Top 8 Chemical Companies In Usa List and Guide: How To Solve Scen…

Introduction: Navigating the Global Market for chemical companies in usa

In today’s complex global marketplace, sourcing reliable chemical companies in the USA presents a significant challenge for international B2B buyers. With diverse applications ranging from agriculture to pharmaceuticals, understanding the vast landscape of chemical suppliers is crucial for making informed purchasing decisions. This guide delves into the intricate world of American chemical manufacturers, offering insights into various types of chemicals, their applications, and essential criteria for supplier vetting.

International buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Germany, will find this resource invaluable in navigating the U.S. chemical market. It covers critical aspects such as cost considerations, regulatory compliance, and market trends, enabling businesses to evaluate potential partners effectively.

By equipping buyers with the knowledge needed to assess supplier capabilities and product offerings, this guide not only simplifies the sourcing process but also mitigates risks associated with international procurement. Whether you’re looking to foster long-term relationships or to secure one-off transactions, understanding the nuances of U.S. chemical companies will empower you to make strategic decisions that drive your business forward.

Top 10 Chemical Companies In Usa Manufacturers & Suppliers List

1. Chemanalyst – Top 100 Chemical Manufacturers 2025

2. BASF – ROUTING Color Collection

Domain: basf.com

Registered: 1995 (30 years)

Introduction: BASF offers a new color collection called ROUTING for automotive designers, and has a Product Finder for detailed information about their products and solutions. They also provide a Product Carbon Footprint (PCF) for all sales products, which includes total values of CO2 emissions related to their products. Additionally, BASF is involved in sustainable agricultural innovations and has co-founded a…

3. Dow – Diverse Product Solutions

Domain: dow.com

Registered: 1992 (33 years)

Introduction: Dow offers a wide range of products across various markets, including:

1. **Agriculture, Feed and Animal Care**: Agricultural Films, Crop Solutions, Pet and Animal Care.

2. **Beauty and Personal Care**: Cleansers, Color Cosmetics, Deodorants, Fragrances, Hair Care, Skin and Body Care, Sun Care.

3. **Building, Construction and Infrastructure**: Building Envelope, Building Materials, Commercial Gl…

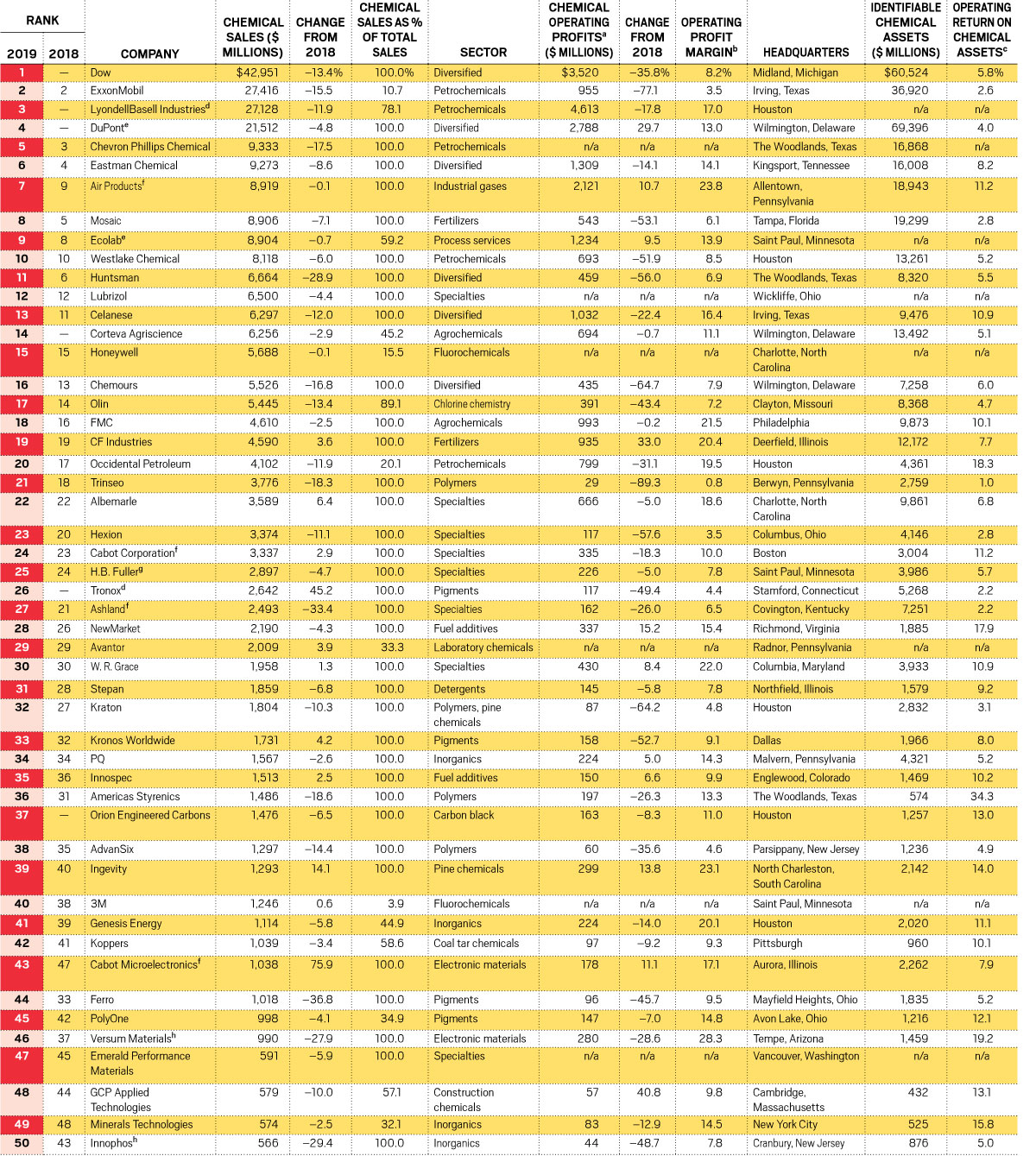

4. Top U.S. Chemical Manufacturers – Key Products

Domain: industryweek.com

Registered: 1996 (29 years)

