Top 5 Riegl Usa List and Guide: How To Solve Scenario 1: Navigati…

Introduction: Navigating the Global Market for riegl usa

In the competitive landscape of sourcing advanced laser scanning solutions, international B2B buyers face the critical challenge of identifying reliable suppliers who can meet diverse operational needs. Riegl USA, a leader in the field of LiDAR technology, provides a comprehensive suite of airborne, mobile, terrestrial, and unmanned laser scanning systems that cater to a wide array of applications, including surveying, civil engineering, and environmental monitoring. This guide is designed to equip you with essential insights into the various types of Riegl products, their applications, and the key considerations for supplier vetting.

Navigating the complexities of the global market requires a strategic approach to purchasing decisions. This guide empowers B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe—including countries like Vietnam and Nigeria—by delivering valuable information on product specifications, cost structures, and support services. By understanding the intricacies of Riegl’s offerings and the broader industry landscape, you can make informed decisions that enhance operational efficiency and drive business growth. Whether you’re evaluating the capabilities of Riegl’s latest scanning technologies or seeking to establish a lasting partnership, this guide serves as your essential resource for successful procurement in the laser scanning domain.

Top 10 Riegl Usa Manufacturers & Suppliers List

1. RIEGL USA – DA Futsal Academy Sponsorship

2. RIEGL – Laser Scanning Solutions

3. Riegl USA – LMS-Q680i Scanner

Domain: qualitydigest.com

Registered: 1996 (29 years)

Introduction: Riegl USA develops and manufactures 3-D laser scanners for airborne lidar, terrestrial mobile mapping, and shipborne hydrographic scanning industries. Key products include the LMS-Q680i scanner with Multiple Time Around (MTA) zone-detection workflow, the RIEGL Software Suite for accurate geo-referenced point clouds, and the VZ-1000 3-D Terrestrial Laser Scanner with a line-scanning mechanism for h…

4. Riegl USA – 3D Laser Scanners and LiDAR Solutions

Domain: us.metoree.com

Registered: 2020 (5 years)

Introduction: Riegl USA manufactures various 3D laser scanners including mobile, terrestrial, and industrial models, as well as LiDAR sensors, cameras, and software. These products are primarily utilized for aerial mapping and surveying, oil and gas exploration, and have applications in forestry, mining, civil engineering, and transportation.

5. RIEGL – Laser Scanning Solutions

Domain: rocketreach.co

Registered: 2015 (10 years)

Introduction: RIEGL is an international provider of airborne, mobile, terrestrial, industrial, and unmanned laser scanning solutions. They focus on pulsed time-of-flight laser radar technology in multiple wavelengths and have developed core Smart-Waveform technologies for digital LiDAR signal processing. Their 3D scanners offer a wide array of performance characteristics and are part of their commitment to “Inn…

Understanding riegl usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Airborne LiDAR Systems | High pulse repetition rates, compact design, versatile scanning angles | Urban mapping, forestry, power line surveys | Pros: High productivity, extensive range. Cons: Requires skilled operators. |

| Mobile LiDAR Systems | Full-circle field of view, real-time data acquisition, robust software integration | Rail surveying, road mapping, infrastructure monitoring | Pros: Efficient data collection in motion. Cons: May be limited by vehicle speed and terrain. |

| Terrestrial LiDAR Systems | High-resolution scanning, long-range capabilities, real-time processing | Topography, civil engineering, archaeology | Pros: Highly accurate and detailed data. Cons: Limited to stationary setups. |

| Unmanned LiDAR Systems | Lightweight, designed for UAV integration, user-friendly | Surveying in hazardous areas, environmental monitoring | Pros: Access to hard-to-reach locations. Cons: Dependent on UAV capabilities and regulations. |

| Industrial LiDAR Systems | Rugged design for harsh environments, compact size, multiple applications | Manufacturing, quality control, safety monitoring | Pros: Durable and versatile for industrial use. Cons: Potentially higher initial investment. |

What Are the Key Characteristics of Airborne LiDAR Systems?

Airborne LiDAR systems, such as the VQ-680 and VQX-2, are engineered for high efficiency in various surveying applications, including urban mapping and forestry. They feature high pulse repetition rates, allowing for rapid data collection over large areas. These systems are suitable for businesses that require extensive mapping capabilities and can handle complex environments. Buyers should consider the need for skilled personnel to operate these systems effectively, as well as the investment in training and support.

How Do Mobile LiDAR Systems Enhance Data Collection?

Mobile LiDAR systems, like the VMY-2 and VMX-RAIL, are designed for dynamic data acquisition from moving platforms, making them ideal for rail and road surveying. They offer a full-circle field of view and seamless integration with data acquisition software. These systems are particularly advantageous for companies needing efficient and accurate data collection in real-time. However, buyers must assess the limitations related to vehicle speed and terrain, which can affect data quality.

What Makes Terrestrial LiDAR Systems Essential for Surveying?

