Top 7 Bry Air Usa List and Guide: How To Solve Scenario 1: Overco…

Introduction: Navigating the Global Market for bry air usa

In an increasingly competitive global market, sourcing reliable dehumidification solutions is paramount for B2B buyers, particularly those in industries prone to moisture-related challenges. Bry-Air USA stands at the forefront of this sector, offering advanced technologies tailored for diverse applications—from industrial drying processes to electronic component protection. This guide provides a comprehensive overview of Bry-Air’s extensive product range, including their renowned desiccant dehumidifiers, gas phase filtration systems, and adsorption chillers, ensuring that international buyers can make informed decisions.

Navigating the complexities of sourcing equipment like Bry-Air’s innovative solutions requires a clear understanding of not only the products but also their applications across various industries, including pharmaceuticals, food processing, and plastics. In addition, this guide delves into essential considerations for supplier vetting, cost evaluation, and the unique challenges faced by businesses in regions such as Africa, South America, the Middle East, and Europe. By equipping buyers with actionable insights and industry knowledge, this guide empowers them to optimize their purchasing strategies, enhance operational efficiency, and ultimately secure the right dehumidification solutions tailored to their specific needs.

Top 10 Bry Air Usa Manufacturers & Suppliers List

1. Bry-Air – Industrial Dehumidifiers & Filtration Systems

Domain: bryair.com

Registered: 1999 (26 years)

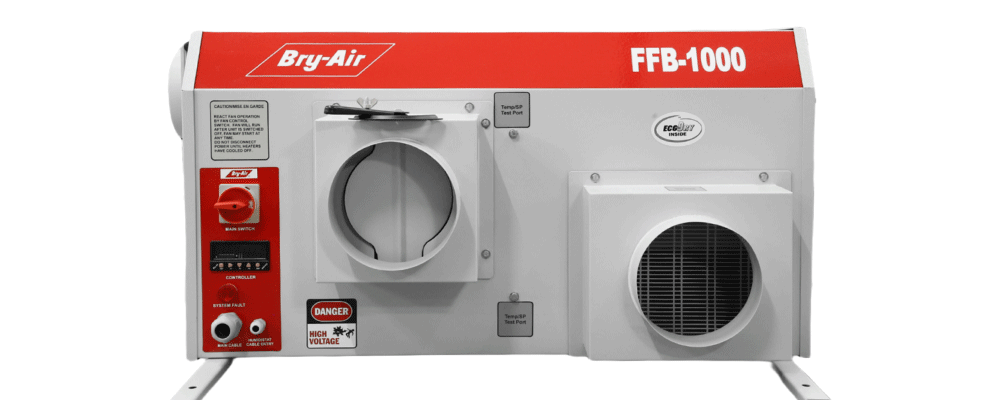

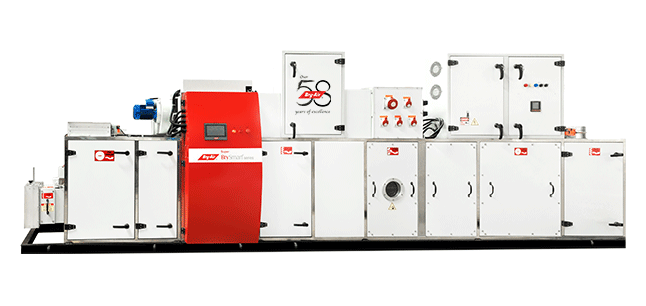

Introduction: Industrial Dehumidifiers, Gas Phase Filtration Systems, Plastic Auxiliary Equipment, Lithium Battery Dry Rooms, Adsorption Chillers, High Temperature Heat Recovery Wheels, Compact Desiccant Dehumidifier (FFB series 170-4500 CMH), Bry-Air BrySmart® Dehumidifier (10000-100000+ CMH), Wonder Dryer (waterless plastic dryers with < (-) 40°C dew point).

2. Bry-Air, Inc. – Humidity Control Solutions

3. Bry-Air – Environmental Control Systems

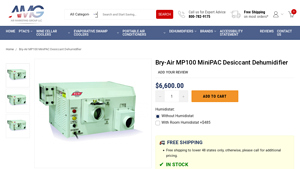

4. Bry-Air – MP100 Mini-PAC Desiccant Dehumidifier

Domain: amgair.com

Registered: 2001 (24 years)

Introduction: Bry-Air MP100 Mini-PAC Desiccant Dehumidifier

– Model No.: MP100

– Water Removal: 75.6 pints per day @ 80°F 60%

– Process Airflow: 100 cfm

– Weight: 139 lbs

– Dimensions: Height: 15 5/16″, Width: 26 5/8″, Depth: 18 1/2″

– Voltage: 208/240/1/60V

– Full Load KW: 4.03

– Phase: 1

– Frequency: 60 Hz

– Process Duct Size: 4″

– Regen Duct Size: 4″

– Min Operating Temperature: -4 °F (-20°C)

– Max Operating…

5. Bry-Air Inc. – Industrial Dehumidification Solutions

Domain: pitchbook.com

Registered: 2004 (21 years)

Introduction: Bry-Air Inc. develops industrial dehumidification and corrosion prevention solutions for complex applications in commercial and industrial markets. Their products and services include:

– Condensation and frost prevention

– Corrosion prevention

– Moisture regain prevention

– Mold and fungus prevention

– Product drying

– Preservation and archival storage

– Aircraft and munitions preservation

They of…

6. Just Food – Moisture Control Solutions

Domain: just-food.com

Registered: 1997 (28 years)

Introduction: Moisture control solutions for the food and beverage industry.