Introduction: The text provides information about the top chemical manufacturers in the U.S. for 2022, including their primary industries and financial performance. Key products mentioned include makeup, paints, engineered polymers, and coatings. The companies listed include Procter & Gamble, Dow Inc., LyondellBasell Industries, 3M Co., Sherwin-Williams, Colgate-Palmolive, PPG Industries, DuPont, Estée Lauder, …

5. Chevron Phillips Chemical – Petrochemical Solutions

Domain: cpchem.com

Registered: 2000 (25 years)

Introduction: Chevron Phillips Chemical offers a wide range of petrochemical solutions essential for various industries, including Automotive, Energy & Chemical, Food & Agriculture, Home & Electronics, Medical & Pharmaceutical, Personal Care, and Recreational. Key product categories include Aromatics, Drilling Specialties, Normal Alpha Olefins, Olefins, Performance Pipe, Polyalphaolefins, Polyethylene, and Spec…

6. Chemical Giants – Daily Market Rankings

7. Chemours – Key Products

Domain: chemours.com

Registered: 2014 (11 years)

Introduction: Chemours offers a range of key products including Teflon™, Ti-Pure™, Opteon™, Freon™, Krytox™, Viton™, and Nafion™. These products are utilized across various industries such as Electric Vehicles, Energy, Connectivity and Advanced Electronics, Architectural Coatings, Medical, and Automotive applications.

8. Prestigious Companies – Opportunities for Chemical Engineers

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Prestigious companies for chemical engineers mentioned include: ExxonMobil, Chevron, Intel, Dow, BASF, Tesla, NextEra, Fluor, Jacobs, Sandia National Laboratories, NASA, Oak Ridge National Laboratory, Google, FAANG companies, Goldman Sachs, McKinsey, BCG, Bain, MIT, Stanford, Caltech, University of Minnesota, Georgia Tech.

Understanding chemical companies in usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Specialty Chemicals | Focus on niche products, often customized for specific needs | Pharmaceuticals, agrochemicals, coatings | Pros: Tailored solutions, high performance; Cons: Higher costs, limited availability. |

| Commodity Chemicals | Bulk production of basic chemicals, often interchangeable | Plastics, fertilizers, detergents | Pros: Lower costs, wide availability; Cons: Less customization, quality variability. |

| Agrochemicals | Chemicals used in agriculture, including fertilizers and pesticides | Crop protection, soil enhancement | Pros: Essential for agricultural productivity; Cons: Regulatory challenges, environmental concerns. |

| Industrial Chemicals | Chemicals used in manufacturing processes | Metal treatment, oil refining | Pros: Vital for production efficiency; Cons: Requires specialized handling and storage. |

| Consumer Chemicals | Chemicals used in everyday consumer products | Personal care, cleaning products | Pros: High demand, brand loyalty; Cons: Price sensitivity, intense competition. |

What are the Characteristics of Specialty Chemicals?

Specialty chemicals are designed for specific applications, often tailored to meet unique customer requirements. These products are typically produced in smaller quantities compared to commodity chemicals and can include items like adhesives, sealants, and performance additives. Buyers in sectors such as pharmaceuticals or high-performance coatings benefit from the specialized nature of these chemicals, which can enhance product performance. However, the customization and specialized nature can lead to higher costs and limited supply chains, making it crucial for buyers to assess their specific needs and potential suppliers’ capabilities.

How Do Commodity Chemicals Differ from Other Types?

Commodity chemicals are produced in large volumes and are generally less expensive due to their standardized nature. Common examples include basic petrochemicals, plastics, and fertilizers. They are interchangeable and widely available, making them suitable for various industries that require bulk quantities. Buyers appreciate the cost-effectiveness and availability, but they must be cautious about quality consistency, as variations can occur between suppliers. Understanding the specific requirements for quality and application is essential for making informed purchasing decisions.

What Role Do Agrochemicals Play in the Chemical Industry?

Agrochemicals encompass a wide range of products, including fertilizers, pesticides, and herbicides, which are crucial for modern agriculture. They help improve crop yields and protect plants from pests and diseases. Buyers in the agricultural sector must navigate complex regulatory environments and sustainability concerns, as the use of these chemicals is often scrutinized. While agrochemicals can significantly enhance agricultural productivity, buyers should consider the environmental impact and seek suppliers who adhere to sustainable practices.

Why Are Industrial Chemicals Important for Manufacturing?

Industrial chemicals are essential in various manufacturing processes, including metal treatment, oil refining, and the production of construction materials. These chemicals often require specialized handling and storage due to their hazardous nature. Buyers in manufacturing sectors must prioritize safety and compliance with regulations when sourcing these chemicals. While they are vital for operational efficiency, the complexity of handling and potential regulatory implications necessitate thorough supplier evaluations and risk assessments.

How Do Consumer Chemicals Impact Everyday Life?

