Top 8 Hermle Usa List and Guide: How To Solve Scenario 1: Navigat…

Introduction: Navigating the Global Market for hermle usa

In the ever-evolving landscape of global manufacturing, sourcing high-precision machine tools like those offered by Hermle USA presents a unique challenge for international B2B buyers. With a reputation for exceptional accuracy and innovative technology, Hermle USA has become a go-to supplier for manufacturers seeking to enhance their operational efficiency. This comprehensive guide aims to equip buyers from diverse regions, including Africa, South America, the Middle East, and Europe—such as Nigeria and Vietnam—with the critical insights needed to make informed purchasing decisions.

Covering a wide array of topics, this guide delves into the various types of Hermle machining centers, their applications across multiple industries, and essential supplier vetting criteria. Additionally, it addresses cost considerations, service and support options, and the implications of automation in manufacturing processes. By providing a holistic view of Hermle USA’s offerings, this resource empowers international buyers to navigate the complexities of the global market confidently. Whether you are looking to upgrade your production capabilities or seeking tailored solutions to meet specific manufacturing needs, this guide serves as a vital tool for optimizing your sourcing strategy and ensuring long-term success.

Top 10 Hermle Usa Manufacturers & Suppliers List

1. HERMLE AG – High Precision CNC Machining Centres

Domain: hermleusa.net

Registered: 2019 (6 years)

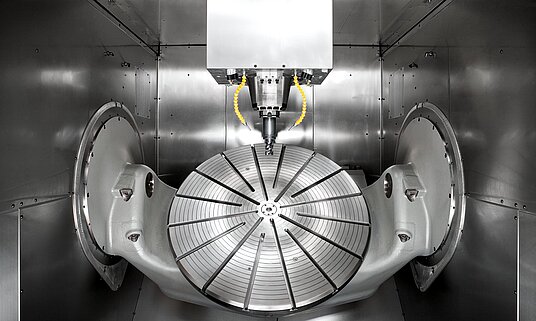

Introduction: HERMLE AG offers a range of high precision machining centres including: C 12, C 22 GEN2, C 32 GEN2, C 42 GEN2, C 52, C 62, C 250 GEN2, C 400 GEN2, and C 650 GEN2. The company specializes in CNC milling machines and special-purpose machines for various industries such as medical technology, machine construction, optical industry, aviation, and automotive. HERMLE emphasizes precision, performance, a…

2. HERMLE USA – Precision Machining Solutions

3. HERMLE – Precision Manufacturing Solutions

4. HERMLE – High Precision Machining Centers

Domain: hermle.de

Introduction: HERMLE USA provides high precision machining centers, including models such as C 12, C 22 GEN2, C 32 GEN2, C 42 GEN2, C 52, C 62, C 250 GEN2, C 400 GEN2, and C 650 GEN2. The company also offers automation solutions including pallet changers, handling systems, and robot systems, as well as digital modules and used machines.

5. Hermle USA – 5-Axis Machining

6. Hermle USA – Precision Machining Solutions

7. Hermle – C20U CNC Mill

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Hermle C20U CNC mill, 5-axis, made in 2008, features Heidenhain control with HSK63 tooling. Known for high dynamic performance and tight tolerances. Reputable brand in the 5-axis machine tool market.

8. Hermle – High Precision Machining Centers

Domain: machinesandmethods.com

Registered: 1996 (29 years)

Introduction: Hermle provides high precision machining centers with true 5-axis milling capabilities. The machines are built to last using the highest quality materials, ensuring exceptional precision and performance. Hermle emphasizes world-class technical customer support and a detailed manufacturing process that results in nimble and powerful machines designed for a lifetime of winning results.

Understanding hermle usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Machining Centers | High precision, 5-axis capabilities, automation-ready | Aerospace, automotive, medical technology | Pros: Exceptional accuracy, versatile applications. Cons: Higher initial investment. |

| Special-Purpose Machines | Customized designs for specific applications | Optical industry, general machine construction | Pros: Tailored solutions, optimized performance. Cons: Longer lead times for customization. |

| Centrifuges | Advanced separation technology, various capacities | Laboratories, research facilities, cannabis extraction | Pros: High efficiency, reliable results. Cons: Specific technical knowledge required for operation. |

| Clock Manufacturing | Combination of craftsmanship and precision | Commercial decor, luxury markets | Pros: Unique designs, high-quality materials. Cons: Limited market appeal for mass production. |

| Automation Solutions | Integration with existing systems, scalable | Manufacturing, logistics, assembly lines | Pros: Increased efficiency, reduced labor costs. Cons: Potential complexity in implementation. |

What Are the Key Characteristics of CNC Machining Centers from Hermle USA?

