Top 6 Usa Ports List and Guide: How To Solve Scenario 1: Navigati…

Introduction: Navigating the Global Market for usa ports

Navigating the complex landscape of USA ports can present significant challenges for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. Understanding how to effectively source and utilize these critical gateways for global trade is essential for maintaining competitive advantage. This guide delves into the diverse types of ports across the United States, offering insights into their applications, operational capacities, and the vital role they play in international logistics.

From the bustling container terminals of Los Angeles to the strategic hubs along the East Coast, each port offers unique advantages and operational efficiencies. This comprehensive resource provides essential information on supplier vetting processes, cost considerations, and logistical best practices. By equipping B2B buyers with the knowledge to make informed purchasing decisions, this guide aims to streamline the sourcing process, ultimately enhancing supply chain efficiency and reducing operational risks.

International buyers, whether in Nigeria or Germany, will find actionable insights tailored to their specific needs, helping them navigate port selection and optimize their import-export strategies. With a focus on strategic planning and informed decision-making, this guide empowers businesses to harness the full potential of USA ports in their global operations.

Top 10 Usa Ports Manufacturers & Suppliers List

1. Cockett USA – Key Product Offerings

Domain: cockettgroup.com

Registered: 2001 (24 years)

Introduction: Cockett USA offers a range of products at various ports along the East Coast of the USA. The key details include:

– Baltimore, MD: 4,000 L minimum order quantity

– Boston, MA: 6,000 L (packed bulk), 12,000 L (drum)

– Bridgeport, CT: 19,000 L

– Charleston, SC: 10,000 L

– Ft Lauderdale (Port Everglades), FL: 6,000 L

– Hampton Roads (Norfolk), VA: 6,000 L

– Jacksonville, FL: 10,000 L

– Miami,…

2. Pangea Network – Top Ports in the USA 2025

Domain: pangea-network.com

Registered: 2010 (15 years)

Introduction: Top 10 Busiest and Biggest Ports in the USA in 2025: 1. Port of Los Angeles, California – 9,911,159 TEUs, -14.53% change, 5,015,315 imports, 4,895,844 exports. 2. Port of Long Beach, California – 9,133,657 TEUs, -2.67% change, 4,526,997 imports, 4,606,660 exports. 3. Port of New York and New Jersey – 9,493,664 TEUs, +5.7% change, 4,825,075 imports, 4,668,589 exports. 4. Port of Savannah, Georgia -…

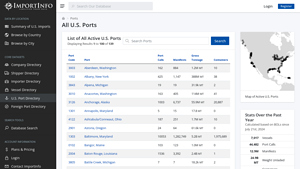

3. ImportInfo – U.S. Ports Data Summary

Domain: importinfo.com

Registered: 2002 (23 years)

Introduction: United States Ports Data by Location Summary of U.S. Imports includes details such as Port Code, Port Name, Port Calls, Manifests, Gross Tonnage, and Containers for various U.S. ports. Key statistics include: 1. Charleston, South Carolina – 10,805 port calls, 2.604M manifests, 1.4B MT gross tonnage, 4,608,018 containers. 2. Houston, Texas – 22,357 port calls, 4.508M manifests, 23.3B MT gross tonna…

4. Marine Insight – Major U.S. East Coast Ports Overview

Domain: marineinsight.com

Registered: 2010 (15 years)

Introduction: The text provides details about major U.S. East Coast ports, including the Port of New York and New Jersey, Port of Savannah, and Port of Virginia. Key details include: Port of New York and New Jersey handles various cargo types, has 6 container terminals, and deepened its harbor to 50 feet to accommodate larger vessels. Port of Savannah features the largest single-terminal container area in North…

5. Reddit – Busiest US Ports by TEUs

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Busiest ports in the US as measured in imported TEUs, indicating a continued eastward shift in activity.

6. Cushman & Wakefield – US Port TEU Growth Analysis

Understanding usa ports Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Container Ports | Specialized terminals for containerized cargo | Import/export of manufactured goods | Pros: High efficiency, strong connectivity. Cons: Congestion during peak seasons. |

| Bulk Ports | Facilities designed for bulk cargo (liquid or solid) | Agriculture, minerals, and chemicals trade | Pros: Suitable for large volumes. Cons: Limited to specific cargo types. |

| Breakbulk Ports | Handle cargo that is not containerized or bulk | Heavy machinery, project cargo | Pros: Flexibility in cargo types. Cons: Slower handling compared to container ports. |

| Ro-Ro (Roll-on/Roll-off) Ports | Designed for wheeled cargo like vehicles | Automotive imports and exports | Pros: Quick loading/unloading. Cons: Limited to wheeled cargo only. |

| Multi-Purpose Ports | Accommodate various cargo types and shipping methods | Diverse industries, including retail and manufacturing | Pros: Versatility in handling cargo. Cons: May lack specialization, affecting efficiency. |

What Are the Characteristics of Container Ports?

Container ports are integral to global trade, designed specifically for the efficient handling of containerized cargo. These ports typically feature advanced loading and unloading equipment, such as cranes and automated systems, which streamline operations. Their strategic locations near major population centers enhance their appeal, as they provide easy access to distribution networks. For B2B buyers, the efficiency and speed of container ports make them ideal for importing and exporting manufactured goods, though congestion during peak seasons can pose challenges.

