonal fluctuations in demand. |

What Are the Key Characteristics of Container Ports?

Container ports are the backbone of international trade, designed specifically to handle containerized cargo efficiently. They feature specialized terminals that allow for rapid loading and unloading, accommodating large vessels and high volumes of goods. For B2B buyers, these ports are ideal for importing and exporting manufactured goods, electronics, and consumer products. However, during peak seasons, congestion can lead to delays, making it essential to plan shipments carefully.

How Do Bulk Ports Differ from Other Types?

Bulk ports are tailored for the handling of bulk commodities, both liquid and dry. This includes raw materials such as grains, coal, and chemicals. The facilities are equipped with specialized equipment for efficient loading and unloading. For businesses that deal in large quantities, bulk ports offer a cost-effective solution. However, their limited flexibility may not suit smaller shipments, necessitating careful consideration of the logistics involved.

What Are the Advantages of RORO Ports for Vehicle Transport?

RORO ports are uniquely designed for the transport of wheeled cargo, such as vehicles and heavy machinery. These ports provide direct access for vehicles, facilitating quick loading and unloading processes. This makes them particularly advantageous for businesses involved in the import and export of automobiles. While RORO ports reduce the risk of damage during transit, they are limited to wheeled cargo, which may not meet the needs of all buyers.

Why Choose Breakbulk Ports for Project Cargo?

Breakbulk ports are essential for handling cargo that cannot be containerized, such as oversized machinery and equipment. These ports offer the flexibility needed for diverse cargo types, making them suitable for businesses engaged in project cargo. However, the handling process is generally slower compared to container ports, which can impact timelines. Buyers should weigh the benefits of flexibility against potential delays in their logistics planning.

How Do Cruise Ports Contribute to the Local Economy?

Cruise ports primarily cater to passenger vessels but can also handle cargo related to tourism. These ports play a vital role in boosting the local economy by attracting tourists and facilitating cruise-related goods and services. While they offer diverse services, the demand can fluctuate seasonally, which may affect the consistency of business operations. Understanding these dynamics is crucial for B2B buyers looking to leverage opportunities in cruise-related sectors.

Key Industrial Applications of east coast ports of usa

| Industry/Sector | Specific Application of east coast ports of usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Import and export of vehicles and parts | Access to North American markets; reduced shipping time for parts | Compliance with U.S. automotive regulations; logistics efficiency |

| Agriculture | Import of agricultural machinery and export of produce | Streamlined supply chain for farming equipment; access to international markets | Seasonal demand fluctuations; quality standards for exports |

| Energy | Import of crude oil and export of refined products | Cost-effective transportation of energy resources; strategic location for energy trade | Regulatory compliance; shipping capacity and storage facilities |

| Manufacturing | Import of raw materials and export of finished goods | Enhanced production capabilities; access to diverse markets | Customs regulations; tariffs and trade agreements |

| Retail | Import of consumer goods and export of local products | Efficient distribution network; faster access to U.S. consumers | Market trends; inventory management and storage options |

How Are East Coast Ports Utilized in the Automotive Industry?

East Coast ports, particularly the Port of New York and New Jersey and the Port of Baltimore, serve as critical gateways for the automotive industry. These ports facilitate the import and export of vehicles and automotive parts, allowing businesses to streamline their supply chains. For international B2B buyers, particularly from Africa and the Middle East, understanding U.S. automotive regulations is crucial to ensure compliance and avoid delays. Efficient logistics management is also necessary to optimize shipping times and costs, maximizing their competitiveness in the global market.

What Role Do East Coast Ports Play in Agriculture?

In the agricultural sector, East Coast ports are vital for the import of machinery and the export of produce. Ports like Savannah and Norfolk enable farmers to access advanced equipment, enhancing productivity and efficiency. For international buyers, especially from South America and Africa, it is essential to consider seasonal demand fluctuations and adhere to quality standards for agricultural exports. These ports also provide a strategic advantage by facilitating access to the vast North American market, promoting growth opportunities for agricultural businesses.

How Are East Coast Ports Important for the Energy Sector?

The energy sector relies heavily on East Coast ports for the import of crude oil and the export of refined products. Ports such as Philadelphia and New York provide cost-effective transportation options for energy resources, capitalizing on their strategic locations. For B2B buyers in the Middle East and Europe, understanding regulatory compliance and the availability of shipping capacity is critical. Additionally, the ports’ storage facilities play a significant role in managing supply and demand fluctuations in the energy market, ensuring timely deliveries and operational efficiency.

