Top 5 Printed Circuit Board Manufacturers In Usa List and Guide: …

Introduction: Navigating the Global Market for printed circuit board manufacturers in usa

In today’s fast-paced technological landscape, sourcing printed circuit board (PCB) manufacturers in the USA can be a daunting challenge for international B2B buyers. With the increasing demand for high-quality, reliable PCBs across various sectors—from aerospace to consumer electronics—finding a trustworthy supplier who can meet specific design and production requirements is crucial. This guide serves as a comprehensive resource, addressing key considerations such as types of PCBs, their applications, supplier vetting processes, and cost implications.

International buyers from regions including Africa, South America, the Middle East, and Europe (notably Germany and Saudi Arabia) often face hurdles in understanding the nuances of the US PCB market. By exploring the diverse landscape of American manufacturers, buyers can identify the best-fit partners for their projects, ensuring optimal quality and compliance with international standards.

This guide empowers decision-makers by providing insights into manufacturing capabilities, certifications, and value-added services that can enhance product development timelines. Whether you’re looking for advanced HDI boards or standard prototypes, navigating the complexities of the US PCB manufacturing sector becomes manageable with the right information. Equip yourself with the knowledge to make informed purchasing decisions and drive your projects to successful fruition.

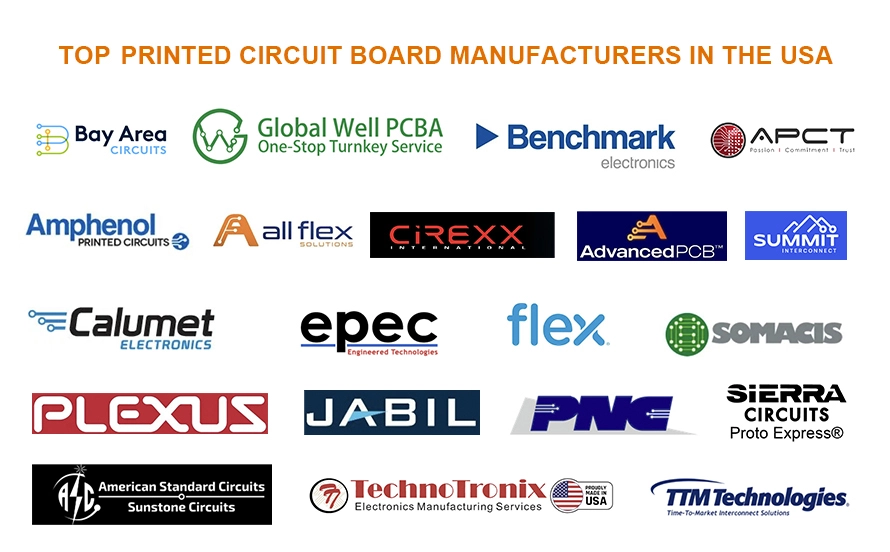

Top 10 Printed Circuit Board Manufacturers In Usa Manufacturers & Suppliers List

1. Sunstone Circuits – End-to-End PCB Solutions

Domain: sunstone.com

Registered: 1995 (30 years)

Introduction: Sunstone Circuits offers end-to-end PCB solutions with over 50 years of combined expertise. Their product offerings include:

– PCB Manufacturing

– ValueProto for quick-turn prototypes

– PCBExpress for advanced builds

– PCBPro for custom quotes

– RF/Microwave capabilities

– PCB123 layout software

– DFMPlus for design for manufacturability

– PCB Stencils

– PCB Assembly capabilities

They provide var…

2. Advanced PCB – Cutting-Edge Printed Circuit Boards

3. OSH Park – Professional Grade PCBs at Hobbyist Prices

Domain: oshpark.com

Registered: 2011 (14 years)

Introduction: OSH Park offers professional grade fabrication of printed circuit boards (PCBs) at hobbyist prices. Key services include: 6 Layer PCBs (3 copies for $15/square inch, ships in 9-14 days), 4 Layer Super Swift (3 copies for $20/square inch, ships in 5-6 business days), After Dark (black substrate and clear mask, 3 copies for $5/square inch, ships in 12-21 days), Prototype (classic 1.6mm PCB service, …

4. American Standard Circuits – Specialized PCB Solutions

Domain: asc-i.com

Registered: 1996 (29 years)

Introduction: American Standard Circuits (ASC) specializes in various types of printed circuit boards (PCBs) including:

– Flex/Rigid Flex PCBs

– Ultra High Density Interconnects (UHDI)

– RF Microwave PCBs

– RF Metal Backed PCBs

– Metal Clad (MCPCB) / Insulated Metal (IMPCB) PCBs

ASC offers services such as quick turns, global sourcing, inventory management, consulting, and custom PCB board manufacturing….

5. PCB Unlimited – PCB Fabrication Services

Domain: pcbunlimited.com

Registered: 2006 (19 years)

Introduction: PCB Unlimited offers a wide range of PCB fabrication services including Prototype PCBs, USA PCBs, Taiwan PCBs, China PCBs, Flex & Rigid-Flex PCBs, Metal Core PCBs, HDI PCBs, Heavy Copper PCBs, and High Frequency PCBs. They provide PCB assembly services in the USA and Mexico, electronic components sourcing, wire harness manufacturing, and PCB testing. Their SMT stencil offerings include laser cut S…