How Do Bulk Ports Differ from Other Types?

Bulk ports are specialized facilities that cater to bulk cargo, either liquid or solid, such as grains, coal, and chemicals. They are equipped with specific handling systems designed for large quantities, allowing for the efficient transfer of goods. This type of port is particularly suited for industries dealing in agriculture, minerals, and chemicals, where large volumes are a common requirement. Buyers should consider the suitability of bulk ports for their needs, as their limitations on cargo types may restrict flexibility.

Why Choose Breakbulk Ports for Heavy Cargo?

Breakbulk ports are designed to handle cargo that cannot be easily containerized, such as heavy machinery and project cargo. They offer flexibility in terms of cargo types and sizes, accommodating various shipping methods. This adaptability makes breakbulk ports a valuable option for businesses involved in heavy industries or construction projects. However, the trade-off is that handling times may be longer compared to container ports, which can impact supply chain efficiency.

What Are the Advantages of Ro-Ro Ports?

Ro-Ro ports, or Roll-on/Roll-off ports, are specifically designed for vehicles and other wheeled cargo. Their loading and unloading processes are quick and efficient, allowing vehicles to be driven on and off vessels with ease. This type of port is particularly beneficial for automotive imports and exports, where speed and efficiency are critical. However, buyers should note that Ro-Ro ports are limited to wheeled cargo, which may not suit all business needs.

How Do Multi-Purpose Ports Serve Diverse Industries?

Multi-purpose ports are versatile facilities that can accommodate various types of cargo and shipping methods. This flexibility allows them to serve a wide range of industries, from retail to manufacturing. While the versatility of multi-purpose ports can be advantageous for businesses requiring different logistics solutions, it may also lead to inefficiencies compared to specialized ports. Buyers should assess their specific needs and consider whether the multi-purpose nature aligns with their logistics strategies.

Key Industrial Applications of usa ports

| Industry/Sector | Specific Application of USA Ports | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Importing and exporting bulk commodities | Access to global markets for agricultural products | Quality of logistics, customs regulations, and tariffs |

| Manufacturing | Supply chain logistics for raw materials | Efficient transport of raw materials and finished goods | Proximity to manufacturing hubs and intermodal facilities |

| Energy | Transporting oil, gas, and renewable energy | Reliable access to energy resources | Infrastructure for handling hazardous materials |

| Retail | Distribution of consumer goods | Faster delivery times to end consumers | Inventory management and warehousing options |

| Pharmaceuticals | Importing medical supplies and equipment | Timely access to critical health products | Compliance with health regulations and customs clearance |

How Are USA Ports Utilized in Agriculture for International Trade?

USA ports serve as vital gateways for agricultural exports and imports, particularly for commodities like grains, fruits, and vegetables. They provide access to global markets, enabling businesses to reach consumers in Africa, South America, and Europe. Efficient logistics at these ports ensure that products are transported swiftly, maintaining freshness and quality. Buyers must consider the quality of logistics services, customs regulations, and potential tariffs when sourcing agricultural goods through USA ports.

What Role Do USA Ports Play in Manufacturing Supply Chains?

In the manufacturing sector, USA ports are crucial for the importation of raw materials and the exportation of finished products. Ports located near major manufacturing hubs facilitate the seamless movement of goods, enhancing supply chain efficiency. This connectivity is essential for reducing lead times and managing costs. International buyers need to assess the proximity of ports to manufacturing sites and the availability of intermodal transport options to optimize their logistics strategies.

How Are USA Ports Essential for the Energy Sector?

The energy industry heavily relies on USA ports for the transportation of oil, gas, and renewable energy resources. Ports equipped with specialized facilities for handling hazardous materials ensure safe and efficient operations. This access is critical for energy companies looking to maintain a reliable supply chain. Buyers in the energy sector should focus on the infrastructure capabilities of ports, including storage facilities and compliance with environmental regulations, to ensure smooth operations.

How Do USA Ports Support Retail Distribution?

For the retail sector, USA ports provide a strategic advantage in distributing consumer goods. They enable quick turnaround times from import to retail shelves, which is crucial in a competitive market. Efficient port operations can significantly reduce delivery times and improve inventory turnover rates. Retailers should consider the logistics capabilities of ports, including warehousing options and customs processing times, to enhance their supply chain efficiency.

What Is the Importance of USA Ports in Pharmaceuticals?

In the pharmaceutical industry, USA ports play a critical role in importing medical supplies and equipment. Timely access to these products is essential for healthcare providers and patients. Ports must comply with strict health regulations, ensuring that all goods meet safety standards before entering the market. International buyers should prioritize ports that have streamlined customs processes and strong compliance records to avoid delays in critical shipments.

3 Common User Pain Points for ‘usa ports’ & Their Solutions

Scenario 1: Navigating Complex Customs Regulations

The Problem:

B2B buyers often face significant challenges when importing goods through U.S. ports due to complex customs regulations. For instance, a company based in Germany may struggle with understanding the specific documentation and compliance requirements necessary to clear goods through U.S. Customs and Border Protection (CBP). Delays can lead to increased costs, lost business opportunities, and strained relationships with clients who are waiting for their shipments. Furthermore, misinterpretation of regulations can result in fines or additional duties that were not anticipated.