CNC Machining Centers from Hermle USA are renowned for their high precision and 5-axis capabilities, making them ideal for complex machining tasks. These machines are equipped with advanced automation features, allowing for seamless integration into existing production lines. They are primarily used in industries such as aerospace, automotive, and medical technology, where accuracy and reliability are paramount. When considering a purchase, buyers should evaluate their specific machining needs, the machine’s adaptability to various materials, and the total cost of ownership, including maintenance and training.

How Do Special-Purpose Machines Cater to Unique Industry Requirements?

Hermle’s Special-Purpose Machines are designed to meet the unique needs of various industries, particularly in the optical sector and general machine construction. These machines can be customized to perform specific tasks, enhancing productivity and efficiency in specialized applications. Buyers should consider the machine’s adaptability to their production processes, the level of customization required, and the potential for future scalability. While these machines may have longer lead times due to their bespoke nature, the benefits often outweigh the drawbacks in specialized production environments.

What Are the Advantages of Hermle USA’s Centrifuges in Laboratory Settings?

Hermle USA offers a range of centrifuges that leverage advanced separation technology, making them suitable for laboratories and research facilities. These centrifuges come in various capacities and configurations, catering to diverse applications, including cannabis extraction and micromaterials filtration. Buyers should assess the centrifuge’s efficiency, ease of use, and compatibility with existing laboratory equipment. While these machines provide reliable results and high efficiency, they may require specialized knowledge for optimal operation, which could be a consideration for potential users.

How Does Hermle USA Combine Craftsmanship with Technology in Clock Manufacturing?

Hermle USA has a rich heritage in clock manufacturing, blending traditional craftsmanship with modern precision technology. Their products cater to commercial decor and luxury markets, featuring unique designs that appeal to discerning customers. Buyers interested in these clocks should consider the brand’s reputation, material quality, and design options. While Hermle clocks stand out for their craftsmanship, their appeal may be limited to niche markets, which could affect broader market viability.

What Benefits Do Automation Solutions from Hermle USA Offer to Manufacturers?

Hermle USA’s Automation Solutions are designed to enhance manufacturing efficiency and streamline logistics processes. These solutions can be integrated with existing systems, offering scalability to meet growing production demands. When evaluating automation options, businesses should focus on the potential return on investment, ease of integration, and the impact on overall labor costs. Although these solutions can complicate initial setups, the long-term benefits of increased efficiency and reduced operational costs often justify the investment.

Key Industrial Applications of hermle usa

| Industry/Sector | Specific Application of hermle usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision CNC Machining for Aircraft Components | Ensures high safety standards and performance | Certification compliance, precision tolerance, and lead times |

| Medical Technology | Manufacturing of Surgical Instruments | Guarantees reliability and precision in critical applications | Material specifications, sterilization processes, and regulatory standards |

| Automotive | Production of Engine Components | Enhances performance and efficiency of vehicles | Scalability, just-in-time delivery, and customization capabilities |

| Optical Industry | Machining of High-Precision Optical Components | Supports innovation in imaging and lens technology | Material compatibility, optical quality requirements, and delivery timelines |

| General Machinery & Apparatus | Custom CNC Solutions for Industrial Equipment | Improves productivity and reduces downtime | Technical support, integration with existing systems, and service agreements |

How Does Hermle USA Support the Aerospace Industry?

Hermle USA’s precision CNC machining capabilities are crucial for the aerospace sector, where stringent safety and performance standards are paramount. By providing high-accuracy machining for aircraft components, Hermle enables manufacturers to meet regulatory compliance while enhancing the reliability of their products. International buyers, particularly from regions like Africa and South America, should consider certification compliance and the ability to meet specific precision tolerances when sourcing these machines.

What Role Does Hermle USA Play in Medical Technology?

In medical technology, Hermle USA specializes in the manufacturing of surgical instruments that require exceptional precision and reliability. These instruments are vital for ensuring patient safety and successful outcomes in surgeries. Buyers in this sector must focus on material specifications, sterilization processes, and adherence to regulatory standards when evaluating Hermle’s offerings to ensure they meet the rigorous demands of healthcare applications.

How Is Hermle USA Transforming Automotive Production?

The automotive industry benefits significantly from Hermle USA’s advanced machining solutions, particularly in the production of engine components. These high-precision tools enhance vehicle performance and fuel efficiency. B2B buyers, especially from the Middle East and Europe, should prioritize scalability and customization capabilities to adapt to evolving automotive technologies and market demands.

Why Choose Hermle USA for Optical Industry Applications?

Hermle USA plays a pivotal role in the optical industry by providing machining solutions for high-precision optical components. These components are essential for advancements in imaging and lens technology. International buyers should consider material compatibility and optical quality requirements when sourcing Hermle’s machines to ensure they align with their specific production needs.

How Can General Machinery Benefit from Custom CNC Solutions?

General machinery and apparatus manufacturers can leverage Hermle USA’s custom CNC solutions to improve productivity and reduce downtime. By tailoring machines to specific operational requirements, businesses can enhance efficiency and optimize production processes. Buyers should evaluate technical support and integration capabilities with existing systems to ensure seamless operations and ongoing service agreements.

