Top 6 Blastline Usa List and Guide: How To Solve Scenario 1: Diff…

Introduction: Navigating the Global Market for blastline usa

In today’s competitive landscape, sourcing quality sandblasting equipment and supplies from reliable suppliers like Blastline USA can be daunting, especially for international B2B buyers navigating diverse regulatory environments and logistical challenges. This guide aims to simplify the procurement process by providing a comprehensive overview of Blastline USA’s product offerings, including sandblasting systems, paints, personal protective equipment (PPE), and cleaning supplies.

Buyers will gain insights into various applications of these products across industries, ensuring they select the right solutions tailored to their specific needs. Furthermore, this guide will delve into essential considerations such as supplier vetting, pricing strategies, and shipping logistics, empowering decision-makers from regions like Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam.

By equipping international buyers with actionable insights and expert recommendations, this resource not only enhances their purchasing decisions but also fosters long-term partnerships with trusted suppliers. Ultimately, understanding the nuances of sourcing from Blastline USA can lead to improved operational efficiency and enhanced project outcomes, positioning businesses for success in a global marketplace.

Top 10 Blastline Usa Manufacturers & Suppliers List

1. Blastline USA – Sandblast Machines

Domain: blastlineind.com

Registered: 2009 (16 years)

Introduction: Blastline USA Inc. offers a diverse line of products including sandblast machines, blast nozzles, blast hoses, and safety equipment. They provide free shipping on orders of $1,000 or more. Featured products include Rubber Crumb Synthetic Turf Infill Material priced at $2.00 per lb and Master MAC-012-FD 12″ x 15′ Flexible Ducting. The company features over 100 top brands with more than 100,000 prod…

2. Blastline USA – Industrial Equipment & More

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Blastline USA offers a wide range of products across various categories including Business & Industrial, Home & Garden, Electronics, Clothing & Accessories, Health & Beauty, Toys & Hobbies, Sporting Goods, Collectibles & Art, and more. Specific subcategories include Hydraulics, Pneumatics, Pumps & Plumbing, Building Materials & Supplies, CNC, Metalworking & Manufacturing, Facility Maintenance & Sa…

3. Blastline USA Inc – Mechanical Engineering Solutions

4. Blastline USA – Sand Blaster

Domain: tool.report

Registered: 2018 (7 years)

Introduction: 1. Blastline USA Sand Blaster (3 Points) – Price: $174.00 – Average Rating: 5.0 out of 5 stars – Features: Excellent craftsmanship, durable, effective for removing rust or tarnish, suitable for both workplace and home use. 2. Blastline USA Sand Blaster (2 Points) – Price: $97.00 – Features: Lightweight, easy to use, excellent quality for the price. Additional Features: Comfortable pistol-grip desi…

5. Blastline USA Inc. – Blast Cleaning Equipment

Domain: us.metoree.com

Registered: 2020 (5 years)

Introduction: Blastline USA Inc. manufactures blast cleaning equipment for fabrication, shipbuilding, and petrochemical industries. Complementary products include blast rooms, dust extraction equipment, airless paint equipment, and media recovery systems.

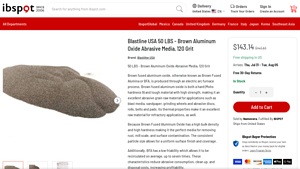

6. Blastline USA – 50 lbs Brown Aluminum Oxide Abrasive Media

Domain: ibspot.com

Registered: 2006 (19 years)

Introduction: Blastline USA 50 lbs Brown Aluminum Oxide Abrasive Media, 120 grit

Understanding blastline usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Sandblasting Equipment | Includes blast machines, nozzles, hoses, and safety gear | Surface preparation, industrial cleaning | Pros: Versatile applications; Cons: Equipment can be costly to maintain. |

| Paints and Coatings | Wide range of protective and decorative coatings | Automotive, construction, and manufacturing | Pros: Enhances durability; Cons: Requires proper application techniques. |

| Personal Protective Equipment | Gear designed to ensure worker safety during operations | Construction, manufacturing, and maintenance | Pros: Essential for worker safety; Cons: May require training for effective use. |

| Abrasives | Various materials for effective surface preparation | Metalworking, automotive, and construction | Pros: Improves surface quality; Cons: Selection can be complex based on application. |

| Cleaning Supplies | Includes chemicals and tools for facility maintenance | Commercial and industrial cleaning applications | Pros: Keeps environments safe and clean; Cons: Environmental regulations may limit options. |

What Are the Key Features of Sandblasting Equipment in B2B Operations?

Sandblasting equipment is essential for surface preparation in various industries, including automotive and manufacturing. This category encompasses machines, nozzles, hoses, and safety gear, allowing for effective cleaning and finishing of surfaces. B2B buyers should consider the compatibility of equipment with their specific applications, maintenance needs, and the potential for scalability as their operations grow.