The Solution:

To effectively navigate these complexities, B2B buyers should invest in a comprehensive understanding of U.S. customs regulations relevant to their specific products. Engaging a knowledgeable customs broker can be invaluable; they can assist in preparing the necessary documentation, ensuring compliance, and providing insights into tariff classifications. Additionally, leveraging technology solutions like customs management software can streamline the documentation process and offer real-time updates on the status of shipments. Regular training sessions for staff on customs compliance can also mitigate risks and enhance operational efficiency.

Scenario 2: Managing Unpredictable Shipping Delays

The Problem:

Unpredictable shipping delays are a common pain point for international buyers using U.S. ports. For example, a buyer in Nigeria might face unexpected hold-ups due to port congestion or adverse weather conditions, leading to a cascading effect on their supply chain. Such delays not only disrupt inventory management but can also jeopardize contracts with local customers who rely on timely deliveries. These challenges can result in financial losses and damage to a company’s reputation.

The Solution:

To mitigate shipping delays, B2B buyers should establish strong relationships with multiple freight forwarders who have expertise in U.S. ports. This diversification allows for flexibility in routing shipments and securing alternative options in case of delays. Furthermore, implementing a robust logistics management system can provide visibility into shipment tracking and expected delivery times. Regular communication with shipping partners and proactive planning for potential disruptions—such as seasonal weather patterns or peak shipping times—can also help in maintaining supply chain continuity.

Scenario 3: Understanding Port Fees and Cost Structures

The Problem:

Many international buyers are caught off guard by the various fees associated with using U.S. ports. A company from South America may find itself facing unexpected charges such as port handling fees, storage fees, and demurrage charges, which can significantly increase the total cost of shipping. Without a clear understanding of these costs, buyers may struggle to budget accurately, leading to financial strain and potential project delays.

The Solution:

To address the issue of port fees, buyers should conduct thorough research on the specific fee structures of the ports they plan to use. Engaging with local logistics consultants or port authorities can provide clarity on all applicable charges and help buyers anticipate costs more accurately. Additionally, buyers should ask their freight forwarders for a detailed breakdown of expected fees prior to shipping. Negotiating terms with shipping companies for better rates or exploring consolidation services can also minimize overall shipping costs. By proactively managing expectations around port fees, buyers can enhance their budgeting processes and reduce the risk of unexpected financial burdens.

Strategic Material Selection Guide for usa ports

What Are the Key Materials Used in USA Ports?

When selecting materials for use in USA ports, several factors come into play, including durability, cost, and compliance with international standards. Here, we analyze four common materials that are critical in port operations.

How Does Steel Perform in Port Applications?

Steel is a widely used material in port infrastructure due to its strength and versatility. Key properties include high tensile strength, excellent load-bearing capacity, and good corrosion resistance when treated. However, it can be susceptible to rust if not properly maintained, especially in coastal environments.

Pros: Steel is durable and can withstand heavy loads, making it suitable for cranes, storage facilities, and other structural applications. It is relatively cost-effective compared to other high-strength materials.

Cons: The need for protective coatings to prevent corrosion can add to maintenance costs. Additionally, steel is heavy, which can complicate transportation and installation.

Impact on Application: Steel is ideal for structures exposed to varying weather conditions, but it requires careful consideration of protective measures against corrosion, especially for international buyers in humid or saline environments.

Considerations for International Buyers: Compliance with ASTM standards is essential. Buyers from regions like Africa and South America should also consider local availability and transportation logistics.

What Role Does Concrete Play in Port Construction?

Concrete is another fundamental material in port construction, known for its compressive strength and durability. It performs well under pressure and is resistant to environmental factors, making it suitable for docks, pavements, and storage areas.

Pros: Concrete is highly durable and requires minimal maintenance over time. Its versatility allows it to be molded into various shapes and sizes, accommodating different design needs.

Cons: Concrete can be prone to cracking under extreme temperature changes, which may necessitate additional reinforcement. The initial cost can also be higher than other materials.

Impact on Application: Concrete is ideal for heavy-load areas, but its weight and rigidity may limit its use in applications requiring flexibility.

Considerations for International Buyers: Buyers should ensure compliance with local building codes and standards, such as DIN in Germany. Understanding the local climate is crucial for selecting the right concrete mix.

How Effective Is Aluminum for Port Equipment?

Aluminum is increasingly used in port applications, particularly for equipment and lightweight structures. It offers excellent corrosion resistance and is lightweight, which enhances ease of handling and installation.

Pros: Aluminum’s lightweight nature allows for easier transportation and installation. It is also resistant to corrosion, making it suitable for marine environments.

Cons: While aluminum is strong, it may not bear as much load as steel or concrete, which limits its use in heavy structural applications. Additionally, it tends to be more expensive than steel.

Impact on Application: Aluminum is ideal for equipment such as ladders, railings, and small structures where weight is a concern. However, it may not be suitable for load-bearing applications.

Considerations for International Buyers: Compliance with JIS standards is important for buyers from Japan and other regions. Understanding the cost implications in comparison to steel is also essential for budget planning.

What Advantages Does Composite Material Offer in Port Operations?

Composite materials are gaining traction in port applications due to their unique properties. They are lightweight, corrosion-resistant, and can be engineered for specific performance characteristics.