3 Common User Pain Points for ‘hermle usa’ & Their Solutions

Scenario 1: Navigating Complex Product Specifications

The Problem: B2B buyers, especially those in industries like aerospace or medical technology, often find it challenging to navigate the intricate specifications of high-precision machine tools from Hermle USA. The overwhelming range of options, including various machining centers, automation solutions, and custom configurations, can lead to confusion and frustration. Buyers may worry about making the wrong choice, which could result in costly delays and inefficiencies in their production processes.

The Solution: To effectively address this challenge, buyers should engage directly with Hermle USA’s technical support and application assistance teams. By arranging a consultation, buyers can gain insights tailored to their specific industry requirements and production goals. During these discussions, it’s crucial to provide detailed information about your current processes, desired outputs, and any existing machinery to facilitate a comprehensive analysis. Additionally, utilizing Hermle’s online resources, such as product catalogs and specification sheets, can help clarify options. Buyers should also consider visiting Hermle’s facility or attending industry trade shows where Hermle showcases its innovations, allowing for hands-on experience with the machinery and direct engagement with experts.

Scenario 2: Ensuring Reliable After-Sales Support and Maintenance

The Problem: After purchasing high-precision equipment, many B2B buyers are often concerned about the reliability of after-sales support, particularly regarding maintenance and troubleshooting. In regions with limited access to technical expertise, such as parts of Africa and South America, the fear of equipment downtime due to inadequate service can be daunting. Buyers may struggle with finding timely assistance for repairs, leading to production halts and significant financial losses.

The Solution: Buyers should prioritize establishing a strong relationship with Hermle USA’s customer service and field service engineers from the outset. This involves not only understanding the warranty and service agreements available but also scheduling regular maintenance checks and service training for their in-house staff. Investing in training ensures that your team can handle minor troubleshooting and maintenance, reducing reliance on external support. Furthermore, buyers should inquire about remote support options, which can provide real-time assistance through video calls or diagnostic software, allowing issues to be resolved quickly, even from a distance.

Scenario 3: Maximizing the Return on Investment (ROI)

The Problem: Many B2B buyers are under pressure to justify the investment in high-precision machinery, particularly in competitive markets. They may be concerned about achieving a favorable return on investment (ROI) quickly, as the initial costs for Hermle USA’s advanced machining centers can be substantial. Without clear strategies for maximizing the use of these machines, buyers may worry about underutilization and the potential for wasted resources.

The Solution: To maximize ROI, buyers should focus on developing a comprehensive training program for their operators and engineers, ensuring that all personnel are proficient in the operation and maintenance of Hermle machinery. Hermle USA offers training sessions that can be customized to the specific applications and workflows of your facility. Additionally, buyers should implement a robust monitoring system to track machine performance and production outputs, allowing for data-driven decisions to optimize processes. Engaging in a continuous improvement mindset, where feedback loops are established to evaluate machine performance regularly, will enable businesses to adapt quickly to changing demands and enhance productivity. By fostering a culture of innovation and operational excellence, companies can significantly improve their ROI and maintain a competitive edge in their respective markets.

Strategic Material Selection Guide for hermle usa

What Are the Key Properties of Common Materials Used in Hermle USA Products?

When selecting materials for machining applications at Hermle USA, it is crucial to consider properties such as temperature and pressure ratings, corrosion resistance, and overall mechanical performance. The following analysis covers four common materials used in Hermle USA’s high-precision machine tools, providing insights into their suitability for various applications.

How Do Aluminum Alloys Perform in Machining Applications?

Aluminum alloys are widely used in CNC machining due to their excellent strength-to-weight ratio and corrosion resistance. They typically have a temperature rating up to 150°C and can withstand moderate pressure. The primary advantage of aluminum alloys is their lightweight nature, which facilitates easier handling and faster machining speeds.

However, aluminum alloys can be more expensive than traditional steel options, and their manufacturing complexity may increase due to the need for specialized tooling. In applications like aerospace and automotive components, aluminum’s compatibility with various media is beneficial, but international buyers must consider compliance with standards such as ASTM B221 for aluminum extrusions.

What Are the Advantages of Using Stainless Steel in Hermle USA Products?

Stainless steel is known for its exceptional corrosion resistance and durability, making it ideal for applications exposed to harsh environments. With a temperature rating of up to 400°C, stainless steel can handle high-pressure situations effectively. Its strength and resistance to wear make it suitable for components in the medical and automotive industries.

On the downside, stainless steel can be more challenging to machine, leading to higher manufacturing costs. Additionally, it may require specific cutting tools and techniques to achieve the desired precision. International buyers should ensure compliance with standards such as ASTM A240 for stainless steel sheets and plates, especially in regions with stringent regulations.

How Does Carbon Steel Compare for Machining Needs?

