Top 6 Electric Vehicle Manufacturers Usa List and Guide: How To S…

Introduction: Navigating the Global Market for electric vehicle manufacturers usa

In an era where sustainable transportation is paramount, navigating the global market for electric vehicle manufacturers in the USA presents a unique challenge for international B2B buyers. As the demand for electric vehicles (EVs) surges, sourcing the right manufacturers can be daunting, especially when considering factors such as vehicle types, applications, and supplier reliability. This guide aims to demystify the landscape of electric vehicle manufacturers in the USA, providing a comprehensive overview of the available options—from luxury sedans to robust commercial fleets.

Within this resource, we delve into the diverse range of electric vehicles, examining their specifications, performance capabilities, and suitability for various markets. Additionally, we offer insights into the supplier vetting process, helping buyers assess manufacturer credibility and product quality. Cost considerations are also addressed, ensuring that stakeholders can make informed financial decisions that align with their business strategies.

This guide is particularly valuable for international buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Vietnam. By empowering these businesses with critical information about the electric vehicle market, we aim to facilitate strategic partnerships and successful procurement processes, ultimately driving the transition to cleaner transportation solutions on a global scale.

Top 10 Electric Vehicle Manufacturers Usa Manufacturers & Suppliers List

1. Lucid Motors – Lucid Air & Gravity

Domain: lucidmotors.com

Registered: 2016 (9 years)

Introduction: Lucid Air: 2025 Air Pure lease from $549/mo, buy from $69,900. 2026 Lucid Air lineup available now. 2025 Lucid Gravity orders open. EPA estimated range up to 450 miles, cargo space up to 120 cubic feet, seating for up to 7 adults. Access to 23,500+ Tesla Superchargers.

2. Tesla – High-Speed Electric Vehicles & Solar Panels

Domain: builtin.com

Registered: 1999 (26 years)

Introduction: Tesla: High-speed electric vehicles and solar panels for businesses and homes. Rivian: Three SUVs and a pickup truck with 100% animal-free interiors and recyclable battery packs; compatible with Tesla Superchargers. Lucid Motors: Luxury electric vehicles reaching 60 mph in under 2 seconds; 200 miles of charging in around 12 minutes; features smart ecosystems. NIO: Nine electric vehicle models incl…

3. Tesla – Automotive Brands

4. VinFast – Electric Vehicles

5. BYD – Electric Vehicles

6. Electric Vehicle Manufacturers – Stock Listed Companies

Domain: companiesmarketcap.com

Registered: 2020 (5 years)

Introduction: This list contains companies that manufacture Electric cars, trucks, and specialty vehicles. Only EV companies that are listed on stock exchanges are shown.

Understanding electric vehicle manufacturers usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Luxury Electric Vehicles | High-performance, premium materials, advanced technology integration | Corporate fleets, high-end transport services | Pros: Superior quality, brand prestige; Cons: High initial cost |

| Commercial Electric Vehicles | Designed for utility, larger capacities, often optimized for range | Delivery services, logistics, fleet management | Pros: Lower operational costs, sustainability; Cons: Limited range in some models |

| Performance Electric Vehicles | Focus on speed and agility, cutting-edge design, often for enthusiasts | High-performance rentals, specialty transport | Pros: Exceptional driving experience; Cons: Higher maintenance costs |

| Electric SUVs | Versatile, spacious, family-friendly, suitable for various terrains | Corporate family vehicles, employee transportation | Pros: Space and comfort; Cons: May lack luxury features compared to high-end models |

| Electric Sedans | Compact and efficient, often resembling traditional sedans | Executive transport, corporate leasing | Pros: Cost-effective, good for urban environments; Cons: Limited space compared to SUVs |

What Are Luxury Electric Vehicles and Their B2B Applications?

Luxury electric vehicles (EVs) are characterized by their high-performance capabilities, premium materials, and advanced technology features. Brands like Lucid Motors and Tesla exemplify this category, offering vehicles that not only provide exceptional driving experiences but also integrate smart technology for enhanced user convenience. For B2B buyers, luxury EVs serve well in corporate fleets and high-end transport services, where brand image and employee satisfaction are paramount. However, the high initial investment can be a drawback for some businesses.

How Do Commercial Electric Vehicles Serve Businesses?

Commercial electric vehicles are tailored for utility, featuring larger capacities and optimized ranges to accommodate business needs. These vehicles, such as electric vans and trucks from brands like Ford and Rivian, are increasingly popular in logistics and delivery services. They help businesses reduce operational costs while promoting sustainability. Although they offer significant advantages, some models may have limited ranges, which can affect long-distance operations.

What Makes Performance Electric Vehicles Unique?

Performance electric vehicles focus on speed and agility, appealing to driving enthusiasts and businesses seeking a distinctive edge. Brands like Tesla and Lucid Motors produce models that deliver exceptional acceleration and handling. These vehicles can be beneficial for high-performance rentals and specialty transport services, appealing to clients looking for an unforgettable experience. However, higher maintenance costs and potential insurance premiums can be a consideration for B2B buyers.

Why Are Electric SUVs Gaining Popularity Among Businesses?

Electric SUVs provide versatility and spaciousness, making them suitable for families and corporate needs alike. Their ability to navigate various terrains while offering ample room for passengers and cargo makes them attractive for corporate family vehicles and employee transportation. Brands such as Ford and BMW are leading this segment. While electric SUVs provide comfort and space, they may not always match the luxury features found in high-end models, which could be a deciding factor for some businesses.

What Are the Benefits of Electric Sedans for Urban Use?