7. Bry-Air Systems – DH-2 HVAC Dehumidifier

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Bry-Air Systems DH-2 HVAC and Dehumidification

Condition: Used (Like New)

Quantity: 1 available

Item number: 203837646708

Shipping cost: $2,122.92

Estimated delivery: Wed, Aug 6 – Fri, Aug 22

Seller: Stillman Company (1214) with 98.8% positive feedback.

Understanding bry air usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compact Desiccant Dehumidifier | Lightweight, fits above false ceilings; 170-4500 CMH capacity. | Pharmaceuticals, Food Processing | Pros: Space-saving, versatile. Cons: Limited capacity for larger operations. |

| BrySmart® Dehumidifier | Optimized for Industry 4.0; 10,000-100,000+ CMH capacity. | Data Centers, Manufacturing | Pros: High efficiency, smart technology. Cons: Higher initial investment. |

| Wonder Dryer | Energy-efficient, delivers <(-)40°C dew point. | Plastics Processing, Electronics | Pros: Energy-saving, effective drying. Cons: Specific to certain applications. |

| Mini-Pac Desiccant Dehumidifier | Compact, maintains humidity below 45%; operates in low temps. | Laboratories, Cold Stores, Food Industry | Pros: Small footprint, low energy use. Cons: Limited to smaller spaces. |

| Adsorption Chillers | Utilizes waste or solar heat; 11 kW to 1180 kW capacity. | Process Industries, Solar Plants | Pros: Sustainable energy use. Cons: Complex installation and maintenance. |

What Are the Key Characteristics of Compact Desiccant Dehumidifiers?

Compact Desiccant Dehumidifiers are designed for space efficiency, making them ideal for installations where space is limited, such as above false ceilings. With a capacity range of 170 to 4500 CMH, they cater to diverse industrial needs, particularly in pharmaceuticals and food processing where humidity control is critical. B2B buyers should consider the specific capacity needed for their operations and whether the compact design aligns with their space constraints.

How Does the BrySmart® Dehumidifier Enhance Industry 4.0 Operations?

The BrySmart® Dehumidifier is engineered for high-capacity operations, ranging from 10,000 to over 100,000 CMH, making it suitable for data centers and large manufacturing environments. Its integration with smart technology allows for dynamic performance optimization, ensuring consistent humidity control. Buyers should evaluate the initial investment against long-term energy savings and operational efficiency, especially in environments where precision is paramount.

What Makes the Wonder Dryer Ideal for Specific Industries?

The Wonder Dryer is known for its energy efficiency and ability to achieve extremely low dew points, making it particularly useful in plastics processing and electronics manufacturing. It operates effectively at high return air temperatures, which enhances its drying capabilities. Businesses should assess the compatibility of this dryer with their production processes and the potential for energy cost reductions.

Why Choose the Mini-Pac Desiccant Dehumidifier for Smaller Applications?

The Mini-Pac Desiccant Dehumidifier is a compact solution that excels in maintaining low humidity levels, making it suitable for laboratories, cold storage, and food processing. Its ability to function in low temperatures and small footprint makes it a practical choice for businesses with limited space. Buyers should consider its efficiency and operating costs when looking for reliable humidity control in smaller settings.

How Do Adsorption Chillers Contribute to Sustainable Practices?

Adsorption Chillers leverage waste heat or solar energy, with capacities ranging from 11 kW to 1180 kW, making them a sustainable choice for process industries and solar plants. They provide an environmentally friendly alternative to traditional chillers, promoting energy efficiency. B2B buyers should weigh the benefits of sustainable energy use against the complexity of installation and maintenance when considering these systems for their operations.

Key Industrial Applications of bry air usa

| Industry/Sector | Specific Application of bry air usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceuticals | Controlled Dry Rooms for Drug Manufacturing | Ensures product integrity and compliance with regulations | Need for precise humidity control and energy efficiency |

| Food Processing | Mould Dehumidification Systems | Reduces spoilage and improves product quality | Consider local climate conditions and energy costs |

| Electronics | Electronic Corrosion Control Systems | Protects sensitive components from moisture damage | Requires customization based on facility layout and product type |

| Plastics Manufacturing | Waterless Plastic Dryers | Enhances drying efficiency and reduces energy consumption | Evaluate compatibility with existing machinery |

| Lithium Battery Production | Humidity Control in Battery Dry Rooms | Prevents battery failure and extends lifespan | Must meet stringent safety standards and material compatibility |

How Does Bry-Air USA Support the Pharmaceutical Industry?

In the pharmaceutical sector, Bry-Air’s controlled dry rooms are critical for maintaining stringent humidity levels during drug manufacturing. Excess moisture can compromise product integrity and lead to regulatory non-compliance. By utilizing desiccant dehumidifiers, businesses can ensure optimal conditions for sensitive formulations. International buyers, particularly from Africa and the Middle East, should prioritize energy efficiency and precise humidity control when sourcing these systems, as they directly impact operational costs and product quality.

What Benefits Do Mould Dehumidification Systems Offer in Food Processing?