How Do Paints and Coatings Benefit B2B Buyers?

Paints and coatings provide protective and aesthetic benefits to a variety of surfaces, making them crucial in sectors like construction and automotive. The selection ranges from industrial-grade coatings to specialized paints, each tailored to specific environments and applications. Buyers should evaluate the durability, application methods, and environmental compliance of these products to ensure optimal performance and longevity.

Why is Personal Protective Equipment Essential for B2B Operations?

Personal protective equipment (PPE) is vital for safeguarding workers in hazardous environments, particularly in construction and manufacturing. This category includes helmets, gloves, and respiratory gear designed to mitigate risks associated with sandblasting and other industrial processes. B2B buyers must prioritize compliance with safety regulations and consider the training required for effective PPE use to ensure worker safety.

What Should B2B Buyers Know About Abrasives?

Abrasives play a pivotal role in surface preparation, with various materials available for different applications in metalworking and automotive industries. Key considerations for B2B buyers include the type of abrasive suited for their specific needs, the desired finish quality, and the cost-effectiveness of the abrasive material. Understanding these factors can lead to improved operational efficiency and product quality.

How Do Cleaning Supplies Support B2B Operations?

Cleaning supplies are essential for maintaining cleanliness and safety in commercial and industrial settings. This category includes a range of chemicals and tools designed for effective cleaning. B2B buyers should be aware of environmental regulations that may affect their choices and consider the effectiveness and safety of cleaning products to ensure compliance and operational efficiency.

Key Industrial Applications of blastline usa

| Industry/Sector | Specific Application of blastline usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Renovation | Surface preparation for concrete and metal surfaces | Enhances adhesion of paints and coatings, ensuring durability and longevity | Quality of abrasives, compliance with local regulations, availability of PPE |

| Automotive Manufacturing | Sandblasting for vehicle parts | Removes rust and prepares surfaces for painting, ensuring high-quality finishes | Consistency of product quality, compatibility with existing systems, and lead times |

| Oil & Gas Industry | Cleaning and maintenance of drilling equipment | Increases equipment lifespan and operational efficiency by preventing corrosion | Availability of specialized cleaning equipment, safety standards, and shipping logistics |

| Aerospace | Surface treatment of aircraft components | Improves performance and safety by ensuring proper surface preparation for coatings | Certification of materials, adherence to industry standards, and international shipping capabilities |

| Marine | Anti-fouling treatments for vessels | Protects hull integrity and reduces maintenance costs over time | Durability of materials, environmental regulations, and sourcing logistics for remote locations |

How is Blastline USA Used in Construction and Renovation Projects?

In the construction and renovation sectors, Blastline USA provides essential sandblasting equipment that facilitates the surface preparation of concrete and metal surfaces. This process is critical for ensuring that paints and coatings adhere properly, significantly extending the lifespan of structures. International buyers from regions like Africa and South America should prioritize sourcing high-quality abrasives and safety equipment, ensuring compliance with local regulations to mitigate risks associated with surface preparation.

What Role Does Blastline USA Play in Automotive Manufacturing?

In the automotive industry, Blastline USA’s sandblasting systems are utilized for cleaning and preparing vehicle parts. By effectively removing rust and contaminants, these systems ensure that surfaces are ready for high-quality painting. For B2B buyers, especially in Europe and the Middle East, it is crucial to consider the consistency of product quality and the compatibility of equipment with existing manufacturing systems to streamline operations and minimize downtime.

How is Blastline USA Beneficial for the Oil and Gas Industry?

The oil and gas sector relies heavily on Blastline USA’s cleaning and maintenance solutions for drilling equipment. Regular sandblasting not only removes corrosive materials but also enhances the operational efficiency of equipment, thereby extending its lifespan. Buyers in remote regions must focus on sourcing specialized cleaning equipment that meets stringent safety standards, alongside effective shipping logistics to ensure timely delivery.

How Does Blastline USA Support Aerospace Applications?

In aerospace, Blastline USA offers surface treatment solutions that are vital for aircraft components. Proper surface preparation is crucial for ensuring that coatings perform as intended, contributing to the safety and efficiency of the aircraft. Buyers should look for certified materials that adhere to industry standards, as well as suppliers with robust international shipping capabilities to facilitate procurement across borders, particularly in regions like Europe and the Middle East.

What Advantages Does Blastline USA Provide for Marine Applications?

For the marine industry, Blastline USA’s anti-fouling treatments are essential for maintaining vessel integrity. These treatments protect hulls from corrosion and marine growth, which can significantly reduce maintenance costs over time. When sourcing these products, businesses should consider the durability of materials used and ensure compliance with environmental regulations, especially in regions where marine conservation is a priority.

