Top 7 Reliable Gaskets Usa List and Guide: How To Solve Scenario …

Introduction: Navigating the Global Market for reliable gaskets usa

In today’s global marketplace, sourcing reliable gaskets in the USA presents a significant challenge for international B2B buyers. The need for high-quality sealing solutions is paramount across various industries, from refrigeration to manufacturing. With diverse applications and specific requirements, identifying the right supplier can be daunting. This guide addresses the complexities of sourcing reliable gaskets by offering insights into types of gaskets, their applications, and essential criteria for supplier vetting.

International buyers from regions such as Africa, South America, the Middle East, and Europe, including Germany and Vietnam, will find actionable information that empowers them to make informed purchasing decisions. The guide delves into critical aspects such as cost considerations, material quality, and the importance of customer service in selecting a supplier. Additionally, it emphasizes the significance of local sourcing in ensuring timely delivery and support.

By navigating through this comprehensive guide, B2B buyers will gain a deeper understanding of the gasket market, allowing them to streamline their procurement processes and enhance operational efficiency. The ultimate goal is to facilitate seamless access to reliable gasket solutions, ensuring that businesses can maintain optimal performance and reliability in their operations.

Top 10 Reliable Gaskets Usa Manufacturers & Suppliers List

1. Reliable Gaskets – Custom Refrigerator Gaskets

Domain: reliablegaskets.com

Registered: 2019 (6 years)

Introduction: Top-Rated Refrigerator Gaskets in Southern California. Custom refrigeration gaskets made locally in Paramount, CA from USA-sourced materials. Gaskets are guaranteed to fit perfectly. Services include walk-in freezer and cooler door replacement, free inspections for refrigeration units, and expert coil cleaning. Additional products include Gasket Magic cleaner, hardware and repair items, custom cut…

2. Reliable Gaskets USA – Custom Gaskets

Domain: gasketsusa.com

Registered: 2008 (17 years)

Introduction: Reliable Gaskets USA offers high-quality gaskets made from materials extruded in the USA, with custom gaskets manufactured in their Southern California headquarters. They provide exceptional customer service, competitive pricing, and expertise in maintaining efficient kitchens and food service facilities.

3. LinkedIn – Refrigeration Gaskets and Hardware

4. Reliable Gaskets – Refrigeration Gasket Replacement

5. Gasket Guy – High-Quality Replacement Parts

Domain: gasketguy.com

Registered: 2000 (25 years)

Introduction: Gasket Guy offers a variety of high-quality replacement parts including:

– Cooler Gaskets: OEM quality high temp oven gaskets, saving over 50% off list price.

– Oven Gaskets: High temperature gaskets for ovens.

– Hardware: Door closers, hinges, latches/handles, and assorted hardware.

– Cutting Boards: Standard and custom sized cutting boards available.

– Strip Curtains: Options to build your own k…

6. Reliable Gaskets USA – Quality Gasket Solutions

7. Reliable Gaskets USA – Commercial Refrigeration Gaskets

Domain: about.me

Registered: 2008 (17 years)

Introduction: Reliable Gaskets USA specializes in commercial refrigeration gasket supply and replacement, providing high-quality freezer gaskets, cooler gaskets, and refrigeration gaskets. They also offer refrigerator door repair services, install safety barriers, sneeze guards, and strip curtains.

Understanding reliable gaskets usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Refrigerator Gaskets | Custom-made, ensures airtight seal, various sizes available | Restaurants, hotels, hospitals, breweries | Pros: Custom fit, energy-efficient, reduces spoilage. Cons: Requires regular inspection and replacement. |

| Walk-In Cooler Gaskets | Designed for large refrigeration units, heavy-duty materials | Food storage facilities, large kitchens | Pros: Durability, energy savings, prevents temperature fluctuations. Cons: Higher upfront costs, may need professional installation. |

| Walk-In Freezer Gaskets | Specialized for extreme cold conditions, robust construction | Supermarkets, distribution centers, catering | Pros: Essential for maintaining freezing temperatures, reduces frost build-up. Cons: Can be more expensive than standard gaskets. |

| Custom Cutting Boards | Made from various materials (HDPE, Richlite), tailored sizes | Commercial kitchens, food prep areas | Pros: Versatile, easy to clean, custom sizes available. Cons: Material selection can affect longevity and pricing. |

| Coil Cleaning Gaskets | Integrated with cleaning systems, facilitates maintenance | Refrigeration maintenance services | Pros: Enhances efficiency, prolongs equipment life. Cons: Requires regular maintenance to ensure effectiveness. |

