Top 4 Toy Companies In Usa List and Guide: How To Solve Scenario …

Introduction: Navigating the Global Market for toy companies in usa

Navigating the dynamic landscape of toy companies in the USA presents a unique challenge for international B2B buyers seeking reliable sourcing options. With an array of manufacturers offering diverse products, from educational toys to innovative playsets, the decision-making process can be daunting. This guide aims to streamline your procurement journey by providing comprehensive insights into the types of toys available, their applications, and the essential criteria for supplier vetting.

As you explore the intricacies of the U.S. toy market, you will gain valuable information about pricing structures, quality assurance, and sustainability practices—key factors that influence purchasing decisions in today’s environmentally conscious landscape. Whether you are a buyer from Africa, South America, the Middle East, or Europe (including Germany and Brazil), understanding these elements is crucial for making informed choices that align with your business objectives.

This guide empowers you with actionable insights, enabling you to navigate the complexities of sourcing from U.S. toy companies confidently. By addressing potential challenges and offering strategic solutions, we ensure you can secure high-quality products that meet the demands of your market while fostering long-term supplier relationships. Discover how to leverage this knowledge to enhance your product offerings and drive sales in your respective regions.

Top 10 Toy Companies In Usa Manufacturers & Suppliers List

1. HABA USA – Children’s Toys by Age Group

Domain: habausa.com

Registered: 1999 (26 years)

Introduction: HABA USA offers a wide range of children’s toys categorized by age groups: 0-12 months, 12-24 months, 2-3 years, 3-5 years, 5-8 years, and 8+ years. Key product categories include:

– **0-12 Months**: Plush baby toys, grasping and teething toys, hanging baby toys, mobiles, play gyms, play mats, and baby’s first dolls.

– **12-24 Months**: Dolls, bath toys, plush toys, baby’s first blocks, lacing to…

2. USTOY – Walkie Talkie

Domain: ustoy.com

Registered: 1999 (26 years)

Introduction: Walkie Talkie Regular Price: $29.99; Whacky Racket Regular Price: $24.99; Balloon Car Racer Regular Price: $41.94; Toy Microscope Regular Price: $24.99; Incredible Noodles Regular Price: $35.76; Light Up Magic Wheel Regular Price: $83.89; Four In A Row Game Regular Price: $26.99; Wooden Kendama W/Red Ball Regular Price: $8.99; Chalkie Fun Chalk Writer Regular Price: $11.99 (Out of stock); Insect I…

3. MGA Entertainment – Playground Equipment

Domain: playgroundequipment.com

Registered: 1996 (29 years)

Introduction: MGA Entertainment Inc.: $9.15 billion, Lego: $6.99 billion, Bandai Namco: $6.8 billion, Hasbro: $5.47 billion, Mattel: $4.6 billion, Monopoly (Hasbro): $1.76 billion, Tomy Company: $1.43 billion, Barbie (Mattel): $1.35 billion, Mega Brands (Mattel): $1.08 billion, Fisher-Price (Mattel): $1.07 billion, Playmobil: $857.9 million, Funko: $653 million, Magic: The Gathering (Hasbro): $581.2 million, JA…

4. Toys R Us – Wide Range of Toys and Games

Domain: toysrus.com

Registered: 1995 (30 years)

Introduction: Toysrus.com offers a wide range of toys, games, and more, categorized by age and type. Key categories include Action Figures & Playsets, Arts & Crafts, Baby & Toddler Toys, Books, Building Sets & Blocks (including LEGO), Collectibles, Dolls & Stuffed Animals, Electronics, Games & Puzzles, Learning & Development, Outdoor Play, Preschool Toys & Activities, Pretend Play & Dress Up, S.T.E.A.M Toys, an…

Understanding toy companies in usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Educational Toy Companies | Focus on developmental benefits and learning outcomes | Schools, educational institutions | Pros: Promotes cognitive skills; Cons: Higher price points may limit accessibility. |

| Traditional Toy Manufacturers | Classic toys made from wood or plastic, emphasizing durability | Retailers, specialty toy shops | Pros: Timeless appeal; Cons: May lack modern technology integration. |

| Licensed Character Toys | Toys based on popular media franchises and characters | Merchandisers, themed retail outlets | Pros: High demand; Cons: Licensing fees can increase costs. |