Electric sedans are compact, efficient, and often resemble traditional vehicles, making them ideal for urban environments. They are particularly well-suited for executive transport and corporate leasing, offering a cost-effective solution for businesses. With brands like Tesla and BMW producing models that combine style and functionality, B2B buyers can benefit from lower operational costs. However, the limited space compared to SUVs may deter some buyers who require additional passenger capacity.

Key Industrial Applications of electric vehicle manufacturers usa

| Industry/Sector | Specific Application of Electric Vehicle Manufacturers USA | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Transport | Electric delivery vans and trucks | Reduced operational costs through lower fuel expenses and maintenance needs. | Fleet size, charging infrastructure availability, and total cost of ownership. |

| Public Transportation | Electric buses and shuttles | Enhanced environmental compliance and reduced noise pollution in urban areas. | Battery range, charging times, and capacity requirements for passenger loads. |

| Construction | Electric construction vehicles | Decreased emissions and improved site safety due to quieter operations. | Equipment durability, battery life, and compatibility with existing machinery. |

| Hospitality and Tourism | Electric shuttle services for hotels and resorts | Improved guest experience and brand image through sustainable practices. | Vehicle range, charging facilities, and fleet management solutions. |

| Agriculture | Electric utility vehicles for farming operations | Lower fuel costs and reduced carbon footprint, enhancing sustainability efforts. | Terrain adaptability, battery performance, and service support availability. |

How Are Electric Vehicles Used in Logistics and Transport?

Electric delivery vans and trucks are becoming increasingly vital in the logistics and transport sector, particularly for businesses focused on sustainability. These vehicles help reduce operational costs by minimizing fuel expenses and lowering maintenance needs compared to traditional combustion engines. For international buyers, especially in regions like Africa and South America, understanding local charging infrastructure and vehicle range is crucial. Buyers should assess fleet size requirements and the total cost of ownership to ensure long-term profitability and efficiency.

What Role Do Electric Buses Play in Public Transportation?

Electric buses and shuttles are transforming public transportation by offering a cleaner, quieter alternative to diesel-powered vehicles. This transition supports environmental compliance, especially in urban areas where emissions regulations are stringent. For B2B buyers in Europe and the Middle East, evaluating battery range, charging times, and passenger capacity is essential. These factors directly impact operational efficiency and the ability to meet local transportation demands while enhancing service quality.

How Can Electric Vehicles Benefit the Construction Industry?

Electric construction vehicles are increasingly adopted to promote sustainability on job sites. They contribute to decreased emissions and improve site safety due to their quieter operation, which is particularly beneficial in residential areas. Buyers in regions such as Africa and South America must consider equipment durability, battery life, and compatibility with existing machinery when sourcing these vehicles. This ensures that the investment aligns with project timelines and operational demands.

Why Are Electric Shuttle Services Important for Hospitality and Tourism?

Electric shuttle services provide hotels and resorts with an opportunity to enhance guest experience while promoting sustainability. By reducing noise and emissions, these services help hotels position themselves as eco-friendly destinations, appealing to a growing segment of environmentally conscious travelers. Buyers in the hospitality sector should focus on vehicle range, charging facilities, and fleet management solutions to ensure seamless operations and guest satisfaction.

How Do Electric Utility Vehicles Support Agricultural Operations?

Electric utility vehicles are becoming essential in agricultural settings, offering a sustainable alternative to traditional fuel-powered machines. They help lower fuel costs and reduce the carbon footprint of farming operations, aligning with global sustainability goals. For agricultural buyers, particularly in regions with diverse terrain, it is vital to assess vehicle adaptability, battery performance, and the availability of service support. These considerations ensure that the vehicles can effectively meet the unique demands of farming operations.

3 Common User Pain Points for ‘electric vehicle manufacturers usa’ & Their Solutions

Scenario 1: Navigating Complex Supply Chains for EV Components

The Problem: B2B buyers often face challenges when sourcing components for electric vehicles due to the complex and fragmented nature of the supply chain. Many manufacturers rely on a network of suppliers for batteries, electric drivetrains, and other critical components. This can lead to delays in production, increased costs, and difficulty in maintaining quality standards. Buyers need to ensure that they have reliable suppliers who can deliver high-quality components on time, which becomes even more challenging when dealing with international suppliers from regions such as Africa or South America.

The Solution: To mitigate supply chain issues, B2B buyers should adopt a multi-sourcing strategy. This involves identifying multiple suppliers for each component, which can reduce reliance on a single source and increase resilience. Buyers should conduct thorough due diligence on potential suppliers, assessing their manufacturing capabilities, quality control processes, and delivery timelines. Establishing clear communication channels and fostering relationships with suppliers can also enhance collaboration. Furthermore, investing in supply chain management software can provide real-time tracking of orders and inventory levels, helping buyers make informed decisions swiftly.

Scenario 2: Understanding Regulatory Compliance Across Borders

The Problem: International buyers often struggle with varying regulatory requirements for electric vehicles in different regions. Compliance with safety, emissions, and import/export regulations can be daunting, especially for companies looking to enter markets in Europe, the Middle East, or Africa. Non-compliance can lead to costly fines, product recalls, and damage to reputation, which can be particularly detrimental for manufacturers looking to establish a foothold in new markets.

The Solution: To address regulatory compliance challenges, B2B buyers should engage legal and regulatory experts who specialize in the automotive and EV sectors. These experts can provide insights into the specific regulations in target markets, ensuring that all products meet local standards. Additionally, buyers should leverage resources such as trade associations and government export promotion agencies that offer guidance on compliance. Developing a comprehensive checklist of regulatory requirements for each market can help streamline the process. Implementing compliance management systems can also automate tracking and reporting, reducing the risk of oversight.