In What Ways Do East Coast Ports Support Manufacturing?

East Coast ports are essential for the manufacturing industry, serving as entry points for raw materials and outlets for finished goods. Ports like Charleston and Baltimore allow manufacturers to efficiently source materials from global suppliers, enhancing production capabilities. International buyers, particularly from Europe and Africa, must navigate customs regulations and tariffs when engaging with U.S. ports. Moreover, understanding the logistics of inventory management is crucial for optimizing supply chains and maintaining competitiveness in the manufacturing sector.

How Do East Coast Ports Enhance Retail Operations?

For the retail sector, East Coast ports facilitate the import of consumer goods and the export of local products. Ports such as New York and Savannah provide efficient distribution networks, enabling businesses to quickly access U.S. consumers. International buyers from regions like South America and Africa should be aware of market trends and inventory management strategies to optimize their operations. These ports also offer significant advantages in terms of shipping speed and cost-effectiveness, which are vital for maintaining a competitive edge in the retail landscape.

3 Common User Pain Points for ‘east coast ports of usa’ & Their Solutions

Scenario 1: Delays in Cargo Handling at East Coast Ports

The Problem: International B2B buyers often face significant delays in cargo handling at East Coast ports, which can disrupt supply chains and impact business operations. These delays may arise from several factors including high traffic volumes, labor shortages, or inadequate infrastructure to handle larger vessels post-Panama Canal expansion. For buyers from regions like Africa or South America, such delays can translate into increased costs and lost sales opportunities, creating frustration and financial strain.

The Solution: To mitigate these delays, B2B buyers should conduct thorough research on port performance metrics before finalizing shipping routes. Utilize online tools and databases that provide real-time data on cargo handling times and port efficiency. Additionally, establishing relationships with logistics providers who have a strong understanding of the East Coast ports can be invaluable. These providers can offer tailored solutions, such as priority scheduling or alternative routing through less congested ports. Regularly reviewing shipping contracts and including performance clauses can also incentivize carriers to prioritize timely deliveries.

Scenario 2: Insufficient Intermodal Connectivity

The Problem: A common challenge for B2B buyers shipping goods through East Coast ports is the lack of seamless intermodal transportation options. This can lead to bottlenecks, especially when moving goods from ports to inland destinations. Buyers from Europe or the Middle East may find that after arriving at a port like Savannah or Norfolk, transferring goods to rail or truck can take longer than anticipated due to limited connections or scheduling conflicts. This can hinder their ability to meet customer demands promptly.

The Solution: To overcome this issue, buyers should focus on selecting ports with robust intermodal facilities and connections. For instance, the Port of Virginia has made significant investments in rail connections that facilitate quicker transfers to major markets. Buyers should inquire about intermodal services when selecting their shipping routes and consider working with logistics companies that specialize in intermodal transportation. Collaborating with these companies can provide insights into optimizing routes and schedules, ensuring goods move efficiently from port to destination.

Scenario 3: Complicated Customs Clearance Processes

The Problem: Navigating customs clearance can be a daunting task for B2B buyers, especially when importing goods through East Coast ports. The complexity of regulations, varying documentation requirements, and potential for inspections can lead to unexpected delays. Buyers from regions like Nigeria or Saudi Arabia may find these hurdles particularly challenging, impacting their ability to get products to market on time.

The Solution: To streamline the customs clearance process, B2B buyers should engage with customs brokers who are experienced in handling shipments through East Coast ports. These professionals can guide buyers through the necessary documentation and compliance requirements, reducing the risk of delays due to paperwork errors. Additionally, investing time in understanding the specific customs regulations relevant to their products can empower buyers to prepare adequately. Utilizing online platforms that offer insights into customs procedures and potential changes in regulations can further enhance preparedness, ensuring smoother transactions and timely deliveries.

Strategic Material Selection Guide for east coast ports of usa

What Are the Key Materials Used in East Coast Ports of the USA?

When considering the materials utilized in the infrastructure and operations of East Coast ports, it is essential to analyze their properties, advantages, and disadvantages. This understanding can significantly impact the decision-making process for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe.

How Does Steel Perform as a Material in Port Operations?

Steel is a primary material in the construction of port facilities, including cranes, storage units, and shipping containers. Its key properties include high tensile strength and excellent durability, making it suitable for heavy loads and harsh environments. Steel is also relatively cost-effective compared to other metals, which is a significant advantage for large-scale projects.