In food processing, Bry-Air’s mould dehumidification systems play a vital role in preventing spoilage and ensuring product quality. These systems mitigate moisture levels that can lead to mould growth, enhancing production efficiency and reducing cycle times. For businesses in humid regions like Brazil and Nigeria, sourcing these systems means investing in technology that not only preserves food quality but also complies with health regulations. Buyers should consider local climate conditions and energy costs to maximize the return on investment.

How Can Electronics Manufacturers Benefit from Bry-Air’s Solutions?

Electronics manufacturers face significant challenges from electronic corrosion due to moisture. Bry-Air’s electronic corrosion control systems effectively mitigate this risk, protecting sensitive components and extending the lifespan of products. For international buyers, particularly in Europe, the need for customization based on facility layout and specific product types is crucial. Investing in these solutions enhances reliability and reduces costly downtime associated with moisture-related failures.

Why Are Waterless Plastic Dryers Essential in Plastics Manufacturing?

In plastics manufacturing, Bry-Air’s waterless plastic dryers significantly enhance drying efficiency while reducing energy consumption. These systems can achieve extremely low dew points, ensuring that moisture does not affect the quality of plastic products. For buyers in regions with fluctuating energy costs, these dryers present an attractive option. When sourcing, businesses should evaluate the compatibility of these dryers with existing machinery to ensure seamless integration.

What Role Does Bry-Air Play in Lithium Battery Production?

In the lithium battery sector, humidity control is paramount to prevent battery failure and extend product lifespan. Bry-Air’s humidity control systems in battery dry rooms ensure that moisture levels are kept at bay, thus safeguarding the integrity of battery components. Buyers from South America and the Middle East should be aware of stringent safety standards and material compatibility when sourcing these systems, as they are critical for operational success in this high-stakes industry.

3 Common User Pain Points for ‘bry air usa’ & Their Solutions

Scenario 1: Overcoming Excess Humidity in Food Processing Facilities

The Problem: In food processing environments, maintaining optimal humidity levels is crucial for product quality and safety. Excess moisture can lead to spoilage, mold growth, and compromised product integrity, resulting in financial losses and potential regulatory issues. B2B buyers in this sector often struggle with outdated dehumidification systems that fail to keep up with fluctuating humidity levels, leading to inefficient operations and increased waste.

The Solution: To tackle this issue, B2B buyers should consider implementing Bry-Air’s industrial desiccant dehumidifiers specifically designed for food processing applications. These systems utilize advanced adsorption technology to effectively reduce humidity levels, ensuring products remain in prime condition. Buyers should assess their specific humidity requirements and select a model that matches their production capacity—options like the BrySmart® Dehumidifier provide dynamic performance tailored to Industry 4.0 needs. Additionally, integrating these systems into existing production lines will require consultation with Bry-Air’s technical team to ensure seamless installation and optimal configuration for maximum efficiency. Regular maintenance and monitoring through Bry-Air’s support services will also help sustain performance levels over time, safeguarding product quality.

Scenario 2: Preventing Electronic Component Corrosion in Manufacturing

The Problem: Electronics manufacturers often face significant challenges related to electronic corrosion, which can result in costly product failures and warranty claims. Humidity levels that are too high can accelerate corrosion, degrading sensitive components and leading to operational downtime. B2B buyers in this industry are particularly concerned about the reliability of their supply chain and the long-term performance of their products, making moisture control a priority.

The Solution: To mitigate the risk of electronic corrosion, manufacturers should invest in Bry-Air’s specialized desiccant dehumidifiers designed for electronic component protection. These units can maintain relative humidity levels below critical thresholds, significantly reducing the likelihood of corrosion. B2B buyers should conduct a thorough analysis of their facility’s humidity patterns to determine the appropriate capacity of the dehumidifier needed. Engaging with Bry-Air’s experts for a humidity audit can provide insights into the specific dehumidification requirements. Furthermore, implementing a proactive maintenance schedule, combined with Bry-Air’s monitoring solutions, ensures that the dehumidifiers operate at peak efficiency, safeguarding valuable electronic components throughout the production process.

Scenario 3: Addressing Mold Growth in Pharmaceutical Manufacturing

The Problem: Pharmaceutical manufacturers must adhere to stringent regulatory standards regarding product cleanliness and safety. Mold growth in manufacturing environments can pose serious risks, including contamination of products and the potential for regulatory non-compliance. B2B buyers in this sector frequently encounter challenges with managing humidity levels that contribute to mold formation, leading to increased operational costs and potential product recalls.

The Solution: Bry-Air’s Mould Dehumidification Systems are specifically engineered to combat moisture-related challenges in pharmaceutical settings. These systems can be tailored to meet the specific needs of the manufacturing environment by effectively controlling humidity levels and preventing mold growth. B2B buyers should begin by assessing their facility layout and identifying areas prone to moisture accumulation. Following this, they can consult with Bry-Air’s specialists to devise a customized dehumidification plan that includes appropriate equipment selection and installation strategies. Regularly scheduled maintenance and performance assessments will help ensure that the systems are functioning optimally and that humidity levels remain within acceptable limits, thereby protecting product integrity and ensuring compliance with industry regulations.

Strategic Material Selection Guide for bry air usa

When selecting materials for Bry-Air products, it’s essential to consider their properties, advantages, and limitations to ensure optimal performance in various applications. Below, we analyze four common materials used in Bry-Air’s dehumidification and filtration systems, focusing on their relevance to international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Aluminum in Bry-Air Applications?