Scenario 3: Ensuring Efficient Charging Infrastructure Development

The Problem: A critical pain point for electric vehicle manufacturers is the lack of sufficient charging infrastructure, particularly in emerging markets. B2B buyers often encounter obstacles when trying to deploy vehicles in regions where charging stations are sparse. This can hinder the adoption of electric vehicles and impact sales, as consumers are less likely to invest in EVs if they perceive charging as inconvenient.

The Solution: To overcome charging infrastructure challenges, B2B buyers should collaborate with local governments and private sector partners to advocate for the development of charging stations. Forming public-private partnerships can leverage resources and expertise to create a robust charging network. Buyers can also explore innovative solutions such as mobile charging units or solar-powered charging stations, which can be deployed in underserved areas. Engaging with technology providers that specialize in charging solutions can help streamline the installation process and ensure compatibility with various EV models. Furthermore, providing education and resources to consumers about charging options can help alleviate concerns and promote the benefits of electric vehicles.

Strategic Material Selection Guide for electric vehicle manufacturers usa

What Are the Key Materials Used in Electric Vehicle Manufacturing in the USA?

Electric vehicle (EV) manufacturers in the USA utilize a variety of materials to optimize performance, safety, and sustainability. Understanding the properties, advantages, and limitations of these materials is crucial for international B2B buyers aiming to source components for electric vehicles. Here, we analyze four common materials: aluminum, lithium-ion battery components, carbon fiber, and high-strength steel.

How Does Aluminum Benefit Electric Vehicle Manufacturing?

Aluminum is a lightweight metal widely used in electric vehicle manufacturing, particularly for body panels and structural components. Its key properties include excellent corrosion resistance, high strength-to-weight ratio, and good thermal conductivity. These attributes contribute to improved energy efficiency and range, as lighter vehicles require less energy to operate.

Pros: Aluminum is durable and can be easily formed into complex shapes, which is advantageous for innovative vehicle designs. However, its cost can be higher compared to traditional steel, and manufacturing processes may require specialized techniques, such as welding and bonding.

Cons: While aluminum is resistant to corrosion, it can be susceptible to galvanic corrosion when in contact with other metals. International buyers should be aware of compliance standards such as ASTM B117 for salt spray testing to ensure durability in various climates.

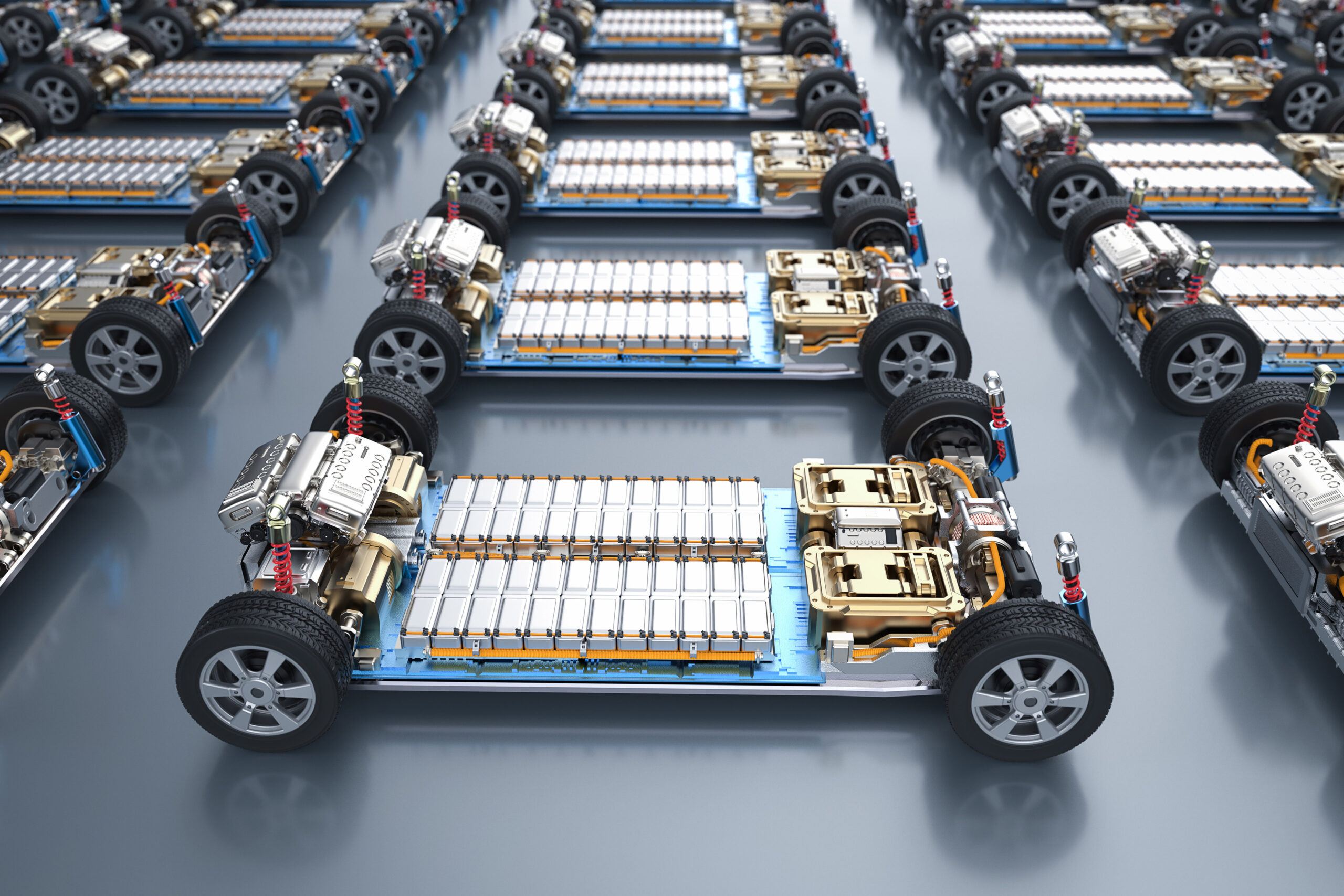

What Role Do Lithium-Ion Battery Components Play in Electric Vehicles?