Understanding printed circuit board manufacturers in usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard PCBs | Basic designs, typically 2-8 layers, cost-effective, quick-turn. | Consumer electronics, basic industrial devices. | Pros: Cost-effective, fast production. Cons: Limited complexity; may not suit advanced applications. |

| Advanced PCBs | High layer counts (up to 30), complex designs, exotic materials. | Aerospace, defense, high-speed communications. | Pros: Supports complex designs, high performance. Cons: Higher costs, longer lead times. |

| Rigid-Flex PCBs | Combination of rigid and flexible materials, versatile designs. | Wearable devices, medical technology, aerospace. | Pros: Space-saving, adaptable design. Cons: More expensive, requires specialized manufacturing. |

| Turnkey Solutions | Full-service approach: design, fabrication, assembly included. | OEMs, large-scale production, rapid prototyping. | Pros: Streamlined process, reduced time to market. Cons: May lack customization for niche needs. |

| HDI PCBs | High-density interconnects, finer traces, advanced capabilities. | Mobile devices, high-performance computing. | Pros: Enhanced performance in compact designs. Cons: Requires advanced manufacturing techniques, higher costs. |

What Are the Characteristics of Standard PCBs?

Standard PCBs are the backbone of basic electronic devices, typically featuring 2-8 layers. They are favored for their cost-effectiveness and quick turnaround times, making them ideal for consumer electronics and basic industrial applications. B2B buyers should consider their specific needs for complexity and performance, as standard PCBs may not meet the requirements for advanced technology applications.

Why Choose Advanced PCBs for Complex Applications?

Advanced PCBs are engineered for high-performance applications, accommodating up to 30 layers and utilizing exotic materials. They are essential in sectors such as aerospace and defense, where reliability and complexity are critical. B2B buyers should weigh the benefits of enhanced performance against the higher costs and longer lead times associated with these boards.

How Do Rigid-Flex PCBs Enhance Design Flexibility?

Rigid-Flex PCBs combine both rigid and flexible substrates, allowing for innovative design solutions in space-constrained applications like wearables and medical devices. Their adaptability enables seamless integration into complex assemblies, but buyers should be prepared for increased costs and the need for specialized manufacturing processes.

What Are the Advantages of Turnkey Solutions?

Turnkey solutions provide a comprehensive approach, covering everything from design to assembly in one package. This method is particularly advantageous for OEMs and companies looking to streamline their production processes. However, while they reduce time to market, buyers may find that customization options are limited compared to sourcing components individually.

Why Are HDI PCBs Important for High-Performance Electronics?

HDI PCBs feature high-density interconnects, enabling finer traces and advanced capabilities, making them a preferred choice for mobile devices and high-performance computing. B2B buyers should consider the advanced manufacturing techniques required and the associated costs, as these boards are tailored for applications demanding superior performance in compact designs.

Key Industrial Applications of printed circuit board manufacturers in usa

| Industry/Sector | Specific Application of printed circuit board manufacturers in usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace & Defense | Complex circuit boards for avionics systems | Ensures high reliability and performance in critical applications | Compliance with military standards; rapid prototyping capabilities |

| Automotive | Advanced driver-assistance systems (ADAS) PCBs | Enhances vehicle safety and functionality | Need for high-temperature materials; rigorous testing protocols |

| Healthcare & Medical Devices | PCB assemblies for diagnostic equipment | Improves patient care through accurate diagnostics | Biocompatibility; adherence to regulatory standards like ISO 13485 |

| Consumer Electronics | PCBs for wearable technology | Supports innovative product features and market competitiveness | Quick turnaround for prototypes; scalability for mass production |

| Industrial Automation | PCBs for control systems in manufacturing equipment | Increases efficiency and automation in production processes | Customization options; durability under industrial conditions |

How Are Printed Circuit Boards Utilized in Aerospace & Defense Industries?

In the aerospace and defense sectors, printed circuit boards (PCBs) are integral to avionics systems that control navigation, communication, and flight management. These applications demand boards that can withstand extreme conditions while maintaining reliability. For international buyers, especially from regions like Africa and the Middle East, sourcing PCBs that comply with military specifications is crucial. This necessitates a focus on manufacturers that offer rapid prototyping and can demonstrate compliance with stringent quality standards.

What Role Do Printed Circuit Boards Play in the Automotive Sector?

In the automotive industry, PCBs are essential for advanced driver-assistance systems (ADAS), which enhance vehicle safety features such as lane-keeping assistance and collision avoidance. These boards must be designed to operate in high-temperature environments and endure vibrations. International buyers, particularly from South America and Europe, should prioritize suppliers that can provide high-quality, durable materials and have a proven track record in automotive applications to ensure compliance with safety regulations.

Why Are Printed Circuit Boards Critical in Healthcare & Medical Devices?

PCBs are vital in medical devices, particularly for diagnostic equipment such as MRI machines and blood analyzers. They must meet high standards for biocompatibility and reliability to ensure patient safety and accurate results. For global buyers from regions like Europe and Africa, sourcing from manufacturers that adhere to ISO 13485 and other regulatory standards is essential. Additionally, the ability to customize designs for specific medical applications can provide a competitive edge in the healthcare market.

How Do Printed Circuit Boards Enhance Consumer Electronics?

In the consumer electronics sector, PCBs are fundamental to the functionality of wearable technology, including fitness trackers and smartwatches. These devices require innovative designs that offer compactness and efficiency. International buyers should seek manufacturers capable of quick turnaround times for prototypes, enabling them to bring products to market rapidly. Scalability for mass production is also a critical consideration to accommodate varying demand levels.

What Is the Importance of Printed Circuit Boards in Industrial Automation?

In industrial automation, PCBs are used in control systems that manage manufacturing equipment, facilitating increased efficiency and automation. These boards must be robust and designed to withstand harsh industrial environments. Buyers from emerging markets should consider sourcing from manufacturers that offer customization options tailored to specific operational needs and durability under challenging conditions, ensuring long-term performance and reliability.