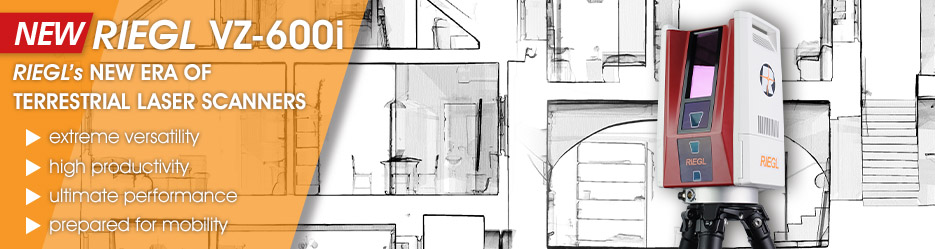

Terrestrial LiDAR systems, such as the VZ-600i and VZ-2000i, provide high-resolution 3D data for applications like topography and civil engineering. Their ability to process data in real-time enhances their utility in projects requiring immediate analysis. These systems are suitable for organizations focused on precision and detailed modeling. However, potential buyers should note that their use is limited to stationary setups, which may affect project timelines in dynamic environments.

Why Are Unmanned LiDAR Systems Gaining Popularity?

Unmanned LiDAR systems, such as the VUX-1UAV, are designed for integration with UAVs, allowing for data collection in hazardous or hard-to-reach locations. Their lightweight design and user-friendly interfaces make them accessible for various surveying missions. These systems are ideal for companies focused on environmental monitoring and safety assessments. However, the effectiveness of these systems is contingent on UAV capabilities and compliance with local regulations.

What Advantages Do Industrial LiDAR Systems Offer?

Industrial LiDAR systems are tailored for demanding environments, featuring rugged designs that withstand harsh conditions. They are compact and versatile, suitable for applications in manufacturing, quality control, and safety monitoring. Businesses in industrial sectors benefit from their durability and reliability. However, prospective buyers should consider the initial investment and ongoing maintenance costs associated with these robust systems.

Key Industrial Applications of riegl usa

| Industry/Sector | Specific Application of riegl usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Surveying | Terrestrial and Airborne LiDAR Scanning | High-precision mapping and data collection for various terrains, leading to improved project outcomes. | Reliability of data acquisition in diverse environments, support for multiple data formats. |

| Mining | Mine Surveying and Volume Calculations | Accurate monitoring of mine conditions and resource estimation, enhancing operational efficiency. | Integration capabilities with existing mining software, ruggedness for harsh environments. |

| Infrastructure | Rail and Road Infrastructure Mapping | Efficient data capture for maintenance and planning, reducing downtime and improving safety. | Compatibility with mobile mapping systems, ability to capture high-density data. |

| Environmental Studies | Forestry and Environmental Monitoring | Detailed analysis of vegetation and terrain changes, aiding in sustainable management practices. | Sensitivity to various environmental conditions, user-friendly data processing software. |

| Forensics | Accident Scene Reconstruction | Precise documentation of accident scenes, facilitating legal and insurance processes. | Training and support for accurate data interpretation, fast data processing capabilities. |

How Does RIEGL USA Enhance Surveying Operations for International Buyers?

RIEGL USA’s terrestrial and airborne LiDAR scanning technologies are pivotal for surveying applications across various terrains. These systems provide high-precision mapping capabilities, allowing businesses to gather detailed topographical data efficiently. For international buyers in regions like Africa and South America, the ability to operate in diverse environmental conditions is crucial. RIEGL’s technology ensures that data acquisition remains reliable, even in challenging terrains, thereby improving project outcomes and reducing costly errors.

What Benefits Does RIEGL USA Offer to the Mining Sector?

In the mining industry, RIEGL USA’s solutions facilitate accurate mine surveying and volume calculations. By utilizing advanced LiDAR technology, companies can monitor mine conditions and estimate resources with unparalleled precision. This capability enhances operational efficiency and decision-making processes. For international buyers, particularly in resource-rich regions like Nigeria, sourcing equipment that integrates seamlessly with existing mining software while withstanding harsh environments is essential for maximizing returns on investment.

How Can Infrastructure Projects Benefit from RIEGL USA’s Solutions?

RIEGL USA’s mobile mapping systems are designed specifically for infrastructure projects, including rail and road maintenance. These systems enable efficient data capture, which is critical for planning and maintaining safety standards. For B2B buyers in Europe and the Middle East, the compatibility of RIEGL’s technology with mobile systems and its ability to capture high-density data can significantly reduce downtime and enhance operational planning.

Why Are RIEGL USA’s Environmental Monitoring Solutions Valuable?

RIEGL USA provides specialized solutions for forestry and environmental monitoring that allow for detailed analysis of vegetation and terrain changes. This capability is particularly beneficial for businesses focused on sustainable management practices. For international buyers, especially in developing regions, the sensitivity of RIEGL’s systems to various environmental conditions ensures that data collection remains robust and reliable, supporting informed decision-making in environmental conservation efforts.

How Does RIEGL USA Support Forensic Applications?

In forensic applications, RIEGL USA’s technology is invaluable for accident scene reconstruction. The precision offered by their scanning systems allows for the accurate documentation of scenes, which is critical for legal and insurance processes. For international buyers in regions with high accident rates, the training and support provided by RIEGL ensure that personnel can interpret data accurately, facilitating swift and efficient investigations.