Lithium-ion batteries are the heart of electric vehicles, providing the energy needed for propulsion. Key properties include high energy density, long cycle life, and low self-discharge rates. These batteries enable longer driving ranges and faster charging times, making them essential for modern EVs.

Pros: The lightweight nature of lithium-ion batteries enhances vehicle efficiency. They are also scalable, allowing manufacturers to customize battery sizes according to vehicle specifications.

Cons: The production of lithium-ion batteries can be complex and costly, with significant environmental concerns related to lithium extraction. Buyers from regions like Africa and South America should consider local sourcing of raw materials and compliance with environmental regulations.

Why Is Carbon Fiber Important for Electric Vehicle Performance?

Carbon fiber is increasingly being used in electric vehicles for its exceptional strength-to-weight ratio and rigidity. It is particularly advantageous in high-performance EVs where weight reduction is critical for speed and efficiency.

Pros: Carbon fiber components can significantly enhance vehicle performance and aesthetics. They are resistant to corrosion and fatigue, contributing to the longevity of the vehicle.

Cons: The primary limitation of carbon fiber is its high cost and complex manufacturing processes, which may not be feasible for all manufacturers. International buyers should also consider the availability of skilled labor for carbon fiber fabrication and compliance with international standards such as ISO 13061.

How Does High-Strength Steel Contribute to Electric Vehicle Safety?

High-strength steel (HSS) is utilized for its robustness and ability to absorb energy during collisions, making it a critical material for safety structures in electric vehicles. HSS offers excellent tensile strength and can be engineered to meet specific performance requirements.

Pros: HSS is generally more affordable than aluminum and carbon fiber, making it a cost-effective option for manufacturers. It also allows for simpler manufacturing processes, such as stamping and welding.

Cons: While HSS is strong, it is heavier than aluminum and carbon fiber, which can impact overall vehicle efficiency. Buyers should ensure compliance with safety standards like FMVSS 214 for side-impact protection, especially in regions with stringent automotive regulations.

Summary Table of Material Selection for Electric Vehicle Manufacturers in the USA

| Material | Typical Use Case for electric vehicle manufacturers usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Body panels, structural components | Lightweight, corrosion-resistant | Higher cost, complex manufacturing | Medium |

| Lithium-Ion Battery | Energy storage for propulsion | High energy density, scalable | Complex production, environmental concerns | High |

| Carbon Fiber | High-performance components, body panels | Exceptional strength-to-weight ratio | High cost, complex manufacturing | High |

| High-Strength Steel | Safety structures, chassis components | Cost-effective, strong | Heavier than alternatives | Low |

This guide provides essential insights for international B2B buyers looking to source materials for electric vehicle manufacturing, considering performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for electric vehicle manufacturers usa

What Are the Main Stages of Manufacturing for Electric Vehicle Manufacturers in the USA?

The manufacturing processes for electric vehicles (EVs) in the USA are intricate and involve several key stages: material preparation, forming, assembly, and finishing. Each stage is critical to ensuring that the final product meets both performance and safety standards.

How Is Material Prepared for Electric Vehicle Production?

Material preparation involves sourcing high-quality components, including battery cells, electric motors, and structural materials such as aluminum and steel. Suppliers often need to comply with international and industry-specific standards, ensuring that materials are tested for safety and performance. For instance, lithium-ion batteries must meet stringent safety regulations to minimize risks like thermal runaway.

What Techniques Are Used in the Forming Stage of EV Manufacturing?

The forming stage typically includes advanced techniques such as stamping, casting, and machining. Stamping is widely used for creating body panels, while die-casting is often employed for producing complex components like battery housings. These methods allow for high precision and can significantly reduce weight, which is crucial for EV performance.

How Does the Assembly Process Work for Electric Vehicles?

In the assembly stage, various components are integrated to create a complete vehicle. This includes the installation of the electric powertrain, battery packs, and electronic control systems. Automation plays a vital role here; robotics are increasingly used to enhance precision and efficiency. For example, Tesla has optimized its assembly lines to reduce production time, allowing for rapid scaling to meet market demand.

What Is Involved in the Finishing Stage of Electric Vehicle Manufacturing?

The finishing stage includes quality checks, painting, and final assembly. This stage is essential for aesthetic appeal and protection against environmental factors. Advanced coatings are applied to ensure durability and corrosion resistance. Additionally, final quality inspections are conducted to ensure that all systems function correctly before the vehicle leaves the factory.

What Are the Key Quality Assurance Practices in Electric Vehicle Manufacturing?

Quality assurance (QA) is critical in the EV manufacturing process, ensuring that vehicles meet both regulatory and customer expectations. Manufacturers in the USA adhere to various international standards, with ISO 9001 being a foundational framework for quality management systems.