3 Common User Pain Points for ‘blastline usa’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Sandblasting Equipment

The Problem: International B2B buyers often struggle to find reliable suppliers for sandblasting equipment that meet stringent quality standards. This challenge is especially pronounced in regions like Africa and South America, where local options may be limited. Buyers might face subpar equipment that leads to inefficiencies, increased downtime, and ultimately, higher operational costs. Furthermore, concerns about the durability and performance of equipment can lead to anxiety over investment decisions.

The Solution: To address sourcing challenges, buyers should leverage Blastline USA’s extensive product catalog, which features over 100,000 items from more than 100 top brands. Conduct thorough research on the specific equipment required for your projects, such as blast machines, nozzles, and hoses. Utilize Blastline’s customer service, which emphasizes 5-star service, to consult with knowledgeable staff who can guide you toward the best products for your needs. Ensure to inquire about certifications and quality assurance measures that the equipment adheres to, providing peace of mind regarding the durability and performance of your investment.

Scenario 2: Navigating Compliance and Safety Standards

The Problem: B2B buyers in the sandblasting industry frequently encounter challenges related to compliance with safety and operational regulations. Different countries have varying standards for workplace safety and equipment usage, leading to confusion about what is required. This issue can hinder project timelines and expose companies to legal liabilities, particularly in regions like the Middle East and Europe, where regulations are stringent.

The Solution: Buyers should prioritize sourcing personal protective equipment (PPE) and safety gear from Blastline USA, which offers a comprehensive selection designed to meet international safety standards. It’s essential to understand the specific regulations applicable in your region; thus, consulting local industry experts or regulatory bodies can provide clarity. Moreover, Blastline USA’s commitment to customer satisfaction means they can assist in ensuring that all equipment purchased meets or exceeds these safety requirements. When ordering, explicitly request documentation confirming compliance with the relevant safety standards to safeguard your operations.

Scenario 3: Managing Cost and Shipping Logistics

The Problem: Cost management is a critical pain point for B2B buyers, particularly when dealing with international shipping and logistics. High shipping costs can significantly impact the overall expenditure on sandblasting supplies, making it difficult to maintain budgetary constraints. Additionally, delays in shipping can lead to project setbacks, causing frustration and potential financial loss.

The Solution: To effectively manage costs, buyers should take advantage of Blastline USA’s low price guarantee and free shipping on orders over $1,000. Planning bulk purchases can not only reduce per-unit costs but also minimize shipping expenses. Buyers should also consider timing their orders strategically to align with promotional offers or seasonal discounts. Communication with Blastline’s customer support can provide insights into shipping timelines and potential cost-saving strategies. Additionally, when placing orders, consider utilizing freight forwarders or local distributors to streamline the logistics process, ensuring timely delivery while keeping costs in check.

Strategic Material Selection Guide for blastline usa

When selecting materials for sandblasting equipment and related applications, international B2B buyers must consider various factors that influence performance, durability, and compliance with industry standards. Below is an analysis of four common materials used in products offered by Blastline USA, focusing on their properties, advantages, disadvantages, and specific considerations for international markets.

What are the Key Properties of Steel in Sandblasting Equipment?

Steel is a widely used material in the construction of sandblasting equipment due to its strength and versatility. It typically exhibits high tensile strength, making it suitable for high-pressure applications. Additionally, steel can be treated for enhanced corrosion resistance, which is crucial for maintaining equipment longevity in harsh environments.

Pros and Cons of Steel:

– Pros: Durable, high load-bearing capacity, and can be coated for corrosion resistance.

– Cons: Heavier than alternative materials, may require more maintenance due to rusting if not properly treated, and can be more expensive to manufacture.

Impact on Application: Steel is compatible with a variety of abrasive media, making it suitable for diverse blasting applications. However, its weight may affect the mobility of portable units.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards, such as ASTM for materials testing. Additionally, the availability of corrosion-resistant coatings may vary, influencing procurement decisions.

How Does Aluminum Compare as a Material for Blast Equipment?

Aluminum is another popular choice for sandblasting equipment, particularly in portable units. It is lightweight and exhibits good corrosion resistance, which is essential for maintaining equipment in outdoor or humid environments.

Pros and Cons of Aluminum:

– Pros: Lightweight, excellent corrosion resistance, and easy to machine.

– Cons: Lower tensile strength compared to steel, may deform under high pressure, and can be more expensive per pound.

Impact on Application: Aluminum’s lightweight nature enhances portability, making it ideal for mobile sandblasting operations. However, it may not be suitable for heavy-duty applications requiring high strength.

Considerations for International Buyers: Compliance with standards such as JIS in Japan or DIN in Germany is crucial for ensuring product quality. Buyers should also consider local market preferences for lightweight equipment.

What Role Does Rubber Play in Sandblasting Equipment?

Rubber is primarily used in hoses and protective gear within sandblasting systems. Its flexibility and resistance to abrasion make it an excellent choice for high-wear applications.