3 Common User Pain Points for ‘riegl usa’ & Their Solutions

Scenario 1: Navigating the Complexity of LiDAR Technology Integration

The Problem: Many B2B buyers, particularly those new to LiDAR technology, face the challenge of integrating RIEGL systems into their existing workflows. This complexity can lead to confusion regarding compatibility, system capabilities, and the steep learning curve associated with advanced features. Buyers often feel overwhelmed by the variety of products offered, such as the VZ-600i for terrestrial scanning or the VUX-1UAV for unmanned applications, making it difficult to choose the right equipment for their specific needs.

The Solution: To effectively integrate RIEGL systems, buyers should start by clearly defining their project requirements and desired outcomes. Engage with RIEGL’s sales and technical support teams for a comprehensive consultation to identify the best-suited equipment. Additionally, consider participating in RIEGL’s training programs and webinars, which provide in-depth knowledge of product functionalities and best practices. This hands-on approach will demystify the technology, allowing users to leverage the full capabilities of their chosen system for efficient project execution.

Scenario 2: Ensuring Accurate Data Collection in Challenging Environments

The Problem: In industries like mining and civil engineering, accurate data collection is crucial. However, B2B buyers often encounter difficulties when deploying LiDAR systems in challenging environments, such as dense urban areas or rugged terrains. Issues such as signal interference, line-of-sight obstructions, and environmental conditions can significantly affect data quality, leading to costly project delays and inaccuracies.

The Solution: To mitigate these challenges, buyers should select RIEGL products designed for specific environments. For instance, the VMX-2HA mobile mapping system is optimized for high-speed data acquisition and is capable of capturing dense, accurate data in complex settings. Moreover, employing RIEGL’s smart-waveform technology enhances signal processing and reduces the likelihood of data loss. Buyers should also invest in pre-deployment assessments to identify potential obstacles in the survey area, enabling them to strategize data collection methods effectively. By combining the right technology with thorough planning, accurate data can be consistently achieved.

Scenario 3: Maximizing Return on Investment through Effective Training and Support

The Problem: B2B buyers often struggle with maximizing their return on investment (ROI) when purchasing high-end LiDAR systems due to inadequate training and support. New users may not fully understand how to utilize the advanced features of their RIEGL equipment, leading to suboptimal usage and wasted resources. This lack of knowledge can hinder productivity and increase operational costs.

The Solution: To ensure that teams are well-equipped to utilize RIEGL products effectively, buyers should prioritize comprehensive training and ongoing support. RIEGL offers tailored training programs that can be conducted on-site or remotely, focusing on the specific applications and features relevant to the buyer’s industry. Additionally, leveraging RIEGL’s extensive documentation and support resources can help users troubleshoot common issues and learn advanced techniques. Establishing a culture of continuous learning within the organization will empower teams to fully exploit the capabilities of their LiDAR systems, ultimately driving greater efficiency and ROI in their projects.

Strategic Material Selection Guide for riegl usa

What Are the Key Materials Used in RIEGL USA Products?

RIEGL USA utilizes a variety of materials in the manufacturing of its advanced laser scanning systems. Each material has distinct properties that impact performance, durability, and application suitability. Below, we analyze four common materials used in RIEGL products: aluminum, carbon fiber, polycarbonate, and stainless steel.

Aluminum: A Lightweight and Versatile Choice

Aluminum is widely used in RIEGL’s laser scanners due to its excellent strength-to-weight ratio and corrosion resistance. Key properties include a temperature rating of approximately -200°C to 600°C, making it suitable for various environmental conditions.

Pros: Aluminum is lightweight, which enhances portability and ease of installation. It is also cost-effective and can be easily machined into complex shapes, making it suitable for intricate designs in laser scanner housings.

Cons: While durable, aluminum can be susceptible to scratching and denting. Its thermal conductivity can also lead to heat dissipation issues in high-temperature environments.

Impact on Application: Aluminum’s lightweight nature allows for easy integration into UAV systems, making it ideal for airborne applications.

Considerations for International Buyers: Compliance with international standards such as ASTM and ISO is crucial. Buyers should ensure that the aluminum used meets local regulations, particularly in the aerospace and automotive sectors prevalent in regions like Europe and the Middle East.

Carbon Fiber: High Strength with Minimal Weight

Carbon fiber is another material employed in RIEGL’s products, particularly in components requiring high rigidity and low weight. It exhibits exceptional tensile strength and can withstand temperatures up to 200°C.

Pros: Carbon fiber is incredibly strong yet lightweight, enhancing the performance of mobile and airborne systems. It also has excellent fatigue resistance and thermal stability.

Cons: The primary drawback is its high cost and complexity in manufacturing, which can limit its use in budget-sensitive projects.

Impact on Application: Carbon fiber is particularly beneficial for UAV applications, where weight savings translate to longer flight times and improved maneuverability.

Considerations for International Buyers: Buyers should be aware of the specific certifications for carbon fiber materials, especially in industries like aerospace. Compliance with standards such as JIS in Japan or DIN in Germany may be necessary.

Polycarbonate: Impact-Resistant and Transparent

Polycarbonate is often used for protective covers and lenses in RIEGL scanners due to its high impact resistance and optical clarity. It can withstand temperatures ranging from -40°C to 120°C.

Pros: Polycarbonate is lightweight, shatter-resistant, and offers excellent UV protection, making it suitable for outdoor applications.