Carbon steel is a popular choice for many machining applications due to its high strength and toughness. It typically has a temperature rating of around 300°C and can endure significant pressure. The primary advantage of carbon steel is its cost-effectiveness and ease of machining, making it suitable for a variety of general-purpose applications.

However, carbon steel is more susceptible to corrosion, which can limit its use in environments where moisture is a concern. Additionally, international buyers should be aware of compliance with standards like ASTM A36, which governs the use of carbon steel in construction and manufacturing.

What Role Do Composites Play in Advanced Machining?

Composite materials, particularly carbon-fiber reinforced polymers, are increasingly used in high-performance applications due to their lightweight and high-strength properties. They can withstand temperatures up to 200°C and offer excellent resistance to corrosion and fatigue. Composites are particularly advantageous in aerospace and automotive applications where weight reduction is critical.

The main drawback of composites is their higher cost and the complexity involved in machining, which may require specialized equipment. International buyers need to consider compliance with standards like ASTM D3039 for tensile properties of composites, ensuring that they meet specific performance criteria.

Summary Table of Material Selection for Hermle USA

| Material | Typical Use Case for hermle usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Aerospace components | Lightweight and corrosion-resistant | Higher manufacturing complexity | Medium |

| Stainless Steel | Medical and automotive components | Exceptional durability and corrosion resistance | Challenging to machine, higher cost | High |

| Carbon Steel | General-purpose machining | Cost-effective and easy to machine | Susceptible to corrosion | Low |

| Composites | Aerospace and automotive applications | Lightweight and high strength | Higher cost and machining complexity | High |

This strategic material selection guide provides B2B buyers with actionable insights into the materials used in Hermle USA products, ensuring informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for hermle usa

What Are the Key Stages in the Manufacturing Process at Hermle USA?

Hermle USA, the North American arm of Maschinenfabrik Berthold HERMLE AG, is renowned for its high-precision machine tools. The manufacturing process at Hermle USA is meticulously structured to ensure top-tier performance, reliability, and quality across all products. The process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

Material Preparation: How Does Hermle USA Source and Prepare Materials?

At Hermle USA, the manufacturing journey begins with the careful selection of raw materials, primarily high-quality metals and alloys. These materials are sourced from reputable suppliers who adhere to stringent quality standards. Once received, the materials undergo rigorous inspection to ensure they meet Hermle’s specifications. This initial stage is crucial as it sets the foundation for the quality of the final product.

Following inspection, materials are prepped through processes such as cutting, machining, and heat treatment. These processes enhance the material properties, ensuring that they can withstand the demanding operational environments typical of high-precision machining.

What Forming Techniques Are Utilized in Hermle USA’s Manufacturing?

In the forming stage, Hermle USA employs advanced CNC (Computer Numerical Control) machining techniques, which allow for exceptional precision in shaping components. Utilizing state-of-the-art 5-axis milling machines, Hermle can produce complex geometries that traditional machining methods might struggle to achieve. This capability is particularly beneficial for industries such as aerospace and medical technology, where precision is non-negotiable.

Additionally, the forming process incorporates automation technologies to streamline production and minimize human error. Robotics are often used for tasks such as loading and unloading materials, which enhances efficiency and safety on the shop floor.

How Is Assembly Conducted to Ensure Quality at Hermle USA?

The assembly stage at Hermle USA is a critical juncture where precision components are brought together to form the final machine. This process is conducted in a clean and controlled environment to prevent contamination and ensure optimal performance. Skilled technicians perform the assembly, closely following standard operating procedures to guarantee that every machine meets rigorous quality benchmarks.

During assembly, multiple checks are performed to verify alignment, fit, and functionality. This attention to detail is vital, as even minor discrepancies can lead to significant performance issues in high-precision machines.

What Finishing Processes Are Implemented to Enhance Product Quality?

Once assembly is complete, the finishing stage involves several processes designed to enhance the durability and aesthetic quality of the machines. Techniques such as surface treatment, coating, and polishing are employed to provide corrosion resistance and improve the overall appearance.

Quality checks are integral during the finishing stage. Each machine is subjected to extensive testing to ensure it meets Hermle’s exacting standards before leaving the facility. This multi-faceted approach to finishing not only enhances product performance but also ensures customer satisfaction.

How Does Hermle USA Ensure Quality Assurance Throughout the Manufacturing Process?

Quality assurance is a cornerstone of Hermle USA’s operations. The company adheres to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards ensures that Hermle USA consistently delivers products that meet or exceed customer expectations.

What Quality Control Checkpoints Are in Place at Hermle USA?

Hermle USA implements a comprehensive quality control (QC) strategy that includes several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Upon receipt of raw materials, a thorough inspection is conducted to verify compliance with specifications. Any materials that do not meet standards are rejected and returned to the supplier.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are performed. This includes monitoring machining tolerances, ensuring that components are produced within specified limits.