Consumer chemicals are found in everyday products such as personal care items and cleaning agents. They are typically marketed to end-users and have a significant impact on consumer behavior and brand loyalty. Buyers in this sector face intense competition and price sensitivity, making it essential to focus on quality and innovation. Understanding consumer trends and preferences can help businesses align their product offerings, but they must also be prepared for fluctuations in demand and potential regulatory changes affecting product formulations.

Key Industrial Applications of chemical companies in usa

| Industry/Sector | Specific Application of chemical companies in usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Production of fertilizers and agrochemicals | Enhances crop yield and quality, ensuring food security | Compliance with local regulations and environmental standards; sourcing from reliable suppliers with proven efficacy. |

| Pharmaceuticals | Development of active pharmaceutical ingredients (APIs) | Ensures the efficacy and safety of medications | Quality assurance certifications; reliable supply chain to meet stringent regulatory requirements. |

| Construction Materials | Manufacturing of specialty chemicals for concrete | Improves durability and performance of construction materials | Technical support for formulation; compatibility with local construction standards and practices. |

| Automotive | Production of coatings and adhesives | Enhances vehicle aesthetics and longevity | Assessment of product durability under varied environmental conditions; adherence to automotive industry standards. |

| Energy | Development of chemicals for battery production | Supports renewable energy technologies and storage solutions | Innovation in product formulations; sustainability practices in sourcing raw materials. |

How Are Chemical Companies in the USA Transforming Agriculture with Fertilizers and Agrochemicals?

Chemical companies in the USA play a pivotal role in agriculture by producing fertilizers and agrochemicals that enhance crop yields and quality. These products are essential for meeting the growing global food demand, particularly in regions like Africa and South America. International buyers should consider sourcing from companies that comply with local regulations and environmental standards, ensuring that the products not only boost productivity but also align with sustainable practices.

What Role Do Chemical Companies Play in the Pharmaceutical Industry?

In the pharmaceutical sector, USA-based chemical companies are crucial for developing active pharmaceutical ingredients (APIs). These compounds are the active components in medications, determining their efficacy and safety. For international buyers, it is essential to prioritize suppliers with robust quality assurance certifications and reliable supply chains that can meet the stringent regulatory requirements imposed by health authorities worldwide.

How Do Chemical Companies Enhance Construction Materials?

The construction industry benefits significantly from specialty chemicals produced by chemical companies, which enhance the performance of materials like concrete. These chemicals improve durability and resistance to environmental factors, ensuring that structures last longer. Buyers in this sector should seek suppliers who provide technical support for product formulation and ensure compatibility with local construction standards and practices.

What Innovations Are Chemical Companies Bringing to the Automotive Sector?

In the automotive industry, chemical companies are responsible for producing coatings and adhesives that enhance the aesthetics and longevity of vehicles. These products help protect against corrosion and wear, contributing to vehicle durability. International buyers must assess the durability of these products under various environmental conditions and ensure compliance with automotive industry standards to achieve optimal results.

How Are Chemical Companies Supporting Energy Solutions?

The energy sector relies on chemical companies for the development of chemicals used in battery production, essential for renewable energy technologies. As the world shifts towards sustainable energy solutions, sourcing innovative chemical formulations is critical. Buyers should focus on suppliers that prioritize sustainability in their raw material sourcing and are committed to advancing energy storage technologies.

3 Common User Pain Points for ‘chemical companies in usa’ & Their Solutions

Scenario 1: Navigating Compliance and Regulatory Hurdles in Chemical Sourcing

The Problem: B2B buyers often grapple with the complex landscape of regulations governing chemical procurement. In the USA, compliance with environmental, health, and safety standards can be daunting, especially for international buyers unfamiliar with local laws. This challenge can lead to delays in sourcing, increased costs due to potential fines, and even reputational damage if non-compliance is discovered. The burden of ensuring that suppliers adhere to all applicable regulations often falls on the buyer, creating stress and uncertainty in the procurement process.

The Solution: To effectively navigate these regulatory hurdles, B2B buyers should prioritize sourcing chemical companies that emphasize transparency in their operations. Start by conducting thorough due diligence on potential suppliers, focusing on their compliance history and certifications. Engage with companies that actively participate in industry associations, as these organizations often provide resources and updates on regulatory changes. Furthermore, consider using third-party compliance verification services to audit suppliers’ practices. This proactive approach not only reduces the risk of non-compliance but also fosters stronger partnerships built on trust and accountability.

Scenario 2: Managing Supply Chain Disruptions in Chemical Procurement

The Problem: Supply chain disruptions are increasingly common, impacting the timely delivery of chemical products. B2B buyers often face challenges due to global events, logistical issues, or unexpected demand fluctuations. These disruptions can result in production delays, increased costs, and lost revenue opportunities. For international buyers, these challenges are compounded by varying lead times and transportation complexities, which can make it difficult to maintain consistent inventory levels.

The Solution: To mitigate supply chain disruptions, buyers should adopt a dual-sourcing strategy, engaging multiple suppliers for critical chemicals. This approach not only provides a safety net in case one supplier faces challenges but also fosters competitive pricing. Additionally, leveraging advanced supply chain management technologies can enhance visibility into inventory levels and supplier performance. Implementing tools that provide real-time tracking and forecasting can help buyers anticipate potential disruptions and adjust their procurement strategies accordingly. Building strong relationships with suppliers also allows for better communication and quicker responses during crises.

Scenario 3: Ensuring Quality Consistency in Chemical Products

The Problem: Quality inconsistency is a prevalent concern for B2B buyers in the chemical sector. Variations in product quality can lead to production inefficiencies, increased waste, and compromised end-product performance. For international buyers, the risk is heightened when sourcing from multiple suppliers or different regions, as variations in manufacturing processes and quality control measures may not meet their specific requirements.