Pros: Composites are resistant to environmental degradation and can be tailored for specific applications, making them highly versatile. They also offer significant weight savings.

Cons: The initial cost of composite materials can be high, and their manufacturing process may be complex. Additionally, they may not be as widely available as traditional materials.

Impact on Application: Composites are well-suited for applications requiring resistance to chemicals and moisture, such as in storage tanks or piping systems.

Considerations for International Buyers: Buyers should be aware of the certification requirements for composites, as standards can vary significantly by region. Understanding the supply chain for these materials is crucial.

Summary Table of Material Selection for USA Ports

| Material | Typical Use Case for USA Ports | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components | High strength and load-bearing | Susceptible to corrosion | Medium |

| Concrete | Docks and pavements | Highly durable | Prone to cracking | Medium |

| Aluminum | Equipment and lightweight structures | Corrosion-resistant and lightweight | Limited load-bearing capacity | High |

| Composite | Tanks and piping systems | Customizable and corrosion-resistant | High initial cost and complexity | High |

This guide provides a comprehensive overview of the materials commonly used in USA ports, helping international B2B buyers make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for usa ports

What Are the Main Stages of Manufacturing Processes in USA Ports?

The manufacturing processes involved in the operations of USA ports are vital to their efficiency and effectiveness in handling cargo. These processes generally comprise four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing and preparing raw materials necessary for port operations. This can include steel for constructing cranes, concrete for port infrastructure, and specialized materials for container handling equipment. Quality checks are essential during this phase to ensure that all materials meet the required specifications.

-

Forming: In this stage, raw materials are transformed into usable components through various techniques such as casting, forging, and machining. For instance, large structural components for cranes may be forged from high-strength steel, while components for conveyor systems might be machined for precision.

-

Assembly: The assembly stage integrates the formed components into larger systems or machines. This can involve assembling cranes, container handling systems, and other port machinery. Automated assembly lines may be employed to enhance efficiency and reduce human error, ensuring that each piece of equipment meets operational standards.

-

Finishing: The final stage involves surface treatment, painting, and quality checks to ensure that the equipment is ready for operational deployment. This may include corrosion-resistant coatings to extend the lifespan of port equipment exposed to harsh marine environments.

What Key Techniques Are Utilized in Port Manufacturing?

Various techniques are employed throughout the manufacturing process to enhance efficiency and quality. Some key techniques include:

-

Lean Manufacturing: This technique focuses on minimizing waste while maximizing productivity. Lean principles can help port manufacturers streamline operations, reduce costs, and improve delivery times.

-

Just-In-Time (JIT) Production: JIT production helps to minimize inventory holding costs by producing goods only as they are needed. This technique is particularly beneficial in port operations, where equipment needs can fluctuate based on shipping schedules.

-

Advanced Robotics: The use of robotics in manufacturing processes enhances precision and speed. Automated systems can perform repetitive tasks, such as welding and assembly, reducing the likelihood of human error.

-

Computer Numerical Control (CNC): CNC machines are widely used in port manufacturing for precision machining. These machines can produce complex parts with high accuracy, ensuring that all components meet strict tolerances.

How Is Quality Assurance Implemented in USA Ports?

Quality assurance (QA) is critical in maintaining the operational integrity of port facilities. Various international and industry-specific standards guide QA processes.

-

International Standards: ISO 9001 is one of the most recognized quality management standards globally. It provides a framework for ensuring that organizations consistently meet customer and regulatory requirements. Ports and their suppliers often seek ISO certification to demonstrate their commitment to quality.

-

Industry-Specific Standards: Depending on the equipment and materials involved, additional certifications such as CE (Conformité Européenne) for European markets, and API (American Petroleum Institute) for oil and gas-related equipment may be necessary.

-

Quality Control Checkpoints: Effective QA involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial inspection ensures that all incoming materials meet specified quality standards before they are used in production.

– In-Process Quality Control (IPQC): During manufacturing, IPQC checks are conducted to monitor the quality of ongoing processes, ensuring any defects are caught early.

– Final Quality Control (FQC): After production, FQC involves thorough testing and inspection of finished products to ensure they meet all specifications before shipment.

What Common Testing Methods Are Used in Port Quality Control?

Quality control in port manufacturing employs various testing methods to verify that products meet required standards:

-

Visual Inspection: A basic yet effective method for identifying surface defects and ensuring that components are free from visible flaws.

-

Dimensional Testing: Utilizing tools such as calipers and gauges to verify that components meet specified dimensions.

-

Load Testing: Particularly for lifting equipment, load testing ensures that cranes and hoists can handle specified weights safely.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle inspection allow for the detection of internal flaws without damaging the components.

How Can B2B Buyers Verify Supplier Quality Control Practices?

International B2B buyers must ensure that their suppliers adhere to stringent quality control practices. Here are some strategies for verification:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes, quality control measures, and compliance with international standards. Audits can help identify any potential risks in the supply chain.

-

Requesting Quality Reports: Buyers should request documentation detailing quality control processes, inspection results, and compliance certifications. This documentation can provide assurance of a supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of a supplier’s quality control practices. These inspections can verify compliance with international standards and provide a detailed report on findings.