Aluminum is a lightweight, corrosion-resistant material commonly used in Bry-Air’s dehumidifiers and filtration systems. It typically has a temperature rating of up to 150°C and excellent strength-to-weight ratio, making it suitable for various applications.

Pros: Aluminum is durable, resistant to rust, and has a relatively low cost compared to other metals. Its lightweight nature simplifies installation and reduces shipping costs, which is beneficial for international buyers.

Cons: While aluminum is resistant to corrosion, it can be susceptible to galvanic corrosion when in contact with other metals. Additionally, it may not perform as well under extreme temperatures compared to stainless steel.

Impact on Application: Aluminum is compatible with most media used in dehumidification systems, but care must be taken in mixed-metal environments to prevent corrosion issues.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers should also consider local climatic conditions that may affect aluminum’s performance.

How Does Stainless Steel Enhance Bry-Air Product Durability?

Stainless steel is another popular material used in Bry-Air products, known for its excellent corrosion resistance and high-temperature tolerance, with ratings often exceeding 300°C.

Pros: Its durability makes it ideal for harsh environments, ensuring a longer lifespan for equipment. Stainless steel also has a high strength-to-weight ratio, making it suitable for various applications.

Cons: The primary drawback is its higher cost compared to aluminum. Additionally, stainless steel can be more challenging to fabricate, which may increase manufacturing complexity.

Impact on Application: Stainless steel is highly compatible with aggressive media and is particularly effective in applications requiring high hygiene standards, such as pharmaceuticals and food processing.

Considerations for International Buyers: Buyers should ensure compliance with standards like JIS and ASTM, especially in regions where hygiene is paramount. The higher initial investment may be justified by the long-term savings on maintenance and replacement.

What Role Does Polypropylene Play in Bry-Air Systems?

Polypropylene is a thermoplastic polymer used in Bry-Air’s filtration systems due to its chemical resistance and lightweight properties. It can withstand temperatures up to 100°C.

Pros: Polypropylene is cost-effective and offers good resistance to a wide range of chemicals, making it suitable for various applications. Its lightweight nature also aids in easy handling and installation.

Cons: While it is resistant to many chemicals, polypropylene can be less durable than metals, particularly under high-stress conditions. It may also deform under high temperatures.

Impact on Application: This material is ideal for applications involving moisture control and filtration, particularly where chemical exposure is a concern.

Considerations for International Buyers: Buyers should verify that polypropylene components meet local and international standards to ensure reliability in diverse environments.

How Does Silica Gel Contribute to Bry-Air’s Efficiency?

Silica gel is a crucial component in Bry-Air’s desiccant dehumidifiers, known for its high moisture absorption capacity and effectiveness in low humidity conditions.

Pros: Silica gel is highly efficient at absorbing moisture, making it ideal for applications requiring low humidity levels. It is also non-toxic and environmentally friendly.

Cons: While silica gel is effective, it can become saturated and require periodic replacement, which may lead to additional operational costs.

Impact on Application: Silica gel is particularly effective in environments needing precise humidity control, such as electronics manufacturing and food storage.

Considerations for International Buyers: Ensure that silica gel meets relevant safety and performance standards, especially in regions with strict environmental regulations.

Summary Table of Material Selection for Bry-Air USA

| Material | Typical Use Case for Bry-Air USA | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Dehumidifiers and filtration systems | Lightweight and cost-effective | Susceptible to galvanic corrosion | Medium |

| Stainless Steel | Harsh environments, food/pharma | Excellent durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Polypropylene | Filtration systems | Cost-effective and chemically resistant | Less durable under high stress | Low |

| Silica Gel | Desiccant dehumidifiers | High moisture absorption capacity | Requires periodic replacement | Medium |

This strategic material selection guide serves as a valuable resource for B2B buyers looking to optimize their equipment choices while ensuring compliance with international standards and regional preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for bry air usa

What Are the Main Stages of Manufacturing at Bry-Air USA?

Bry-Air USA employs a robust manufacturing process that ensures the delivery of high-quality dehumidification and air control solutions. The typical stages of manufacturing include material preparation, forming, assembly, and finishing.

Material Preparation

The manufacturing process begins with the careful selection and preparation of raw materials. Bry-Air sources high-grade components such as silica gel, metal alloys, and advanced plastics. These materials undergo rigorous quality checks to ensure they meet industry specifications and standards. Suppliers are evaluated based on their ability to deliver consistent quality, and materials are tested for properties such as moisture absorption capacity and durability.

Forming Techniques

Once the materials are prepared, they undergo various forming techniques. For metal components, processes such as CNC machining and laser cutting are utilized to achieve precise dimensions. Plastic parts are typically produced using injection molding techniques, which allow for high-volume production while maintaining tight tolerances. The use of automated machinery in forming processes enhances efficiency and reduces the likelihood of human error, crucial for maintaining consistent quality.

Assembly Process

The assembly stage is where the dehumidifiers and related systems take shape. Bry-Air employs both automated and manual assembly techniques to ensure each unit is assembled correctly. Skilled technicians oversee the assembly, ensuring that each component is fitted accurately. The assembly lines are designed for flexibility, allowing for the production of various models without significant downtime.

Finishing Touches

Finishing processes include powder coating and quality checks. Powder coating not only enhances the aesthetic appeal of the products but also provides additional protection against corrosion and wear. After finishing, each unit undergoes a series of quality control checks to ensure it meets Bry-Air’s stringent performance standards. This final inspection is critical, as it verifies that the product is ready for deployment in demanding industrial environments.