The Solution: To ensure consistent quality in chemical products, buyers should implement a rigorous supplier evaluation and selection process. Establish clear quality standards and specifications before engaging with suppliers. Conduct regular quality audits and performance assessments to monitor compliance with these standards. Additionally, consider utilizing a third-party quality assurance service to validate product quality before shipment. Implementing a robust feedback loop with suppliers can also help address quality issues proactively. By fostering an environment of continuous improvement, buyers can work collaboratively with their suppliers to enhance product consistency and reliability.

Strategic Material Selection Guide for chemical companies in usa

What Are the Key Materials Used in Chemical Manufacturing in the USA?

In the chemical industry, the selection of materials is crucial for ensuring product performance, safety, and compliance with international standards. Below, we analyze four common materials used by chemical companies in the USA, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand high temperatures (up to 1,500°F). It is often used in environments where chemical exposure is significant.

Pros & Cons:

The durability of stainless steel makes it ideal for long-term applications. However, it can be relatively expensive compared to other materials like carbon steel. Manufacturing complexity can also be higher due to the need for specialized welding techniques.

Impact on Application:

Stainless steel is compatible with a wide range of chemicals, making it suitable for storage tanks, piping, and reactors. Its resistance to pitting and crevice corrosion is particularly beneficial in harsh environments.

Considerations for International Buyers:

International buyers must ensure compliance with standards such as ASTM A240 for stainless steel sheets and plates. Additionally, understanding local regulations regarding food-grade materials is essential for applications in the food and pharmaceutical sectors.

2. Polypropylene

Key Properties:

Polypropylene is a thermoplastic polymer characterized by its chemical resistance, lightweight, and low moisture absorption. It can withstand temperatures up to 200°F and is often used in applications requiring flexibility.

Pros & Cons:

The main advantage of polypropylene is its cost-effectiveness and ease of fabrication. However, it has a lower temperature tolerance compared to metals and may degrade under UV exposure.

Impact on Application:

Polypropylene is commonly used in chemical storage tanks and piping systems due to its resistance to acids and bases. Its compatibility with various media makes it a versatile choice for many chemical processes.

Considerations for International Buyers:

Buyers should be aware of compliance with standards such as ASTM D4101 for polypropylene materials. Understanding the local market preferences for material types can also influence purchasing decisions.

3. Glass-Lined Steel

Key Properties:

Glass-lined steel combines the strength of steel with the chemical resistance of glass. It can handle temperatures up to 500°F and is resistant to corrosion from aggressive chemicals.

Pros & Cons:

The key advantage of glass-lined steel is its ability to provide a non-reactive surface for chemical processes. However, it can be more expensive and requires careful handling to avoid chipping or cracking.

Impact on Application:

This material is commonly used in reactors and storage tanks for corrosive substances. Its smooth surface also aids in cleaning and reduces contamination risks.

Considerations for International Buyers:

International buyers should verify compliance with relevant standards such as ASTM A-381 for glass-lined equipment. Understanding the local repair and maintenance capabilities for glass-lined systems is also crucial.

4. Carbon Steel

Key Properties:

Carbon steel is a strong and durable material, suitable for high-pressure applications. It can handle temperatures up to 1,200°F but is susceptible to corrosion without proper treatment.

Pros & Cons:

Carbon steel is relatively inexpensive and widely available, making it a popular choice for many applications. However, its susceptibility to rust and corrosion can lead to increased maintenance costs.

Impact on Application:

Carbon steel is often used in pipelines and storage tanks for non-corrosive liquids. Proper coating or lining is essential to extend its lifespan in chemical applications.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM A106 for carbon steel pipes. Understanding the local climate and environmental conditions is crucial for selecting appropriate protective coatings.

Summary Table of Strategic Material Selection

| Material | Typical Use Case for chemical companies in usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Storage tanks, piping, reactors | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Polypropylene | Chemical storage tanks, piping systems | Cost-effective and easy to fabricate | Lower temperature tolerance | Low |

| Glass-Lined Steel | Reactors, storage tanks for corrosive substances | Non-reactive surface and easy to clean | Expensive and requires careful handling | High |

| Carbon Steel | Pipelines, storage tanks for non-corrosive liquids | Inexpensive and widely available | Susceptible to corrosion without treatment | Low |

This guide provides actionable insights for international B2B buyers, enabling informed decisions when selecting materials for chemical manufacturing applications.

In-depth Look: Manufacturing Processes and Quality Assurance for chemical companies in usa

What Are the Key Stages of Manufacturing Processes in Chemical Companies in the USA?

The manufacturing processes in chemical companies encompass several critical stages that ensure efficiency, safety, and product quality. These stages typically include material preparation, forming, assembly, and finishing, each employing various techniques tailored to specific chemical products.

How Is Material Prepared in Chemical Manufacturing?

Material preparation is the initial stage where raw materials are sourced and processed. This involves the selection of appropriate chemicals, which may include gases, liquids, and solids. Companies often utilize advanced technologies such as automated systems for weighing and mixing components to ensure precise formulations. Pre-treatment processes, such as drying or grinding, may also be employed to optimize the material’s properties before it enters the manufacturing phase.

What Techniques Are Commonly Used in Forming Chemical Products?

In the forming stage, raw materials undergo chemical reactions to create intermediate or final products. Techniques such as batch processing, continuous flow, and extrusion are commonly used. For instance, batch processing is prevalent in specialty chemicals, allowing for flexibility in production volumes. Continuous flow processes are typically used for high-volume production, ensuring uniform quality and efficiency. The choice of technique often depends on the chemical nature of the product and market demand.