What Are the Quality Control and Certification Nuances for International Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is crucial, especially when dealing with suppliers from different regions.

-

Cultural Differences: Different countries may have varying attitudes towards quality assurance. Buyers should be aware of these differences and adapt their expectations accordingly.

-

Regulatory Compliance: Buyers must ensure that suppliers comply with both local regulations and international standards. This may involve understanding specific certifications required for different regions, such as the EU’s CE mark for products sold within Europe.

-

Language Barriers: Language can be a barrier in understanding quality documentation and certifications. Buyers should consider engaging local experts or translators to ensure clarity.

-

Supply Chain Transparency: Establishing transparent communication channels with suppliers can help address any quality concerns promptly. Regular updates and open dialogue can enhance trust and collaboration.

In conclusion, understanding the manufacturing processes and quality assurance practices at USA ports is essential for international B2B buyers. By focusing on these key areas, buyers can make informed decisions, ensuring that they partner with suppliers who meet their quality expectations and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘usa ports’

Introduction

Navigating the complexities of sourcing through U.S. ports can be challenging for international B2B buyers. This practical sourcing guide provides a step-by-step checklist to streamline the process, ensuring you make informed decisions that enhance your supply chain efficiency. By following these steps, you can effectively evaluate and select the right U.S. port for your business needs.

Step 1: Identify Your Shipping Requirements

Understanding your shipping needs is the foundation of effective sourcing. Consider the type of goods you will be transporting, their volume, and the desired delivery timelines. This clarity will help you narrow down which ports are best suited for your specific logistics requirements.

– Goods Type: Different ports specialize in various types of cargo, such as containers, bulk materials, or specialized freight.

– Volume and Frequency: Evaluate whether your shipments are one-time or recurring, as this will influence your port selection.

Step 2: Research U.S. Ports and Their Capabilities

Conduct thorough research on the ports you are considering. Look into their operational capabilities, such as cargo handling efficiency, available facilities, and technology used. This assessment will help you determine which ports can meet your logistical demands.

– Port Specialization: Identify ports that specialize in your goods to ensure optimal handling.

– Technology and Infrastructure: Ports with advanced technology and infrastructure can facilitate faster processing times.

Step 3: Evaluate Transportation Connectivity

Assess the transportation links available at each port. A port’s connectivity to rail, road, and air transport is crucial for seamless logistics. Efficient intermodal connections can significantly reduce transit times and costs.

– Proximity to Major Routes: Ports located near major highways and railroads are often more efficient for distribution.

– Access to Warehousing: Consider nearby warehousing options that can support your supply chain.

Step 4: Verify Compliance and Regulatory Standards

Ensure that the ports you are considering comply with international trade regulations and safety standards. Non-compliance can lead to delays and additional costs. Familiarize yourself with customs procedures and any specific certifications required for your goods.

– Customs Procedures: Understand the customs clearance processes at each port to avoid unforeseen delays.

– Safety Regulations: Verify that the port adheres to safety and environmental regulations to ensure smooth operations.

Step 5: Request Quotes and Compare Costs

Once you have shortlisted potential ports, request detailed quotes from each. Compare not only the shipping rates but also additional fees such as handling, storage, and customs clearance. This comprehensive cost analysis will help you identify the most cost-effective option.

– Hidden Costs: Look out for any hidden fees that may not be included in the initial quote.

– Long-term Costs: Consider the total cost of ownership over time, including potential delays and efficiency gains.

Step 6: Consult with Logistics Experts

Engage with logistics professionals or freight forwarders who have experience with U.S. ports. Their insights can provide valuable information on the nuances of port operations, potential challenges, and best practices.

– Local Knowledge: Experts can offer tips on navigating local regulations and optimizing your supply chain.

– Network Recommendations: Leverage their network for referrals to reputable service providers.

Step 7: Finalize Your Decision and Establish Relationships

After thorough evaluation, finalize your port choice and establish relationships with relevant stakeholders, including port authorities and logistics providers. Building a solid partnership will enhance your operations and ensure smoother transactions in the future.

– Long-term Collaboration: Focus on establishing long-term relationships that can provide ongoing support.

– Continuous Evaluation: Regularly assess your port’s performance to ensure it continues to meet your business needs.

By following this checklist, you can effectively navigate the complexities of sourcing through U.S. ports, ensuring a streamlined and efficient process tailored to your business requirements.

Comprehensive Cost and Pricing Analysis for usa ports Sourcing

What Are the Key Cost Components in Sourcing from USA Ports?

When engaging in B2B sourcing through USA ports, understanding the cost structure is vital for effective budgeting and decision-making. The primary cost components typically include:

-

Materials: The choice of materials significantly affects costs. Bulk purchasing or sourcing from suppliers with competitive pricing can yield cost savings.

-

Labor: Labor costs vary by region and the complexity of operations at each port. Ports with automated systems may incur lower labor costs, while those relying on manual processes may see higher expenses.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient port operations can help minimize these overheads.

-

Tooling: For customized orders, tooling costs can be significant. These costs are influenced by the complexity of the tooling required and the volume of the order.

-

Quality Control (QC): Ensuring compliance with international standards necessitates investment in quality control processes. This may include third-party inspections and certifications.