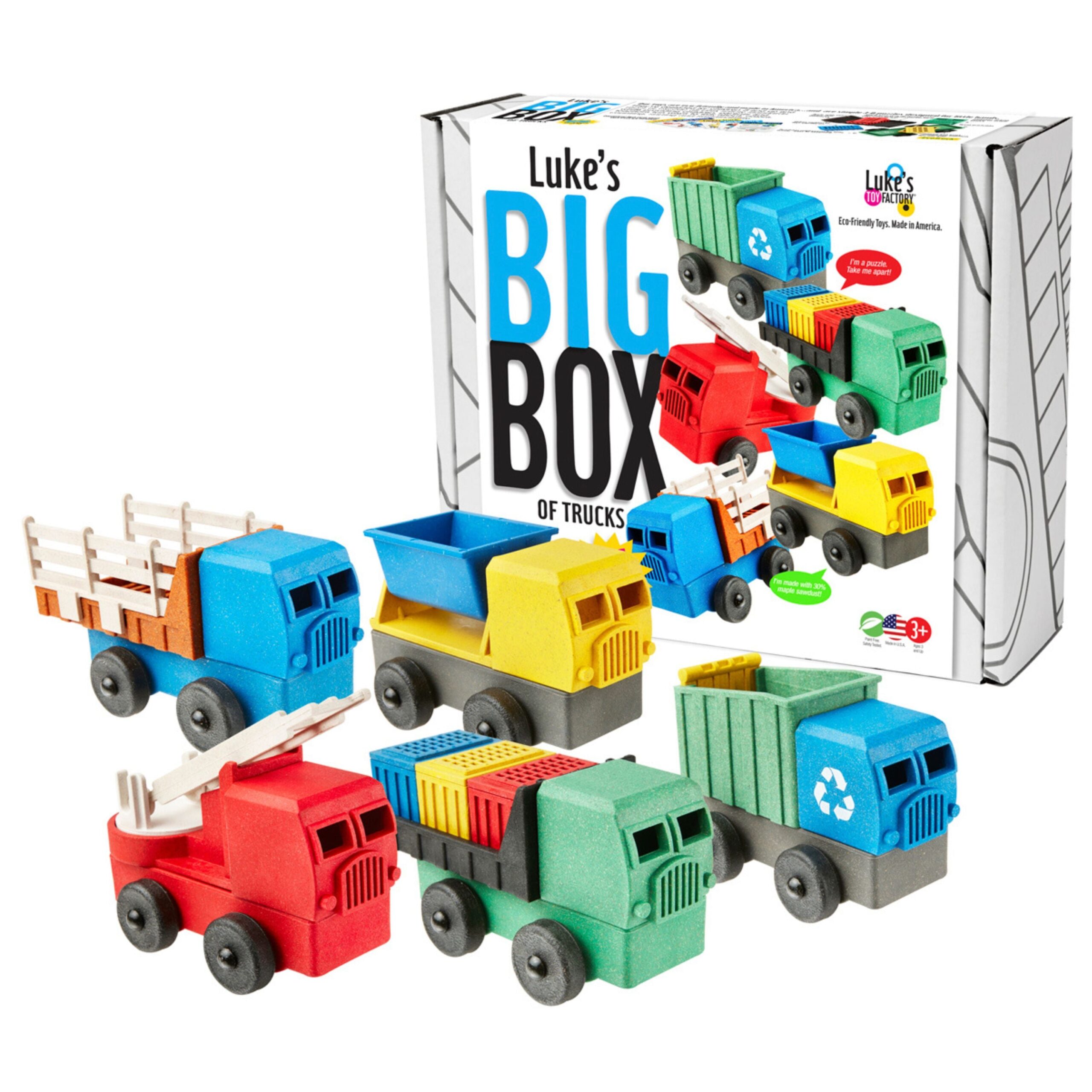

| Eco-Friendly Toy Brands | Sustainable materials and manufacturing processes | Green retailers, eco-conscious markets | Pros: Appeals to environmentally conscious consumers; Cons: Often more expensive. |

| Innovative Tech Toy Companies | Integration of technology into traditional playthings | Tech retailers, educational tech suppliers | Pros: Captivates tech-savvy children; Cons: Rapid obsolescence of tech features. |

What Are the Characteristics of Educational Toy Companies?

Educational toy companies specialize in products designed to foster learning and development in children. These toys often incorporate elements that enhance cognitive skills, motor skills, and social interaction. B2B buyers, such as schools and educational institutions, value these products for their ability to engage students while meeting curriculum standards. However, the higher price points associated with these toys may limit their accessibility for some buyers.

How Do Traditional Toy Manufacturers Stand Out?

Traditional toy manufacturers create timeless toys, often made from durable materials like wood or high-quality plastic. These toys appeal to buyers seeking classic options that have stood the test of time. Retailers and specialty toy shops often stock these items, as they cater to parents looking for reliable and safe toys. While they offer a nostalgic appeal, these toys may not incorporate the latest technological advancements, which can be a drawback for tech-savvy consumers.

Why Are Licensed Character Toys Popular Among B2B Buyers?

Licensed character toys are based on popular media franchises, such as movies, cartoons, and video games. This type of toy has a strong market presence and is often in high demand, making them attractive for merchandisers and themed retail outlets. However, the costs associated with licensing can inflate retail prices, which may deter some buyers. Despite this, the brand recognition can lead to increased sales and customer loyalty.

What Makes Eco-Friendly Toy Brands a Viable Option?

Eco-friendly toy brands focus on sustainability, using materials that minimize environmental impact. These companies appeal to green retailers and eco-conscious markets, as their products align with the values of environmentally aware consumers. While eco-friendly toys can command higher prices due to sustainable practices, they often attract a dedicated customer base willing to pay a premium for responsible products. B2B buyers must consider the balance between cost and the growing demand for sustainable options.

How Do Innovative Tech Toy Companies Cater to Modern Consumers?

Innovative tech toy companies integrate technology into traditional playthings, creating products that engage children in new ways. These toys often include interactive features, apps, or augmented reality, making them appealing to tech-savvy children and their parents. Tech retailers and educational tech suppliers are primary B2B buyers for these products. However, the rapid pace of technological advancement can lead to obsolescence, posing a challenge for buyers who must stay updated with the latest offerings.

Key Industrial Applications of toy companies in usa

| Industry/Sector | Specific Application of Toy Companies in USA | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Development of Educational Toys and Learning Aids | Enhances cognitive skills and promotes interactive learning. | Safety standards, educational value, adaptability to curricula. |

| Retail | Supply of Diverse Toy Lines for Retail Outlets | Attracts a broad customer base, increasing sales potential. | Product variety, seasonal trends, pricing strategies. |

| Entertainment | Licensing and Merchandise for Film/TV Characters | Expands brand presence and engages fans across demographics. | Licensing agreements, market trends, alignment with brand values. |

| Healthcare | Therapeutic Toys for Child Development | Supports emotional and physical development for children. | Safety certifications, therapeutic benefits, age-appropriate design. |

| E-commerce | Online Distribution of Toys and Games | Facilitates global reach and convenience for international buyers. | Logistics, shipping costs, online marketing strategies. |

How Are Educational Toys Used in the Education Sector?