How Are Chemical Products Assembled and Finished?

Once formed, products may require assembly, particularly in cases where multiple components are combined. This can involve blending, compounding, or coating processes. The finishing stage ensures the product meets specific standards, often involving filtration, drying, or packaging. Quality control during this stage is crucial, as it guarantees that the final product adheres to both company specifications and regulatory requirements.

What Quality Assurance Standards Are Relevant for Chemical Companies?

Quality assurance (QA) in the chemical industry is vital for maintaining product integrity and compliance with international standards. The most recognized standard is ISO 9001, which focuses on quality management systems and continual improvement. Additionally, industry-specific standards such as CE marking for safety and API standards for pharmaceuticals play a significant role in ensuring product quality.

How Are Quality Control Checkpoints Implemented?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet required specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process allows for immediate identification of deviations from quality standards.

- Final Quality Control (FQC): After production, final products undergo rigorous testing to confirm compliance with specifications before they are released to the market.

What Common Testing Methods Are Used in Chemical Quality Control?

Chemical companies employ various testing methods to ensure product quality. Common techniques include:

- Spectroscopy (e.g., IR, UV-Vis): Used for analyzing chemical compositions.

- Chromatography (e.g., HPLC, GC): Essential for separating and identifying compounds.

- Mechanical Testing: Evaluates physical properties such as tensile strength and viscosity.

- Microbiological Testing: Critical for pharmaceutical and food-related chemicals to ensure safety.

These methods help verify that products meet industry regulations and customer requirements.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are key approaches:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, processes, and adherence to quality standards.

- Quality Reports: Requesting detailed QC reports can provide insights into the supplier’s testing methods, results, and compliance with industry standards.

- Third-Party Inspections: Engaging independent inspection agencies can offer an unbiased evaluation of the supplier’s processes and products.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Navigating quality control and certification can present challenges for international buyers. It is essential to understand regional regulations and standards that may differ from those in the USA. For instance, European buyers may prioritize REACH compliance, while buyers from Africa might focus on local certifications. Additionally, buyers should be aware of the implications of certifications like ISO and API, as they can significantly influence supplier reliability and product quality.

Conclusion: Ensuring Quality in Chemical Manufacturing

Understanding the manufacturing processes and quality assurance practices in chemical companies is critical for B2B buyers. By focusing on the stages of manufacturing, the implementation of quality standards, and effective verification methods, buyers can make informed decisions when selecting suppliers. This knowledge not only fosters trust but also ensures the procurement of high-quality chemical products that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chemical companies in usa’

Introduction

This practical sourcing guide aims to assist international B2B buyers in navigating the procurement process of chemical companies in the USA. Understanding the nuances of the chemical industry, supplier qualifications, and regulatory requirements is crucial for making informed purchasing decisions. This checklist outlines essential steps to streamline your sourcing process effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for the chemicals you need is the foundation of a successful procurement process. Specify the chemical composition, purity levels, quantity, and any specific compliance or safety standards required for your industry. This clarity will help you communicate your needs effectively to potential suppliers.

Step 2: Conduct Market Research

Before reaching out to suppliers, conduct thorough market research to understand the landscape of chemical manufacturers in the USA. Identify key players, their product offerings, and market trends. Pay attention to factors such as pricing, quality, and delivery times to gauge competitive advantages and align your expectations accordingly.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it is essential to conduct a comprehensive evaluation. Request detailed company profiles, including their history, production capabilities, and case studies demonstrating their experience in your specific sector. Additionally, seek references from other buyers, particularly those within your industry, to validate their credibility and reliability.

Step 4: Verify Certifications and Compliance

Ensure that potential suppliers hold the necessary certifications and comply with industry regulations. This may include ISO certifications, environmental compliance (such as EPA regulations), and safety standards relevant to your region. Compliance not only guarantees product quality but also minimizes legal risks associated with non-compliance.

Step 5: Request Samples for Quality Assessment

Once you have shortlisted potential suppliers, request samples of the chemicals you intend to purchase. Testing samples allows you to assess quality, consistency, and suitability for your intended application. Take note of the supplier’s responsiveness and willingness to provide samples, as this can indicate their level of service and commitment to customer satisfaction.

Step 6: Negotiate Terms and Conditions

Engage in negotiations with your selected supplier regarding pricing, payment terms, delivery schedules, and other contractual obligations. Clearly outline expectations to avoid misunderstandings later. Ensure that both parties agree on terms related to quality assurance, return policies, and liability in case of product issues.

Step 7: Establish a Communication Plan

Effective communication is key to a successful partnership. Establish a clear communication plan that outlines how and when you will engage with the supplier throughout the procurement process. Regular updates and open lines of communication can help address issues proactively and build a strong working relationship.

By following this step-by-step checklist, international B2B buyers can effectively navigate the complexities of sourcing chemicals from US-based suppliers, ensuring that they select the right partners for their business needs.

Comprehensive Cost and Pricing Analysis for chemical companies in usa Sourcing

What Are the Key Cost Components for Chemical Companies in the USA?

Understanding the cost structure of chemical companies in the USA is essential for international B2B buyers looking to source materials effectively. The primary cost components include:

-

Materials: Raw materials constitute the largest portion of costs for chemical manufacturers. Prices fluctuate based on market demand, availability, and global commodity trends. Buyers should monitor market indices for key chemicals to anticipate price changes.

-

Labor: Labor costs encompass wages, benefits, and training for skilled workers. The chemical industry often requires specialized labor, which can drive costs higher. Understanding regional labor markets in the USA can help buyers gauge potential cost variations.

