Top 9 Backflow Parts USA Manufacturers Reviewed

Are you tired of dealing with unreliable backflow parts that compromise your plumbing systems? You’re not alone! Many professionals struggle to find quality suppliers that deliver consistent performance and durability. In this competitive market, selecting the right manufacturer can make all the difference. The best factories provide not just parts, but peace of mind, ensuring your projects run smoothly and efficiently. Imagine saving time and resources by partnering with top-tier suppliers who understand your needs and exceed your expectations.

Ready to discover the top 30 backflow parts manufacturers in the USA? Dive into our comprehensive guide and find the perfect supplier for your business today!

Top 9 Backflow Parts Usa Manufacturers

Backflowpartsusa – Backflow Prevention Parts & Accessories

Domain: backflowpartsusa.com

Registered: 2010 ( 15 years )

Introduction: Backflow prevention parts and accessories for various applications.

Backflowparts – Repair Parts & Preventers Solutions

Domain: backflowparts.com

Registered: 1998 ( 27 years )

Introduction: Backflow Repair Parts & Preventers, including repair parts, complete assemblies, specialty tools, accessories, testing equipment, enclosures & cages, shutoff valves, and fire protection products.

BAVCO – Backflow Prevention Parts Distributor

Domain: bavco.com

Registered: 1996 ( 29 years )

Introduction: BAVCO is the largest master parts distributor of original factory repair parts for backflow prevention assemblies, offering a wide range of products from various manufacturers.

Backflow Parts Depot – Backflow Repair Parts & Supplies

Domain: backflowpartsdepot.com

Registered: 2012 ( 13 years )

Introduction: Backflow Parts Depot offers a wide range of backflow repair parts and plumbing supplies, including repair kits, assemblies, accessories, fittings, test gauges, shutoff valves, and fire protection equipment.

Backflow Parts Connection – Backflow Prevention Solutions

Domain: backflowpartsconnection.com

Registered: 2008 ( 17 years )

Introduction: Backflow prevention parts and accessories for various applications.

American Backflow – Genuine Backflow Parts & Repair Kits

Domain: americanbackflow.com

Registered: 1999 ( 26 years )

Introduction: American Backflow Specialties offers a comprehensive inventory of Genuine Manufacturer Backflow Parts & Repair Kits from major manufacturers including Watts, Wilkins, Febco, Ames, Apollo, and Cla-Val.

Backflow Supply – Backflow Repair Kits

Domain: backflow-supply.com

Registered: 1997 ( 28 years )

Introduction: The company primarily offers a wide range of backflow repair kits for various models, including AMES, APOLLO, CONBRACO, FEBCO, and WATTS. These kits are designed for different sizes and specifications, catering to both residential and commercial applications.

Backflow Direct – Quality Backflow Prevention Parts

Equiparts – Backflow Preventer Repair Parts

Domain: equiparts.com

Registered: 1998 ( 27 years )

Introduction: Equiparts offers a wide range of backflow preventer repair parts, accessories, and enclosures from trusted manufacturers, including Ames, Febco, Watts, Conbraco, and Wilkins. They provide parts for double check valve assemblies, vacuum breaker assemblies, and reduced pressure zone assemblies.

Category Information

The category of “backflow parts USA” encompasses components and accessories used in backflow prevention systems, which are essential for maintaining safe and potable water supply in residential, commercial, and industrial settings. Backflow prevention devices are designed to protect drinking water from contamination due to the reverse flow of water, which can occur due to pressure changes in the plumbing system.

Common parts include valves, assemblies, and repair kits, each playing a critical role in ensuring the effectiveness of the backflow prevention system. The significance of backflow parts lies in their contribution to public health and safety. With rising concerns over water quality and environmental protection, maintaining functional backflow prevention systems is paramount. Proper installation and maintenance of these components help prevent the risk of hazardous substances entering the water supply, thereby safeguarding communities and adhering to regulatory standards.

As such, the availability of reliable backflow parts in the USA is crucial for both compliance and the protection of water resources.

Application Information

Backflow parts in the USA are crucial in various industries that require the prevention of contaminated water from flowing back into clean water supplies. One primary application area is in municipal water systems, where backflow preventers are installed to protect drinking water from pollutants and ensure public health. These devices are essential in maintaining the integrity of water distribution networks.

Another significant use is in commercial and industrial facilities, such as food processing plants and manufacturing facilities, where the risk of backflow can lead to severe contamination. Additionally, residential applications are common, particularly in homes with irrigation systems or swimming pools, where backflow prevention is vital to safeguard potable water. Overall, backflow parts play a crucial role in environmental protection and public safety across diverse sectors.

Production Process Information

The production process for backflow parts in the USA typically involves several key stages. First, the design phase is crucial, where engineers create detailed specifications for the parts, ensuring they meet safety and regulatory standards. This includes selecting materials that can withstand pressure and corrosion, which are common in plumbing systems. Once the design is finalized, the manufacturing stage begins. This involves using machinery to cut, mold, or assemble the components according to the specifications.

Quality control is vital here, as each part must be tested to ensure it functions correctly and meets industry standards. After production, the parts are packaged and distributed to retailers or directly to customers, completing the process. Overall, attention to design, manufacturing precision, and quality assurance are essential to delivering reliable backflow parts.

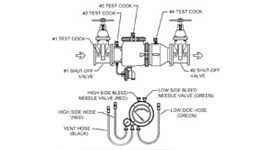

Related Video

Frequently Asked Questions (FAQs)

What should I look for in a backflow parts manufacturer?

When searching for a backflow parts manufacturer, prioritize quality certifications, industry experience, and a solid reputation. Ensure they comply with local regulations and standards, such as ANSI and ASSE. Additionally, check for a diverse product range and reliable customer support to assist with any inquiries or issues.

How can I verify the reliability of a backflow parts supplier?

To verify a supplier’s reliability, read customer reviews and testimonials, and check their business credentials. Ask for references and consider visiting their facility if possible. Additionally, look for manufacturers who offer warranties and have a history of timely deliveries and good customer service.

Are there specific certifications I should look for in backflow parts?

Yes! Look for certifications such as NSF/ANSI 61 for drinking water system components and ASSE 1013 for backflow prevention devices. These certifications ensure that the parts meet safety and performance standards, providing peace of mind regarding quality and compliance.

How can I find local backflow parts manufacturers in the USA?

You can find local manufacturers by searching online directories, trade association websites, or industry trade shows. Networking with plumbing professionals or local contractors can also lead to recommendations for reliable suppliers in your area.

What is the typical lead time for backflow parts orders?

Lead times can vary based on the manufacturer, order size, and stock availability. Generally, expect anywhere from a few days to several weeks. Always ask the supplier for estimated delivery times upfront to ensure they meet your project deadlines.