Toy companies in the USA play a vital role in the education sector by providing educational toys and learning aids that enhance cognitive skills and foster interactive learning experiences. These toys are designed to align with educational curricula, helping children grasp complex concepts through play. International buyers, particularly from regions like Africa and South America, must consider safety standards and the educational value of products to ensure they meet local regulations and learning objectives. Additionally, adaptability to various educational environments is crucial for maximizing impact.

What Role Do Toy Companies Play in Retail Supply Chains?

In the retail sector, toy companies are essential suppliers of diverse toy lines that cater to various consumer demographics. By offering a wide range of products, they help retailers attract a broader customer base, ultimately increasing sales potential. For international retailers, understanding seasonal trends and pricing strategies is key to optimizing inventory and maximizing profits. Sourcing considerations also include the reliability of supply chains and the ability to respond quickly to changing market demands.

How Do Toy Companies Enhance Entertainment Experiences?

The entertainment industry benefits from toy companies through the licensing and merchandising of toys based on popular film and television characters. This collaboration not only expands the brand presence of both the toy and entertainment companies but also engages fans across different age groups. For international buyers, understanding licensing agreements and market trends is essential for successful partnerships. Aligning product offerings with brand values ensures a cohesive message that resonates with consumers.

What Are the Benefits of Therapeutic Toys in Healthcare?

In the healthcare sector, toy companies contribute by developing therapeutic toys that aid in the emotional and physical development of children. These toys are particularly valuable in therapeutic settings, helping children cope with various challenges. For international healthcare providers, sourcing toys that meet safety certifications and offer therapeutic benefits is critical. Additionally, ensuring that products are age-appropriate and culturally relevant enhances their effectiveness in diverse settings.

How Do E-commerce Platforms Benefit from Toy Companies?

E-commerce platforms rely heavily on toy companies for the online distribution of toys and games, facilitating global reach and convenience for buyers. This model allows international customers to access a wide variety of products without geographical limitations. Key sourcing considerations for e-commerce buyers include logistics, shipping costs, and effective online marketing strategies to attract customers. Understanding consumer behavior and preferences in different regions is also vital for tailoring offerings that resonate with diverse markets.

3 Common User Pain Points for ‘toy companies in usa’ & Their Solutions

Scenario 1: Navigating Diverse Regulatory Standards for Toy Safety

The Problem: B2B buyers sourcing toys from companies in the USA often encounter the challenge of navigating complex safety regulations. Different countries have distinct safety standards, such as EN71 in Europe or ASTM F963 in the USA. This can lead to confusion, potential delays in product launches, and increased costs if toys need to be re-tested or modified to meet varying compliance requirements. Buyers may feel overwhelmed by the documentation and testing processes needed to ensure their products meet international safety standards while maintaining their market competitiveness.

The Solution: To effectively manage regulatory compliance, B2B buyers should establish a strong partnership with toy manufacturers that have robust quality assurance processes in place. It is essential to request detailed documentation of safety testing and compliance certifications from suppliers. Buyers can benefit from seeking manufacturers that have experience exporting to their target markets, as they will likely have a better understanding of the necessary compliance protocols. Additionally, engaging a third-party compliance consultant can provide valuable insights into specific regulations and help streamline the testing process. Utilizing an online database of regulatory requirements for different markets can also aid in keeping track of necessary certifications and updates, ensuring smooth product launches.

Scenario 2: Managing Supply Chain Disruptions in Toy Manufacturing

The Problem: Recent global events have highlighted vulnerabilities in supply chains, particularly for toy companies reliant on overseas manufacturing. B2B buyers may face delays in receiving orders, fluctuations in product availability, and increased shipping costs, which can severely impact inventory management and sales forecasts. This unpredictability can lead to stockouts during peak seasons or excess inventory during slower periods, affecting profitability.

The Solution: To mitigate supply chain disruptions, B2B buyers should diversify their supplier base and consider sourcing from multiple manufacturers within the USA. This strategy reduces dependence on a single supplier and allows for greater flexibility in response to market changes. Buyers can also implement just-in-time inventory management practices to optimize stock levels based on real-time sales data and trends. Collaborating with suppliers to develop contingency plans, such as alternative shipping routes or emergency stockpiles, can further enhance resilience. Additionally, investing in supply chain management software can provide visibility into inventory levels and help forecast demand more accurately, allowing for proactive adjustments.

Scenario 3: Competing in a Crowded Market with Unique Toy Offerings

The Problem: The toy market is saturated with numerous companies and products, making it challenging for B2B buyers to differentiate their offerings and attract customers. Buyers may struggle to find unique, high-quality toys that resonate with their target audience, leading to stagnant sales and diminished brand reputation. The challenge is not only in sourcing products but also in ensuring that the toys align with current consumer trends, such as educational value or sustainability.

The Solution: To stand out in a crowded marketplace, B2B buyers should focus on curating a unique product portfolio that emphasizes quality and educational value. This can be achieved by researching emerging trends in the toy industry, such as eco-friendly materials or STEM-focused toys, and collaborating with manufacturers that align with these values. Buyers can also consider exclusive partnerships with innovative toy companies to offer unique products that competitors do not have. Attending industry trade shows and networking events can provide insights into upcoming trends and allow buyers to form relationships with emerging brands. Finally, leveraging social media and online marketing strategies to promote the unique aspects of their toy offerings can help capture consumer attention and drive sales.