-

Final Quality Control (FQC): Once assembly is complete, the final product undergoes rigorous testing. This includes functional tests and performance evaluations to ensure that each machine operates as intended.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance practices is essential. Here are several actionable steps:

-

Conduct Audits: Buyers should consider conducting on-site audits of Hermle USA’s manufacturing facility. This not only provides insights into the manufacturing processes but also allows for a firsthand assessment of quality control measures in place.

-

Request Quality Reports: Buyers can request documentation related to quality inspections and testing results. This transparency helps to build trust and ensures that the supplier adheres to international quality standards.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the manufacturing process and product quality. These inspectors can offer detailed reports and insights into compliance with industry standards.

What International Standards and Certifications Are Relevant for Hermle USA?

Hermle USA’s commitment to quality is further demonstrated by its adherence to various international certifications. In addition to ISO 9001, the company complies with other industry-specific standards such as CE marking for products sold within the European Union and API (American Petroleum Institute) standards for components used in the oil and gas sector.

What Are the Nuances of Quality Control for International B2B Buyers?

When engaging with Hermle USA, international buyers must be aware of specific nuances in quality control that may affect their purchasing decisions. Factors such as regional regulatory requirements, shipping and handling conditions, and local market standards can influence the final product’s compliance and performance.

Understanding these nuances is crucial for B2B buyers to make informed decisions, ensuring that the machines they procure will meet their operational needs and regulatory obligations in their respective markets.

In conclusion, Hermle USA’s rigorous manufacturing processes and quality assurance protocols not only enhance product performance but also build trust with international B2B buyers. By understanding these processes and the importance of quality checks, buyers can make informed decisions that align with their business objectives.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hermle usa’

This guide serves as a practical checklist for B2B buyers interested in procuring high-precision machine tools and automation solutions from Hermle USA. Ensuring that you have a comprehensive understanding of your needs and the supplier’s capabilities is vital for making informed purchasing decisions. Follow these steps to navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Start by clearly outlining your technical requirements for the machinery you intend to purchase. This includes specifications such as size, precision, capacity, and any specialized features necessary for your manufacturing processes. Having a detailed list allows for more accurate quotations and ensures that the equipment will meet your operational needs.

Step 2: Research Hermle USA’s Product Range

Familiarize yourself with the types of machines and automation solutions offered by Hermle USA. They specialize in high-precision CNC milling machines and customized solutions for various industries, including aerospace and medical technology. Understanding their product portfolio will help you identify which machines align with your operational objectives.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that Hermle USA holds relevant industry certifications and complies with international standards. Certifications such as ISO 9001 for quality management systems can indicate a commitment to quality and reliability. Additionally, check for compliance with safety regulations to ensure the machinery will meet operational safety standards in your region.

Step 4: Request Detailed Quotations

Once you’ve identified suitable products, request detailed quotations from Hermle USA. Ensure that the quote includes pricing, delivery timelines, and warranty information. This transparency is essential for budgeting and planning, allowing you to compare Hermle USA’s offerings with other suppliers effectively.

Step 5: Assess After-Sales Support and Service

Investigate the after-sales support options available from Hermle USA. High-precision machinery often requires ongoing maintenance and technical support. Look for details on their service agreements, training programs, and availability of spare parts, as these factors can significantly affect your operational efficiency.

Step 6: Check Customer References and Case Studies

Ask for references or case studies from Hermle USA that relate to similar industries or applications. Speaking to current customers can provide insight into their experiences regarding machine performance, reliability, and the level of service received. This step helps validate the supplier’s claims and gives you confidence in your purchasing decision.

Step 7: Negotiate Terms and Finalize Your Order

Once you are satisfied with the information gathered, negotiate the terms of the sale, including payment terms, delivery schedules, and any additional services required. Finalizing a contract with clear terms helps protect your investment and ensures both parties are aligned on expectations.

By following this step-by-step checklist, you can confidently navigate the sourcing process with Hermle USA and make informed decisions that will benefit your manufacturing operations.

Comprehensive Cost and Pricing Analysis for hermle usa Sourcing

What Are the Key Cost Components in Sourcing from Hermle USA?

When considering sourcing high-precision machinery from Hermle USA, understanding the cost structure is crucial for B2B buyers. The cost components typically include:

-

Materials: The raw materials used in manufacturing Hermle machines, such as high-grade steel and electronic components, significantly impact the overall cost. Hermle’s commitment to quality means that materials are sourced from reliable suppliers, which can raise costs but ensures durability and performance.

-

Labor: Skilled labor is essential for producing high-precision machine tools. The labor costs in the U.S. are relatively high compared to other regions, which may influence the pricing for international buyers. Additionally, the expertise required in assembly and quality control adds to this cost.

-

Manufacturing Overhead: This encompasses expenses related to facility maintenance, utilities, and administrative costs. Given that Hermle USA operates out of a state-of-the-art facility, these overhead costs are factored into the pricing.