How Does Bry-Air Ensure Quality Control Throughout the Manufacturing Process?

Quality assurance at Bry-Air is integral to their manufacturing process and adheres to international standards, particularly ISO 9001. This commitment to quality is reflected in their systematic approach to quality control.

What International Standards Guide Bry-Air’s Quality Assurance Practices?

Bry-Air’s adherence to ISO 9001 ensures a structured framework for quality management. This standard emphasizes continuous improvement and customer satisfaction. In addition to ISO 9001, Bry-Air also complies with industry-specific standards such as CE marking for products sold in the European market and API standards for applications in the petroleum and petrochemical industries.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are embedded at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves testing raw materials upon receipt to verify they meet specified quality standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, inspections are conducted at various stages to ensure that components are being produced within the required tolerances and specifications.

-

Final Quality Control (FQC): After assembly and finishing, each product undergoes a final inspection. This includes performance testing to confirm that the product operates according to design specifications.

What Common Testing Methods Are Employed by Bry-Air?

Bry-Air employs several testing methods to ensure product reliability and performance. Common tests include:

-

Moisture Absorption Tests: To verify the efficiency of desiccant materials used in the dehumidifiers.

-

Pressure Testing: Ensures that the units can withstand operational pressures without failure.

-

Operational Testing: Each unit is run through its paces in a controlled environment to confirm its performance metrics, such as airflow and moisture removal capabilities.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial in maintaining product integrity and reliability.

What Steps Can B2B Buyers Take to Audit Quality Control Practices?

-

Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should request access to quality management systems and any relevant certifications.

-

Request Quality Reports: Buyers can ask for detailed quality assurance reports that outline the processes and results of various quality checks performed throughout production.

-

Engage Third-Party Inspections: Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. These inspections can be particularly valuable for verifying compliance with international standards.

Are There Any Nuances in Quality Control for International B2B Buyers?

Yes, international B2B buyers must navigate various nuances related to quality control. Factors such as regional standards, language barriers, and differing regulations can impact the quality assurance processes.

How Should Buyers Approach Different Quality Standards?

Buyers should familiarize themselves with the relevant quality standards in their region and how these may differ from those upheld by their suppliers. It is essential to ensure that the products they are purchasing not only meet the supplier’s standards but also comply with local regulations and industry requirements.

What Additional Considerations Should B2B Buyers Keep in Mind?

When dealing with international suppliers, buyers should consider the potential for discrepancies in quality assurance practices due to cultural differences or varying levels of regulatory enforcement. Engaging in open communication about quality expectations and maintaining a collaborative relationship can significantly enhance the reliability of the supply chain.

In conclusion, Bry-Air USA’s commitment to quality through a structured manufacturing process and adherence to international standards positions them as a reliable partner for B2B buyers seeking effective dehumidification solutions. By understanding the manufacturing and quality assurance processes, buyers can make informed decisions that align with their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bry air usa’

In this practical sourcing guide, international B2B buyers will find a step-by-step checklist tailored for procuring solutions from Bry-Air USA. This guide aims to streamline the purchasing process, ensuring that businesses in Africa, South America, the Middle East, and Europe can effectively meet their humidity control needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. Consider the specific applications for which you need Bry-Air products, such as industrial dehumidifiers or gas phase filtration systems. Identifying parameters like airflow capacity, dew point, and installation space will help you select the most suitable equipment for your operational needs.

Step 2: Research Bry-Air Product Range

Familiarize yourself with the diverse range of products Bry-Air offers. From compact desiccant dehumidifiers to advanced adsorption chillers, understanding the features and capabilities of each option is crucial. Pay attention to energy efficiency ratings, maintenance requirements, and any industry-specific solutions that align with your business operations.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request detailed company profiles, case studies, and references from other buyers within your industry or region. This step ensures that you are partnering with a reputable supplier capable of delivering quality products and reliable after-sales support.

Step 4: Check for Certifications and Compliance

Ensure that the products you are considering comply with international standards and certifications relevant to your industry. Check for certifications such as ISO, CE, or UL, which demonstrate a commitment to quality and safety. Compliance with these standards can prevent costly delays and complications during installation and operation.

Step 5: Assess Warranty and Support Services

Examine the warranty terms and support services offered by Bry-Air. A robust warranty not only protects your investment but also indicates the manufacturer’s confidence in their products. Additionally, inquire about after-sales service, including technical support, maintenance plans, and availability of spare parts.

Step 6: Request Quotations and Compare Pricing

Once you have narrowed down your options, request detailed quotations from your shortlisted suppliers. Ensure that the quotes include all relevant costs such as shipping, installation, and potential customs duties. Comparing these quotations will help you make an informed decision while considering your budget constraints.

Step 7: Finalize the Purchase Agreement

After selecting the most suitable supplier and product, finalize the purchase agreement. Pay close attention to the terms of payment, delivery schedules, and installation timelines. A clear contract will help avoid misunderstandings and ensure that both parties are aligned on expectations throughout the procurement process.

By following this checklist, international buyers can effectively navigate the sourcing process for Bry-Air USA products, ensuring they select the right solutions for their humidity and moisture control challenges.

Comprehensive Cost and Pricing Analysis for bry air usa Sourcing

What Are the Key Cost Components in Sourcing Bry-Air Products?