3 Common User Pain Points for ‘printed circuit board manufacturers in usa’ & Their Solutions

Scenario 1: Navigating Long Lead Times for PCB Production

The Problem: B2B buyers often face significant delays when sourcing printed circuit boards (PCBs) from manufacturers in the USA. These lead times can stretch from weeks to months, jeopardizing project timelines and delaying product launches. For international buyers, time zone differences and logistical hurdles can complicate communication, leading to misunderstandings and further delays. This challenge is particularly acute for businesses in fast-paced industries, such as technology and consumer electronics, where speed to market is critical.

The Solution: To mitigate long lead times, buyers should prioritize manufacturers that offer rapid prototyping and expedited production services. Research and select PCB manufacturers that provide online quoting and ordering systems, allowing for instant price and turnaround time estimates. This approach not only speeds up the ordering process but also enhances transparency regarding production timelines. Additionally, engaging in clear and proactive communication with manufacturers about project timelines and specifications can help identify potential bottlenecks early on. Establishing a relationship with a dedicated account manager can facilitate smoother interactions and expedite issue resolution, ensuring that your PCB needs are met promptly.

Scenario 2: Ensuring Quality and Compliance in PCB Manufacturing

The Problem: Quality assurance is a major concern for B2B buyers, particularly those in regulated industries such as aerospace, medical devices, and automotive. International buyers may struggle with ensuring that PCBs meet specific industry standards and certifications, such as IPC or ISO qualifications. Inconsistent quality can lead to product failures, increased costs, and damage to brand reputation. The challenge is compounded when sourcing from overseas manufacturers who may not adhere to the same stringent quality controls as U.S. manufacturers.

The Solution: To ensure quality and compliance, buyers should meticulously vet PCB manufacturers before placing orders. This includes reviewing their certifications, quality control processes, and past performance in similar projects. Opt for manufacturers that provide detailed documentation of their compliance with industry standards. Additionally, consider conducting factory audits or requesting samples before committing to larger orders. Leveraging technology, such as utilizing a digital platform that tracks production quality in real-time, can also provide peace of mind. By implementing these practices, buyers can significantly reduce the risk of quality issues in their final products.

Scenario 3: Managing Component Sourcing and Supply Chain Issues

The Problem: Another prevalent challenge for B2B buyers is managing the sourcing of components needed for PCB assembly. Fluctuating prices, shortages, and long lead times for electronic components can disrupt manufacturing schedules and inflate costs. This issue is particularly pronounced in a global market where many components are sourced from different regions, leading to complexities in logistics and inventory management.

The Solution: To navigate component sourcing effectively, buyers should consider partnering with PCB manufacturers that offer turnkey services, which include component procurement along with PCB fabrication and assembly. This integrated approach streamlines the supply chain, reduces the risk of component shortages, and ensures that all parts meet compatibility and quality standards. Buyers should also maintain open lines of communication with their manufacturers regarding component availability and pricing trends. Utilizing inventory management tools can help forecast demand and monitor stock levels, allowing businesses to make informed purchasing decisions and avoid production delays. By taking these proactive steps, buyers can enhance supply chain resilience and maintain smoother operations.

Strategic Material Selection Guide for printed circuit board manufacturers in usa

What Are the Key Properties of Common PCB Materials?

Printed circuit boards (PCBs) are critical components in electronic devices, and the choice of materials significantly influences their performance and reliability. Here, we analyze four common materials used in PCB manufacturing in the USA, focusing on their properties, advantages, disadvantages, and implications for international buyers.

FR-4: The Standard Material for PCBs

Key Properties:

FR-4 is a glass-reinforced epoxy laminate material that offers excellent electrical insulation, thermal stability, and mechanical strength. It typically operates at temperatures up to 130°C and has good flame resistance.

Pros & Cons:

FR-4 is widely regarded for its balance of performance and cost, making it a popular choice for a variety of applications. However, it has limitations in high-frequency applications due to its dielectric properties, which can affect signal integrity.

Impact on Application:

FR-4 is suitable for most consumer electronics, automotive, and industrial applications. However, its performance may degrade in high-frequency or high-temperature environments, necessitating careful consideration of the application requirements.

Considerations for International Buyers:

Buyers from regions such as Africa, South America, and Europe should ensure that the FR-4 materials comply with international standards such as ASTM or DIN. This is particularly important in industries like automotive and aerospace, where regulatory compliance is critical.

Rogers Materials: High-Frequency Performance

Key Properties:

Rogers materials, such as RO4350B, are designed for high-frequency applications, featuring low dielectric loss and high thermal conductivity. They can withstand temperatures up to 200°C.

Pros & Cons:

The primary advantage of Rogers materials is their ability to maintain signal integrity in high-speed applications. However, they are more expensive than FR-4 and may require specialized manufacturing processes.

Impact on Application:

These materials are ideal for RF and microwave applications, making them suitable for telecommunications and aerospace. Their performance in high-frequency scenarios is a significant advantage, but the cost may limit their use in low-budget projects.

Considerations for International Buyers:

International buyers should verify that Rogers materials meet specific compliance standards relevant to their regions, such as JIS in Japan or EN standards in Europe. Understanding the local market’s preferences for high-frequency applications can also guide material selection.

Polyimide: Flexibility and Durability

Key Properties:

Polyimide is known for its exceptional thermal stability, operating at temperatures up to 260°C. It is also highly flexible, making it suitable for applications requiring bending or folding.

Pros & Cons:

Polyimide offers excellent chemical resistance and is ideal for flexible PCBs. However, its manufacturing process can be complex and more costly compared to FR-4.