Which International Standards Are Relevant for Electric Vehicle Manufacturers?

In addition to ISO 9001, other relevant standards include ISO 14001 for environmental management and ISO 45001 for occupational health and safety. For specific components, certifications like UL 2580 (for batteries) and IEC 62133 (for battery safety) are crucial. Compliance with these standards not only enhances product reliability but also builds trust with international buyers.

What Are the QC Checkpoints in Electric Vehicle Manufacturing?

Quality control checkpoints typically include:

- Incoming Quality Control (IQC): This involves inspecting materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing help identify defects early and ensure that processes remain within acceptable limits.

- Final Quality Control (FQC): Comprehensive testing of the completed vehicle, including performance, safety, and durability tests.

These checkpoints help to minimize defects and ensure that any issues are addressed before the product reaches the customer.

What Common Testing Methods Are Used in Electric Vehicle Manufacturing?

Electric vehicle manufacturers utilize various testing methods to ensure product integrity and performance. Common methods include:

- Functional Testing: Verifying that all systems (e.g., powertrain, electronics) operate as intended.

- Environmental Testing: Assessing how vehicles perform under extreme conditions, such as high temperatures or humidity.

- Crash Testing: Ensuring that vehicles meet safety standards through rigorous crash simulations and physical tests.

- Battery Testing: Evaluating the performance and safety of battery packs under various operating conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential for ensuring product reliability and compliance with local regulations. Several strategies can be employed:

- Supplier Audits: Conducting on-site audits of manufacturing facilities can provide insight into their quality management systems and adherence to standards.

- Quality Reports: Requesting detailed quality reports, including testing results and certifications, can help buyers assess a supplier’s capabilities.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of a supplier’s quality practices and product integrity.

What Are the QC and Certification Nuances for International B2B Buyers?

For buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial. Different regions may have varying regulatory requirements and standards. For example, buyers in the EU must be aware of the CE marking, which indicates compliance with European health, safety, and environmental protection standards.

Additionally, cultural differences in business practices may affect how quality assurance is implemented. B2B buyers should communicate clearly about their expectations and compliance requirements to ensure alignment with suppliers.

Conclusion: Ensuring Quality and Efficiency in Electric Vehicle Manufacturing

The electric vehicle manufacturing process in the USA is characterized by advanced techniques and rigorous quality assurance practices. For international B2B buyers, understanding these processes and how to verify supplier quality is essential for making informed purchasing decisions. By focusing on quality at every stage, from material preparation to final assembly, manufacturers can produce reliable electric vehicles that meet the growing global demand.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric vehicle manufacturers usa’

In the rapidly evolving landscape of electric vehicle (EV) manufacturing in the USA, international B2B buyers must navigate various factors to make informed sourcing decisions. This guide provides a practical step-by-step checklist to streamline your procurement process and ensure you partner with the right manufacturers.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline the technical specifications you require from the electric vehicles. This includes vehicle type (e.g., sedan, SUV, commercial), battery capacity, range, and performance metrics. Having precise specifications allows you to filter potential manufacturers more effectively and ensures that you receive offerings that meet your operational needs.

Step 2: Research Market Leaders and Emerging Brands

Identify both established manufacturers and emerging players in the EV market. Companies like Tesla and Ford are well-known, but also consider innovative brands such as Rivian and Lucid Motors, which may offer unique features or technologies. Understanding the competitive landscape will help you assess which manufacturers align with your business goals and market demands.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Check for their production capabilities, delivery timelines, and after-sales support to ensure they can meet your needs.

- Review Certifications: Ensure that potential suppliers have the necessary certifications and compliance with local regulations, which can significantly impact vehicle performance and safety.

- Assess Technological Advancements: Investigate whether the manufacturers are investing in R&D and technological innovations, as this can indicate their commitment to quality and future-proofing their products.

Step 4: Analyze Supply Chain Stability

A robust supply chain is essential for timely delivery and quality assurance. Investigate the manufacturer’s sourcing of materials and components, especially battery technology, which is critical for EV performance. Understanding their supply chain will provide insights into potential risks and the manufacturer’s ability to scale production.

Step 5: Check Financial Stability

Review the financial health of potential suppliers to ensure they can sustain operations in the competitive EV market. Request financial statements and look for signs of profitability or stable investment backing. A financially sound manufacturer is more likely to deliver consistent quality and service.

Step 6: Negotiate Terms and Conditions

Once you’ve shortlisted potential suppliers, engage in negotiations regarding pricing, payment terms, and warranty conditions. Be clear about your expectations for service levels and support post-purchase. A well-structured agreement will help mitigate risks and ensure a smooth business relationship.

Step 7: Plan for After-Sales Support and Maintenance

Consider the manufacturer’s capabilities for after-sales support, including maintenance services and spare parts availability. Strong after-sales support is crucial for minimizing downtime and ensuring the longevity of your fleet. Establish clear communication channels and support structures before finalizing the deal.

By following this checklist, international B2B buyers can streamline their sourcing process and form successful partnerships with electric vehicle manufacturers in the USA, ultimately enhancing their operational efficiency and market competitiveness.

Comprehensive Cost and Pricing Analysis for electric vehicle manufacturers usa Sourcing

What Are the Key Cost Components for Electric Vehicle Manufacturing in the USA?

When analyzing the cost structure for electric vehicle (EV) manufacturing in the USA, several components must be taken into account:

-

Materials: The cost of raw materials is significant, especially for battery production, which requires lithium, cobalt, and nickel. The increasing demand for EVs has led to fluctuations in these prices. Additionally, the use of advanced materials for lightweighting and improved performance can further influence costs.