However, steel is prone to corrosion, particularly in marine environments, necessitating protective coatings or treatments that can increase long-term costs. For international buyers, compliance with standards such as ASTM A36 or ASTM A992 is crucial for ensuring quality and safety in construction.

What Role Does Concrete Play in Port Infrastructure?

Concrete is another fundamental material used extensively in port construction, particularly for docks and storage facilities. It offers impressive compressive strength and durability, making it ideal for heavy traffic and extreme weather conditions. Additionally, concrete can be molded into various shapes, allowing for flexibility in design.

On the downside, concrete can be susceptible to cracking under extreme temperature fluctuations and may require regular maintenance to prevent deterioration. For international buyers, understanding local regulations regarding concrete composition and environmental standards (such as those set by ACI or ASTM) is essential for compliance.

Why is Aluminum Important for Port Equipment?

Aluminum is increasingly being used in port operations due to its lightweight nature and resistance to corrosion. Its properties allow for easy handling and reduced energy costs during transportation. Aluminum is particularly advantageous in applications like gangways and lightering equipment, where weight savings can lead to efficiency improvements.

However, aluminum generally has a higher upfront cost compared to steel and concrete, which may deter some buyers. For B2B buyers from regions like Nigeria or Saudi Arabia, familiarity with international standards such as ASTM B221 for aluminum extrusions can facilitate smoother procurement processes.

How Does Composite Material Enhance Port Operations?

Composite materials, often made from a combination of plastic and fiberglass, are gaining traction in port applications due to their lightweight and corrosion-resistant properties. They are particularly useful in constructing fenders, walkways, and other structures exposed to harsh marine environments. Their resistance to rust and rot makes them a long-lasting option.

Despite their advantages, composites can be more expensive than traditional materials and may require specialized manufacturing processes. International buyers should consider local availability and compliance with standards such as ASTM D638 for tensile properties when selecting composite materials for their projects.

Summary Table of Material Selection for East Coast Ports

| Material | Typical Use Case for East Coast Ports of USA | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Cranes, storage units, shipping containers | High tensile strength and durability | Prone to corrosion, requires protective coatings | Medium |

| Concrete | Docks, storage facilities | Impressive compressive strength and durability | Susceptible to cracking, maintenance required | Low |

| Aluminum | Gangways, lightering equipment | Lightweight, corrosion-resistant | Higher upfront cost compared to steel | High |

| Composite | Fenders, walkways | Lightweight, long-lasting, corrosion-resistant | More expensive, specialized manufacturing needed | Medium |

This analysis provides a comprehensive overview of the materials commonly used in East Coast ports, offering valuable insights for international B2B buyers. Understanding these materials’ properties, advantages, and limitations can significantly influence procurement decisions and project success.

In-depth Look: Manufacturing Processes and Quality Assurance for east coast ports of usa

What Are the Main Stages of Manufacturing Processes at East Coast Ports?

Manufacturing processes at East Coast ports are integral to ensuring efficient cargo handling and supply chain management. The primary stages of manufacturing in this context can be categorized into four main areas: material preparation, forming, assembly, and finishing.

-

Material Preparation: This stage involves the initial handling of raw materials and goods. For ports, this includes the receipt and inspection of cargo, which may involve quality checks to ensure that the materials meet the required specifications. B2B buyers should ensure that their suppliers have robust systems for verifying the quality and integrity of incoming materials.

-

Forming: In the context of ports, forming refers to the manipulation and arrangement of goods for transport. This may include containerization, palletization, or bulk loading techniques. Techniques such as automated stacking and loading systems are often employed to maximize space and efficiency. B2B buyers should inquire about the technologies and methods used by their suppliers to ensure optimal cargo handling.

-

Assembly: While ports do not typically engage in assembly in the traditional manufacturing sense, they do play a critical role in consolidating shipments. This process may involve bundling products together for shipping or assembling parts into larger units before export. Understanding how suppliers manage these processes can provide insights into their operational capabilities.

-

Finishing: This stage often involves the final touches to cargo, such as packaging and labeling. Proper finishing is crucial for ensuring that products arrive in good condition. B2B buyers must verify that their suppliers adhere to industry standards for packaging and labeling, which can vary significantly across different regions.

How Are Quality Assurance Practices Implemented in East Coast Ports?