Pros and Cons of Rubber:

– Pros: Flexible, good abrasion resistance, and can be manufactured in various grades for specific applications.

– Cons: Limited temperature resistance and may degrade when exposed to certain chemicals.

Impact on Application: Rubber hoses are compatible with a wide range of abrasive materials, providing reliable performance in various conditions. However, the temperature limitations may restrict their use in high-heat environments.

Considerations for International Buyers: Buyers should verify that rubber products meet relevant safety standards, particularly in regions with stringent regulations. Understanding local preferences for rubber grades can also influence purchasing decisions.

How Does Plastic Fit into the Material Selection for Blastline USA Products?

Plastic, particularly high-density polyethylene (HDPE), is increasingly used in sandblasting applications due to its lightweight and chemical resistance. It is commonly found in protective equipment and certain components of sandblasting machines.

Pros and Cons of Plastic:

– Pros: Lightweight, resistant to chemicals, and cost-effective.

– Cons: Lower durability compared to metals, can be affected by UV exposure, and may have limited temperature resistance.

Impact on Application: Plastic components can enhance the overall efficiency of sandblasting systems by reducing weight. However, their lower durability may necessitate more frequent replacements.

Considerations for International Buyers: Compliance with local environmental regulations regarding plastic use is essential, particularly in Europe where regulations may be stricter. Understanding the chemical compatibility of plastics with various abrasives is also vital.

Summary Table of Material Selection for Blastline USA

| Material | Typical Use Case for blastline usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Sandblasting machines and components | High strength and durability | Heavier and requires maintenance | Medium |

| Aluminum | Portable sandblasting units | Lightweight and corrosion-resistant | Lower strength under pressure | High |

| Rubber | Hoses and protective gear | Flexible and abrasion-resistant | Limited temperature resistance | Medium |

| Plastic | Protective equipment and components | Lightweight and chemical-resistant | Lower durability compared to metals | Low |

This guide provides valuable insights into material selection for sandblasting equipment, helping international B2B buyers make informed decisions tailored to their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for blastline usa

What Are the Key Stages of Manufacturing at Blastline USA?

Blastline USA employs a comprehensive manufacturing process to ensure high-quality sandblasting equipment and supplies. This process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The initial stage involves sourcing high-grade materials that comply with international standards. This includes metals, plastics, and other composites essential for durability and performance. Suppliers are carefully vetted to ensure they provide materials that meet stringent specifications.

-

Forming: Once materials are prepared, they undergo various forming techniques, such as cutting, bending, and machining. Advanced technologies like CNC (Computer Numerical Control) machining are utilized for precision and consistency. This stage is crucial for creating components that fit seamlessly into the final product.

-

Assembly: After forming, components are meticulously assembled. Skilled technicians follow detailed assembly instructions to ensure that each product meets operational standards. Quality control checkpoints are integrated throughout this stage to catch any issues early.

-

Finishing: The final stage includes surface treatment processes such as sandblasting, painting, and applying protective coatings. This not only enhances the aesthetic appeal but also ensures that products can withstand harsh industrial environments. The finishing process is critical for maintaining the longevity of the equipment.

How Does Blastline USA Ensure Quality Assurance in Manufacturing?

Quality assurance is integral to Blastline USA’s operations, ensuring that products meet both domestic and international standards. The company adheres to several quality control measures throughout the manufacturing process.

-

International Standards Compliance: Blastline USA is committed to maintaining ISO 9001 certification, which outlines the requirements for a quality management system. This certification demonstrates the company’s ability to consistently provide products that meet customer and regulatory requirements.

-

Industry-Specific Certifications: In addition to ISO standards, Blastline USA also complies with other relevant industry standards such as CE marking for European markets and API standards for oil and gas applications. These certifications are essential for B2B buyers seeking assurance that products meet specific safety and performance criteria.

-

Quality Control Checkpoints: The quality control process includes several critical checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from quality standards in real-time.

– Final Quality Control (FQC): Once products are completed, they undergo rigorous testing and inspection to ensure they meet all quality benchmarks before shipping.

What Common Testing Methods Are Used in Quality Assurance?

Blastline USA employs a variety of testing methods to validate the quality and performance of its products. Some of the common testing methods include:

- Dimensional Inspection: Using precision measurement tools to ensure that components meet specified dimensions.

- Functional Testing: Assessing the operational efficiency of equipment under various conditions to verify performance.

- Durability Testing: Subjecting products to stress tests to evaluate their resistance to wear and tear over time.

- Safety Testing: Ensuring that products meet safety standards to protect users from potential hazards.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are some actionable steps to ensure supplier compliance:

-

Request Audits and Certifications: Buyers should ask for copies of relevant certifications (e.g., ISO 9001, CE) and audit reports to confirm that the supplier adheres to recognized quality standards.