-

Labor: Labor costs in the U.S. are generally higher than in many other countries. Skilled labor is essential for EV manufacturing, particularly in areas such as engineering, assembly, and quality control. Companies often invest in training programs to ensure their workforce can handle advanced manufacturing techniques.

-

Manufacturing Overhead: This includes utilities, rent, maintenance, and other operational costs associated with running a manufacturing facility. With the increasing complexity of EVs, overhead costs are likely to rise due to the need for specialized equipment and technology.

-

Tooling: Tooling costs can be substantial, particularly when producing custom components or low-volume parts. Companies need to factor in the expenses associated with designing and fabricating molds and dies, which can be a significant upfront investment.

-

Quality Control (QC): Given the safety and performance standards required for EVs, stringent QC measures are necessary. This includes testing battery performance, safety features, and overall vehicle reliability, which can increase manufacturing costs.

-

Logistics: The transportation of raw materials and finished products adds another layer of expense. Companies must consider freight costs, storage, and distribution, which can vary based on location and market conditions.

-

Margin: Manufacturers typically aim for a healthy profit margin to sustain operations and fund research and development. The margin can vary widely based on the vehicle segment, brand positioning, and market competition.

How Do Price Influencers Affect Electric Vehicle Sourcing?

Several factors can influence the pricing of electric vehicles, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in better pricing due to economies of scale. Buyers should negotiate MOQs that align with their purchasing capabilities to maximize cost efficiency.

-

Specifications and Customization: Customized vehicles with specific features or performance standards can significantly alter the price. Buyers should clearly define their requirements to avoid unexpected costs later in the procurement process.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications can impact pricing. Buyers seeking high-performance or sustainable materials may face higher costs but should consider the long-term benefits and total cost of ownership.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established manufacturers may offer higher-quality products but at a premium, while newer entrants might provide competitive pricing to gain market share.

-

Incoterms: Understanding the implications of Incoterms is critical for international transactions. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect the total landed cost of the vehicles.

What Buyer Tips Can Help Optimize Costs in Electric Vehicle Sourcing?

-

Negotiation Strategies: Effective negotiation can lead to better pricing. Buyers should be prepared to discuss terms, including payment schedules and delivery timelines, to find a mutually beneficial agreement.

-

Cost-Efficiency Analysis: Conduct a thorough analysis of the total cost of ownership, which includes not just the purchase price but also maintenance, insurance, and energy costs. This will help in making informed purchasing decisions.

-

Understanding Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of local regulations, import duties, and market conditions that could affect pricing. Building relationships with local suppliers or distributors can also provide insights into cost-saving opportunities.

-

Long-Term Partnerships: Establishing long-term partnerships with manufacturers can lead to more favorable pricing and priority access to new technologies and products.

Disclaimer on Indicative Prices

Prices for electric vehicles can vary widely based on specifications, market conditions, and other factors. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing electric vehicle manufacturers usa With Other Solutions

Understanding Alternatives in the Electric Vehicle Market

As the global push for sustainability and eco-friendly solutions intensifies, businesses are increasingly exploring alternatives to traditional vehicles and energy sources. While electric vehicle (EV) manufacturers in the USA are at the forefront of this shift, it is essential to evaluate other viable technologies and approaches that may also fulfill similar goals. This comparative analysis will help international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—make informed decisions based on performance, cost, and other relevant factors.

Comparison Table

| Comparison Aspect | Electric Vehicle Manufacturers USA | Hydrogen Fuel Cell Vehicles | Biofuel-Powered Vehicles |

|---|---|---|---|

| Performance | High torque and acceleration, range varies (up to 450 miles) | Comparable range (300-400 miles), longer refueling time | Lower energy density, range varies (up to 500 miles) |

| Cost | Initial high investment, lower long-term operating costs | High production and infrastructure costs | Moderate initial cost, fluctuating feedstock prices |

| Ease of Implementation | Growing charging infrastructure, established market | Limited hydrogen stations, requires new infrastructure | Widely available biofuels, existing engine compatibility |

| Maintenance | Generally low, fewer moving parts | Requires specialized maintenance | Similar to gasoline engines, may require modifications |

| Best Use Case | Urban and suburban applications, fleet vehicles | Long-haul transport, fleet operations | Agricultural and regional transportation |

Detailed Breakdown of Alternatives

Hydrogen Fuel Cell Vehicles

Hydrogen fuel cell vehicles (FCVs) utilize hydrogen gas to power electric motors, producing only water vapor as a byproduct. Their performance is notable, offering a range that can compete with traditional gasoline vehicles. However, the high costs associated with hydrogen production and the limited availability of refueling infrastructure hinder widespread adoption. For businesses focused on long-distance transport or operating fleets in regions with established hydrogen stations, FCVs can be a suitable alternative, despite the challenges in implementation.

Biofuel-Powered Vehicles

Biofuels, derived from organic materials, serve as an alternative energy source for traditional internal combustion engines. They can utilize existing vehicle infrastructure, making them easier to adopt in regions with limited access to EV charging stations. While biofuels generally have a lower energy density than electric batteries, they present a practical solution for agricultural businesses or companies in rural areas where electric charging infrastructure may be lacking. However, the fluctuating prices of feedstocks can impact the overall cost-effectiveness of this option.