-

Manufacturing Overhead: This includes expenses related to utilities, equipment maintenance, and facility management. Efficient manufacturing processes can reduce these overhead costs, and companies often seek to optimize operations to maintain competitive pricing.

-

Tooling and Equipment: Investment in specialized machinery and tooling is crucial for production. While high initial costs can deter some buyers, advanced equipment can enhance productivity and reduce long-term costs.

-

Quality Control (QC): Ensuring product quality is vital in the chemical industry, particularly for buyers requiring specific certifications. Effective QC processes incur costs but are necessary to avoid expensive recalls and reputational damage.

-

Logistics: Transportation and warehousing costs are significant in the chemical supply chain. Factors like distance, mode of transport, and storage requirements can greatly influence logistics expenses.

-

Margin: Manufacturers set profit margins based on their operational costs and market positioning. Understanding typical margins in the industry can aid buyers in identifying reasonable pricing.

How Do Price Influencers Affect Chemical Sourcing?

Several factors influence the pricing of chemicals, which international buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to better pricing due to economies of scale. Buyers should evaluate their needs against suppliers’ MOQ to negotiate favorable terms.

-

Specifications and Customization: Custom formulations or specific grades of chemicals often come at a premium. Clear communication of requirements can help avoid unexpected costs.

-

Materials Quality and Certifications: Higher quality materials with certifications (e.g., ISO, REACH) may incur additional costs. Buyers must weigh the importance of these certifications against their budget constraints.

-

Supplier Factors: Reliability, reputation, and financial stability of suppliers can impact pricing. Conducting thorough supplier assessments can mitigate risks related to pricing fluctuations.

-

Incoterms: The agreed terms of delivery (e.g., FOB, CIF) affect the total landed cost. Understanding Incoterms is essential for managing logistics costs effectively.

What Negotiation Strategies Can Help Buyers Achieve Cost-Efficiency?

To optimize sourcing costs, buyers should consider the following strategies:

-

Conduct Thorough Market Research: Stay informed about market trends, price fluctuations, and competitor pricing. This knowledge will strengthen your negotiating position.

-

Build Strong Supplier Relationships: Long-term partnerships can lead to more favorable terms and pricing. Engage in regular communication and foster trust with suppliers.

-

Evaluate Total Cost of Ownership (TCO): Consider all costs associated with sourcing, including logistics, duties, and potential quality issues. A lower upfront price may not always lead to the best TCO.

-

Be Flexible with Specifications: If possible, be open to alternative materials or formulations that meet your needs while potentially reducing costs.

-

Leverage Volume Discounts: If your purchasing volume allows, negotiate for discounts on bulk orders or explore shared purchasing agreements with other companies.

What Are the Pricing Nuances for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, face unique challenges:

-

Currency Fluctuations: Exchange rates can significantly impact pricing. Consider hedging strategies or negotiating contracts in stable currencies.

-

Import Duties and Tariffs: Understand the customs regulations and potential tariffs that may apply to imported chemicals, as these can add to the total cost.

-

Logistical Complexities: Shipping times and costs can vary widely. Ensure clarity on delivery timelines and potential delays that could affect your supply chain.

Disclaimer on Indicative Prices

Prices for chemicals can fluctuate based on numerous factors, including market demand, geopolitical events, and changes in supply chains. Always consult with suppliers for the most accurate and current pricing information tailored to your specific needs.

Alternatives Analysis: Comparing chemical companies in usa With Other Solutions

Introduction: Understanding Alternatives in Chemical Supply

In the dynamic landscape of the chemical industry, B2B buyers are often faced with various sourcing options beyond traditional chemical companies in the USA. Understanding these alternatives is essential for making informed decisions that align with specific business needs, cost structures, and operational requirements. This analysis will explore viable alternatives to sourcing chemicals from U.S. manufacturers, including international suppliers, specialty chemical distributors, and green chemistry solutions.

Comparison Table

| Comparison Aspect | Chemical Companies In USA | International Suppliers | Specialty Chemical Distributors | Green Chemistry Solutions |

|---|---|---|---|---|

| Performance | High-quality standards; established reputation | Variable quality; may require additional vetting | Consistent quality; tailored solutions | Innovative; often more sustainable |

| Cost | Generally higher due to operational expenses | Potentially lower; influenced by exchange rates and tariffs | Competitive; varies by service level | Can be higher initially; long-term savings possible |

| Ease of Implementation | Well-defined processes and support | Complex due to logistics and compliance | Streamlined ordering and delivery processes | May require training and adaptation |

| Maintenance | Ongoing support and service | Variable; may depend on supplier reliability | Strong support; often includes technical assistance | Requires ongoing R&D and adaptation |

| Best Use Case | Large-scale manufacturing and established supply chains | Cost-sensitive projects needing flexibility | Niche applications requiring specific expertise | Environmentally-focused projects or innovation-driven companies |

Detailed Breakdown of Alternatives

International Suppliers

Sourcing chemicals from international suppliers can provide significant cost advantages, especially for bulk purchases. Countries such as China and India often offer lower manufacturing costs due to reduced labor expenses. However, the variable quality of products and the complexities involved in logistics and compliance with international regulations can pose challenges. Buyers must conduct thorough due diligence to ensure the quality and reliability of these suppliers.

Specialty Chemical Distributors

Specialty chemical distributors serve as intermediaries that can offer tailored solutions and a diverse range of products. They often have established relationships with multiple manufacturers, allowing for flexible sourcing options. The streamlined ordering and delivery processes provided by these distributors can enhance operational efficiency. However, their services may come at a premium, and buyers should assess the balance between cost and the added value of expertise and support.