-

Conduct On-Site Visits: If feasible, visiting the manufacturing facility allows buyers to observe the quality control processes firsthand. This can provide valuable insights into the supplier’s operational practices.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control measures. These services can conduct audits and provide detailed reports on compliance with international standards.

-

Evaluate Supplier Track Record: Researching the supplier’s history, including customer feedback and complaint resolution, can provide insights into their commitment to quality. Platforms like the Better Business Bureau (BBB) can offer useful information about the supplier’s reputation.

What Are the Quality Control Nuances for International Buyers?

When engaging with suppliers from different regions, B2B buyers should be aware of the nuances in quality control practices:

-

Cultural Differences: Different regions may have varying attitudes toward quality assurance. Understanding these cultural differences can facilitate better communication and expectations.

-

Regulatory Variations: International buyers should familiarize themselves with local regulations that may affect product compliance. For instance, products sold in the European Union must meet specific CE marking requirements.

-

Language Barriers: Clear communication is essential. Buyers should ensure that all quality specifications and standards are documented in a language that both parties understand.

-

Logistical Considerations: Shipping and handling can impact product quality. Buyers should discuss packaging and transportation standards with suppliers to minimize damage during transit.

By taking these steps, B2B buyers can effectively assess the quality assurance processes of Blastline USA and make informed purchasing decisions that align with their operational requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘blastline usa’

This guide serves as a practical resource for B2B buyers interested in procuring products from Blastline USA, a leading supplier of sandblasting equipment and surface preparation products. By following this step-by-step checklist, you can ensure a streamlined and effective sourcing process.

Step 1: Define Your Technical Specifications

Before initiating contact with suppliers, clearly outline your project requirements. This includes the types of sandblasting equipment needed, material specifications, and any regulatory compliance requirements. Detailed specifications help in obtaining accurate quotes and ensure that the products meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research on Blastline USA and its offerings. Review their website to understand the range of products available, including sandblasting machines, nozzles, and personal protective equipment (PPE). Investigating customer reviews and testimonials can also provide insights into product quality and service reliability.

Step 3: Evaluate Supplier Credentials

Verify the credentials of Blastline USA, including their years in business and industry certifications. Given that they have been operational since 2002, understanding their experience can provide confidence in their ability to meet your needs. Additionally, check for any ratings from organizations like the Better Business Bureau (BBB) to gauge their reputation in the market.

Step 4: Request Quotes and Compare Prices

Once you have identified your specifications and vetted the supplier, request detailed quotes from Blastline USA. Pay attention to pricing structures, including potential discounts for bulk purchases. Comparing these quotes with competitors can help you secure the best deal while ensuring you are getting quality products.

Step 5: Assess Customer Service and Support

Evaluate the customer service offered by Blastline USA. Effective communication is crucial for resolving issues and ensuring smooth transactions. Reach out with questions regarding products, warranties, and return policies. A responsive and knowledgeable support team is indicative of a reliable supplier.

Step 6: Review Shipping and Payment Terms

Clarify the shipping options and payment terms with Blastline USA. Look for details such as shipping costs, delivery timelines, and any free shipping thresholds (e.g., orders over $1,000). Understanding payment methods accepted, including credit terms, can also impact your cash flow management.

Step 7: Finalize the Order and Monitor Delivery

After selecting the best offer, finalize your order with Blastline USA. Ensure you receive a confirmation that outlines all agreed-upon terms. Once the order is placed, monitor the delivery process closely and maintain communication with the supplier to address any potential delays or issues.

By following this comprehensive checklist, B2B buyers can navigate the procurement process effectively, ensuring they select the right products from Blastline USA while minimizing risks and maximizing value.

Comprehensive Cost and Pricing Analysis for blastline usa Sourcing

What Are the Key Cost Components for Sourcing from Blastline USA?

When evaluating sourcing options from Blastline USA, it is essential to understand the core cost components that contribute to the total price of products. These components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts the overall cost. Blastline USA offers a wide range of products, from abrasives to PPE, which can vary in quality and price. Buyers should assess the material specifications to ensure they meet their operational needs without overpaying.

-

Labor: Labor costs are influenced by the complexity of the manufacturing process. For specialized equipment such as sandblasting machines, skilled labor is required, which can increase the cost. Understanding the labor dynamics within the supply chain is crucial for accurate budgeting.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Blastline USA operates with a focus on efficiency, which can help mitigate these overheads. However, buyers should inquire about how these costs are factored into product pricing.

-

Tooling: Custom tooling for specific product requirements can add to the initial costs. Buyers interested in custom solutions should be aware of potential tooling fees and lead times.

-

Quality Control (QC): Ensuring product quality can involve additional costs, particularly for items that require certifications or compliance with international standards. Buyers should evaluate the QC processes in place to mitigate risks associated with product failures.