Quality assurance (QA) is vital for maintaining the integrity of goods transported through East Coast ports. Effective QA practices ensure compliance with international standards and foster trust between suppliers and B2B buyers.

-

Relevant International Standards: East Coast ports and their associated suppliers often adhere to international quality standards such as ISO 9001. This standard outlines a framework for quality management systems (QMS) that can help organizations consistently meet customer and regulatory requirements. Buyers should prioritize suppliers that are ISO-certified, as this demonstrates a commitment to quality.

-

Industry-Specific Standards: In addition to ISO standards, certain industries may require compliance with specific regulations such as CE marking for products sold in Europe or API standards for oil and gas equipment. Understanding these industry-specific requirements is crucial for B2B buyers, particularly when sourcing specialized products.

-

Quality Control Checkpoints: Quality control (QC) is typically segmented into three critical checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the port to ensure they meet specifications.

– In-Process Quality Control (IPQC): This stage involves monitoring production processes to identify and rectify any issues during manufacturing.

– Final Quality Control (FQC): This includes a thorough inspection of finished goods before they are shipped out to ensure they are free from defects. -

Common Testing Methods: Various testing methods are employed to ensure quality, including visual inspections, functional testing, and stress testing. B2B buyers should request detailed information about the testing methods used by suppliers to ensure compliance with their quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must have mechanisms in place to verify the quality control practices of their suppliers. This is particularly important for international buyers who may face different regulatory environments.

-

Supplier Audits: Conducting regular audits of suppliers is an effective way to assess their quality control processes. These audits can help identify any gaps in compliance with international standards and provide insights into the supplier’s operational efficiency.

-

Quality Control Reports: Buyers should request comprehensive QC reports from their suppliers. These reports should detail the results of inspections and testing conducted at various stages of the manufacturing process. Regular reporting can help buyers stay informed about the quality of the products they are sourcing.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control practices. This is particularly useful for international transactions where buyers may not have the resources to conduct on-site inspections.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification.

-

Cultural and Regulatory Differences: Different regions have varying standards and regulations regarding quality control. Buyers should familiarize themselves with the local laws and customs of the supplier’s country to ensure compliance and avoid potential pitfalls.

-

Documentation Requirements: Buyers must ensure that suppliers provide all necessary documentation, including certificates of compliance, testing reports, and quality assurance certifications. This documentation is essential for customs clearance and can prevent delays in the supply chain.

-

Communication and Relationship Management: Establishing strong communication channels with suppliers is crucial for addressing any quality issues that may arise. Buyers should maintain an ongoing dialogue with suppliers to ensure that quality standards are upheld throughout the manufacturing process.

-

Understanding Certification Bodies: Different countries may have various certification bodies that oversee quality standards. Buyers should verify that the certifications held by their suppliers are recognized in their home markets to ensure that they meet local compliance requirements.

Conclusion

Understanding the manufacturing processes and quality assurance practices at East Coast ports is essential for international B2B buyers. By familiarizing themselves with the key stages of manufacturing, quality control standards, and verification methods, buyers can make informed decisions that enhance their supply chain efficiency and product quality. Engaging with suppliers who prioritize quality assurance will ultimately lead to a more reliable and successful business relationship.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘east coast ports of usa’

This practical sourcing guide is designed to assist international B2B buyers in effectively navigating the procurement process for using East Coast ports in the USA. With a focus on key action steps, this checklist will help ensure a seamless and efficient experience when accessing these vital trade hubs.

Step 1: Identify Your Shipping Needs

Before engaging with ports, clearly define your shipping requirements. This includes the type of cargo, volume, and frequency of shipments. Understanding these factors will help you choose the most suitable port that can accommodate your logistical needs.

- Considerations:

- Type of cargo (bulk, containerized, RORO, etc.)

- Expected shipping frequency (weekly, monthly)

- Destination markets (domestic or international)

Step 2: Research Port Facilities and Capabilities

Evaluate the facilities and capabilities of the East Coast ports you are considering. Each port has unique strengths, such as container handling capacity, depth of berths, and available services.

- Key Ports to Review:

- Port of New York and New Jersey: Known for its diverse cargo handling and strategic location.

- Port of Savannah: Recognized for its single-terminal container area and efficient intermodal connections.

Step 3: Verify Port Accessibility and Connectivity

Assess how accessible the port is to your supply chain and distribution network. Look into the availability of transportation options such as rail, road, and nearby airports.