Cons: While it is durable, polycarbonate can scratch easily and may yellow over time when exposed to UV light.

Impact on Application: Its transparency and impact resistance are critical for ensuring the integrity of laser data collection in various environments, particularly in civil engineering and urban mapping.

Considerations for International Buyers: Buyers should verify that the polycarbonate used complies with relevant safety and environmental standards, especially in regions where UV exposure is significant, such as Africa and South America.

Stainless Steel: Robust and Corrosion-Resistant

Stainless steel is utilized in RIEGL products for components that require high corrosion resistance and durability. It can withstand extreme temperatures, typically from -200°C to 800°C.

Pros: Stainless steel is highly durable, resistant to corrosion, and can endure harsh environmental conditions, making it ideal for industrial applications.

Cons: The weight of stainless steel can be a disadvantage in portable systems, and it is generally more expensive than other materials.

Impact on Application: Its robustness is particularly beneficial for industrial scanning applications where equipment may be exposed to harsh conditions.

Considerations for International Buyers: Buyers should ensure that the stainless steel used meets international corrosion resistance standards, particularly in coastal or humid environments common in regions like the Middle East and South America.

Summary Table of Material Selection for RIEGL USA

| Material | Typical Use Case for RIEGL USA | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | UAV and mobile laser scanner housings | Lightweight and cost-effective | Susceptible to scratching | Medium |

| Carbon Fiber | UAV components for enhanced performance | High strength-to-weight ratio | High cost and manufacturing complexity | High |

| Polycarbonate | Protective covers and lenses | Impact-resistant and UV stable | Scratches easily, may yellow | Medium |

| Stainless Steel | Industrial scanning components | Highly durable and corrosion-resistant | Heavier and more expensive | High |

This strategic material selection guide provides insights for international B2B buyers, assisting them in making informed decisions when procuring RIEGL USA products.

In-depth Look: Manufacturing Processes and Quality Assurance for riegl usa

What Are the Key Stages in the Manufacturing Process of RIEGL USA’s Laser Scanners?

RIEGL USA employs a sophisticated manufacturing process that encompasses several stages, ensuring the production of high-quality laser scanning systems. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The manufacturing process begins with the careful selection and preparation of materials. RIEGL prioritizes high-grade metals and polymers that are specifically chosen for their durability and performance characteristics. These materials undergo stringent quality assessments to ensure they meet the required specifications for laser scanning applications.

Forming Techniques

Once materials are prepared, forming techniques come into play. RIEGL utilizes advanced machining processes, including CNC (Computer Numerical Control) milling and turning, to create precision components. This level of accuracy is crucial for the intricate parts of laser scanners, which must meet exacting tolerances to function correctly.

Assembly Process

The assembly of laser scanners is conducted in a cleanroom environment to prevent contamination. Skilled technicians assemble components using both automated and manual processes, ensuring that each scanner is built to the highest standards. RIEGL employs advanced robotics for certain assembly tasks, which enhances precision and efficiency.

Finishing Touches

After assembly, the finishing stage involves rigorous testing and calibration. This includes applying protective coatings to enhance durability and performance in various environments. The scanners are fine-tuned for optimal performance before they proceed to quality assurance checks.

How Does RIEGL USA Ensure Quality Control Throughout the Manufacturing Process?

Quality control (QC) is integral to RIEGL USA’s manufacturing philosophy. The company adheres to both international and industry-specific standards to ensure the reliability and accuracy of its products.

Adherence to International Standards

RIEGL USA is certified under ISO 9001, which outlines the requirements for a quality management system. This certification ensures that RIEGL maintains consistent quality in its processes and products. The company also complies with CE marking, which indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

Industry-Specific Certifications

In addition to ISO and CE certifications, RIEGL’s products may also meet industry-specific standards, such as API (American Petroleum Institute) standards for applications in the oil and gas sector. These certifications demonstrate RIEGL’s commitment to quality and safety in diverse applications.

What Are the QC Checkpoints in RIEGL’s Manufacturing Process?

RIEGL employs a multi-tiered approach to quality control, incorporating several checkpoints throughout the manufacturing process:

Incoming Quality Control (IQC)

At the outset, incoming materials undergo rigorous quality checks to ensure they meet the required specifications. Any subpar materials are rejected, preventing defects from entering the production line.

In-Process Quality Control (IPQC)

During the manufacturing stages, IPQC checkpoints are established to monitor the production processes. Technicians conduct random sampling and testing to ensure that all components are manufactured to specifications. This real-time monitoring allows for immediate corrective actions if any discrepancies are identified.

Final Quality Control (FQC)

Once the assembly is complete, each laser scanner undergoes final quality control testing. This includes functional testing, calibration, and performance assessments against predetermined standards. Only products that pass this rigorous testing are approved for shipping.

What Testing Methods Are Commonly Used by RIEGL USA?

RIEGL employs a variety of testing methods to validate the performance and reliability of its laser scanners:

Functional Testing

Each scanner is subjected to functional tests to ensure that all features operate correctly. This includes assessing the scanner’s range, accuracy, and data processing capabilities.