Green Chemistry Solutions

Green chemistry focuses on designing chemical processes and products that minimize waste and reduce environmental impact. This approach is increasingly favored by companies looking to enhance sustainability in their operations. While initial costs for green solutions may be higher, they often lead to long-term savings through reduced waste disposal costs and compliance with environmental regulations. Adopting green chemistry requires a commitment to ongoing research and development, making it best suited for organizations prioritizing innovation and sustainability.

Conclusion: Choosing the Right Chemical Sourcing Solution

For B2B buyers navigating the complexities of chemical sourcing, understanding the diverse alternatives to U.S. chemical companies is crucial. Each option presents unique advantages and challenges, from cost considerations to implementation ease. Buyers should assess their specific needs, including budget constraints, quality requirements, and sustainability goals, to make an informed decision. By evaluating the alternatives—international suppliers, specialty distributors, and green chemistry solutions—companies can position themselves for success in an evolving market landscape.

Essential Technical Properties and Trade Terminology for chemical companies in usa

What Are the Critical Technical Properties Relevant to Chemical Companies in the USA?

Understanding the technical specifications of chemical products is essential for international buyers engaging with chemical companies in the USA. Below are key properties that play a significant role in the B2B procurement process:

1. Material Grade

Material grade refers to the classification of a chemical based on its purity and composition. Higher grades often indicate fewer impurities and better performance in industrial applications. For B2B buyers, selecting the appropriate material grade is crucial, as it can affect product quality, safety, and regulatory compliance.

2. Tolerance

Tolerance defines the acceptable limits of variation in a chemical’s physical properties, such as dimensions or chemical concentrations. In industries like pharmaceuticals or food processing, precise tolerances are critical to ensure product efficacy and safety. For buyers, understanding tolerance levels helps in sourcing materials that meet specific regulatory standards.

3. Viscosity

Viscosity measures a fluid’s resistance to flow and is a critical property for chemicals used in coatings, adhesives, and lubricants. Higher viscosity can indicate thicker formulations, which may be necessary for certain applications. Buyers should consider viscosity when evaluating product performance in their specific applications.

4. Solubility

Solubility indicates the ability of a chemical to dissolve in a solvent, which can significantly influence product formulation and application. For instance, in agrochemicals, solubility affects how well a pesticide can be absorbed by plants. Understanding solubility is essential for buyers to ensure compatibility with other products in their supply chain.

5. Shelf Life

Shelf life refers to the duration a chemical can be stored without significant degradation. This property is vital for buyers in planning inventory and ensuring product quality over time. Understanding shelf life can prevent costly waste and ensure that products meet performance standards upon use.

What Are Common Trade Terminologies Used in the Chemical Industry?

Familiarity with industry jargon can facilitate smoother transactions and negotiations between international buyers and chemical suppliers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the chemical industry, this term is often used to describe suppliers who create formulations or compounds that are branded under another company’s name. Understanding OEM relationships can help buyers identify potential suppliers and the scope of their capabilities.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is critical for buyers as it impacts inventory management and procurement strategies. Knowing the MOQ helps in budgeting and understanding supplier capabilities.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific quantities of products. It is a crucial step in procurement, allowing buyers to compare costs and terms from various suppliers to make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, thus reducing misunderstandings. For international buyers, understanding Incoterms is vital for ensuring smooth logistics and compliance with trade regulations.

5. SDS (Safety Data Sheet)

An SDS is a document that provides detailed information about a chemical’s properties, hazards, handling, and emergency measures. For B2B buyers, reviewing SDS ensures compliance with safety regulations and helps in making informed decisions regarding the use and storage of chemicals.

By understanding these technical properties and trade terminologies, international buyers can effectively navigate the complexities of engaging with chemical companies in the USA, ensuring that their procurement processes are efficient and compliant with industry standards.

Navigating Market Dynamics and Sourcing Trends in the chemical companies in usa Sector

What Are the Current Market Dynamics and Key Trends in the U.S. Chemical Sector?

The U.S. chemical industry is witnessing robust growth fueled by several global drivers, including the increasing demand for sustainable products and advancements in technology. Key trends influencing the market include the rise of digital transformation, which is reshaping sourcing strategies through data analytics, artificial intelligence, and supply chain visibility. Companies are increasingly adopting platforms that enhance collaboration and streamline procurement processes, making it easier for international buyers from regions like Africa, South America, the Middle East, and Europe to connect with suppliers.

Moreover, the market is experiencing a shift towards circular economy practices, emphasizing recycling and resource efficiency. This trend is particularly relevant for buyers looking to source eco-friendly chemicals, as manufacturers are investing in technologies that minimize waste and optimize resource use. Additionally, geopolitical factors and trade regulations are prompting companies to diversify their supply chains, ensuring that sourcing strategies are resilient against global disruptions. For international buyers, understanding these dynamics is crucial for navigating the competitive landscape and making informed purchasing decisions.

How Is Sustainability Shaping the Sourcing Practices of Chemical Companies in the U.S.?

Sustainability has become a cornerstone of sourcing strategies in the U.S. chemical sector, driven by increasing regulatory pressures and consumer expectations. Companies are actively seeking to reduce their environmental footprint by prioritizing ethical supply chains and sustainable practices. This involves not only minimizing emissions and waste but also ensuring that raw materials are sourced responsibly.

International buyers are particularly interested in suppliers that offer ‘green’ certifications and materials, such as those compliant with ISO 14001 or those that are part of recognized sustainability initiatives. These certifications not only demonstrate a commitment to environmental stewardship but also provide assurance that products meet specific sustainability standards. By aligning with suppliers who prioritize sustainability, buyers can enhance their own corporate responsibility efforts and appeal to environmentally conscious consumers.