Strategic Material Selection Guide for toy companies in usa

What Are the Key Materials Used by Toy Companies in the USA?

When selecting materials for toy manufacturing, companies must consider a variety of factors including safety, durability, and compliance with international standards. Here, we analyze four common materials used in the toy industry: plastic, wood, metal, and fabric. Each material comes with its own set of properties, advantages, and challenges that can significantly impact product performance and marketability.

How Does Plastic Perform as a Material for Toys?

Plastic is one of the most widely used materials in the toy industry due to its versatility and cost-effectiveness. Key properties include resistance to moisture and chemicals, which makes it suitable for a variety of applications. However, the specific type of plastic (e.g., ABS, PVC, or polyethylene) can affect its temperature tolerance and durability.

Pros: Plastics are lightweight, durable, and can be molded into intricate shapes, making them ideal for complex designs. They are also relatively inexpensive to produce, allowing for lower retail prices.

Cons: However, some plastics can be less environmentally friendly and may not meet international safety standards. Additionally, certain types of plastic can become brittle over time or degrade when exposed to UV light.

For international buyers, it is crucial to ensure that the chosen plastic complies with standards such as ASTM F963 in the USA or EN71 in Europe, which govern toy safety.

What Are the Benefits of Using Wood in Toy Manufacturing?

Wood is a traditional material that is gaining popularity for its natural aesthetic and durability. Key properties include strength, resistance to wear, and a natural feel that appeals to consumers.

Pros: Wooden toys are often perceived as safer and more environmentally friendly, especially when sourced from sustainable forests. They also have a longer lifespan compared to plastic toys, which can enhance brand reputation.

Cons: On the downside, wood can be more expensive to source and manufacture. It is also susceptible to moisture and may require additional treatments to prevent warping or splintering.

International buyers should look for certifications like FSC (Forest Stewardship Council) to ensure that the wood is sustainably sourced and compliant with safety standards.

How Does Metal Compare as a Material for Toys?

Metal is often used in toys that require additional strength and durability, such as construction sets or vehicles. Key properties include high tensile strength and resistance to impact.

Pros: Metal toys can withstand rough play and have a premium feel that appeals to consumers. They can also be recycled, which aligns with sustainability goals.

Cons: However, metal can be heavier and more expensive to produce than plastic or wood. Additionally, metal toys must be treated to prevent rust and corrosion, particularly if they will be exposed to moisture.

For international buyers, compliance with safety standards is critical, as metal toys may pose choking hazards or sharp edges if not manufactured correctly.

What Role Does Fabric Play in Toy Production?

Fabric is commonly used in soft toys and dolls, providing a tactile experience that is appealing to younger children. Key properties include flexibility and comfort, making fabric toys ideal for cuddling.

Pros: Fabric toys are often machine washable and can be produced in a variety of textures and colors, enhancing their appeal. They are generally lightweight and safe for young children.

Cons: However, fabric toys may not be as durable as plastic or wood, and they can be prone to wear and tear over time. Additionally, they may require special treatments to ensure they are flame-resistant and free from harmful chemicals.

International buyers should ensure that fabric toys meet standards such as Oeko-Tex certification, which guarantees that textiles are free from harmful substances.

Summary Table of Material Selection for Toy Companies

| Material | Typical Use Case for toy companies in usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Action figures, building blocks | Versatile and cost-effective | Environmental concerns and potential brittleness | Low |

| Wood | Educational toys, puzzles | Durable and eco-friendly | Higher cost and moisture susceptibility | Medium |

| Metal | Construction sets, vehicles | Strong and premium feel | Heavier and requires rust protection | Medium |

| Fabric | Soft toys, dolls | Safe and washable | Less durable and requires special treatments | Low |

This strategic material selection guide aims to help international B2B buyers understand the implications of material choices in toy production, ensuring compliance with safety standards while meeting market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for toy companies in usa

What Are the Main Stages of Manufacturing for Toy Companies in the USA?

The manufacturing process for toy companies in the USA typically consists of several main stages: material preparation, forming, assembly, and finishing. Each stage plays a critical role in ensuring the quality and safety of the toys produced.

Material Preparation

The first stage involves sourcing raw materials, which may include plastics, wood, textiles, and metals. Sustainable sourcing has gained prominence, with companies seeking eco-friendly materials to meet growing consumer demands for sustainability. Suppliers often undergo rigorous vetting to ensure compliance with safety and environmental regulations.

How Is Forming Done in Toy Manufacturing?

Forming is the next step, where raw materials are shaped into components. Techniques such as injection molding, blow molding, and CNC machining are commonly employed. For instance, injection molding is particularly popular for plastic toys, allowing for intricate designs and high production rates. In contrast, wooden toys often utilize cutting and assembly methods that emphasize craftsmanship.

What Is Involved in the Assembly Process?

Once components are formed, they move to the assembly stage. This can involve manual labor or automated processes, depending on the complexity of the toy. For example, toys with multiple interactive parts may require skilled workers for precise assembly, while simpler products might be assembled using automated machinery. Quality checks are often integrated at this stage to catch defects early.

What Finishing Techniques Are Commonly Used?

The final stage is finishing, where toys are painted, coated, or packaged. This stage is crucial for aesthetic appeal and safety. Non-toxic paints and finishes are increasingly preferred to align with safety standards. Packaging is also designed to be attractive while ensuring product safety during transportation.