-

Logistics: Transportation costs, including freight and handling fees, are crucial. These vary based on distance, mode of transport, and the efficiency of the logistics network.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the supplier’s pricing strategy can help buyers negotiate better deals.

How Do Price Influencers Affect Sourcing from USA Ports?

Several factors can influence pricing when sourcing through USA ports:

-

Volume/MOQ: Larger order volumes often lead to lower per-unit costs due to economies of scale. Establishing minimum order quantities (MOQs) can impact pricing significantly.

-

Specifications/Customization: Customized products can incur higher costs due to additional labor and material requirements. Clear specifications can help mitigate unexpected costs.

-

Materials: The choice of materials directly affects pricing. High-quality or specialized materials will typically result in higher costs.

-

Quality/Certifications: Products that require certifications or meet specific quality standards may have increased costs associated with compliance.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their reliability and service quality.

-

Incoterms: Understanding Incoterms is crucial for determining the responsibilities of buyers and sellers in terms of shipping costs, insurance, and risk management.

What Are the Best Buyer Tips for Sourcing from USA Ports?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance sourcing efficiency:

-

Negotiate Terms: Leverage your volume and commitment to negotiate better pricing and terms with suppliers. A well-prepared negotiation can lead to significant cost savings.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership rather than just the purchase price. This includes logistics, maintenance, and potential downtime costs.

-

Understand Pricing Nuances: Familiarize yourself with the pricing structure and potential hidden costs associated with sourcing from USA ports. This includes customs duties, tariffs, and local taxes.

-

Build Relationships: Establish long-term relationships with suppliers. Trust can lead to better pricing, priority service, and favorable terms.

-

Stay Informed: Regularly update yourself on market trends and changes in logistics costs. This knowledge can empower better decision-making and sourcing strategies.

Disclaimer on Indicative Prices

Pricing structures can fluctuate based on market conditions, regulatory changes, and other external factors. Therefore, the prices discussed here are indicative and may vary. Buyers are encouraged to conduct thorough research and obtain quotes directly from suppliers for the most accurate pricing.

Alternatives Analysis: Comparing usa ports With Other Solutions

Understanding Alternatives for International Shipping Solutions

In the context of global trade, businesses often seek efficient methods to transport goods. While USA ports play a crucial role in maritime logistics, alternative solutions can offer different advantages depending on specific needs. This analysis explores viable alternatives to USA ports, focusing on their unique benefits and challenges.

| Comparison Aspect | USA Ports | Air Freight | Rail Freight |

|---|---|---|---|

| Performance | High capacity for bulk goods; effective for containerized cargo. | Fast transit times; ideal for perishable or urgent goods. | Reliable for large volumes; consistent schedules. |

| Cost | Moderate to high, affected by tariffs and port fees. | Generally high due to fuel and handling costs. | Competitive, especially for long distances; lower than air. |

| Ease of Implementation | Requires logistics planning and port access; complex customs procedures. | Easier setup with less regulatory hassle; direct airport access. | Requires infrastructure for loading and unloading; can be more straightforward in rail-centric regions. |

| Maintenance | Significant upkeep needed for port facilities and equipment. | Lower maintenance; primarily aircraft and handling equipment. | Moderate; requires upkeep of rail infrastructure and rolling stock. |

| Best Use Case | Bulk commodities, containerized goods, and large shipments. | High-value, low-volume items, perishables, and urgent deliveries. | Heavy goods, raw materials, and intermodal transport in landlocked areas. |

What Are the Pros and Cons of Air Freight as an Alternative?

Air freight is renowned for its speed, making it an excellent option for businesses needing to move goods quickly. It offers a streamlined process with fewer regulatory hurdles compared to maritime transport. However, the cost of air freight can be significantly higher, which may not be feasible for all types of cargo, especially bulk items. Additionally, the environmental impact of air transport is greater, which could be a consideration for companies focused on sustainability.

How Does Rail Freight Compare to USA Ports?

Rail freight is a robust alternative, especially in regions with established rail networks. It is typically more cost-effective than air freight and can handle larger shipments over long distances efficiently. Rail is particularly advantageous for transporting heavy goods and raw materials. However, its effectiveness can be limited by the availability of rail infrastructure and the need for intermodal connections at both ends of the journey. Additionally, rail transport can be slower than both air and maritime options, which might not suit all business needs.

Conclusion: Which Solution Should a B2B Buyer Choose?

When considering the right shipping solution, B2B buyers should assess their specific requirements, including the nature of their goods, urgency, budget constraints, and logistical capabilities. USA ports remain an essential choice for bulk and containerized shipments, while air freight offers unmatched speed for high-value items. Rail freight stands out as a cost-effective solution for heavy goods, particularly in regions well-served by rail infrastructure. By evaluating these alternatives against their unique shipping needs, businesses can make informed decisions that enhance their supply chain efficiency.

Essential Technical Properties and Trade Terminology for usa ports

What Are the Key Technical Properties of USA Ports?

Understanding the technical properties of USA ports is crucial for international B2B buyers. These properties can significantly influence shipping decisions, cost calculations, and overall logistics planning. Here are some critical specifications to consider:

1. Berth Depth

Berth depth refers to the water depth at the dock where ships are moored. This specification is vital for determining whether a port can accommodate larger vessels, such as Panamax or Post-Panamax ships. A deeper berth allows for handling bigger ships, which can lead to reduced shipping costs due to economies of scale. For businesses involved in shipping goods, knowing the berth depth helps in planning cargo volumes and choosing appropriate shipping routes.