Environmental Testing

Given the varied applications of RIEGL’s products, environmental testing is conducted to ensure durability in harsh conditions. This may include temperature, humidity, and vibration tests to simulate real-world usage.

Calibration

Calibration is critical to ensure accuracy in measurements. RIEGL utilizes state-of-the-art calibration techniques to verify that each scanner meets its performance specifications.

How Can B2B Buyers Verify RIEGL’s Quality Control Practices?

For B2B buyers, particularly those from international markets, verifying a supplier’s quality control practices is essential. Here are several ways to do so:

Supplier Audits

Conducting on-site audits can provide insights into the manufacturing processes and quality assurance practices at RIEGL. These audits can help buyers assess the adherence to quality standards and the overall reliability of the supplier.

Quality Assurance Reports

Requesting quality assurance reports can provide valuable information about the product testing and compliance with international standards. RIEGL should be able to provide documentation that details the results of various quality checks conducted during the manufacturing process.

Third-Party Inspections

Engaging third-party inspection services can add an additional layer of assurance. Independent inspectors can verify that RIEGL’s products meet the specified quality standards before they are shipped.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of certain nuances regarding quality control and certifications:

Understanding Regional Standards

Buyers should familiarize themselves with regional standards and certifications that may be required in their specific markets. For instance, the CE mark is crucial for products entering the European market, while other regions may have unique compliance requirements.

Documentation and Traceability

Ensure that suppliers can provide thorough documentation and traceability for their quality control processes. This includes records of inspections, testing, and compliance with international standards.

Cultural and Regulatory Considerations

Cultural differences and varying regulatory environments can affect how quality assurance is perceived and implemented. Buyers should engage in open communication with suppliers to clarify expectations and requirements related to quality assurance.

In conclusion, RIEGL USA’s commitment to high-quality manufacturing processes and rigorous quality control ensures that its laser scanning solutions meet the demands of a global market. B2B buyers can leverage their understanding of these processes to make informed purchasing decisions, ensuring they partner with a reliable supplier that adheres to the highest standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘riegl usa’

Introduction

This practical sourcing guide aims to assist international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, in navigating the procurement process for RIEGL USA’s advanced laser scanning solutions. By following this checklist, you will ensure that your purchasing decision aligns with your technical requirements and business objectives.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the selected RIEGL product meets your specific needs. Consider the application—whether it’s for airborne, mobile, terrestrial, or industrial scanning—and determine the required accuracy, range, and scanning speed. Documenting these specifications will help streamline discussions with suppliers and avoid costly miscommunications.

Step 2: Research RIEGL Product Offerings

Familiarize yourself with the various laser scanning solutions offered by RIEGL, including their airborne, mobile, and terrestrial systems. Each product line has unique features tailored for specific applications, such as urban mapping or industrial scanning. Understanding these offerings will enable you to make informed comparisons and select the best fit for your project.

Step 3: Evaluate Supplier Certifications

Before engaging with RIEGL USA, verify their certifications and industry standards compliance. Certifications such as ISO 9001 (Quality Management) or specific environmental standards indicate a commitment to quality and sustainability. Additionally, ensure that the supplier has a robust support and maintenance framework to address any operational challenges post-purchase.

Step 4: Request Demonstrations and Trial Use

It’s essential to see the technology in action. Request a demonstration of the RIEGL systems relevant to your needs, whether through webinars, online demos, or on-site trials. This step will allow you to assess the user interface, data quality, and overall functionality of the equipment, helping you gauge its suitability for your applications.

Step 5: Inquire About Training and Support

Effective training and ongoing support are vital for maximizing your investment in RIEGL’s technology. Inquire about the training programs they offer, including both initial training and advanced options for staff development. Additionally, understand the support structure—response times, availability of technical assistance, and access to resources like manuals and online forums.

Step 6: Assess Total Cost of Ownership

When evaluating potential purchases, consider the total cost of ownership (TCO), which includes purchase price, maintenance, training, and any additional software or hardware required. A comprehensive understanding of TCO will enable you to budget accurately and avoid unexpected expenses in the future.

Step 7: Finalize Agreements and Terms

Once you have selected a supplier and product, carefully review and finalize all agreements. Ensure that the terms of sale, warranty, and service agreements are clearly defined and meet your operational requirements. Pay attention to delivery timelines and any conditions related to returns or exchanges, as these can significantly impact your project planning.

By following these steps, you can navigate the sourcing process for RIEGL USA’s advanced laser scanning solutions with confidence, ensuring that your procurement aligns with both technical and business objectives.

Comprehensive Cost and Pricing Analysis for riegl usa Sourcing

What Are the Key Cost Components of RIEGL USA Products?

When evaluating the cost structure for sourcing RIEGL USA products, several critical components contribute to the overall pricing. These include:

-

Materials: The quality and type of materials used in RIEGL’s laser scanning systems significantly influence costs. High-performance components, such as specialized optics and advanced electronic systems, add to the base price.

-

Labor: Skilled labor is essential for both the manufacturing and assembly processes of sophisticated LiDAR systems. RIEGL’s commitment to quality necessitates a workforce with specialized expertise, which can affect pricing.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, rent, and maintenance of manufacturing facilities. Given RIEGL’s advanced technology and facilities, overhead costs can be substantial.