-

Tooling: Specialized tooling required for manufacturing specific components can be a significant expense. Buyers may need to consider these costs, especially when requesting custom machinery.

-

Quality Control (QC): Hermle places a strong emphasis on quality assurance, which includes rigorous testing and inspection processes. The costs associated with QC are integrated into the overall pricing structure.

-

Logistics: Shipping and handling costs are critical, particularly for international buyers. Incoterms play a vital role in determining who is responsible for shipping costs and risks during transportation.

-

Margin: Hermle’s pricing strategy includes a profit margin that reflects the value of its high-quality machinery and services. Understanding this margin can help buyers gauge the overall pricing competitiveness.

How Do Pricing Influencers Affect Sourcing Costs?

Several factors can influence the pricing of Hermle machinery:

-

Volume/MOQ: Buyers ordering in larger quantities often benefit from bulk pricing discounts. Understanding the minimum order quantities (MOQs) can help buyers negotiate better deals.

-

Specifications and Customization: Customized machines tailored to specific applications will typically incur higher costs due to additional design and manufacturing efforts. Buyers should clearly outline their requirements to receive accurate pricing.

-

Materials and Quality Certifications: The choice of materials directly impacts the price. Additionally, certifications such as ISO or specific industry standards can add to the costs but assure quality and compliance.

-

Supplier Factors: The reputation and reliability of Hermle as a supplier contribute to pricing. Established brands often command higher prices due to perceived value and service levels.

-

Incoterms: The agreed-upon Incoterms can significantly impact the final cost. Buyers should be aware of who bears the shipping costs, insurance, and risk of loss during transit.

What Are the Best Negotiation Tips for International Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to cost savings:

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational costs, and potential downtime. A machine with a higher upfront cost might offer better long-term savings due to its reliability and lower maintenance needs.

-

Leverage Relationships: Building a strong relationship with Hermle USA representatives can lead to better pricing and terms. Regular communication can also provide insights into upcoming promotions or discounts.

-

Be Informed About Market Prices: Conducting market research to understand the pricing landscape for similar machinery can empower buyers during negotiations.

-

Discuss Payment Terms: Flexible payment terms can ease cash flow concerns. Buyers should discuss options that can be beneficial for both parties.

-

Request Detailed Quotations: Ensure that quotations break down costs clearly, allowing for easier comparison and negotiation on specific line items.

Conclusion

Sourcing from Hermle USA involves a multifaceted cost structure influenced by various factors. By understanding these components and employing effective negotiation strategies, international buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that pricing can vary, and it is advisable to seek indicative prices and terms before making a commitment.

Alternatives Analysis: Comparing hermle usa With Other Solutions

Introduction: Understanding the Landscape of Alternatives

When evaluating precision machining solutions, it’s crucial for B2B buyers to explore alternatives to ensure they choose the best fit for their operational needs. Hermle USA stands out in the CNC milling machine sector, but several other options may also meet the diverse requirements of manufacturers. This analysis will compare Hermle USA with two viable alternatives: Haas Automation and DMG Mori, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Hermle USA | Haas Automation | DMG Mori |

|---|---|---|---|

| Performance | High precision, 5-axis capabilities | Good performance for general use | Excellent for complex applications |

| Cost | Premium pricing | Competitive pricing | High-end pricing |

| Ease of Implementation | Requires skilled personnel | User-friendly setup | Moderate complexity |

| Maintenance | Comprehensive service and support | Solid support, parts availability | Excellent service, but costly |

| Best Use Case | Aerospace, medical technology | General manufacturing | Aerospace, automotive, medical |

Detailed Breakdown of Alternatives

Haas Automation

Haas Automation is renowned for its cost-effective CNC machines, providing a solid option for general manufacturing applications. The performance of Haas machines is commendable, especially for straightforward machining tasks. One of the key advantages of Haas is their competitive pricing, making them accessible for small to mid-sized enterprises. They are also user-friendly, allowing for relatively easy implementation. However, for high-precision tasks, such as those in aerospace or medical fields, Haas may not match the accuracy offered by Hermle USA.

DMG Mori

DMG Mori is a leader in the realm of advanced machining solutions, particularly for complex applications that require high levels of precision. Their machines are equipped with cutting-edge technology, making them suitable for sectors like aerospace and automotive. While DMG Mori machines can be on the higher end of the pricing spectrum, they deliver exceptional performance and durability. The maintenance requirements are generally high due to the sophisticated technology involved, but they offer excellent support services. DMG Mori is ideal for companies looking for high-end solutions that demand precision and advanced capabilities.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting a precision machining solution, B2B buyers should assess their specific operational requirements, budget constraints, and the skill level of their workforce. Hermle USA excels in high-precision environments, making it suitable for specialized industries like aerospace and medical technology. On the other hand, Haas Automation offers a more budget-friendly option for general manufacturing, while DMG Mori provides advanced technology for complex applications at a premium price. By weighing these factors, buyers can make informed decisions that align with their strategic goals and operational capabilities.