-

Logistics: Shipping costs can vary based on the destination, volume, and weight of orders. Blastline USA offers free shipping on orders over $1,000, which can be a significant cost-saving factor for bulk buyers.

-

Margin: Understanding the profit margin that Blastline USA applies to its products can help buyers gauge the competitiveness of pricing. Engaging in discussions about pricing structures can reveal flexibility in margins based on order size or long-term partnerships.

How Do Price Influencers Affect Sourcing Decisions from Blastline USA?

Several factors influence the pricing structure for products sourced from Blastline USA, making it vital for buyers to consider these when negotiating.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract discounts, reducing the unit price. Buyers should assess their purchasing capacity and negotiate terms that align with their needs to maximize savings.

-

Specifications and Customization: Customized products can lead to increased costs due to additional manufacturing requirements. Buyers need to balance their need for customization with their budget constraints.

-

Materials Quality and Certifications: Higher-quality materials or those with specific certifications (e.g., ISO, ANSI) typically come at a premium. Buyers should evaluate whether the additional cost aligns with their quality standards and regulatory requirements.

-

Supplier Factors: The reliability and reputation of Blastline USA as a supplier can influence pricing. Engaging with suppliers who have a proven track record can lead to better pricing negotiations and terms.

-

Incoterms: Understanding the shipping terms is crucial for international buyers. Incoterms dictate who is responsible for shipping costs, insurance, and risk during transportation, which can significantly affect the total cost.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing from Blastline USA?

To maximize value when sourcing from Blastline USA, international B2B buyers should consider the following tips:

-

Negotiate Pricing: Always engage in discussions about pricing. Suppliers may offer discounts for larger orders or long-term contracts, which can lead to substantial cost savings.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price to evaluate the total cost of ownership, which includes maintenance, operational costs, and potential downtime. This comprehensive view can lead to more informed purchasing decisions.

-

Understand Pricing Nuances for International Buyers: When sourcing from regions like Africa, South America, the Middle East, and Europe, be aware of currency fluctuations, import duties, and local taxes that can impact the final cost.

-

Utilize Bulk Purchasing: If feasible, consider consolidating orders to meet the free shipping threshold or to negotiate better pricing.

-

Stay Informed on Market Trends: Being aware of market dynamics and competitor pricing can empower buyers to negotiate better deals and identify the best times to purchase.

Disclaimer

Prices and terms mentioned are indicative and subject to change based on market conditions and specific buyer negotiations. It is advisable for buyers to directly contact Blastline USA for the most accurate and updated pricing information.

Alternatives Analysis: Comparing blastline usa With Other Solutions

Understanding Alternatives in Surface Preparation Solutions

When evaluating surface preparation solutions, it’s essential for international B2B buyers to consider various options available in the market. Different products can offer unique advantages tailored to specific operational needs, budgets, and implementation scenarios. This analysis compares Blastline USA with two viable alternatives: Graco and Axxiom Manufacturing, focusing on their performance, cost, ease of implementation, maintenance requirements, and best use cases.

Comparison Table

| Comparison Aspect | Blastline USA | Graco | Axxiom Manufacturing |

|---|---|---|---|

| Performance | High-quality sandblasting systems | Versatile spray equipment | Specialized surface preparation |

| Cost | Competitive pricing, free shipping | Mid-range pricing | Premium pricing for high-end products |

| Ease of Implementation | User-friendly systems | Requires training for optimal use | Straightforward installation |

| Maintenance | Moderate maintenance | Low maintenance, durable | High maintenance, but reliable |

| Best Use Case | General surface preparation needs | Industrial coating applications | High-precision surface finishing |

Detailed Breakdown of Alternatives

Graco

Graco is well-known for its versatile spray equipment that can be used for a range of applications, including painting and coating. The primary advantage of Graco products is their adaptability to various materials and surfaces, making them suitable for industrial coatings. However, the mid-range pricing may be a barrier for smaller businesses. Additionally, while their equipment is durable, optimal use often requires training, which can add to initial setup time.

Axxiom Manufacturing

Axxiom Manufacturing focuses on providing high-precision surface preparation solutions, particularly for industries requiring meticulous surface finishing. Their products are engineered for durability and reliability, ensuring consistent performance. However, the premium pricing associated with Axxiom products may not be justifiable for every business, particularly for those with tighter budgets. Furthermore, the maintenance requirements can be higher than average, necessitating more frequent checks and servicing.

Conclusion: How to Choose the Right Surface Preparation Solution

Selecting the right surface preparation solution requires a thorough understanding of your specific operational needs and budget. Buyers should consider performance requirements—whether general preparation or specialized finishing is needed—as well as cost implications and maintenance capabilities. It’s also vital to evaluate how easily the equipment can be integrated into existing workflows. By weighing these factors against the strengths and weaknesses of alternatives like Graco and Axxiom Manufacturing, buyers can make informed decisions that align with their business goals and operational efficiency.