-

Tooling: The design and creation of specialized tools for manufacturing unique components can incur significant costs. This is particularly relevant for custom or modified systems tailored to specific client needs.

-

Quality Control (QC): RIEGL’s rigorous QC processes ensure high standards in product performance and reliability. This emphasis on quality may result in higher upfront costs but ultimately ensures product longevity and reliability.

-

Logistics: Shipping and handling costs can vary based on destination and the size of the equipment. As RIEGL products are often large and sensitive, logistics planning is crucial to mitigate potential damages during transit.

-

Margin: As a premium provider, RIEGL typically includes a higher profit margin in its pricing to reflect the advanced technology and exceptional support services offered.

How Do Pricing Influencers Affect RIEGL USA’s Products?

Several factors can influence the pricing of RIEGL products, particularly for international B2B buyers:

-

Volume/MOQ: Bulk purchases often allow for economies of scale, leading to reduced per-unit pricing. Understanding minimum order quantities (MOQ) can help buyers negotiate better deals.

-

Specifications/Customization: Customized solutions tailored to specific applications can lead to higher costs. Buyers should clearly communicate their requirements to receive accurate quotes and avoid unexpected expenses.

-

Materials: The choice of materials directly impacts cost. Buyers may opt for alternative materials if they seek to reduce expenses, but this could affect product performance.

-

Quality/Certifications: Products that meet international quality standards and certifications may carry a premium. Buyers should weigh the importance of certifications against potential cost savings.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established companies like RIEGL may command higher prices due to their proven track record and customer support.

-

Incoterms: Understanding the terms of trade (Incoterms) is crucial for international buyers. Terms dictate the responsibilities of buyers and sellers in logistics, which can affect overall costs.

What Tips Can Buyers Use to Negotiate Better Prices?

To maximize value when sourcing RIEGL USA products, buyers should consider the following strategies:

-

Effective Negotiation: Build a strong relationship with suppliers and engage in open discussions about pricing, potential discounts, and flexible payment terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. A higher upfront investment may yield long-term savings.

-

International Pricing Nuances: Be aware of currency fluctuations, import duties, and local regulations when sourcing from RIEGL USA. Understanding these factors can help mitigate unexpected costs.

-

Leverage Expertise: Utilize RIEGL’s comprehensive support services for training and implementation. This can reduce the costs associated with system integration and operational inefficiencies.

Disclaimer on Indicative Prices

It is essential to note that pricing can vary widely based on the specific configuration and features of the equipment, as well as market conditions. Buyers are encouraged to obtain tailored quotes directly from RIEGL or authorized representatives to ensure accurate pricing aligned with their needs.

Alternatives Analysis: Comparing riegl usa With Other Solutions

Understanding Alternatives for RIEGL USA’s Laser Scanning Solutions

In the competitive landscape of laser scanning technologies, businesses often find themselves evaluating various solutions to meet their specific surveying needs. RIEGL USA is known for its advanced laser scanning systems, but there are several other viable alternatives that also cater to diverse applications. This analysis aims to provide a comparative overview of RIEGL USA against two notable alternatives: Leica Geosystems and Faro Technologies.

Comparison Table

| Comparison Aspect | RIEGL USA | Leica Geosystems | Faro Technologies |

|---|---|---|---|

| Performance | High precision with advanced waveform processing | Excellent accuracy with robust software integration | Good accuracy with versatile applications |

| Cost | Premium pricing for advanced features | Mid-range pricing with various options | Competitive pricing, often more affordable |

| Ease of Implementation | Requires specialized training for optimal use | User-friendly interfaces, moderate training needed | Intuitive setup, minimal training required |

| Maintenance | Regular updates and support available | Strong customer support, periodic updates | Good support, but less frequent updates |

| Best Use Case | Large-scale aerial surveys and industrial applications | Construction, surveying, and GIS applications | Forensic investigations and architectural projects |

Pros and Cons of Alternatives

Leica Geosystems

Leica Geosystems offers a range of laser scanning solutions renowned for their accuracy and integration capabilities. The systems are particularly well-suited for construction and civil engineering projects, where precise measurements are crucial. Pros include a user-friendly interface and strong customer support, which facilitate easier adoption among teams. However, their cost can be a barrier for smaller organizations, as the advanced features come at a premium.

Faro Technologies

Faro Technologies is recognized for its versatile laser scanning solutions that cater to a wide array of applications, including architecture, engineering, and construction. Their products tend to be more affordable, making them accessible for businesses with budget constraints. The ease of implementation is a significant advantage, as users can quickly set up and start scanning. However, while Faro offers good accuracy, it may not match the high precision of RIEGL systems in specialized applications, such as large-scale industrial surveys.

Making the Right Choice for Your Needs

When selecting a laser scanning solution, B2B buyers should consider their specific application requirements, budget, and the level of technical expertise available within their organization. RIEGL USA stands out for its high-performance capabilities and advanced technology, making it ideal for complex surveying tasks. Conversely, Leica Geosystems provides a balanced option with strong support and accuracy, while Faro Technologies offers cost-effective solutions with ease of use. By carefully evaluating these factors, organizations can choose the laser scanning technology that best aligns with their operational goals and project demands.