2. Container Handling Capacity

This metric indicates the number of containers a port can handle within a specific timeframe, usually expressed in TEUs (Twenty-foot Equivalent Units). High container handling capacity is essential for efficient operations, reducing turnaround time for vessels, and ensuring timely delivery of goods. Buyers should prioritize ports with robust infrastructure and technology to manage high volumes of containers efficiently.

3. Intermodal Connectivity

Intermodal connectivity refers to the ease with which goods can be transferred between different transportation modes, such as ships, trucks, and trains. Ports with strong intermodal connections facilitate smoother logistics operations, enabling quicker delivery times and reduced shipping costs. For B2B buyers, selecting ports with excellent intermodal facilities can enhance supply chain efficiency.

4. Customs Processing Speed

The speed at which customs processes shipments can significantly impact overall logistics efficiency. Ports with streamlined customs procedures reduce the time goods spend in transit, minimizing delays and storage costs. B2B buyers should consider ports known for their efficient customs operations to ensure that their shipments clear quickly and avoid unnecessary charges.

What Are Common Trade Terms Used in USA Ports?

Familiarity with industry jargon is essential for effective communication and negotiation in the logistics and shipping sectors. Here are some common trade terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of ports, OEMs often supply specialized equipment used for cargo handling, storage, and logistics operations. Understanding OEM relationships can help buyers negotiate better terms and ensure they source high-quality equipment.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management. Ports may have specific MOQs for shipping services or equipment, impacting overall logistics costs.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request price quotes from suppliers for specific goods or services. In the context of ports, issuing an RFQ can help businesses compare costs and services from different shipping lines or port operators, facilitating informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Understanding these terms is vital for B2B buyers to avoid misunderstandings and ensure compliance with international trade regulations.

5. Lead Time

Lead time refers to the amount of time from placing an order to receiving the goods. In port operations, lead time can be affected by factors such as customs clearance and vessel schedules. Knowing the lead time helps buyers plan their inventory and manage customer expectations effectively.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when engaging with USA ports, ultimately optimizing their logistics and supply chain strategies.

Navigating Market Dynamics and Sourcing Trends in the usa ports Sector

What Are the Key Market Dynamics and Trends Influencing the USA Ports Sector?

The USA ports sector is undergoing transformative changes driven by global trade dynamics, technological advancements, and evolving buyer preferences. Internationally, the demand for efficient logistics solutions is on the rise, particularly among B2B buyers from Africa, South America, the Middle East, and Europe. Key trends include the integration of digital technologies such as blockchain for enhanced transparency, artificial intelligence for predictive analytics, and automation for operational efficiency. These technologies are reshaping how ports manage logistics, streamline supply chains, and reduce turnaround times, making them increasingly attractive to global buyers.

Moreover, sustainability has emerged as a significant driver in the ports sector. As businesses worldwide prioritize environmental stewardship, ports are adopting greener practices and technologies. This shift includes investing in electric cargo handling equipment, implementing waste reduction strategies, and enhancing energy efficiency. Buyers from regions like Nigeria and Germany are particularly focused on sourcing from ports that demonstrate a commitment to sustainability, influencing their purchasing decisions.

The competitive landscape of USA ports is also evolving. While traditional ports like Los Angeles and New York remain vital, emerging ports in the Southeast and Gulf regions are gaining traction due to their strategic locations and improved infrastructure. This diversification offers international buyers more options, encouraging them to assess not only cost but also service quality and logistical capabilities.

How Is Sustainability and Ethical Sourcing Reshaping the USA Ports Sector?

Sustainability and ethical sourcing have become paramount in the USA ports sector, reflecting the growing awareness of environmental impacts and social responsibility among international B2B buyers. The environmental footprint of shipping activities, including greenhouse gas emissions and marine pollution, has prompted ports to adopt sustainable practices. For instance, many ports are investing in renewable energy sources, such as solar and wind, to power operations, thus reducing their reliance on fossil fuels.

Ethical supply chains are also gaining importance, as buyers increasingly seek partners that adhere to fair labor practices and responsible sourcing. Ports that implement transparent supply chain management practices and engage in community development initiatives are viewed more favorably by international buyers. Certifications such as ISO 14001 for environmental management and LEED for green buildings are becoming essential benchmarks for assessing sustainability credentials.

Furthermore, the demand for ‘green’ materials and certifications is on the rise. Ports that prioritize environmentally friendly operations and work with suppliers who adhere to sustainable practices are better positioned to attract global buyers. This trend is particularly relevant for buyers from Europe and the Middle East, where regulatory frameworks and consumer preferences are increasingly favoring sustainability.

What Is the Historical Context of the USA Ports Sector and Its Impact on Current Trends?

The evolution of the USA ports sector can be traced back to the early 20th century, marked by significant advancements in maritime technology and international trade. The establishment of the Interstate Highway System in the 1950s further integrated land and sea transport, enhancing the efficiency of goods movement. Over the decades, ports have adapted to changes in global trade patterns, containerization, and logistics innovations.