What Quality Assurance Practices Are Essential for Toy Manufacturers?

Quality assurance (QA) is paramount in the toy industry, especially given the focus on safety and durability. Toy companies in the USA adhere to various international standards such as ISO 9001, which outlines requirements for a quality management system.

Which International Standards Are Relevant to Toy Quality Control?

In addition to ISO 9001, toy manufacturers often comply with industry-specific standards like the EN71 (European Standard for toy safety), ASTM F963 (Standard Consumer Safety Specification for Toy Safety), and the CE marking for toys sold in Europe. These standards cover aspects such as mechanical safety, chemical safety, and age appropriateness.

What Are the Key Quality Control Checkpoints in Toy Manufacturing?

Quality control (QC) checkpoints are crucial for maintaining high standards throughout the manufacturing process. Typically, the QC process includes three main checkpoints:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival. Suppliers must provide certifications and test reports to ensure materials meet safety and quality standards.

-

In-Process Quality Control (IPQC): During manufacturing, random samples are taken to assess quality at various stages. This proactive approach helps identify defects early, allowing for corrective actions before products reach the final stage.

-

Final Quality Control (FQC): Once the toys are fully assembled, a thorough inspection is conducted. This includes visual checks, functional tests, and safety assessments to ensure that the final products meet all regulatory requirements.

What Testing Methods Are Commonly Used in Toy Quality Assurance?

Common testing methods include:

- Mechanical Testing: Evaluating the toy’s strength and durability under stress.

- Chemical Testing: Assessing for harmful substances, particularly in paint and plastics.

- Safety Testing: Checking for choking hazards, sharp edges, and other potential risks.

These tests are essential for compliance with safety standards and to instill confidence in buyers regarding the safety of the toys.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Here are actionable strategies:

-

Supplier Audits: Conduct on-site audits to assess manufacturing practices and quality control measures. This helps ensure that suppliers adhere to their stated processes and standards.

-

Request Quality Reports: Buyers should request documentation of previous quality control tests, including IQC, IPQC, and FQC reports. This transparency helps validate the supplier’s commitment to quality.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. These inspectors can conduct tests and audits according to international standards.

What Are the Nuances of Quality Control for International Buyers?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. For instance, toys sold in the EU must meet CE marking standards, while those in the US need to comply with ASTM regulations.

-

Cultural Expectations: Understanding the cultural context can influence expectations around safety and quality. For example, buyers from Germany may have stricter requirements compared to those in Brazil.

-

Communication Barriers: Language differences can pose challenges in understanding quality reports and specifications. It’s beneficial to work with suppliers who can provide documentation in the buyer’s preferred language.

Conclusion: Ensuring Quality in Toy Manufacturing

For international B2B buyers, understanding the manufacturing processes and quality assurance practices of toy companies in the USA is essential. By familiarizing themselves with the stages of production, relevant standards, and effective verification methods, buyers can make informed decisions that ensure they source safe, high-quality toys for their markets. This knowledge not only facilitates better supplier relationships but also enhances the overall purchasing experience.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘toy companies in usa’

In the ever-evolving landscape of the toy industry, sourcing from reputable companies in the USA is essential for international buyers aiming to deliver quality products. This practical guide serves as a comprehensive checklist to streamline your procurement process, ensuring that you choose the right suppliers and products for your market.

Step 1: Identify Your Target Market Needs

Understanding your target market is crucial. Analyze demographic factors such as age, cultural preferences, and purchasing power in your region. This insight will help you select toys that resonate with your customers and ensure you meet demand.

- Consider regional trends: Research popular toy categories in your market, such as educational toys or outdoor play items.

- Assess competition: Review what similar companies offer to identify gaps and opportunities.

Step 2: Define Your Product Specifications

Clearly outlining your product specifications is vital for successful sourcing. This includes details on materials, safety standards, and design features.

- Safety compliance: Ensure the toys meet international safety regulations, such as ASTM and EN71 standards, which are critical for market acceptance.

- Sustainability factors: Increasingly, consumers prefer eco-friendly toys. Specify whether you want sustainable materials or ethical manufacturing processes.

Step 3: Research Potential Suppliers

Conduct thorough research to find reputable toy manufacturers in the USA. Use industry directories, trade shows, and online platforms to compile a list of potential suppliers.

- Evaluate company backgrounds: Look for suppliers with a strong track record and positive reviews from other international buyers.

- Check certifications: Verify that suppliers have necessary certifications for safety and quality, such as ISO 9001.

Step 4: Request Samples and Prototypes

Before making bulk orders, always request samples or prototypes. This step allows you to assess product quality firsthand.

- Quality assessment: Examine the samples for durability, design accuracy, and adherence to your specifications.

- User testing: Consider testing samples with a focus group to gather feedback on appeal and functionality.

Step 5: Negotiate Terms and Pricing

Once you’ve identified suitable suppliers, enter negotiations to secure favorable terms. Pricing, payment methods, and delivery timelines are key points to discuss.

- Bulk discounts: Inquire about price breaks for larger orders to optimize your budget.

- Payment flexibility: Discuss payment terms that suit both parties, including deposits or credit options.

Step 6: Verify Logistics and Shipping Options

Understanding logistics is crucial for timely delivery and cost management. Confirm that your supplier can accommodate your shipping needs.

- Shipping methods: Evaluate options such as air freight for urgent deliveries versus sea freight for cost efficiency.

- Customs compliance: Ensure the supplier can provide necessary documentation for smooth customs clearance in your country.