Impact on Application:

This material is perfect for applications in wearable technology and medical devices, where flexibility is crucial. Its durability makes it suitable for harsh environments, but the higher cost may deter some manufacturers.

Considerations for International Buyers:

Buyers should consider the specific applications in their markets, particularly in sectors like healthcare, where compliance with standards such as ISO 13485 is essential. Understanding the material’s certifications and performance in local environments is also critical.

Aluminum Clad: Thermal Management

Key Properties:

Aluminum clad PCBs provide excellent thermal management, making them suitable for high-power applications. They can handle temperatures up to 150°C, with good electrical insulation.

Pros & Cons:

The key advantage is their ability to dissipate heat effectively, which enhances the reliability of high-power devices. However, they can be more expensive and may require specialized assembly processes.

Impact on Application:

Aluminum clad PCBs are commonly used in LED lighting and power electronics, where heat dissipation is a priority. Their performance in thermal management is a significant benefit, but the cost and complexity may limit their use in simpler applications.

Considerations for International Buyers:

International buyers should assess the thermal requirements of their applications and ensure that aluminum clad materials comply with relevant standards. Understanding local market trends in power electronics can also inform material selection.

Summary Table of PCB Materials

| Material | Typical Use Case for printed circuit board manufacturers in usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| FR-4 | Consumer electronics, automotive, industrial applications | Balanced performance and cost | Limited in high-frequency applications | Medium |

| Rogers | RF and microwave applications | Excellent signal integrity | Higher cost and specialized manufacturing | High |

| Polyimide | Wearable technology, medical devices | Exceptional flexibility and durability | Complex manufacturing and higher cost | High |

| Aluminum Clad | LED lighting, power electronics | Superior thermal management | More expensive and complex assembly | High |

This analysis provides a comprehensive overview of key materials used in PCB manufacturing, enabling international B2B buyers to make informed decisions based on their specific application requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for printed circuit board manufacturers in usa

What Are the Main Stages of PCB Manufacturing for B2B Buyers?

The manufacturing process of printed circuit boards (PCBs) in the USA is a meticulous journey that involves several key stages, each integral to ensuring the final product meets stringent quality standards. Understanding these stages helps international B2B buyers make informed decisions when selecting a PCB manufacturer.

1. Material Preparation: What Materials Are Used in PCB Manufacturing?

The first step in PCB manufacturing involves selecting high-quality materials, typically copper-clad laminates, which form the basis of the circuit boards. These materials are chosen based on their electrical, thermal, and mechanical properties. Key considerations include:

- Copper Thickness: The thickness of the copper layer, typically ranging from 1 oz to 6 oz, impacts the board’s conductivity and current-carrying capacity.

- Substrate Type: Options like FR-4, Rogers, and polyimide are common, each offering unique benefits for different applications.

- Surface Finish: Various finishes, such as ENIG (Electroless Nickel Immersion Gold) and HASL (Hot Air Solder Leveling), protect the copper and improve solderability.

After material selection, the laminates are cut to size and prepared for the next stage.

2. Forming: How Are PCBs Formed?

The forming stage involves several sub-processes, including etching, drilling, and lamination:

- Etching: The copper layers are etched to create the circuit patterns. Advanced techniques, such as photo-engraving and laser etching, are employed to achieve high precision.

- Drilling: Holes for vias and component leads are drilled with high-speed drills. This is critical for multilayer boards where vias connect different layers.

- Lamination: For multilayer boards, layers are stacked and laminated under heat and pressure to bond them together, ensuring structural integrity.

This stage requires a keen eye for detail, as any errors can lead to significant defects down the line.

3. Assembly: What Techniques Are Used in PCB Assembly?

Once the boards are formed, they move to the assembly stage, which can be either through-hole technology (THT) or surface mount technology (SMT). Each method has distinct advantages:

- Surface Mount Technology (SMT): This method allows for the placement of components directly onto the surface of the PCB. SMT is preferred for its ability to accommodate smaller components and higher density layouts.

- Through-Hole Technology (THT): Involves inserting component leads through holes in the PCB and soldering them on the opposite side. THT is often used for components that require more mechanical strength.

The assembly process is typically automated, enhancing speed and accuracy. However, some manufacturers still employ manual assembly for complex components or prototypes.

4. Finishing: What Are the Final Steps in PCB Manufacturing?

The finishing stage involves several processes to ensure the board is ready for use:

- Solder Mask Application: A protective layer is applied to prevent solder from bridging between conductive paths during assembly.

- Silkscreen Printing: This step involves printing labels and identifiers on the board for easier assembly and troubleshooting.

- Final Inspection: Before shipping, each board undergoes a thorough inspection to ensure it meets the required specifications.

How is Quality Assurance Integrated into PCB Manufacturing?

Quality assurance (QA) is a critical component of the PCB manufacturing process. Adhering to international and industry-specific standards ensures that products are reliable and safe for use.

What International Standards Apply to PCB Manufacturers?

Prominent standards include:

- ISO 9001: This quality management standard ensures consistent quality across processes. Manufacturers certified under ISO 9001 demonstrate their commitment to quality and customer satisfaction.

- IPC Standards: IPC (Institute of Printed Circuits) standards, such as IPC-A-610 for acceptability of electronic assemblies, provide guidelines on quality criteria for PCBs.

B2B buyers should prioritize manufacturers with relevant certifications, as these indicate a commitment to quality and reliability.

What Are the Key Quality Control Checkpoints in PCB Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): Conducted during manufacturing, IPQC ensures that processes are followed correctly and identifies defects early.

- Final Quality Control (FQC): A comprehensive inspection of the finished product, FQC verifies that the PCB meets all specifications and standards.