- Check for:

- Proximity to major highways and rail lines

- Availability of intermodal transport options

- Connections to other logistics hubs

Step 4: Understand Customs and Regulatory Requirements

Familiarize yourself with the customs regulations and documentation required for imports and exports at the selected ports. Compliance with U.S. Customs and Border Protection (CBP) standards is essential to avoid delays.

- Important Documents:

- Bill of Lading

- Commercial Invoice

- Import/export permits as necessary

Step 5: Engage with Port Authorities and Service Providers

Contact port authorities and relevant service providers to gather information on fees, services, and operational guidelines. Building relationships with these entities can facilitate smoother operations.

- Inquire About:

- Terminal handling fees and other costs

- Availability of warehousing and storage facilities

- Support services such as customs brokerage and freight forwarding

Step 6: Evaluate Logistics and Transportation Partners

Select reliable logistics and transportation partners who have experience with the East Coast ports. Their expertise can significantly enhance your supply chain efficiency and help navigate challenges.

- Criteria for Selection:

- Track record with similar shipments

- Knowledge of port operations and procedures

- Ability to provide real-time tracking and updates

Step 7: Monitor Performance and Adjust Strategies

After establishing operations, continuously monitor the performance of your logistics and port services. Be prepared to adjust your strategies based on changing market conditions or service levels.

- Performance Indicators:

- Timeliness of shipments

- Cost-effectiveness of logistics solutions

- Customer feedback on service quality

By following this step-by-step checklist, B2B buyers can effectively leverage the advantages offered by East Coast ports, ensuring a streamlined and successful procurement process.

Comprehensive Cost and Pricing Analysis for east coast ports of usa Sourcing

What Are the Key Cost Components in Sourcing from East Coast Ports?

When sourcing goods via East Coast ports in the USA, understanding the cost structure is essential for international buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin. Materials can vary significantly based on the type of cargo, whether it’s bulk, containerized, or specialized goods. Labor costs are influenced by local wage rates and the complexity of handling specific cargo types.

Manufacturing overhead encompasses indirect costs such as utilities and facility maintenance, while tooling may be relevant for specialized operations. Quality control is crucial for ensuring that goods meet specifications and certifications, especially when dealing with international standards. Logistics costs can fluctuate based on distance, transportation modes, and the efficiency of port operations.

How Do Pricing Influencers Affect Sourcing Costs at East Coast Ports?

Several factors influence pricing at East Coast ports. Volume and minimum order quantity (MOQ) often dictate price breaks; larger shipments can lead to significant cost savings. Custom specifications can also affect pricing, as more complex requirements may necessitate additional resources or time. Material quality and certifications are essential, as higher standards typically come with increased costs.

Supplier factors, including reputation and reliability, can influence pricing as well. For international transactions, Incoterms play a critical role in defining responsibilities and costs associated with shipping, insurance, and customs clearance, impacting the final price significantly.

What Buyer Tips Can Help Optimize Costs When Sourcing from East Coast Ports?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, strategic negotiation is vital. Understanding the total cost of ownership (TCO) — which includes all costs associated with procurement, delivery, and potential duties — can provide a clearer picture of the actual expenditure.

Buyers should also be aware of pricing nuances specific to their regions. For instance, freight costs may vary based on trade agreements or tariffs, and understanding these can lead to better negotiation outcomes. Additionally, leveraging relationships with local suppliers or agents can yield insights into cost-saving opportunities.

Why Is It Important to Consider Indicative Prices When Sourcing?

It’s essential to note that indicative prices can fluctuate based on market conditions, seasonal demands, and geopolitical factors. Therefore, while estimates can serve as a guideline, they should not be viewed as fixed rates. Buyers should conduct thorough research and engage in regular communication with suppliers to obtain the most accurate and up-to-date pricing information.

In conclusion, navigating the cost and pricing landscape of East Coast ports requires a thorough understanding of the various components and influencers. By leveraging this knowledge, international B2B buyers can make more informed decisions, optimize their sourcing strategies, and ultimately enhance their competitiveness in the global market.

Alternatives Analysis: Comparing east coast ports of usa With Other Solutions

Understanding Alternatives to East Coast Ports of the USA

When considering logistics and shipping solutions for international trade, businesses often explore various options for transporting goods. While the East Coast ports of the USA offer strategic advantages, it’s essential to evaluate alternative solutions that may also meet shipping needs effectively. This analysis compares East Coast ports against two viable alternatives: inland rail transport and direct shipping from South American ports.