Essential Technical Properties and Trade Terminology for blastline usa

What Are the Essential Technical Properties of Blastline USA Products?

When sourcing equipment and supplies from Blastline USA, understanding key technical properties is crucial for making informed purchasing decisions. Here are some critical specifications that buyers should consider:

-

Material Grade

Material grade refers to the quality and type of materials used in manufacturing products like blast hoses and nozzles. High-grade materials ensure durability and performance under high pressure and abrasive conditions. Selecting the appropriate material grade can significantly impact the longevity and efficiency of sandblasting operations, reducing downtime and maintenance costs. -

Tolerance Levels

Tolerance levels indicate the allowable deviation in the dimensions of a product. For instance, precision in the diameter of a blast nozzle affects the flow rate and effectiveness of the blasting process. Understanding tolerance levels is essential to ensure that the equipment fits seamlessly into existing systems and meets operational requirements, thereby enhancing productivity. -

Operating Pressure

This specification denotes the maximum pressure at which equipment can safely operate. In sandblasting applications, operating pressure affects the speed and quality of the surface preparation. Buyers need to select equipment that matches their operational pressure requirements to optimize performance and minimize safety risks. -

Abrasive Compatibility

Different blasting applications require various types of abrasives. Understanding which abrasives are compatible with specific blasting equipment is essential for achieving desired results. Buyers should ensure that the equipment from Blastline USA is suitable for the abrasives they plan to use, as this will affect both efficiency and surface finish quality. -

Safety Standards Compliance

Safety standards such as OSHA regulations must be adhered to when using blasting equipment. Products that meet these standards not only ensure compliance but also protect workers from potential hazards. Buyers should prioritize equipment that is certified for safety, thereby mitigating risks associated with surface preparation tasks.

What Are Common Trade Terms Relevant to Blastline USA?

Familiarity with industry jargon is vital for effective communication and negotiation in the procurement process. Here are some commonly used terms in the context of Blastline USA’s offerings:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another company. Understanding OEM relationships is important for buyers as it indicates the quality and authenticity of the products, ensuring that they meet the required specifications. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers, particularly for small businesses or those looking to test new products without incurring excessive costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. This process is essential for buyers seeking competitive pricing and ensuring they receive the best value for their procurement needs. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand the logistics and costs associated with their orders, facilitating smoother transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the products. Understanding lead times is vital for planning and inventory management, as delays can impact project timelines and operational efficiency.

By grasping these technical properties and trade terms, international B2B buyers can make well-informed decisions, ensuring they procure the right equipment and supplies from Blastline USA to meet their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the blastline usa Sector

What Are the Key Market Dynamics and Trends Influencing the Blastline USA Sector?

The market for surface preparation equipment, particularly in the blastline USA sector, is experiencing significant shifts driven by various global factors. The rise in construction and manufacturing activities across Africa, South America, the Middle East, and Europe is a substantial catalyst for growth. As industries seek to enhance operational efficiencies, the demand for advanced sandblasting systems and related products is surging. Additionally, technological advancements, including automation and digitization, are reshaping the way businesses source and procure equipment. International B2B buyers are increasingly utilizing e-commerce platforms to streamline procurement processes, enabling them to access a broader range of products and competitive pricing.

Emerging trends such as the integration of IoT devices in machinery are also gaining traction, allowing for better monitoring and maintenance of equipment. This trend enhances operational efficiency and reduces downtime, a critical consideration for businesses aiming to optimize performance. Moreover, the focus on safety and compliance continues to grow, pushing companies to invest in high-quality personal protective equipment (PPE) and safety gear as part of their procurement strategy.

For international buyers, understanding these dynamics is essential. Companies in regions like Germany and Vietnam are particularly focused on sourcing reliable suppliers that can offer comprehensive solutions, from sandblasting equipment to safety gear, while ensuring competitive pricing and robust customer service.

How Can Sustainability and Ethical Sourcing Impact B2B Buyers in the Blastline USA Sector?

Sustainability is becoming a paramount concern for businesses globally, and the blastline USA sector is no exception. The environmental impact of sandblasting operations necessitates a shift toward more sustainable practices. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainable manufacturing processes. This includes the use of eco-friendly materials and practices that reduce waste and emissions.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are seeking suppliers who can provide transparency regarding their sourcing practices and the environmental impact of their products. Certifications such as ISO 14001 (Environmental Management) and other green certifications are becoming essential criteria for selection. By choosing suppliers with these certifications, businesses not only contribute to environmental sustainability but also enhance their brand reputation, aligning with the values of environmentally conscious consumers and stakeholders.

In addition, the use of sustainable materials in products, such as recyclable blast media, is gaining traction. This not only reduces the ecological footprint of operations but also often leads to cost savings in the long run. B2B buyers who prioritize these aspects in their sourcing strategies can create a competitive advantage while fostering positive environmental impact.