These checkpoints help minimize defects and ensure that products are manufactured to the highest standards.

What Testing Methods Are Commonly Used in PCB Quality Assurance?

Manufacturers employ various testing methods to verify PCB functionality and reliability:

- Electrical Testing: Includes continuity testing and functional testing to ensure that all circuits perform as intended.

- Thermal Cycling Tests: Assess how well the PCB can withstand temperature fluctuations, which is critical for reliability in various environments.

- X-Ray Inspection: Used to inspect solder joints and internal layers of multilayer boards, ensuring there are no hidden defects.

International B2B buyers should inquire about the testing methods used by potential suppliers to ensure they meet their quality expectations.

How Can B2B Buyers Verify a PCB Manufacturer’s Quality Control Processes?

To ensure that a PCB manufacturer meets quality standards, international buyers can take several steps:

- Supplier Audits: Conducting on-site audits can provide insights into the manufacturer’s processes, equipment, and quality control measures.

- Quality Reports: Requesting detailed quality reports can help buyers understand the manufacturer’s performance history and defect rates.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality practices.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, must consider additional nuances in quality control:

- Regulatory Compliance: Ensure that the manufacturer complies with local regulations and standards relevant to your region.

- Cultural Differences: Understanding different business practices and communication styles can aid in establishing a successful partnership.

- Logistics and Shipping: Ensure that the manufacturer has robust logistics in place to handle international shipping, as delays can impact project timelines.

By paying close attention to these factors, B2B buyers can enhance their sourcing decisions and ensure they partner with reputable PCB manufacturers committed to quality and excellence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘printed circuit board manufacturers in usa’

Introduction

Navigating the landscape of printed circuit board (PCB) manufacturing in the USA can be challenging, especially for international B2B buyers. This step-by-step checklist is designed to help you identify, evaluate, and select the right PCB manufacturer that meets your specific needs, ensuring a smooth procurement process and high-quality outputs.

Step 1: Define Your Technical Specifications

Before initiating contact with potential suppliers, clearly outline your technical requirements. This includes details such as the type of PCB (e.g., rigid, flex, or rigid-flex), layer count, dimensions, materials, and any specific industry standards (like IPC-6012).

- Why It Matters: Having precise specifications helps manufacturers provide accurate quotes and ensures that the final product meets your design needs.

- What to Look For: Be prepared to discuss tolerances, surface finishes, and any unique features required for your application.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable PCB manufacturers in the USA. Utilize online directories, industry forums, and reviews from other international buyers to compile a list of potential suppliers.

- Why It Matters: A well-informed selection process increases the likelihood of finding a manufacturer with the capabilities to meet your needs.

- What to Look For: Pay attention to the manufacturer’s experience, specialization, and customer feedback, particularly in your industry.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant industry certifications such as ISO 9001, IPC-A-610, or MIL-SPEC qualifications. These certifications demonstrate a commitment to quality management and adherence to industry standards.

- Why It Matters: Certifications provide assurance that the manufacturer maintains high-quality production processes and is capable of meeting international standards.

- What to Look For: Request documentation of certifications and inquire about the processes used to maintain compliance.

Step 4: Request Samples and Prototypes

Before finalizing your decision, ask for samples or prototypes of their previous work. This will allow you to assess the quality and precision of their PCB manufacturing capabilities firsthand.

- Why It Matters: Samples provide tangible evidence of a manufacturer’s ability to deliver the quality you require, helping you avoid costly mistakes later.

- What to Look For: Examine the finish, layer alignment, and overall craftsmanship of the samples to ensure they meet your standards.

Step 5: Understand Lead Times and Pricing Structures

Discuss lead times and pricing structures with your shortlisted suppliers. Different manufacturers may offer varying turnaround times and pricing models based on order size, complexity, and additional services like assembly or component sourcing.

- Why It Matters: Understanding the cost implications and delivery timelines is crucial for aligning with your project’s budget and schedule.

- What to Look For: Request detailed quotes that break down costs for different services and ask about any potential hidden fees.

Step 6: Assess Communication and Support

Evaluate the level of communication and support provided by potential manufacturers. Effective communication is essential for addressing any issues that may arise during the manufacturing process.

- Why It Matters: A responsive supplier can significantly enhance the collaboration process and ensure timely resolutions to any problems.

- What to Look For: Test their responsiveness by asking questions and observe how quickly and thoroughly they provide answers.

Step 7: Finalize Your Decision and Place an Order

After careful evaluation, select the manufacturer that best aligns with your technical needs, quality expectations, and budget. Ensure that all terms are clearly outlined in a formal agreement before placing your order.

- Why It Matters: A clear agreement helps prevent misunderstandings and ensures both parties are aligned on expectations.

- What to Look For: Confirm details such as delivery schedules, payment terms, and warranty policies before finalizing your order.

By following this practical sourcing guide, international B2B buyers can effectively navigate the complexities of procuring PCBs from manufacturers in the USA, ensuring quality and reliability in their supply chain.

Comprehensive Cost and Pricing Analysis for printed circuit board manufacturers in usa Sourcing

What Are the Key Cost Components in PCB Manufacturing in the USA?

Understanding the cost structure of printed circuit board (PCB) manufacturing is crucial for international B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials, such as copper, FR-4 substrates, and specialized coatings, can significantly impact pricing. High-quality materials may increase initial costs but can enhance durability and performance, offering long-term savings.

-

Labor: Labor costs vary depending on the complexity of the PCB and the skill level required. Advanced manufacturing processes, like HDI (High-Density Interconnect) boards, typically demand a higher labor investment due to the specialized skills needed.