Comparison Table

| Comparison Aspect | East Coast Ports of USA | Inland Rail Transport | Direct Shipping from South America |

|---|---|---|---|

| Performance | High capacity, efficient handling of diverse cargo types | Moderate capacity, dependent on rail infrastructure | High capacity, but longer transit times |

| Cost | Competitive, but varies by port and cargo type | Generally lower, but can incur additional handling fees | Can be cost-effective, but depends on distance and destination |

| Ease of Implementation | Requires coordination with port schedules and customs | Streamlined for domestic shipments, but limited international reach | Requires knowledge of local regulations and logistics |

| Maintenance | Ongoing investments in infrastructure | Limited maintenance needs, dependent on rail operators | Varies by shipping line and port conditions |

| Best Use Case | Ideal for high-volume international trade with diverse cargo | Best for domestic shipments and bulk goods | Suitable for regional trade and specific goods from South America |

Exploring Inland Rail Transport

Inland rail transport is a formidable alternative for logistics, especially for businesses focused on domestic shipments within the USA. It offers a reliable and often cost-effective solution for transporting bulk goods over long distances. The pros of this method include lower shipping costs compared to truck transport and a reduced environmental footprint. However, its cons include limitations on the types of cargo that can be transported and potential delays due to rail infrastructure issues.

Evaluating Direct Shipping from South America

Direct shipping from South American ports presents a unique opportunity for businesses looking to source goods closer to their suppliers. This method can be particularly advantageous for trade with countries like Brazil or Argentina, where specific products are abundant. The primary benefit is the potential for lower shipping costs and shorter supply chains. However, businesses must be aware of longer transit times and the need for robust customs handling, which can complicate logistics.

Conclusion: Choosing the Right Solution for Your Business Needs

Selecting the most suitable shipping solution requires a thorough understanding of your business’s unique requirements. East Coast ports offer significant advantages for high-volume international trade, particularly for diverse cargo types. Conversely, inland rail transport may be more appropriate for domestic shipments, while direct shipping from South America could be ideal for specific regional trades. B2B buyers should consider factors such as cost, performance, and ease of implementation to make informed decisions that align with their logistical strategies. By carefully analyzing these alternatives, businesses can optimize their supply chain and enhance their global trade capabilities.

Essential Technical Properties and Trade Terminology for east coast ports of usa

What Are the Essential Technical Properties of East Coast Ports in the USA?

Understanding the technical specifications of East Coast ports is crucial for international B2B buyers, particularly when considering shipping logistics and operations. Here are some critical properties that impact trade efficiency:

-

Depth of Berths

The depth of berths, often measured in feet, determines the size of vessels that can dock. For instance, the Port of New York and New Jersey has deepened its harbor to accommodate vessels up to 18,000 TEU (Twenty-foot Equivalent Units). This property is essential for ensuring that larger ships can access ports, reducing delays and costs associated with transshipment. -

Container Capacity

Each port has a specific capacity for container handling, often measured in TEUs. The Port of Savannah, for example, boasts the largest single-terminal container facility in North America, which significantly enhances its ability to handle high volumes of cargo. For B2B buyers, understanding a port’s capacity can influence supply chain planning and inventory management. -

Operational Hours

Ports operate on varying schedules, often influenced by local regulations and demand. For example, many East Coast ports offer 24/7 operations, which can be a critical factor for businesses needing flexibility in shipping schedules. Knowing operational hours helps buyers plan shipments more effectively, avoiding potential delays. -

Intermodal Connections

The availability of intermodal facilities—such as rail and trucking connections—can dramatically affect logistics efficiency. Ports like Virginia and Charleston have invested in rail infrastructure to facilitate quick transfer of goods from ship to rail or truck. For B2B buyers, these connections can reduce transit times and transportation costs. -

Customs Clearance Facilities

Efficient customs processing is vital for reducing delays in cargo movement. Ports with advanced customs facilities can expedite the clearance process, allowing for quicker access to goods. For international buyers, understanding customs procedures at a specific port can impact overall logistics planning.

What Are Common Trade Terms Used in East Coast Port Operations?