What Is the Historical Context of Blastline USA and Its Relevance to Today’s Market?

Blastline USA Inc. was established in 2002, carving a niche in the surface preparation industry by offering an extensive array of sandblasting equipment and supplies. Over the years, the company has grown to provide over 100,000 products from more than 100 top brands, making it a significant player in the B2B marketplace. The company’s long-standing presence in the industry has allowed it to build a reputation for quality and customer service, which are critical factors for international buyers.

The evolution of Blastline USA reflects broader market trends, including the increasing reliance on e-commerce for industrial supplies and the growing importance of safety and compliance in operational practices. As the company continues to adapt to changing market dynamics, its history serves as a testament to its resilience and commitment to meeting the diverse needs of its international clientele. This historical context is not only relevant for understanding the company’s current offerings but also highlights the importance of adaptability in the fast-evolving landscape of B2B sourcing.

Frequently Asked Questions (FAQs) for B2B Buyers of blastline usa

-

How can I ensure the quality of blastline USA products before purchasing?

To verify the quality of products from Blastline USA, consider requesting product samples or detailed specifications. It’s also beneficial to check customer reviews and testimonials regarding specific items. Engaging with the company’s customer service can provide insights into their quality assurance processes. Additionally, reviewing their certifications and compliance with international standards can further affirm the quality and reliability of their offerings. -

What types of sandblasting equipment does Blastline USA offer?

Blastline USA provides a comprehensive range of sandblasting equipment, including various blast machines, nozzles, hoses, and personal protective equipment (PPE). They cater to diverse industries, offering both standard and customized solutions. It’s advisable to visit their website or contact their sales team to discuss specific needs and explore available options, ensuring you find the best fit for your projects. -

What is the minimum order quantity (MOQ) for products from Blastline USA?

The minimum order quantity at Blastline USA may vary depending on the type of product. Typically, bulk orders may be required for specific items, especially for industrial-grade equipment. For precise information, it is recommended to reach out directly to their sales department. They can provide tailored advice based on your purchasing needs and volume. -

What payment terms does Blastline USA offer for international buyers?

Blastline USA generally offers flexible payment terms, including credit card payments, wire transfers, and possibly letters of credit for larger orders. Specific payment terms can depend on the order size and buyer’s credit history. It’s advisable to discuss your payment preferences with their account manager to ensure a smooth transaction process. -

How does Blastline USA handle international shipping and logistics?

Blastline USA offers shipping options for international orders, typically partnering with reliable logistics providers. The shipping costs and delivery times will vary based on the destination and order size. It’s important to confirm shipping details, including customs duties and any necessary documentation, with their customer service to ensure compliance with local regulations. -

What customization options are available for sandblasting equipment?

Blastline USA understands that different projects may require specific configurations. They offer customization options for certain products, such as tailored blast machine sizes or specific nozzle types. To explore customization possibilities, it is advisable to directly contact their sales team, who can guide you through the available options to meet your unique requirements. -

How can I vet Blastline USA as a reliable supplier?

To vet Blastline USA, consider researching their business history, customer reviews, and industry reputation. Check their BBB rating and any complaints filed against them, as these can provide insight into customer satisfaction. Additionally, engaging in direct communication with their customer service can help assess their responsiveness and willingness to address your concerns. -

What types of personal protective equipment (PPE) does Blastline USA provide?

Blastline USA offers a wide array of personal protective equipment designed to ensure safety during sandblasting operations. This includes helmets, gloves, respiratory protection, and eye protection. It’s crucial to evaluate your specific safety requirements and consult their product catalog or customer service for recommendations tailored to your operational needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for blastline usa

What Are the Key Benefits of Partnering with Blastline USA for Your Sourcing Needs?

In conclusion, Blastline USA stands out as a reliable partner for international B2B buyers seeking quality surface preparation solutions. With over 100,000 products from more than 100 trusted brands, the company ensures a diverse selection that meets various industry needs. Their commitment to customer satisfaction is evident through their low price guarantee and exceptional service, which includes free shipping on orders over $1,000.

Strategic sourcing with Blastline USA not only enhances procurement efficiency but also fosters long-term relationships built on trust and quality. For businesses in Africa, South America, the Middle East, and Europe, leveraging Blastline’s expertise can lead to significant cost savings and improved operational performance.

How Can You Capitalize on Opportunities with Blastline USA?

Looking ahead, now is an opportune moment for international buyers to engage with Blastline USA. By exploring their extensive catalog and taking advantage of their competitive pricing, companies can position themselves for success in their respective markets. Don’t miss out on the chance to partner with a leader in the sandblasting equipment industry—reach out today to discover how Blastline USA can elevate your procurement strategy and drive your business forward.