-

Manufacturing Overhead: This encompasses costs associated with factory operations, including utilities, rent, equipment maintenance, and salaries of non-production staff. Overhead can add a substantial percentage to the final price.

-

Tooling: The initial setup and tooling costs can be significant, especially for custom designs. These costs are often amortized over larger production runs, making high-volume orders more cost-effective.

-

Quality Control (QC): Rigorous QC processes ensure that PCBs meet industry standards and specifications. While this may increase upfront costs, it minimizes defects and rework, ultimately saving money.

-

Logistics: Shipping and handling costs can vary based on the destination and the chosen Incoterms. Buyers should factor in these logistics costs when calculating the total expenditure.

-

Margin: Manufacturers will add a margin to cover their profit. Understanding the typical margins in the PCB industry can help buyers gauge whether a quote is competitive.

How Do Price Influencers Affect PCB Quotes?

Several factors can influence the pricing of PCBs:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes typically lead to lower per-unit costs due to economies of scale. Buyers should evaluate their needs against MOQ to optimize cost efficiency.

-

Specifications and Customization: Custom designs or specific requirements (e.g., multilayer boards, special finishes) can drive up costs. Standard products usually come at a lower price point.

-

Material Choices: The choice of materials significantly affects pricing. Premium materials, while more expensive, may offer better performance and longevity.

-

Quality and Certifications: PCBs that meet higher quality standards or certifications (e.g., ISO, IPC) will command higher prices. Buyers in regulated industries, such as aerospace or healthcare, may need to prioritize these certifications.

-

Supplier Factors: The reputation and capabilities of the supplier can also impact pricing. Established manufacturers may charge a premium for their expertise and reliability.

-

Incoterms: The agreed-upon shipping terms can affect the overall cost. Buyers should clarify who bears the shipping costs and responsibilities to avoid unexpected expenses.

What Tips Can Help Buyers Negotiate Better PCB Prices?

B2B buyers from regions like Africa, South America, the Middle East, and Europe should consider several strategies to improve their sourcing outcomes:

-

Negotiate Volume Discounts: If you anticipate ongoing needs, negotiate for better pricing based on projected order volumes. Manufacturers often provide discounts for larger commitments.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes maintenance, reliability, and performance over time. A slightly more expensive PCB may save costs in the long run through reduced failures or replacements.

-

Understand Pricing Nuances: Be aware of seasonal trends, supplier promotions, or changes in raw material costs that might affect pricing. Timing your orders can yield better rates.

-

Engage Multiple Suppliers: Request quotes from several manufacturers to create a competitive environment. This can lead to better pricing and terms.

-

Clarify Payment Terms: Explore different payment options that could provide financial flexibility. Some suppliers may offer better pricing for upfront payments or longer payment terms.

Disclaimer on Indicative Prices

PCB pricing can vary widely based on the aforementioned factors and specific project requirements. It is essential for buyers to request personalized quotes from manufacturers to obtain accurate pricing tailored to their needs.

Alternatives Analysis: Comparing printed circuit board manufacturers in usa With Other Solutions

Exploring Alternatives to Printed Circuit Board Manufacturers in the USA

In the competitive landscape of electronics manufacturing, businesses often seek alternatives to traditional printed circuit board (PCB) manufacturers in the USA. These alternatives can provide unique advantages in terms of cost, speed, and technology. By evaluating different solutions, B2B buyers can make informed decisions that align with their specific project requirements and budget constraints.

| Comparison Aspect | Printed Circuit Board Manufacturers In USA | Alternative 1 Name: Offshore PCB Manufacturing | Alternative 2 Name: 3D Printed Circuits |

|---|---|---|---|

| Performance | High precision, tailored to complex designs | Variable quality, dependent on vendor | Limited complexity, ideal for prototypes |

| Cost | Higher due to labor and material standards | Generally lower due to cheaper labor costs | Moderate, but can be cost-effective for small runs |

| Ease of Implementation | Streamlined processes, often with online quotes | Can be complex due to international logistics | Simple for small batches, requires specific design software |

| Maintenance | Strong support and warranty options | Limited support, potential language barriers | Minimal maintenance, but technology is evolving |

| Best Use Case | Aerospace, medical devices, automotive | High-volume consumer electronics | Rapid prototyping, educational projects |

What Are the Advantages and Disadvantages of Offshore PCB Manufacturing?

Offshore PCB manufacturing often presents a cost-effective alternative for companies looking to produce large volumes of printed circuit boards. By leveraging cheaper labor and materials, businesses can reduce production costs significantly. However, the trade-off often includes variable quality and longer lead times, which can complicate project timelines. Additionally, communication issues and logistical challenges may arise, making it essential for buyers to thoroughly vet potential vendors to ensure quality and reliability.

How Do 3D Printed Circuits Compare to Traditional PCB Manufacturing?

3D printed circuits are an innovative alternative that allows for rapid prototyping and lower setup costs, especially for small production runs. This method can quickly produce functional prototypes, making it particularly appealing for startups and educational projects. However, the technology is still evolving, and 3D printed circuits often lack the complexity and durability of traditional PCBs. As such, they may not be suitable for high-performance applications like aerospace or medical devices, where reliability is crucial.

Conclusion: How Should B2B Buyers Choose the Right PCB Solution?

For international B2B buyers, the choice between printed circuit board manufacturers in the USA and alternative solutions hinges on specific project needs. Buyers should assess factors such as performance requirements, budget constraints, and production volume. If high quality and precision are paramount, U.S. manufacturers may be the best option. Conversely, for cost-sensitive projects or rapid prototyping needs, offshore manufacturing or 3D printed circuits may provide viable alternatives. Ultimately, a thorough evaluation of the pros and cons of each option will enable buyers to select the most suitable solution for their unique requirements.