Step 7: Establish a Communication Plan

Maintain ongoing communication with your suppliers to ensure transparency and quick resolution of any issues.

- Regular updates: Set up a schedule for progress reports on production and shipping.

- Feedback loop: Create channels for providing feedback on quality and service, which can enhance long-term partnerships.

By following this structured approach, international buyers can effectively navigate the complexities of sourcing from toy companies in the USA, ensuring they deliver quality products that meet their market’s needs.

Comprehensive Cost and Pricing Analysis for toy companies in usa Sourcing

What Are the Key Cost Components for Toy Companies in the USA?

When sourcing toys from American manufacturers, understanding the cost structure is essential for B2B buyers. The primary components that contribute to the overall cost include:

-

Materials: The choice of materials significantly impacts pricing. Sustainable options, like wood or organic textiles, may come at a premium but appeal to eco-conscious consumers. Conversely, cheaper plastics can lower costs but may compromise quality.

-

Labor: Labor costs in the USA are relatively high compared to some regions globally. This includes wages, benefits, and compliance with labor laws. Companies often invest in skilled labor to ensure quality, particularly for educational or developmental toys.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Initial tooling costs for custom designs can be substantial. These costs cover the creation of molds and equipment necessary for production. Buyers should inquire about tooling costs and consider them when evaluating overall pricing.

-

Quality Control (QC): Rigorous QC processes ensure safety and compliance with standards, particularly crucial for children’s toys. Investing in QC can add to costs but is necessary to mitigate risks associated with product recalls.

-

Logistics: Transportation and warehousing costs are significant, especially for international buyers. Shipping fees, import duties, and insurance should all be factored into the total cost.

-

Margin: Manufacturers typically add a profit margin to their costs, which can vary widely based on market demand, brand positioning, and competition.

How Do Price Influencers Affect Toy Sourcing in the USA?

Several factors can influence the pricing of toys sourced from the USA:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for bulk pricing, significantly reducing the per-unit cost. Buyers should consider their inventory needs and negotiate accordingly.

-

Specifications and Customization: Unique designs or features can increase costs. Understanding the balance between customization and standard offerings is crucial for budget management.

-

Material Quality and Certifications: Higher-quality materials and certified products (e.g., ASTM, EN71) usually come at a higher price. Buyers should weigh the benefits of certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established manufacturers may charge more due to their brand value and customer service, while emerging companies might offer competitive pricing to gain market share.

-

Incoterms: The chosen Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers during shipping. Understanding these terms can help buyers anticipate additional costs associated with transportation and insurance.

What Are the Essential Buyer Tips for Cost-Efficiency in Toy Sourcing?

To maximize cost-efficiency when sourcing toys from the USA, international buyers should consider the following strategies:

-

Negotiate Pricing: Always engage in negotiations with suppliers. Many manufacturers are open to discussing pricing, especially for bulk orders or long-term partnerships.

-

Evaluate Total Cost of Ownership (TCO): Assess all costs associated with sourcing, including production, shipping, duties, and potential tariffs. This holistic view will provide better insights into the true cost of purchasing decisions.

-

Understand Pricing Nuances: Be aware of regional pricing trends, as costs can vary significantly between different manufacturers and regions within the USA. Conduct market research to compare pricing and quality.

-

Plan for Currency Fluctuations: For buyers from regions like Africa or South America, currency fluctuations can impact overall costs. Consider hedging strategies or negotiating pricing in a stable currency to mitigate risks.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better terms, faster turnaround times, and increased flexibility in negotiations.

Disclaimer on Indicative Prices

Prices for toys can vary widely based on specifications, order size, and other factors. The prices mentioned are indicative and should be verified with suppliers to ensure accuracy at the time of purchase.

Alternatives Analysis: Comparing toy companies in usa With Other Solutions

Exploring Alternatives to Toy Companies in the USA for International Buyers

In the dynamic landscape of the toy industry, international B2B buyers must consider various options beyond traditional toy companies in the USA. As markets evolve, alternative solutions can provide unique advantages in terms of product offerings, sustainability, and cost-effectiveness. This analysis will compare toy companies in the USA with two viable alternatives: international toy manufacturers and digital toy platforms.

Comparison Table

| Comparison Aspect | Toy Companies In USA | International Toy Manufacturers | Digital Toy Platforms |

|---|---|---|---|

| Performance | High-quality, diverse product range with established safety standards. | Offers innovative designs, often with local cultural relevance and unique materials. | Engages users through interactive and educational content; however, physical product limitations exist. |

| Cost | Moderate to high prices depending on brand and product type. | Competitive pricing, often lower due to local production; however, shipping costs can be high for international orders. | Typically lower upfront costs; subscription models may lead to long-term expenses. |

| Ease of Implementation | Established supply chains and distribution networks facilitate easy access. | Varies by manufacturer; may require more effort in terms of logistics and compliance. | Simple integration into existing sales platforms; no physical inventory required. |

| Maintenance | Requires ongoing inventory management and customer service support. | May involve more complex maintenance due to international regulations and standards. | Minimal maintenance; updates and content management handled digitally. |

| Best Use Case | Ideal for companies seeking reliable, high-quality toys with brand recognition. | Suitable for businesses looking for unique, culturally relevant toys at competitive prices. | Best for companies focusing on educational products or digital engagement with consumers. |

What Are the Advantages and Disadvantages of International Toy Manufacturers?

International toy manufacturers often provide unique advantages, such as access to innovative designs and culturally relevant products. These manufacturers can leverage local materials and craftsmanship to create toys that resonate with specific markets. However, the challenges include navigating different regulatory environments and potential shipping delays, which can impact delivery times and overall inventory management. Additionally, compliance with international safety standards may require more rigorous oversight.