Conclusion: How to Choose the Right Solution for Your Business Needs

Selecting the most appropriate vehicle technology for your business requires a thorough understanding of your specific operational needs, budget constraints, and environmental goals. Electric vehicle manufacturers in the USA offer cutting-edge technology with impressive performance and lower long-term costs, making them ideal for urban applications. Conversely, hydrogen fuel cell vehicles may be beneficial for long-haul operations, while biofuel-powered vehicles provide a practical solution for businesses in regions with existing infrastructure. By carefully evaluating these alternatives, B2B buyers can align their transportation strategies with sustainability objectives while optimizing operational efficiency.

Essential Technical Properties and Trade Terminology for electric vehicle manufacturers usa

What Are the Key Technical Properties for Electric Vehicle Manufacturers in the USA?

Understanding essential technical properties is vital for international B2B buyers seeking to engage with electric vehicle (EV) manufacturers in the USA. Here are some critical specifications that should be considered:

-

Battery Capacity (kWh)

– Battery capacity, measured in kilowatt-hours (kWh), indicates the amount of energy stored in the battery. This directly correlates to the vehicle’s range, or how far it can travel on a single charge. For manufacturers, optimizing battery capacity is crucial for meeting consumer expectations and regulatory standards. -

Charging Speed (kW)

– Charging speed, expressed in kilowatts (kW), refers to the rate at which a battery can be charged. Fast-charging capabilities enhance user convenience and can significantly influence purchasing decisions. Manufacturers must balance charging speed with battery longevity to ensure reliability and customer satisfaction. -

Vehicle Range (miles)

– Vehicle range measures how far an EV can travel on a full charge, typically expressed in miles. This property is essential for market competitiveness. Manufacturers need to provide vehicles with sufficient range to meet diverse consumer needs, especially in regions with limited charging infrastructure. -

Weight Distribution

– Weight distribution affects the handling and performance of an electric vehicle. A well-balanced weight distribution can improve driving dynamics and safety. Manufacturers must consider this property when designing vehicles, as it influences not only performance but also efficiency and battery life. -

Material Grade

– The choice of materials in EV manufacturing impacts vehicle weight, safety, and cost. High-strength, lightweight materials such as aluminum and carbon fiber are often preferred for their durability and performance benefits. Understanding material grade is essential for manufacturers aiming to optimize production processes and product lifecycle. -

Thermal Management System

– A thermal management system regulates the temperature of the battery and electric drive components. Effective thermal management is crucial for performance, longevity, and safety. Manufacturers must invest in advanced cooling technologies to ensure optimal operation under varying conditions.

What Are Common Trade Terms Used in the Electric Vehicle Industry?

Familiarity with industry jargon can significantly enhance communication and negotiation with EV manufacturers. Here are several common terms:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the EV sector, OEMs play a critical role in supplying components like batteries, electric motors, and electronic systems. Understanding OEM relationships is vital for ensuring product quality and compliance. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest amount of product that a supplier is willing to sell. This term is crucial for B2B buyers to understand, as it impacts inventory management and supply chain efficiency. Knowing the MOQ helps in planning orders and ensuring that procurement aligns with business needs. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting a price quote for specific products or services. In the EV industry, RFQs facilitate the procurement process by allowing manufacturers to compare costs and terms from different suppliers. This helps in making informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding Incoterms is essential for navigating cross-border trade effectively. -

BOM (Bill of Materials)

– A BOM is a comprehensive list of raw materials, components, and assemblies required to manufacture a product. In the context of EV manufacturing, a detailed BOM helps in cost estimation, procurement planning, and inventory management, ensuring that all necessary parts are available for production. -

EVSE (Electric Vehicle Supply Equipment)

– EVSE refers to the equipment used to deliver electricity to an electric vehicle, including charging stations and connectors. Knowledge of EVSE is crucial for manufacturers and buyers, as it affects charging infrastructure planning and compatibility with different vehicle models.

By understanding these technical properties and trade terms, international B2B buyers can better navigate the complex landscape of electric vehicle manufacturing in the USA, enabling informed decision-making and fostering successful partnerships.

Navigating Market Dynamics and Sourcing Trends in the electric vehicle manufacturers usa Sector

What Are the Key Trends Shaping the Electric Vehicle Manufacturers USA Market?

The electric vehicle (EV) market in the USA is undergoing a transformative phase, driven by a convergence of technological advancements, regulatory changes, and shifting consumer preferences. The global push for sustainability and carbon neutrality is catalyzing a surge in EV adoption, with projections indicating that the market will exceed $1 trillion by 2029. This growth is further fueled by innovations in battery technology, enhancing range and reducing charging times, which are critical factors for B2B buyers in sectors such as logistics and transportation.

Emerging technologies such as Vehicle-to-Grid (V2G) systems and autonomous driving capabilities are also gaining traction, offering new business models and revenue streams for manufacturers. B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of the increasing importance of partnerships with tech companies for integrated solutions that extend beyond vehicle manufacturing. Additionally, the expansion of charging infrastructure, particularly in urban areas, is vital for supporting widespread EV adoption and is a key consideration for international buyers looking to invest in the EV ecosystem.

How Are Sustainability and Ethical Sourcing Impacting the Electric Vehicle Manufacturers USA Sector?

Sustainability is at the forefront of the EV manufacturing sector, with a growing emphasis on ethical sourcing of materials. The environmental impact of battery production, particularly lithium, cobalt, and nickel extraction, poses significant challenges. International B2B buyers must prioritize manufacturers that demonstrate a commitment to ethical supply chains and sustainable practices, such as using recycled materials and renewable energy in production processes.