Essential Technical Properties and Trade Terminology for hermle usa

What Are the Critical Technical Properties of Hermle USA Products?

Understanding the technical specifications of Hermle USA’s machine tools is essential for B2B buyers to ensure they select the right equipment for their manufacturing needs. Here are some critical specifications:

-

Material Grade

Hermle machining centers are typically constructed from high-grade materials such as cast iron and aluminum alloys. These materials are chosen for their durability and resistance to deformation, ensuring long-term precision and stability during high-speed operations. For buyers, selecting machines made from superior materials means lower maintenance costs and increased operational longevity. -

Tolerance Levels

The precision of Hermle machines is often measured in micrometers, with tolerances as tight as ±5 microns. Such precision is critical in industries like aerospace and medical technology, where even minor deviations can result in significant issues. Understanding tolerance levels allows B2B buyers to assess whether a machine meets their specific manufacturing requirements. -

Spindle Speed

Spindle speed, measured in revolutions per minute (RPM), indicates how fast the cutting tool can operate. Hermle machines can achieve spindle speeds of up to 20,000 RPM, which is vital for efficient material removal and achieving fine surface finishes. Higher spindle speeds can lead to increased productivity, making it an essential factor for decision-makers. -

Axis Configuration

Hermle offers various configurations, including 3-axis and 5-axis CNC machines. The choice between these configurations affects the complexity of parts that can be manufactured. For instance, 5-axis machines allow for more intricate designs and reduce the need for multiple setups, which can streamline production processes. -

Automation Compatibility

Many Hermle machining centers are designed for integration with automation systems, including robotic loading and unloading solutions. This compatibility enhances productivity and reduces labor costs. B2B buyers should consider automation features if they aim to optimize their manufacturing operations and improve efficiency. -

Power Consumption

The energy efficiency of Hermle machines is an important consideration for companies looking to reduce operational costs and adhere to sustainability practices. Machines with lower power consumption not only reduce utility bills but also contribute to a smaller carbon footprint, aligning with global trends toward sustainability.

What Are Common Trade Terms Relevant to Hermle USA?

Navigating the world of B2B transactions involves understanding specific trade terminology. Here are some key terms frequently encountered when dealing with Hermle USA:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Hermle, it means that their machines are often used by other manufacturers to produce components for various industries. Understanding OEM relationships helps buyers identify the quality and reliability of the equipment they are purchasing. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for inventory planning and cost management, especially when purchasing high-precision equipment like Hermle machines, which can represent a significant investment. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. In the context of Hermle, an RFQ allows buyers to obtain pricing and availability information for their desired machining solutions, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping and freight. Understanding these terms helps B2B buyers clarify who is responsible for shipping costs, insurance, and risk during transit, which is essential for international transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. For Hermle products, lead times can vary based on customization and production schedules. Knowledge of lead times helps businesses plan their production schedules effectively. -

TCO (Total Cost of Ownership)

TCO is the comprehensive assessment of all costs associated with purchasing and operating a product over its entire lifespan. For Hermle machines, considering TCO helps buyers understand not just the upfront cost but also maintenance, operational, and potential downtime costs, enabling more strategic financial planning.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make more informed decisions when selecting Hermle USA products for their manufacturing needs.

Navigating Market Dynamics and Sourcing Trends in the hermle usa Sector

What Are the Key Market Dynamics and Sourcing Trends in the Hermle USA Sector?

The Hermle USA sector operates within a dynamic landscape shaped by global manufacturing demands and technological advancements. Key drivers include the increasing need for precision machining in industries such as aerospace, automotive, and medical technology. As manufacturers seek to enhance productivity and reduce lead times, the adoption of high-precision CNC milling machines is on the rise. Furthermore, the integration of automation technologies, including robotics and AI, is transforming traditional manufacturing processes, allowing for greater efficiency and reduced operational costs.

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are particularly interested in sourcing high-quality machinery that offers not only precision but also reliability and long-term service support. The emergence of Industry 4.0 has also prompted companies to invest in smart manufacturing solutions that leverage data analytics for improved decision-making. For buyers from countries like Nigeria and Vietnam, understanding these trends is crucial for making informed purchasing decisions that align with their operational goals.

How Are Sustainability and Ethical Sourcing Addressed in the Hermle USA Sector?

Sustainability and ethical sourcing have become critical considerations for B2B buyers, particularly as global awareness of environmental issues rises. Hermle USA is committed to reducing its environmental footprint through responsible manufacturing practices. This includes the use of energy-efficient machinery and the implementation of waste reduction initiatives.

Moreover, ethical sourcing involves ensuring that the materials and components used in production are obtained from responsible suppliers. Buyers can look for certifications that indicate adherence to environmental standards, such as ISO 14001, which focuses on effective environmental management systems. The use of “green” materials in manufacturing not only enhances brand reputation but also aligns with the growing consumer preference for sustainable products. For international buyers, partnering with suppliers like Hermle USA that prioritize sustainability can significantly enhance their own corporate responsibility initiatives.