How Do Digital Toy Platforms Compare in the Toy Industry?

Digital toy platforms offer a modern approach to engaging consumers through interactive and educational experiences. These platforms can provide a vast array of products without the need for physical inventory, allowing businesses to scale quickly and adapt to market trends. However, they may lack the tactile experience of traditional toys, which can be a drawback for certain demographics. Moreover, while upfront costs can be lower, subscription models may lead to higher long-term expenditures, making it essential for businesses to evaluate their financial strategies carefully.

Conclusion: How Should B2B Buyers Choose the Right Toy Solution?

When selecting the right toy solution, B2B buyers must carefully evaluate their specific needs and market conditions. Considerations such as product quality, cost structure, and supply chain logistics are critical to making an informed decision. Toy companies in the USA offer established reliability and brand recognition, while international manufacturers provide unique and culturally relevant products at competitive prices. Digital platforms present an innovative approach, especially for educational toys, albeit with their own set of challenges. By aligning their strategic goals with the strengths of these alternatives, buyers can effectively meet consumer demands and enhance their market presence.

Essential Technical Properties and Trade Terminology for toy companies in usa

What are the Key Technical Properties Critical for Toy Manufacturing?

When engaging in the toy industry, understanding the technical properties of products is essential for ensuring quality, safety, and compliance with regulations. Here are several critical specifications:

-

Material Grade: This refers to the quality and type of materials used in toy manufacturing, such as plastics, wood, or fabrics. For instance, toys made from high-grade ABS plastic are known for their durability and safety. B2B buyers should prioritize suppliers who utilize non-toxic, child-safe materials, as these are crucial for meeting safety standards and consumer expectations.

-

Safety Standards Compliance: Compliance with regulations such as ASTM F963 in the USA is vital. This standard outlines safety requirements for toys, including mechanical and physical properties, flammability, and chemical composition. For international buyers, ensuring that the toys meet both local and international safety standards can prevent costly recalls and enhance marketability.

-

Tolerance Levels: Tolerance refers to the permissible limit of variation in a physical dimension or measured value. For example, if a toy part must fit precisely with another, the tolerance level must be defined to ensure proper assembly and function. High tolerance levels minimize defects and enhance the overall quality of the toy, which is a key consideration for B2B buyers looking for reliability.

-

Durability Testing: This involves assessing how well a toy withstands wear and tear over time. B2B buyers should look for suppliers that conduct rigorous durability tests to ensure their products can endure rough play and last through multiple uses, which is essential for customer satisfaction and brand loyalty.

-

Age Appropriateness: Toys should be designed and tested for specific age groups, which influences material choices and safety features. Understanding age appropriateness not only guides product development but also informs marketing strategies to target the right demographics effectively.

What are Common Trade Terminology and Concepts in the Toy Industry?

Familiarity with industry jargon can significantly enhance communication and negotiation between buyers and suppliers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For toy companies, working with an OEM can help streamline production processes while ensuring high-quality components.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it affects inventory management and cost efficiency. Negotiating favorable MOQs can help businesses maintain cash flow and reduce excess stock.

-

RFQ (Request for Quotation): An RFQ is a document used to solicit price quotes from suppliers. This is an important step in the procurement process, allowing buyers to compare costs and terms from different manufacturers, ultimately aiding in decision-making.

-

Incoterms (International Commercial Terms): These are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms can prevent misunderstandings about shipping, insurance, and delivery costs, which is especially important for international B2B transactions.

-

Lead Time: This refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is critical for inventory planning and customer satisfaction, as longer lead times can impact sales and market responsiveness.

-

Sustainability Certifications: These indicate that a toy manufacturer adheres to environmentally friendly practices, such as using recycled materials or maintaining eco-friendly production processes. Sustainability certifications can enhance brand reputation and appeal to increasingly eco-conscious consumers.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring they partner with reliable manufacturers that meet quality, safety, and sustainability standards.

Navigating Market Dynamics and Sourcing Trends in the toy companies in usa Sector

What Are the Key Trends Shaping the Toy Companies in the USA Market?

The toy industry in the USA is currently experiencing significant shifts driven by evolving consumer preferences and technological advancements. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, should be aware of several key trends. Firstly, there is a growing demand for educational and STEM-focused toys that cater to the cognitive development of children. This trend is being fueled by parents’ increasing awareness of the importance of early childhood education. Additionally, the rise of e-commerce platforms has transformed how toys are marketed and sold, allowing companies to reach global customers more effectively.

Moreover, the incorporation of digital technology into toys—such as augmented reality and interactive gaming—has created new opportunities for innovation. B2B buyers should pay attention to companies that are investing in these technologies as they are likely to capture a larger share of the market. Sustainability is also becoming a significant factor, with consumers preferring brands that demonstrate commitment to eco-friendly practices. As a result, sourcing trends are shifting towards suppliers who can provide sustainable materials and ethical manufacturing processes, a vital consideration for international buyers looking to align with consumer expectations in their respective markets.

How Is Sustainability Influencing Sourcing Practices in the Toy Industry?

Sustainability is no longer just a buzzword; it has become a critical component of business strategy in the toy industry. The environmental impact of toy production, particularly regarding plastic waste, has led many companies to reevaluate their sourcing practices. Ethical supply chains are increasingly important, as consumers demand transparency in the origins of the products they purchase. For international B2B buyers, partnering with toy companies that prioritize sustainability can enhance brand reputation and appeal to eco-conscious consumers.