When considering sourcing from Bry-Air USA, understanding the cost structure is essential. The primary cost components include:

-

Materials: The quality and type of materials significantly influence the pricing of Bry-Air products. High-performance components, such as advanced desiccants and specialized filters, can drive up costs. Buyers should inquire about material specifications to ensure they meet their operational needs without overspending.

-

Labor: Labor costs encompass the workforce involved in manufacturing, assembly, and installation. Bry-Air’s commitment to quality and innovation may require skilled labor, which can impact overall pricing. Understanding the labor dynamics in Bry-Air’s production facilities can help buyers gauge potential cost variations.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance. Bry-Air’s extensive manufacturing capabilities, including 13 facilities worldwide, contribute to operational efficiency but also add to overhead costs that are reflected in product pricing.

-

Tooling: Specific tooling and machinery required for manufacturing certain products can add to costs. Custom solutions may necessitate unique tooling, which can lead to higher upfront expenses.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with industry standards. While this adds to the overall cost, it also guarantees that buyers receive high-quality, dependable products.

-

Logistics: Transportation and shipping costs are critical, especially for international buyers. Factors such as distance, shipping method, and tariffs can significantly affect the final price.

-

Margin: Bry-Air, like any manufacturer, includes a profit margin in its pricing. This margin can vary based on product type, market demand, and competitive landscape.

What Influences Pricing for Bry-Air Products?

Several factors can influence pricing when sourcing Bry-Air products:

-

Volume/MOQ: Larger orders often lead to reduced per-unit costs. Buyers should consider negotiating minimum order quantities (MOQs) to take advantage of bulk pricing.

-

Specifications and Customization: Custom products tailored to specific applications may incur additional costs. Buyers should clearly communicate their requirements to receive accurate quotes.

-

Materials: As mentioned earlier, the choice of materials directly impacts pricing. High-grade materials that enhance performance may lead to higher costs, but they can also provide long-term savings through efficiency.

-

Quality and Certifications: Products with recognized certifications (e.g., ISO, CE) may command higher prices due to the assurance of quality and compliance. Buyers should evaluate the importance of these certifications in their purchasing decisions.

-

Supplier Factors: The relationship with suppliers, including their reliability and service levels, can influence pricing. Established suppliers like Bry-Air may charge a premium for their reputation and customer support.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost and should be factored into pricing negotiations.

What Are Some Buyer Tips for Cost-Efficiency When Sourcing Bry-Air Products?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Wisely: Leverage volume discounts and establish long-term relationships with suppliers to negotiate better pricing and terms.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, energy efficiency, and operational costs. Investing in higher-quality equipment may yield savings over time.

-

Understand Pricing Nuances: Be aware of currency fluctuations, import duties, and other factors that can affect final pricing. Stay informed about market conditions in both the supplier’s and buyer’s countries.

-

Request Detailed Quotes: Ask for itemized quotes that break down costs. This transparency helps identify areas where savings can be achieved.

-

Research Competitors: Understanding alternative suppliers and their offerings can empower buyers to negotiate better terms with Bry-Air.

Disclaimer

Pricing information provided is indicative and subject to change based on market conditions, product specifications, and buyer negotiations. Always consult directly with Bry-Air or authorized distributors for the most accurate and current pricing.

Alternatives Analysis: Comparing bry air usa With Other Solutions

Introduction: Understanding Alternatives in Dehumidification Solutions

In the realm of industrial dehumidification, selecting the right technology is crucial for optimizing production processes and maintaining product integrity. While Bry-Air USA offers a robust range of desiccant dehumidifiers and moisture control solutions, there are viable alternatives that cater to various industrial needs. Evaluating these options based on performance, cost, ease of implementation, maintenance, and best use cases can help B2B buyers make informed decisions tailored to their specific operational requirements.

Comparison Table

| Comparison Aspect | Bry-Air USA | Alternative 1: Refrigerant Dehumidifiers | Alternative 2: Peltier Dehumidifiers |

|---|---|---|---|

| Performance | High efficiency, low dew points, ideal for variable humidity | Effective in high humidity, limited low dew points | Best for small spaces, low humidity levels |

| Cost | Higher initial investment, but low operational costs | Moderate initial cost, higher energy consumption | Lower initial cost, but limited efficiency |

| Ease of Implementation | Requires professional installation, adaptable to various settings | Generally easier to install, often portable | Very easy to install, plug-and-play units |

| Maintenance | Moderate; requires regular servicing | Low; simple maintenance routines | Very low; minimal servicing needed |

| Best Use Case | Industrial applications requiring precise humidity control | Warehouses, manufacturing with high humidity | Home use, small commercial spaces |

Detailed Breakdown of Alternatives

Refrigerant Dehumidifiers

Refrigerant dehumidifiers operate by cooling air to condense moisture, making them effective in high-humidity environments. They are generally easier to install, often available as portable units suitable for various applications. However, they have limitations in achieving low dew points, which can be a disadvantage in sensitive industrial processes. While the initial investment is moderate, their operational costs can be higher due to energy consumption, making them less economical over time in environments that require continuous operation.

Peltier Dehumidifiers

Peltier dehumidifiers utilize thermoelectric cooling, making them ideal for smaller spaces where humidity control is essential. They are very easy to install and operate, often requiring only a power outlet. The initial investment is relatively low, making them attractive for budget-conscious buyers. However, they are less efficient in large-scale applications and may struggle to maintain low humidity levels in high-demand environments. Their limited capacity makes them suitable primarily for home or small commercial applications rather than extensive industrial use.