Essential Technical Properties and Trade Terminology for printed circuit board manufacturers in usa

What Are the Key Technical Properties of Printed Circuit Boards (PCBs) for Manufacturers in the USA?

When selecting a PCB manufacturer, understanding the essential technical properties is crucial for ensuring that the product meets your specifications. Here are some critical specifications that buyers should consider:

1. Material Grade

The material grade of a PCB primarily refers to the substrate used, with common materials including FR-4, Rogers, and Polyimide. FR-4 is the most widely used due to its excellent electrical insulating properties and cost-effectiveness. Higher-grade materials, like Rogers, are preferred for high-frequency applications due to their superior thermal stability and lower dielectric loss. Selecting the right material is vital for performance and reliability, especially in demanding applications like aerospace or medical devices.

2. Layer Count

The number of layers in a PCB can significantly influence its complexity, functionality, and manufacturing cost. Common configurations include 2-layer, 4-layer, and up to 30-layer boards for advanced applications. A higher layer count allows for more complex circuitry but also increases production costs and lead times. Understanding your project’s requirements helps in choosing the appropriate layer count without overspending.

3. Minimum Trace Width and Spacing

Trace width and spacing are critical for ensuring signal integrity and preventing short circuits. The minimum trace width can range from 4 mils (0.004 inches) to as low as 1.5 mils (0.0015 inches) for advanced designs. Selecting the right specifications is essential for high-density applications, ensuring that your PCB can handle the required current without overheating or failing.

4. Tolerance

Tolerance refers to the allowable deviation from specified dimensions and is crucial for ensuring that components fit correctly on the PCB. Tolerances can range from ±0.1mm to ±0.01mm, depending on the complexity of the design. Tight tolerances are essential in high-precision applications, such as in medical devices or aerospace components, where any deviation could lead to device failure.

5. Surface Finish

The surface finish of a PCB affects solderability and the overall longevity of the board. Common finishes include ENIG (Electroless Nickel Immersion Gold), HASL (Hot Air Solder Leveling), and OSP (Organic Solderability Preservative). The choice of finish impacts both the assembly process and the final product’s performance, making it a vital consideration in the manufacturing process.

What Are Common Trade Terminology and Jargon Used in PCB Manufacturing?

Understanding industry-specific terminology can enhance communication and ensure more effective collaboration with PCB manufacturers. Here are several key terms frequently encountered in the PCB sector:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the PCB industry, OEMs often rely on PCB manufacturers to create custom boards that meet specific requirements for their products. Understanding the OEM relationship is crucial for international buyers looking to streamline their supply chain.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a manufacturer is willing to sell. This is particularly important for international buyers who may need to balance cost efficiency with inventory management. Understanding the MOQ helps businesses plan their purchasing strategy to avoid excess stock or missed opportunities.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to bid on supplying specific products or services. It typically includes detailed specifications, quantities, and delivery timelines. This process is essential for ensuring transparency and competitiveness in pricing, helping buyers secure the best possible deal.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, clarifying who pays for shipping, insurance, and tariffs. Familiarity with Incoterms is vital for international buyers to avoid misunderstandings and ensure smooth logistics.

5. DFM (Design for Manufacturability)

DFM refers to the engineering practice of designing products in a way that optimizes their manufacturability. This includes considerations for material selection, assembly processes, and cost implications. Engaging in DFM discussions with manufacturers can lead to more efficient production processes and reduced costs.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when engaging with PCB manufacturers in the USA, ensuring that their projects meet quality standards while remaining cost-effective.

Navigating Market Dynamics and Sourcing Trends in the printed circuit board manufacturers in usa Sector

What Are the Current Market Dynamics and Trends in the PCB Manufacturing Sector?

The printed circuit board (PCB) manufacturing sector in the USA is experiencing significant growth driven by technological advancements and increased demand across various industries. Key global drivers include the surge in electronic devices, the rise of electric vehicles (EVs), and the expansion of the Internet of Things (IoT). For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Emerging trends in the PCB sector include the adoption of advanced manufacturing technologies such as automation and artificial intelligence, which enhance production efficiency and accuracy. Furthermore, there is a noticeable shift towards flexible and high-density interconnect (HDI) PCBs, which cater to the miniaturization of electronic products. Another trend is the increasing use of turnkey solutions offered by manufacturers, providing a streamlined process that integrates design, fabrication, and assembly. This approach is particularly appealing to international buyers looking for cost-effective and reliable sourcing options.

Market dynamics are also influenced by geopolitical factors and supply chain disruptions, which underscore the importance of choosing manufacturers with strong domestic capabilities. For international buyers, establishing partnerships with American PCB manufacturers can mitigate risks associated with overseas sourcing, ensuring quality and compliance with industry standards.

How Are Sustainability and Ethical Sourcing Shaping the PCB Manufacturing Landscape?

Sustainability is becoming a critical factor for international B2B buyers in the PCB manufacturing sector. The environmental impact of PCB production, including hazardous waste and resource consumption, has prompted manufacturers to adopt greener practices. This shift is essential not only for regulatory compliance but also for meeting the growing consumer demand for environmentally friendly products.

Ethical sourcing is equally important, as buyers increasingly prioritize suppliers that demonstrate transparency and responsibility in their supply chains. Manufacturers that hold certifications such as ISO 14001 for environmental management systems or use green materials (like lead-free solder and recyclable substrates) are more likely to attract discerning clients from Europe and other regions that emphasize corporate responsibility.