In the USA, many toy manufacturers are now seeking certifications such as FSC (Forest Stewardship Council) for wooden toys, and using non-toxic, recyclable materials in their products. These certifications not only reassure buyers about the safety and environmental impact of their products but also enhance marketability in regions that emphasize sustainability. International buyers should actively seek partnerships with companies that are committed to sustainable practices, as this aligns with global trends towards greener products and corporate responsibility.

What Is the Historical Context of the Toy Industry in the USA for B2B Buyers?

Understanding the historical evolution of the toy industry in the USA can provide valuable insights for B2B buyers. The industry has roots dating back to the 19th century, initially dominated by wooden toys and handcrafted items. The post-World War II era marked a significant transformation with the introduction of mass production techniques, leading to the creation of iconic brands such as Hasbro and Mattel. These companies set the standard for innovation and marketing strategies that have shaped the industry.

In recent decades, the rise of digital technology has prompted a new wave of innovation, moving beyond traditional toys to include interactive and digital play experiences. This evolution reflects broader societal changes, including the integration of technology into everyday life. B2B buyers today must navigate a complex landscape that encompasses not only traditional toys but also tech-driven products that cater to modern children’s preferences. Understanding this historical context allows international buyers to make informed decisions about which companies to partner with, considering both legacy brands and emerging innovators in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of toy companies in usa

-

1. How do I ensure the quality of toys when sourcing from US manufacturers?

To ensure quality when sourcing toys from US manufacturers, conduct thorough research on potential suppliers. Look for certifications that indicate compliance with safety standards, such as ASTM F963 or EN71. Request samples to assess product quality firsthand, and consider visiting the manufacturing facility if possible. Establish clear quality assurance processes and communicate specific requirements to the supplier. Engaging third-party inspection services can also help verify that products meet your standards before shipment. -

2. What are the typical payment terms offered by toy companies in the USA?

Payment terms can vary significantly among toy companies in the USA, but common practices include a deposit (typically 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer net terms (e.g., net 30 or net 60) for established relationships. It’s essential to discuss payment terms upfront and ensure clarity in contracts to avoid misunderstandings. Consider using secure payment methods to protect both parties during transactions. -

3. What is the minimum order quantity (MOQ) when ordering toys from US suppliers?

Minimum order quantities (MOQs) can vary widely depending on the manufacturer and the type of toys being ordered. Generally, MOQs can range from 100 to 1,000 units or more for custom designs. It’s advisable to inquire about MOQs during initial discussions with suppliers and negotiate terms based on your needs. If your order falls below the MOQ, some manufacturers may offer flexibility or suggest alternative products that meet your requirements. -

4. How can I customize toys for my target market?

Customizing toys for your target market involves collaborating closely with manufacturers to tailor designs, colors, and packaging to suit local preferences. Begin by providing clear specifications and examples of desired changes. Many US toy companies offer customization services, but it’s important to confirm their capabilities and lead times. Consider market research to understand cultural preferences and trends, ensuring that the final products resonate with your audience. -

5. What steps should I take to vet potential toy suppliers in the USA?

To vet potential toy suppliers, start by reviewing their business credentials, certifications, and industry experience. Request references from other B2B clients to gauge their reliability and quality. Assess their production capabilities and compliance with safety regulations. Conduct site visits or virtual audits to evaluate their facilities. Finally, consider ordering samples to assess product quality before committing to larger orders, ensuring they meet your specifications. -

6. What are the logistics considerations when importing toys from the USA?

When importing toys from the USA, consider logistics factors such as shipping methods, costs, and delivery times. Decide between air and ocean freight based on your budget and urgency. Familiarize yourself with import duties, taxes, and customs regulations in your country. It’s also crucial to choose a reliable freight forwarder who can manage the complexities of international shipping and ensure compliance with documentation requirements. -

7. How can I stay informed about trends in the US toy market?

Staying informed about trends in the US toy market requires ongoing research and engagement with industry publications, trade shows, and market reports. Subscribe to newsletters from toy associations and follow relevant blogs and social media channels. Networking with other B2B buyers and attending industry events can also provide valuable insights into emerging trends and consumer preferences. Engaging with suppliers can help you understand their innovations and product developments. -

8. What are the key safety standards for toys in the USA?

In the USA, toys must comply with safety standards set forth by the Consumer Product Safety Commission (CPSC), including ASTM F963, which outlines safety requirements for toys. Compliance ensures that toys are free from hazardous materials and designed to minimize choking hazards. It’s essential to verify that your suppliers adhere to these standards and provide necessary documentation. Regular testing and certification by accredited laboratories can help maintain safety compliance throughout the production process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for toy companies in usa

In navigating the dynamic landscape of the toy industry in the USA, strategic sourcing emerges as a vital component for international B2B buyers. By fostering relationships with established manufacturers such as HABA and US Toy Company, buyers can access a diverse range of high-quality, innovative products that cater to various age groups and developmental needs. Emphasizing sustainability and educational value, these companies not only enhance product offerings but also align with the growing consumer demand for responsible sourcing.

Moreover, the trend towards digital platforms and e-commerce is reshaping how toy companies engage with global markets. This shift allows buyers from regions such as Africa, South America, the Middle East, and Europe to easily explore a multitude of options, streamlining the purchasing process while ensuring product safety and compliance with international standards.

As the toy market continues to evolve, the potential for collaboration with American manufacturers remains robust. International buyers are encouraged to leverage these strategic sourcing opportunities to enrich their portfolios and meet the diverse needs of their customers. Engaging with US toy companies today can position your business advantageously for tomorrow’s market demands.