Essential Technical Properties and Trade Terminology for riegl usa

What Are the Essential Technical Properties of RIEGL USA Products?

RIEGL USA is recognized for its advanced laser scanning technologies, which are characterized by several critical technical properties. Understanding these specifications can help B2B buyers make informed purchasing decisions.

1. Pulse Repetition Rate (PRR)

The pulse repetition rate, measured in Hertz (Hz), indicates how many laser pulses are emitted per second. RIEGL scanners offer PRRs up to 2.4 MHz, allowing for rapid data acquisition. A higher PRR is essential for capturing dense point clouds, which enhances the accuracy and detail of 3D models. This is particularly beneficial in applications such as urban mapping and forestry, where precision is paramount.

2. Measurement Rate

This specification refers to the number of measurements the scanner can take per second, with RIEGL’s systems capable of reaching up to 2,000,000 measurements per second. A high measurement rate is crucial for efficiently gathering large datasets, particularly in extensive surveying projects. It directly impacts project timelines and productivity, making it an important factor for B2B buyers seeking efficiency.

3. Range Performance

RIEGL scanners boast impressive range capabilities, with some models like the VZ-2000i achieving operational ranges up to 2,500 meters. This long-range performance is vital for applications in mining, forestry, and large-scale infrastructure projects where accessing distant or hard-to-reach areas is necessary. Understanding range specifications helps buyers evaluate the suitability of a scanner for their specific applications.

4. Point Density

Point density refers to the number of points captured per square meter during scanning. RIEGL scanners provide high point densities, which ensure that even intricate details in the surveyed environment are accurately recorded. This is particularly important in applications such as architecture and archaeology, where detail can significantly affect analysis and outcomes.

5. Integration Capabilities

RIEGL products offer seamless integration with various platforms, including UAVs and mobile mapping systems. This flexibility allows users to adapt the technology to their specific operational needs, enhancing the versatility of the equipment. For B2B buyers, understanding integration capabilities is essential for ensuring compatibility with existing systems and maximizing the return on investment.

What Are Common Trade Terms Relevant to RIEGL USA?

Familiarity with trade terminology can streamline communications and negotiations for international buyers. Here are some key terms frequently used in the context of RIEGL USA’s offerings.

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. RIEGL’s technology can be integrated into other systems, making it important for buyers to understand the OEM relationships that may exist, especially when seeking customized solutions.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to ensure they can meet the supplier’s requirements while also aligning with their project needs and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit pricing information from suppliers. It typically outlines the specific requirements for products or services. For buyers considering RIEGL products, issuing an RFQ can lead to competitive pricing and detailed proposals from multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers to understand shipping costs, risks, and delivery obligations when purchasing RIEGL products from overseas.

5. Calibration

Calibration involves adjusting the scanner to ensure its measurements are accurate. RIEGL provides calibration services to maintain the precision of their products. For buyers, understanding the calibration requirements and schedules is vital for ensuring ongoing accuracy in data collection.

By grasping these essential technical properties and trade terms, B2B buyers can make more informed decisions when considering RIEGL USA’s cutting-edge laser scanning solutions.

Navigating Market Dynamics and Sourcing Trends in the riegl usa Sector

What Are the Key Market Dynamics and Trends Affecting RIEGL USA?

The global landscape for laser scanning technology is evolving rapidly, driven by advancements in LiDAR systems, increasing demand for precision data collection, and a growing focus on automation. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe look to invest in technology, RIEGL USA stands out as a leader in providing innovative laser scanning solutions. Key trends influencing the market include the integration of artificial intelligence with LiDAR technology, enabling faster data processing and enhanced accuracy. Additionally, the surge in demand for remote sensing applications, particularly in urban planning, forestry, and infrastructure development, is creating new opportunities for suppliers.

Emerging markets are particularly keen on adopting advanced scanning technologies to address challenges in surveying and mapping. In regions like Nigeria and Vietnam, where infrastructure development is booming, RIEGL’s robust mobile and airborne systems can facilitate large-scale projects by delivering high-resolution data efficiently. The company’s commitment to integrating cutting-edge technology with user-friendly interfaces allows buyers to streamline their operations, making RIEGL a preferred partner for businesses looking to enhance their surveying capabilities.

How Is Sustainability and Ethical Sourcing Addressed by RIEGL USA?

In today’s B2B environment, sustainability and ethical sourcing have become paramount for businesses looking to align with global standards and consumer expectations. RIEGL USA recognizes its responsibility in minimizing environmental impact through its innovative product designs, which prioritize energy efficiency and reduce waste during manufacturing processes. The use of compact and lightweight materials in their laser scanners not only enhances portability but also contributes to lower emissions during transportation.

Moreover, RIEGL is committed to ethical supply chain practices, ensuring that all components sourced for their products meet rigorous environmental and social standards. This commitment is reflected in their partnerships with certified suppliers who prioritize sustainable practices. By investing in ‘green’ certifications and eco-friendly materials, RIEGL USA enhances its market appeal, especially among international buyers who are increasingly prioritizing sustainability in their procurement decisions. Such initiatives not only contribute to a cleaner environment but also position RIEGL as a forward-thinking leader in the laser scanning industry.

What Is the Historical Context of RIEGL USA’s Development?