What Is the Evolution of Hermle USA in the B2B Landscape?

Founded in 1987 as the North American headquarters of Maschinenfabrik Berthold HERMLE AG, Hermle USA has established itself as a leader in high-precision machining solutions. The company has continuously evolved by integrating cutting-edge technologies and responding to the specific needs of the North American market. With nearly 90 years of expertise in precision engineering, Hermle has expanded its offerings to include a comprehensive range of CNC milling machines and automation solutions.

This evolution reflects a commitment to innovation and customer satisfaction, which are critical for maintaining a competitive edge in the global B2B landscape. Hermle USA’s focus on training and customer support further enhances its value proposition, making it a preferred partner for international buyers seeking reliable and advanced manufacturing solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of hermle usa

-

1. How do I ensure the quality of Hermle USA products before purchasing?

To ensure product quality from Hermle USA, consider requesting product samples or visiting the facility for a firsthand look at the manufacturing processes. Additionally, reviewing certifications and compliance documents, such as ISO standards, can provide insights into their quality assurance practices. Engaging with existing customers for testimonials can also be beneficial. Finally, inquire about the warranty and service options available, as these reflect the manufacturer’s confidence in their products. -

2. What customization options are available for Hermle USA machining tools?

Hermle USA offers a range of customization options tailored to specific industry needs. Buyers can discuss their requirements with sales representatives to explore modifications in machine specifications, tooling, and software integration. Custom solutions are particularly available for specialized sectors like medical technology and aerospace. It’s advisable to communicate your needs early in the procurement process to facilitate a seamless customization experience. -

3. What are the minimum order quantities (MOQs) for Hermle USA products?

Minimum order quantities can vary depending on the specific product line and customization requirements. Generally, larger orders may yield better pricing and terms, while smaller orders may have higher per-unit costs. It’s essential to discuss your purchasing needs directly with a Hermle USA sales representative to understand the MOQ applicable to your situation and to explore potential flexibility based on your business model. -

4. What payment terms does Hermle USA offer for international buyers?

Hermle USA typically offers various payment terms to accommodate international buyers, including wire transfers, letters of credit, and installment payments for larger orders. The specifics can depend on the buyer’s creditworthiness and the size of the order. It is recommended to discuss payment options upfront during negotiations to ensure clarity and alignment with your financial processes. -

5. How does Hermle USA handle logistics and shipping for international orders?

Hermle USA coordinates closely with logistics partners to ensure timely and efficient shipping for international orders. They provide various shipping options based on urgency, cost, and destination. Buyers should discuss specific shipping requirements, including customs documentation and insurance, during the order process to avoid delays. Additionally, understanding the estimated lead times is crucial for planning your operations effectively. -

6. What support services does Hermle USA provide after purchase?

Hermle USA emphasizes customer support with comprehensive post-purchase services. This includes installation, training, and ongoing technical support to ensure optimal machine performance. Their service team is available for troubleshooting and preventive maintenance, which is vital for minimizing downtime. Regular follow-up communication can help buyers stay informed about updates and service options tailored to their equipment. -

7. How can I verify the reliability of Hermle USA as a supplier?

To verify Hermle USA’s reliability as a supplier, consider conducting thorough research, including checking their industry reputation, customer reviews, and case studies. Engage in discussions with current customers to gather insights about their experiences. Additionally, review their financial stability and history in the market, which can be indicative of their long-term viability as a supplier for your business needs. -

8. What industries does Hermle USA primarily serve with its machining tools?

Hermle USA caters to a diverse array of industries, including aerospace, automotive, medical technology, and optical industries. Their high-precision machining centers are designed to meet the rigorous demands of these sectors. If your business operates in a niche market, it’s advisable to discuss your specific applications with Hermle representatives to ensure their products align with your operational requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for hermle usa

As businesses navigate the complexities of global supply chains, strategic sourcing emerges as a critical component for success, particularly for international buyers seeking precision machinery. Hermle USA stands out with its commitment to high-quality, precision-engineered machining solutions tailored to diverse industries, including medical technology, automotive, and aerospace. By leveraging Hermle’s expertise and advanced manufacturing capabilities, companies can enhance their operational efficiency and stay ahead of the competition.

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, sourcing from Hermle USA not only ensures access to state-of-the-art technology but also fosters long-term partnerships built on reliability and exceptional service. The company’s focus on customer training and support enhances the value proposition, making it an ideal choice for businesses aiming to invest in high-performance machine tools.

Looking ahead, the demand for precision and innovation in manufacturing will only grow. Now is the time for international buyers to engage with Hermle USA, explore tailored solutions, and capitalize on the opportunities that strategic sourcing presents. Connect with Hermle USA today to discover how their cutting-edge technology can elevate your business operations.