Conclusion: Choosing the Right Dehumidification Solution

When selecting a dehumidification solution, B2B buyers must consider their specific operational requirements, including the scale of application, desired humidity levels, and budget constraints. Bry-Air USA’s advanced desiccant technology is particularly suited for industries that demand precise humidity control, despite its higher initial cost. Conversely, refrigerant and Peltier dehumidifiers offer flexibility and lower upfront costs but may not meet the stringent needs of all industrial environments. By evaluating these alternatives against their unique needs, buyers can make a strategic decision that enhances operational efficiency and product quality.

Essential Technical Properties and Trade Terminology for bry air usa

What Are the Key Technical Properties of Bry-Air Products?

Understanding the essential technical properties of Bry-Air products is crucial for B2B buyers looking to make informed purchasing decisions. Here are some critical specifications that define the effectiveness and efficiency of these industrial solutions:

-

Airflow Capacity (CFM)

Airflow capacity, measured in cubic feet per minute (CFM), indicates the volume of air a dehumidifier can process. For instance, the Bry-Air BrySmart® Dehumidifiers range from 10,000 to over 100,000 CFM. A higher CFM is essential for large-scale applications in industries such as pharmaceuticals and food processing, where moisture control is vital for product quality and safety. -

Dew Point Temperature

The dew point is the temperature at which air becomes saturated with moisture, leading to condensation. Bry-Air dehumidifiers can achieve dew points as low as -40°C. This capability is particularly important in environments like lithium battery production, where even minimal moisture can impact product integrity and performance. -

Energy Efficiency Ratio (EER)

The Energy Efficiency Ratio measures the energy output for every unit of energy consumed, which is critical for operational cost management. Bry-Air’s products are designed to minimize energy consumption while maximizing moisture removal, providing a sustainable solution that can lead to significant savings over time. -

Material Grade and Construction

The construction materials of dehumidifiers, such as corrosion-resistant metals or high-grade polymers, ensure durability and longevity. Bry-Air employs advanced materials that withstand harsh industrial environments, reducing maintenance costs and downtime, which is crucial for continuous operations in sectors like manufacturing and agriculture. -

Operating Temperature Range

The operational temperature range indicates the environmental conditions under which the equipment can function effectively. Bry-Air products can operate in extreme temperatures, from sub-zero conditions to 104°F (40°C). This versatility allows businesses in diverse climates to utilize Bry-Air solutions without compromising performance. -

Moisture Removal Rate

This specification, often expressed in pints per day (ppd), quantifies how much moisture a dehumidifier can extract from the air. For example, the Bry-Air MP100 MiniPAC can remove approximately 75.6 pints per day at 80°F and 60% relative humidity. This metric is critical for applications requiring precise humidity control, such as in data centers or cold storage facilities.

What Are Common Trade Terms Relevant to Bry-Air Buyers?

Familiarizing oneself with industry-specific terminology can enhance communication and streamline procurement processes. Here are several common trade terms that are particularly relevant for international buyers:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Bry-Air, it means that their dehumidifiers and related equipment are often supplied to other brands, ensuring high-quality standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to gauge their purchasing capabilities and negotiate effectively with Bry-Air, especially when planning for large-scale projects or multiple installations. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to invite suppliers to submit price proposals for specific products or services. For international buyers, issuing an RFQ to Bry-Air can help clarify pricing structures and lead times, enabling better budget management. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers. Familiarity with Incoterms is crucial for international transactions to avoid misunderstandings regarding shipping, insurance, and delivery responsibilities. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Knowing the lead times for Bry-Air products can help businesses plan their operations and avoid disruptions, particularly in industries where timely humidity control is essential.

By understanding these technical properties and trade terms, international B2B buyers can make more informed decisions when engaging with Bry-Air USA, ensuring they select the right solutions for their specific industry needs.

Navigating Market Dynamics and Sourcing Trends in the bry air usa Sector

What are the Current Market Dynamics and Key Trends in the Bry-Air USA Sector?

The Bry-Air sector is experiencing significant growth driven by an increasing global focus on climate control and moisture management across various industries. Key drivers include the rising demand for efficient dehumidification solutions in manufacturing, pharmaceuticals, food processing, and electronics. As international buyers from regions like Africa, South America, the Middle East, and Europe seek reliable partners, they must navigate a market characterized by technological advancements in desiccant dehumidifiers and gas phase filtration systems. The integration of Industry 4.0 principles is also reshaping sourcing strategies, with buyers favoring products like Bry-Air’s BrySmart® Dehumidifiers, which offer continuous performance optimization.

Emerging trends highlight the growing importance of energy-efficient solutions. As industries strive to reduce operational costs, products that minimize energy consumption, such as the Wonder Dryer and Adsorption Chillers, are gaining traction. Additionally, the emphasis on reliability and after-sales service is paramount for international buyers, who often seek suppliers with proven track records in diverse markets. Understanding these dynamics will empower B2B buyers to make informed decisions that align with their operational goals and market demands.

How is Sustainability and Ethical Sourcing Relevant in the Bry-Air USA Sector?