Founded over 40 years ago, RIEGL has established itself as a pioneer in the laser scanning sector, rooted in a strong foundation of research and innovation. The company’s history began in Austria, where it developed a reputation for excellence in laser measurement technology. RIEGL USA was launched in 1993, marking a significant step in expanding its global footprint. With offices in Florida and Los Angeles, RIEGL USA has successfully penetrated various sectors, including mining, civil engineering, and urban planning.

The evolution of RIEGL’s technology reflects its commitment to continuous improvement and adaptation to market needs. Over the years, the company has introduced a range of products that cater to diverse applications, from industrial scanning to unmanned aerial systems. This historical context not only underscores RIEGL’s expertise but also reassures international B2B buyers of the reliability and performance that characterize its offerings. As RIEGL continues to innovate, it remains a vital player in the global laser scanning market, well-equipped to meet the demands of its diverse clientele.

Frequently Asked Questions (FAQs) for B2B Buyers of riegl usa

-

How do I solve issues related to LiDAR data integration?

To effectively solve integration challenges with LiDAR data, begin by ensuring that your software tools are compatible with RIEGL’s output formats. Familiarize yourself with RIEGL’s data acquisition software suite, which facilitates seamless integration and processing of LiDAR data. Collaborating with RIEGL’s technical support team can also provide insights on best practices for data integration. Lastly, consider investing in training sessions offered by RIEGL to enhance your team’s proficiency in managing and utilizing LiDAR data effectively. -

What is the best RIEGL scanner for urban mapping projects?

For urban mapping applications, the RIEGL VQ-680 is highly recommended. It boasts high pulse repetition rates of up to 2.4 MHz, allowing for detailed and rapid data collection. Additionally, its versatility in scanning directions (+20 to -20 degrees) makes it ideal for capturing complex urban environments. The scanner’s compact design enhances its usability in various settings, ensuring optimal performance in urban mapping tasks. -

What are the payment terms for purchasing RIEGL products?

RIEGL typically offers flexible payment terms to accommodate international buyers. Payment options may include upfront payments, installment plans, or letters of credit, depending on the order size and buyer’s creditworthiness. It’s advisable to discuss specific payment terms during the negotiation phase to align with your company’s financial practices. Ensure that all terms are clearly documented in the purchase agreement to avoid any misunderstandings. -

What is the minimum order quantity (MOQ) for RIEGL products?

RIEGL does not generally enforce a strict minimum order quantity (MOQ) for its laser scanning systems; however, larger orders may benefit from volume discounts. It’s important to communicate your specific needs and project requirements to RIEGL’s sales team, who can provide guidance on optimal ordering strategies based on your operational needs. Custom solutions may also be available based on the scale of your project. -

How can I vet RIEGL as a reliable supplier for my business?

To vet RIEGL as a supplier, start by reviewing their extensive history and experience in the laser scanning industry, which spans over 40 years. Research client testimonials and case studies that showcase their successful deployments in various sectors such as mining, construction, and urban planning. Additionally, ensure they offer robust after-sales support, including training and maintenance, which is crucial for long-term satisfaction and operational efficiency. -

What logistics options are available for shipping RIEGL products internationally?

RIEGL provides a range of logistics options for international shipping, including standard freight, express shipping, and customized logistics solutions based on urgency and destination. It’s recommended to discuss your shipping preferences with RIEGL during the order process to ensure timely delivery. Additionally, inquire about any potential customs requirements or duties that may apply to your specific region to avoid delays. -

Can RIEGL products be customized for specific applications?

Yes, RIEGL offers customization options for many of its laser scanning systems to better suit specific applications or project requirements. Collaborating with RIEGL’s engineering team can help identify the necessary modifications, such as specific sensor configurations or software integrations. Initiating this discussion early in the purchasing process will ensure that the final product aligns perfectly with your operational needs. -

What quality assurance measures does RIEGL implement?

RIEGL maintains rigorous quality assurance measures throughout the production process of its laser scanning systems. This includes thorough testing of all products to ensure they meet the highest standards of performance and reliability. RIEGL also provides documentation and certification of their products, which can be crucial for compliance in various industries. Regular updates and maintenance services further support ongoing quality assurance for international buyers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for riegl usa

How Can RIEGL USA Enhance Your Strategic Sourcing?

In summary, RIEGL USA stands out as a premier provider of advanced laser scanning technologies, offering unparalleled precision and versatility across various applications such as surveying, mining, and urban mapping. The company’s commitment to innovation, backed by over 40 years of experience, ensures that international B2B buyers can rely on RIEGL for cutting-edge solutions that enhance operational efficiency and data accuracy.

Strategic sourcing from RIEGL USA not only provides access to state-of-the-art LiDAR systems but also benefits from their robust support and training services. This is particularly valuable for businesses in Africa, South America, the Middle East, and Europe, where the need for reliable data collection and analysis is paramount in industries like construction, transportation, and environmental monitoring.

Looking ahead, RIEGL USA is poised for continued growth and innovation in the laser scanning market. International buyers are encouraged to explore partnership opportunities and leverage RIEGL’s expertise to gain a competitive edge. Investing in RIEGL’s advanced technologies today will position your business for success in an increasingly data-driven world.