Certifications such as ISO 14001 for environmental management and adherence to the Responsible Minerals Initiative are becoming essential for manufacturers seeking to differentiate themselves in a competitive market. Buyers should also look for companies that engage in transparent reporting and are willing to share their sustainability goals and achievements. This not only aligns with global sustainability targets but also enhances brand reputation in increasingly eco-conscious markets.

How Has the Electric Vehicle Sector Evolved Over Time?

The evolution of electric vehicles in the USA can be traced back to the late 20th century, but the real resurgence began in the late 2000s with the introduction of models like the Nissan Leaf and Tesla Roadster. Initially seen as niche luxury products, EVs have now penetrated various market segments, including SUVs, trucks, and commercial vehicles, catering to a broader audience.

As technology has advanced, manufacturers have prioritized performance and convenience, leading to significant improvements in range, charging infrastructure, and vehicle features. This shift is not only reshaping consumer perceptions but also altering the landscape for international B2B buyers, who now have access to a diverse range of products tailored to meet their operational needs. The ongoing investment in research and development further signals a commitment to innovation, ensuring that the electric vehicle sector will continue to expand and evolve in the coming years.

Frequently Asked Questions (FAQs) for B2B Buyers of electric vehicle manufacturers usa

-

How do I evaluate electric vehicle manufacturers for quality and reliability?

To assess the quality and reliability of electric vehicle manufacturers, start by reviewing their certifications and compliance with international standards such as ISO and SAE. Investigate their production processes, material sourcing, and quality assurance measures. Customer reviews and case studies can provide insight into their performance and reliability. Additionally, consider manufacturers with a track record of successful deployments in similar markets, as this indicates their capability to meet diverse demands. -

What are the key features to look for in electric vehicles for commercial use?

When sourcing electric vehicles for commercial applications, prioritize features such as battery range, charging time, payload capacity, and durability. Evaluate the availability of advanced technologies like telematics for fleet management and connectivity options for remote diagnostics. Additionally, consider the manufacturer’s support for after-sales service and maintenance, as well as the vehicle’s adaptability to local regulations and road conditions. -

What is the typical minimum order quantity (MOQ) for electric vehicles?

The minimum order quantity (MOQ) for electric vehicles can vary significantly based on the manufacturer and the type of vehicle. Generally, large-scale manufacturers may set an MOQ between 10 to 50 units for commercial orders. Smaller manufacturers or startups might have more flexible MOQs, sometimes allowing for orders as low as 5 units. Always negotiate with the supplier to find a quantity that aligns with your business needs and logistics capabilities. -

What payment terms should I expect when sourcing electric vehicles internationally?

Payment terms for international purchases of electric vehicles typically include options such as letters of credit, advance payments, or net payment terms (e.g., net 30 or net 60 days). It is crucial to establish clear terms before finalizing the deal, including currency, payment method, and any applicable taxes or tariffs. Additionally, consider using escrow services for high-value transactions to mitigate risks associated with international trade. -

How can I ensure compliance with local regulations when importing electric vehicles?

To ensure compliance with local regulations when importing electric vehicles, first research the specific laws and standards in your target market, such as safety, emissions, and import tariffs. Engage with local authorities or industry associations for guidance on regulatory requirements. Additionally, work closely with your supplier to obtain all necessary documentation, including certifications and compliance declarations, to facilitate a smooth import process. -

What logistics considerations should I take into account when importing electric vehicles?

When importing electric vehicles, consider logistics factors such as shipping methods, transit times, and the handling of batteries, which may require special transport conditions. Choose a freight forwarder experienced in automotive logistics to navigate customs procedures and ensure compliance with international shipping regulations. Additionally, plan for local transportation and delivery to your facility, factoring in potential delays due to customs clearance. -

How can I customize electric vehicles to meet my business needs?

Many electric vehicle manufacturers offer customization options tailored to business requirements. Discuss your specific needs with potential suppliers, such as modifications in design, equipment, or software integration. Ensure the manufacturer has the capability and flexibility to accommodate customizations while maintaining compliance with safety and regulatory standards. Request prototypes or samples to evaluate the modifications before making a bulk order. -

What is the warranty coverage typically offered for electric vehicles?

Warranty coverage for electric vehicles generally includes a combination of vehicle warranty and battery warranty. Most manufacturers offer a standard vehicle warranty ranging from 3 to 5 years, while battery warranties can extend up to 8 years or a specified mileage (e.g., 100,000 miles). Review the terms carefully to understand what components are covered and any exclusions. Additionally, inquire about extended warranty options or maintenance plans to safeguard your investment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electric vehicle manufacturers usa

In the rapidly evolving landscape of electric vehicle (EV) manufacturing in the USA, strategic sourcing has become a critical component for international buyers seeking competitive advantages. With a diverse array of manufacturers—from established giants like Ford and GM to innovative newcomers such as Lucid Motors—B2B buyers can access a broad spectrum of electric models tailored to various market demands. This diversification not only enhances product offerings but also facilitates entry into new markets by leveraging unique design and technology features.

Establishing strong relationships with American EV manufacturers allows international businesses to capitalize on the growing global EV market, projected to exceed $1 trillion by 2029. By strategically sourcing from this dynamic sector, buyers can ensure they are equipped with cutting-edge technology, sustainability initiatives, and robust supply chains.

As electric vehicles increasingly dominate the automotive landscape, now is the time for B2B buyers from Africa, South America, the Middle East, and Europe to engage with US manufacturers. Explore opportunities for collaboration and investment in this transformative industry to secure a sustainable and profitable future. Your strategic sourcing decisions today can position you as a leader in tomorrow’s electric mobility revolution.