Sustainability is becoming a critical consideration in B2B purchasing decisions, particularly for international buyers who are increasingly aware of environmental impacts. The Bry-Air USA sector is committed to minimizing its ecological footprint through innovative product designs that enhance energy efficiency and reduce waste. For instance, the use of adsorption chillers and energy-efficient dehumidifiers not only lowers operational costs but also contributes to a greener supply chain.

The importance of ethical sourcing cannot be overstated. B2B buyers are urged to collaborate with suppliers who prioritize sustainable practices and transparency in their supply chains. This includes the use of green certifications and materials that meet international environmental standards. By choosing suppliers like Bry-Air, which invests in patented technologies and adheres to stringent environmental regulations, buyers can ensure that their sourcing decisions align with their corporate social responsibility goals. This commitment to sustainability is not only beneficial for the environment but also enhances brand reputation in increasingly eco-conscious markets.

What is the Evolution and History of Bry-Air in the B2B Context?

Bry-Air has a rich legacy spanning over six decades, emerging as a pioneer in dehumidification and environmental control solutions. Founded on patented technology, the company has consistently evolved its product offerings to meet the changing needs of various industries. With installations in over 80 countries and a robust manufacturing presence, Bry-Air has established itself as a trusted partner for B2B buyers seeking advanced humidity control solutions.

The company’s focus on research and development has led to significant innovations, such as the compact desiccant dehumidifiers and specialized systems for lithium battery dry rooms. This commitment to excellence and innovation has allowed Bry-Air to maintain a competitive edge in the global market, making it an attractive option for international buyers looking for reliable and effective moisture management solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of bry air usa

-

How do I solve humidity-related issues in my facility?

To address humidity-related challenges, consider implementing Bry-Air’s industrial desiccant dehumidifiers tailored to your specific application. These units effectively manage moisture levels, preventing condensation, electronic corrosion, and product spoilage. Start by assessing your facility’s humidity levels and identifying critical areas that require dehumidification. Bry-Air offers a range of solutions, from compact systems for small spaces to large-scale setups for extensive operations, ensuring you find the right fit for your needs. -

What is the best dehumidification solution for food processing industries?

For food processing, Bry-Air’s specialized dehumidifiers are designed to maintain optimal humidity levels, preventing spoilage and ensuring product quality. The Mould Dehumidification System, for example, helps avoid mould growth and reduces cycle times. When selecting a solution, consider factors such as the size of your operation, the specific humidity challenges you face, and your energy efficiency goals. Consulting with Bry-Air’s experts can help you identify the most effective system for your requirements. -

Can Bry-Air products be customized for specific industry needs?

Yes, Bry-Air understands that different industries have unique requirements. Their products can be customized based on specific application needs, including airflow capacity, energy efficiency, and additional features like remote monitoring. Engaging with their technical team during the purchasing process will allow you to discuss your requirements in detail and ensure the solution is tailored to your operational challenges. -

What is the minimum order quantity (MOQ) for Bry-Air products?

The minimum order quantity for Bry-Air products may vary depending on the specific equipment and your location. Typically, larger orders may benefit from better pricing and terms. It’s advisable to consult with a Bry-Air representative to discuss your needs and determine the MOQ applicable to your order, especially for international shipments. -

What payment terms can I expect when purchasing from Bry-Air?

Bry-Air offers flexible payment terms tailored to meet the needs of international B2B buyers. Common arrangements may include upfront payments, net terms, or financing options, depending on the order size and buyer’s creditworthiness. It’s crucial to discuss payment options with your sales representative to align on terms that suit your business model. -

What quality assurance measures does Bry-Air have in place?

Bry-Air is committed to maintaining high-quality standards across its product range. They employ rigorous testing protocols and adhere to international quality certifications. Each product undergoes thorough inspections during manufacturing to ensure reliability and performance. Buyers can request specific quality assurance documentation to verify compliance with industry standards. -

How does Bry-Air handle logistics and international shipping?

Bry-Air has extensive experience in international logistics, ensuring efficient delivery of products worldwide. They collaborate with trusted freight partners to manage customs clearance, shipping timelines, and delivery to your specified location. For optimal coordination, it is recommended to communicate your shipping requirements upfront, allowing Bry-Air to provide accurate shipping estimates and timelines. -

What support services does Bry-Air offer post-purchase?

Bry-Air prides itself on exceptional customer support, providing comprehensive after-sales services including installation assistance, maintenance, and troubleshooting. Their technical support team is available for ongoing consultations, ensuring your dehumidification systems operate efficiently. Buyers can also benefit from training sessions for their staff to maximize the effectiveness of the equipment and address any operational challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for bry air usa

In the evolving landscape of industrial solutions, Bry-Air USA stands out as a leader in dehumidification technology, offering a diverse range of products tailored to meet the specific needs of various industries. With over six decades of experience and a commitment to innovation, Bry-Air provides effective solutions that tackle moisture-related challenges across sectors such as pharmaceuticals, food processing, and electronics. Their patented desiccant technology ensures optimal performance in environments where humidity control is critical.

For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, strategic sourcing from Bry-Air represents an opportunity to enhance operational efficiency and product quality. The company’s global presence, with installations in over 80 countries and a robust after-sales support system, underscores their reliability as a partner.

Looking ahead, the demand for advanced moisture control solutions will only grow, driven by the need for sustainable practices and product integrity. Engaging with Bry-Air USA today can position your organization at the forefront of innovation and efficiency. Explore how their tailored solutions can meet your unique requirements and drive your business forward.