The rise of globalization in the late 20th century positioned USA ports as critical gateways for international trade. As trade volumes soared, ports invested heavily in infrastructure and technology to accommodate larger vessels and increased cargo. This historical context has shaped the current landscape, where modern ports leverage cutting-edge technology and sustainability practices to remain competitive.

Today, understanding this historical evolution is crucial for international B2B buyers. It highlights the ongoing transformation of the ports sector and the need for buyers to align their sourcing strategies with the emerging trends of efficiency, sustainability, and ethical practices. By recognizing the historical dynamics, buyers can better navigate the complexities of the modern ports environment and make informed sourcing decisions that align with their business objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of usa ports

-

How do I choose the right port for my shipping needs?

Selecting the appropriate port for your shipping requirements involves assessing several factors. First, consider the port’s geographical location and its proximity to your suppliers and target markets. Evaluate the port’s capacity and efficiency, including the availability of modern facilities and technology for cargo handling. Additionally, review the port’s connectivity with other transportation modes, such as rail and road, which can affect logistics costs and timelines. Lastly, check the port’s reputation for reliability and the quality of its customs procedures to ensure smooth operations. -

What are the key factors affecting port selection for international trade?

When choosing a port for international trade, several critical factors come into play. These include the port’s operational efficiency, which reflects its ability to handle cargo swiftly and minimize delays. The availability of services such as customs clearance, warehousing, and intermodal transport options is also crucial. Additionally, consider the regulatory environment, including tariffs and trade agreements, as these can impact overall costs. Lastly, assess the port’s safety and security measures to protect your goods during transit. -

What are the minimum order quantities (MOQ) at US ports?

Minimum order quantities at US ports can vary significantly depending on the type of goods and the specific port’s policies. Generally, bulk goods may have higher MOQs due to the logistics involved in transporting large volumes. For containerized cargo, suppliers might set MOQs based on container capacity. It’s essential to communicate directly with your suppliers to understand their specific MOQs and negotiate terms that align with your business needs, especially if you’re working with smaller shipments. -

How can I ensure the quality of goods shipped through US ports?

To ensure the quality of goods shipped through US ports, establish stringent quality assurance protocols with your suppliers. Request certifications and compliance documents that verify the quality standards of the products. Conduct regular audits and inspections of the suppliers’ facilities to assess their production processes. Additionally, consider using third-party inspection services to evaluate the goods before shipment. Clear communication about quality expectations and penalties for non-compliance can help maintain high standards throughout the supply chain. -

What payment terms are common for international shipments through US ports?

Payment terms for international shipments can vary, but common practices include letters of credit, advance payments, and open account terms. Letters of credit offer security for both parties, ensuring that payment is made only when terms are met. Advance payments may be required for custom orders or new suppliers. Open accounts can foster long-term relationships but may require a higher level of trust. Always negotiate terms that align with your cash flow and risk management strategies, and ensure that all agreements are documented. -

How do I vet suppliers when sourcing through US ports?

Vetting suppliers is critical for ensuring reliability and quality. Start by researching potential suppliers’ backgrounds, including their history, reputation, and financial stability. Request references and case studies from previous clients to gauge their performance. Conduct site visits if possible, or utilize third-party verification services to assess their facilities and operations. Additionally, review their compliance with industry standards and regulations. Establishing clear communication and understanding their production capabilities will further ensure they meet your requirements. -

What are the logistics considerations when shipping goods through US ports?

Logistics considerations for shipping through US ports include understanding the transportation network, lead times, and customs procedures. Evaluate the port’s accessibility to major highways and railroads to facilitate efficient inland transport. Be aware of the typical lead times for shipping and customs clearance to plan your inventory effectively. Additionally, familiarize yourself with the customs regulations to avoid delays and unexpected costs. Collaborating with experienced freight forwarders can streamline the logistics process and ensure compliance with all requirements. -

What should I know about customs regulations when shipping through US ports?

Understanding customs regulations is vital for smooth international shipments. Each port has specific requirements regarding documentation, duties, and taxes. Familiarize yourself with the Harmonized System (HS) codes relevant to your products, as these will determine applicable tariffs. Ensure all necessary paperwork, such as commercial invoices and packing lists, is complete and accurate. Engaging a customs broker can help navigate complex regulations and ensure compliance, reducing the risk of delays or penalties during the importation process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for usa ports

In navigating the complexities of international trade, strategic sourcing through U.S. ports emerges as a pivotal factor for success. The geographical advantages, robust infrastructure, and advanced operational efficiencies of ports such as Los Angeles, New York, and Savannah position them as key gateways for global commerce. International B2B buyers from regions like Africa, South America, the Middle East, and Europe can leverage these ports to enhance their supply chains and reduce lead times.

Emphasizing strategic partnerships with reliable port operators will not only streamline logistics but also optimize costs and improve service levels. Understanding the nuances of each port’s capabilities, including intermodal connectivity and customs efficiency, is essential for making informed sourcing decisions.

Looking ahead, as global trade continues to evolve, U.S. ports are set to play an increasingly critical role in facilitating international commerce. B2B buyers are encouraged to engage actively with U.S. port authorities and logistics providers to harness the full potential of these vital trade hubs. By doing so, they can ensure a competitive edge in their respective markets and contribute to a more resilient global supply chain.