In the world of shipping and logistics, specific terminology is frequently used. Familiarity with these terms can help international B2B buyers navigate trade negotiations and agreements more effectively:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In port operations, understanding OEM relationships can help buyers identify quality suppliers for necessary equipment or services. -

MOQ (Minimum Order Quantity)

This term indicates the smallest quantity of a product that a supplier is willing to sell. For port-related services or products, knowing the MOQ can help buyers manage inventory and budget more efficiently, ensuring they meet supplier requirements. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. B2B buyers often utilize RFQs to compare costs and services from different ports, aiding in decision-making for logistics partnerships. -

Incoterms (International Commercial Terms)

These are a set of predefined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to clarify shipping costs, risks, and responsibilities during the logistics process. -

TEU (Twenty-foot Equivalent Unit)

TEU is a standard measure used to describe cargo capacity in container shipping. Understanding TEU is essential for buyers to gauge the capacity of shipping options available at various ports, ensuring they select appropriate vessels for their cargo needs. -

VGM (Verified Gross Mass)

This term refers to the total weight of a container, including its contents and packaging. Accurate VGM is vital for safety and compliance with international shipping regulations. B2B buyers should ensure that their cargo is weighed and documented correctly to avoid delays and penalties.

By understanding these essential properties and trade terms, international B2B buyers can make informed decisions regarding logistics and trade through East Coast ports, enhancing their overall operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the east coast ports of usa Sector

What Are the Current Market Dynamics and Key Trends Affecting East Coast Ports of the USA?

The East Coast ports of the USA are experiencing a transformative phase, driven by several global factors. Increased international trade, particularly from Asia, is reshaping logistics strategies for B2B buyers. The expansion of the Panama Canal has significantly altered shipping routes, enabling larger vessels to access East Coast ports directly, reducing transit times and costs. As a result, ports like Savannah and Charleston have seen substantial growth in containerized shipments, making them competitive alternatives to traditional West Coast hubs.

Emerging B2B technology trends are also impacting the sector. The adoption of digital platforms for tracking shipments, automating customs processes, and enhancing supply chain visibility is becoming essential for international buyers. Technologies like blockchain and IoT are improving transparency and efficiency, allowing businesses to manage inventory better and respond swiftly to market changes. For buyers from regions such as Africa, South America, and the Middle East, these advancements facilitate smoother transactions and reduce risks associated with international shipping.

Furthermore, sustainability is becoming a crucial factor in sourcing decisions. Many buyers are increasingly conscious of the environmental impact of their supply chains. This awareness is prompting ports to adopt greener practices, influencing buyer preferences towards ports that prioritize eco-friendly operations. These dynamics are essential for international B2B buyers to consider, as they navigate sourcing strategies that align with both economic and environmental goals.

How Are Sustainability and Ethical Sourcing Influencing the East Coast Ports of the USA?

Sustainability and ethical sourcing are gaining prominence in the East Coast ports sector, reflecting a growing global awareness of environmental issues. The impact of maritime operations on local ecosystems has led to a push for greener practices within port management. For instance, many ports are investing in renewable energy solutions, such as solar and wind power, to reduce their carbon footprints. This transition not only helps in minimizing environmental degradation but also aligns with the increasing demand for sustainable sourcing among international buyers.

Ethical supply chains are becoming a priority for businesses looking to establish a responsible image in their markets. Buyers from regions like Africa and the Middle East are particularly keen on sourcing from suppliers who adhere to stringent environmental standards. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are increasingly sought after. These certifications assure buyers that the ports and their associated logistics partners are committed to sustainable practices.

Moreover, the trend towards using ‘green’ materials in shipping operations is influencing sourcing decisions. Ports are increasingly adopting eco-friendly packaging and biodegradable materials, which resonate well with the values of environmentally conscious buyers. As a result, international businesses can enhance their reputations and market positions by partnering with East Coast ports that prioritize sustainability and ethical practices.

What Is the Historical Context Behind the Growth of East Coast Ports?

Historically, East Coast ports have played a significant role in the U.S. economy, serving as key gateways for international trade. The strategic location of these ports made them essential for transatlantic trade routes, particularly during the colonial and post-colonial eras. Over the years, ports like New York and Savannah have evolved, adapting to changes in global trade patterns and technological advancements.

The expansion of the Panama Canal in 2016 marked a pivotal moment for East Coast ports, allowing larger vessels to enter these waters. This development prompted significant investments in port infrastructure, enabling them to handle increased cargo volumes efficiently. The historical context of these ports highlights their resilience and adaptability, qualities that continue to attract international B2B buyers seeking reliable and efficient shipping solutions.