In addition, the growing trend of green chemistry is fostering innovation in product development, leading to the creation of safer and more sustainable chemicals. This shift is essential for international buyers who are looking to source products that comply with evolving environmental regulations in their respective markets.

What Is the Historical Context of the U.S. Chemical Industry and Its Relevance to B2B Buyers?

The U.S. chemical industry has a rich history dating back to the early 19th century, where it began with the production of basic chemicals and evolved through several technological advancements. The post-World War II era marked significant growth, driven by innovations in petrochemicals and synthetic materials. This evolution has positioned the U.S. as a leading global player in the chemical sector, with a diverse range of products catering to various industries, including pharmaceuticals, agriculture, and manufacturing.

Understanding this historical context is essential for international B2B buyers as it provides insight into the industry’s resilience and adaptability. The U.S. chemical sector has continually embraced innovation and responded to market demands, ensuring a steady supply of high-quality products. Buyers can leverage this historical knowledge to identify reliable suppliers and make strategic sourcing decisions that align with their business objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of chemical companies in usa

-

How do I ensure product quality when sourcing from chemical companies in the USA?

To ensure product quality, begin by requesting certifications such as ISO 9001 or specific industry-related standards from potential suppliers. Conduct thorough research on their manufacturing processes and quality control systems. Consider requesting samples for testing before committing to larger orders. Additionally, establish clear quality specifications and incorporate them into your contract to ensure compliance. Regular communication and scheduled audits can also help maintain quality standards throughout the partnership. -

What are the common payment terms offered by chemical suppliers in the USA?

Payment terms can vary widely among suppliers, but common practices include payment in advance, net 30, net 60, or even net 90 days. Some suppliers may offer discounts for early payments. It’s crucial to discuss and negotiate payment terms upfront to align with your cash flow needs. Be sure to include these terms in your contract to avoid any misunderstandings later. Additionally, consider using letters of credit for larger transactions to protect both parties. -

What is the minimum order quantity (MOQ) when sourcing chemicals in the USA?

Minimum order quantities (MOQ) differ significantly by supplier and type of chemical. Typically, MOQs can range from small quantities, such as 100 kg for specialty chemicals, to several tons for bulk commodities. Discuss your specific needs with potential suppliers to determine their flexibility regarding MOQs. Some suppliers may accommodate lower MOQs for new customers or trial orders, so it’s advisable to negotiate these terms based on your business requirements. -

How can I effectively vet potential chemical suppliers in the USA?

Start by researching the supplier’s reputation and history in the industry. Look for customer reviews, case studies, and references. Evaluate their financial stability through credit checks and financial statements. Conduct site visits if possible to assess their manufacturing facilities and processes. Additionally, inquire about their compliance with regulatory standards and safety protocols. Establishing clear communication channels and asking detailed questions about their operations will further aid in your vetting process. -

What types of customization options are available when sourcing chemicals?

Many chemical suppliers in the USA offer customization options to meet specific needs, including formulation adjustments, packaging sizes, and labeling. Discuss your requirements with potential suppliers early in the negotiation process. Some companies may provide tailored solutions based on your application, while others might have limitations based on their production capabilities. Be prepared to provide detailed specifications and potential volumes to help suppliers assess feasibility. -

What logistics considerations should I keep in mind when importing chemicals from the USA?

Logistics play a crucial role in importing chemicals. Consider factors such as shipping methods, costs, and transit times. Collaborate with a freight forwarder experienced in chemical transportation to navigate regulations and safety requirements. Ensure compliance with both US export regulations and the import laws of your country. Additionally, factor in storage solutions, handling procedures, and potential customs duties to avoid delays and unexpected expenses. -

How do I handle compliance and regulatory issues when sourcing chemicals internationally?

Compliance with international regulations is essential when sourcing chemicals. Familiarize yourself with both US regulations and those of your home country regarding chemical imports. Ensure that your suppliers provide necessary documentation, such as Safety Data Sheets (SDS) and compliance certifications. It may be beneficial to consult with legal or compliance experts familiar with chemical trade regulations to navigate complex requirements and avoid penalties. -

What are the best practices for establishing long-term relationships with chemical suppliers?

Building long-term relationships with suppliers involves open communication, transparency, and mutual trust. Regularly engage with your suppliers to discuss performance, feedback, and potential improvements. Consider collaborating on joint projects or innovations that benefit both parties. Timely payments and honoring contracts will help establish your reliability as a buyer. Additionally, being flexible and understanding during challenging times can foster loyalty and strengthen the partnership over time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for chemical companies in usa

How Can Strategic Sourcing Enhance Your Competitive Advantage in the Chemical Industry?

As the chemical industry in the USA continues to evolve, the importance of strategic sourcing cannot be overstated. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, leveraging strategic sourcing can lead to significant cost reductions, improved quality, and enhanced supplier relationships. By focusing on key players in the market, such as BASF and Dow, buyers can tap into innovative products and sustainable practices that align with global standards.

Furthermore, understanding market trends and supplier dynamics is crucial for making informed purchasing decisions. With many chemical manufacturers investing in research and development, companies that prioritize strategic sourcing are well-positioned to gain access to cutting-edge technologies and solutions.

Looking ahead, international buyers should actively seek partnerships with established U.S. chemical companies to capitalize on their expertise and resources. Engaging in strategic sourcing not only facilitates competitive pricing but also fosters collaboration in sustainability initiatives, which are increasingly vital in today’s market. Take the next step to enhance your supply chain resilience and explore new opportunities in the U.S. chemical sector.