B2B buyers should look for PCB manufacturers that actively engage in sustainability initiatives and provide comprehensive information about their sourcing practices. This includes assessing the lifecycle of materials used and ensuring that their supply chains adhere to ethical standards. By choosing suppliers committed to sustainability, buyers not only enhance their corporate image but also contribute to a more sustainable future.

What Is the Historical Context of PCB Manufacturing in the USA?

The printed circuit board industry in the USA has evolved significantly since its inception in the mid-20th century. Initially focused on simple designs for military and aerospace applications, the sector has transformed into a complex landscape catering to various industries, including consumer electronics, automotive, and medical devices.

Technological advancements have played a pivotal role in this evolution, with the introduction of computer-aided design (CAD) tools revolutionizing PCB design and production processes. As demand for more sophisticated electronics grew, manufacturers adapted by developing advanced PCB technologies such as multilayer boards and flexible circuits.

Today, the USA stands as a leader in PCB manufacturing, known for high-quality standards and innovation. This historical context provides valuable insights for international B2B buyers, highlighting the reliability and expertise of American manufacturers in delivering cutting-edge PCB solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of printed circuit board manufacturers in usa

-

How do I choose the right PCB manufacturer for my project?

Choosing the right PCB manufacturer involves assessing their capabilities, experience, and industry certifications. Start by reviewing their portfolio to ensure they have experience with projects similar to yours. Check for certifications like ISO 9001 and IPC standards, which indicate quality assurance. It’s also essential to evaluate their production capacity, turnaround time, and customer support. Engaging in direct communication with potential manufacturers can provide insights into their processes and reliability. -

What is the best way to communicate my PCB design requirements?

To effectively communicate your PCB design requirements, provide detailed documentation that includes Gerber files, Bill of Materials (BOM), and design specifications. Clearly outline key parameters such as layer count, material type, surface finish, and any specific assembly instructions. Using standardized formats and ensuring all files are accurate will minimize misunderstandings. Additionally, maintaining open lines of communication with the manufacturer can help address any questions or concerns during the fabrication process. -

What are the typical minimum order quantities (MOQ) for PCBs?

Minimum order quantities (MOQ) for PCBs vary by manufacturer and can range from a single prototype to thousands for mass production. Many manufacturers offer flexible MOQs for prototyping, which can be as low as one unit. However, for bulk orders, MOQs might be higher, often influenced by the complexity of the design and the materials used. It’s advisable to discuss your specific needs with potential suppliers to find a suitable arrangement that meets your production goals. -

How can I ensure quality assurance during PCB manufacturing?

To ensure quality assurance during PCB manufacturing, select a manufacturer with robust quality control processes. Look for certifications such as ISO 9001 and IPC standards that demonstrate a commitment to quality. Request details about their inspection methods, including automated optical inspection (AOI) and functional testing. Regular communication during production can also help address any quality concerns promptly. Consider conducting a factory audit or requesting samples before finalizing large orders to verify the manufacturer’s quality standards. -

What payment terms should I expect when sourcing PCBs from the USA?

Payment terms for PCB manufacturing can vary widely, but common practices include upfront deposits of 30-50% with the balance due upon completion. Some manufacturers may offer net 30 or net 60 terms for established clients. It’s essential to clarify payment methods accepted, such as credit cards, wire transfers, or PayPal. Be aware that international buyers may incur additional fees related to currency exchange or international wire transfers, so it’s advisable to discuss these aspects upfront. -

What are the shipping options for international PCB orders from the USA?

International PCB orders from the USA can typically be shipped via air or sea freight, depending on your urgency and budget. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but takes longer. Many manufacturers partner with logistics companies to streamline shipping processes and provide tracking options. It’s important to discuss shipping preferences and costs upfront to ensure timely delivery to your location. -

How do I vet a PCB manufacturer before placing an order?

Vetting a PCB manufacturer involves researching their reputation, capabilities, and customer feedback. Start by reviewing online testimonials and case studies from previous clients. Request references and reach out to them for insights on their experiences. Additionally, assess the manufacturer’s certifications, production capabilities, and compliance with industry standards. If possible, arrange a visit to their facility to observe their operations and quality control measures firsthand. -

What customization options are available for PCBs?

Most PCB manufacturers offer various customization options to meet specific project needs. This includes choices in materials, layer counts, surface finishes, and component placements. Advanced capabilities may include the use of exotic materials, special coatings, or unique stack-ups for high-frequency applications. When discussing your project, be clear about your requirements and inquire about any limitations or additional costs associated with customization to ensure the final product aligns with your expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for printed circuit board manufacturers in usa

In navigating the landscape of printed circuit board (PCB) manufacturing in the USA, strategic sourcing emerges as a pivotal component for international buyers. By partnering with reputable manufacturers such as Sierra Circuits, Sanmina, and TTM Technologies, businesses can leverage advanced technologies, stringent quality controls, and rapid turnaround times. These attributes not only enhance product reliability but also significantly reduce time-to-market, providing a competitive edge in fast-paced industries.

Moreover, understanding the diverse capabilities offered—from turnkey solutions to specialized services—allows buyers to tailor their sourcing strategies to meet specific project requirements. As global supply chains evolve, the emphasis on sourcing from U.S. manufacturers provides not only quality assurance but also transparency and responsiveness, essential for businesses operating in regions like Africa, South America, the Middle East, and Europe.

Looking ahead, the PCB industry is poised for growth driven by innovations in technology and an increasing demand for high-quality electronic components. International buyers are encouraged to explore partnerships with American manufacturers, ensuring they remain at the forefront of technological advancements while optimizing their production processes. Engage with U.S. PCB suppliers today to explore how strategic sourcing can elevate your product offerings and meet the demands of tomorrow’s markets.