In summary, the East Coast ports of the USA are positioned at the forefront of international trade dynamics, driven by technological advancements, sustainability initiatives, and their historical significance in global commerce. For B2B buyers, these factors are crucial in making informed sourcing decisions that align with their business objectives and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of east coast ports of usa

-

How do I solve shipping delays when importing through East Coast ports?

To mitigate shipping delays, it’s essential to maintain open communication with your logistics provider and the port authorities. Track your shipments closely and anticipate potential bottlenecks by monitoring port congestion reports. Consider using multiple shipping routes or diversifying your supplier base to reduce dependency on a single port. Additionally, ensure that all documentation is accurate and complete to avoid customs delays, which can further extend shipping times. -

What is the best East Coast port for importing goods from Africa?

The Port of New York and New Jersey is often considered the best option for importing goods from Africa due to its extensive infrastructure and connectivity. It handles a wide range of cargo and offers numerous shipping lines that facilitate direct routes to various African countries. The port also provides robust customs processing capabilities and access to major distribution networks, making it easier to reach markets across the United States. -

How can I vet suppliers when sourcing through East Coast ports?

Vetting suppliers is crucial to ensure quality and reliability. Start by reviewing their business credentials, including licenses and certifications relevant to your industry. Request references from past clients and conduct site visits if possible. Utilize third-party verification services to assess their financial stability and operational capacity. Additionally, consider engaging with local trade associations or chambers of commerce for further insights into the supplier’s reputation. -

What are the minimum order quantities (MOQs) for products imported through East Coast ports?

Minimum order quantities (MOQs) can vary significantly based on the supplier and type of goods. Generally, larger suppliers may have higher MOQs, while smaller or more specialized manufacturers might accommodate lower quantities. It’s advisable to discuss MOQs upfront during negotiations and explore options for bulk purchasing if you need larger volumes. Understanding the supplier’s production capabilities will help you set realistic expectations for order sizes. -

What payment terms should I expect when sourcing from East Coast ports?

Payment terms can vary based on the supplier’s policies and your negotiation power. Common terms include payment upfront, net 30, or letters of credit. It’s important to clarify these terms before finalizing contracts to avoid misunderstandings. For international transactions, consider using secure payment methods that offer protection against fraud, such as escrow services. Establishing a good relationship with your supplier can also lead to more favorable payment terms over time. -

How do I ensure quality assurance when importing through East Coast ports?

To ensure quality assurance, implement a comprehensive quality control plan that includes product inspections at various stages of production. Consider hiring third-party inspection services to evaluate goods before shipment. Establish clear quality standards with your suppliers and include them in your contracts. Additionally, conduct regular audits of your suppliers to verify compliance with your quality requirements and industry standards. -

What logistics considerations should I keep in mind when using East Coast ports?

When planning logistics, consider factors such as transportation costs, lead times, and the availability of intermodal connections. Evaluate the port’s proximity to your distribution centers to minimize inland transportation expenses. Ensure that your logistics provider has experience with customs clearance and can navigate the complexities of international shipping. Additionally, assess the port’s capacity for handling your specific cargo type to avoid delays during peak seasons. -

How can I stay updated on changes in regulations impacting East Coast port trade?

To stay informed about regulatory changes, subscribe to industry newsletters, government updates, and port authority announcements. Joining trade associations can also provide access to valuable resources and networking opportunities with other businesses facing similar challenges. Engaging with a customs broker can help you navigate the complexities of compliance and ensure that you are aware of any new regulations that may affect your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for east coast ports of usa

As the East Coast ports of the USA continue to evolve, they present a significant opportunity for international B2B buyers seeking efficient and cost-effective logistics solutions. These ports, including the Port of New York and New Jersey, Port of Savannah, and Port of Virginia, are enhancing their capabilities through substantial investments in infrastructure, allowing them to handle larger vessels and increased cargo volumes. The strategic location of these ports, coupled with the recent expansion of the Panama Canal, positions them as viable alternatives to their West Coast counterparts, particularly for goods coming from Asia.

For businesses in Africa, South America, the Middle East, and Europe, leveraging the East Coast ports can lead to reduced shipping times and costs, ultimately enhancing supply chain efficiency. Engaging in strategic sourcing from these ports not only supports operational objectives but also fosters stronger trade relationships across regions.

Looking ahead, international buyers should actively consider the East Coast ports as critical nodes in their supply chains. By aligning with these dynamic gateways, companies can capitalize on the growing trade flows and secure a competitive edge in the global marketplace. Embrace the opportunity to partner with East Coast ports today and drive your business towards greater success.