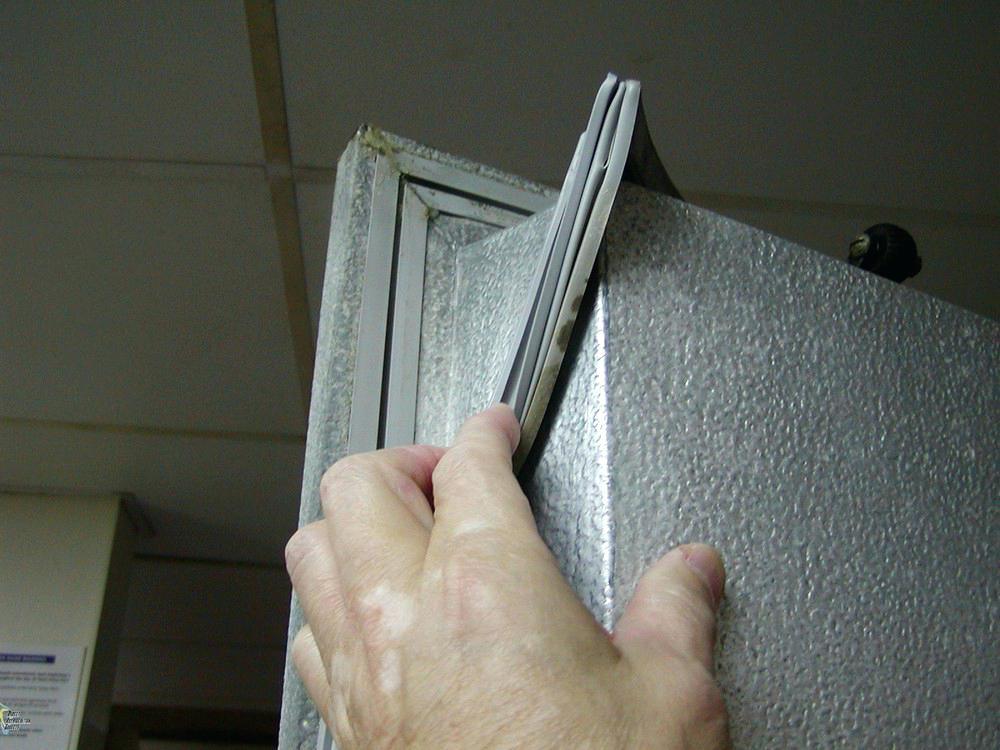

What Are Refrigerator Gaskets and Their Importance for B2B Buyers?

Refrigerator gaskets are critical components designed to create an airtight seal around refrigerator doors. Custom-made to fit various models, these gaskets help maintain optimal temperatures, preventing energy loss and spoilage. B2B buyers in the food service industry, such as restaurants and hotels, should consider the longevity and energy efficiency of these gaskets. Regular inspection and timely replacement are essential to maximize their benefits.

How Do Walk-In Cooler Gaskets Differ From Standard Gaskets?

Walk-in cooler gaskets are specifically engineered for large refrigeration units, utilizing heavy-duty materials to withstand frequent use. They are vital in maintaining consistent temperatures in food storage facilities and large kitchens. B2B buyers should assess the durability and installation requirements, as these gaskets can lead to significant energy savings and prevent temperature fluctuations, which are crucial for food safety.

Why Are Walk-In Freezer Gaskets Essential for Cold Storage?

Walk-in freezer gaskets are designed to perform under extreme cold conditions, ensuring that freezers maintain their temperatures effectively. This is especially important for supermarkets and distribution centers where product integrity is paramount. While they may come at a higher cost than standard gaskets, their durability and efficiency can justify the investment, particularly in high-volume operations.

What Should B2B Buyers Consider When Choosing Custom Cutting Boards?

Custom cutting boards offer versatility for commercial kitchens, available in various materials such as HDPE and Richlite. Tailored to specific sizes, these boards are easy to clean and maintain. Buyers should consider the material’s longevity and suitability for their kitchen environment. While they provide significant benefits in terms of functionality, the choice of material can impact pricing and durability.

How Do Coil Cleaning Gaskets Enhance Maintenance Efficiency?

Coil cleaning gaskets are integrated into refrigeration systems to facilitate maintenance. They play a crucial role in enhancing the efficiency of refrigeration units by preventing dirt and debris buildup, which can lead to energy waste. For B2B buyers in maintenance services, investing in these gaskets can prolong equipment life and improve operational efficiency, although they require regular upkeep to maintain effectiveness.

Key Industrial Applications of reliable gaskets usa

| Industry/Sector | Specific Application of Reliable Gaskets USA | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Custom refrigeration gaskets for commercial kitchens | Ensures optimal temperature control, reducing energy costs and spoilage | Quality of materials, customization options, lead time for production |

| Healthcare | Gaskets for medical refrigeration units | Maintains strict temperature requirements for pharmaceuticals and vaccines | Compliance with health regulations, material certifications, reliability of supply |

| Hospitality | Gaskets for walk-in coolers and freezers | Enhances food safety and operational efficiency in restaurants and hotels | Installation support, emergency repair services, warranty terms |

| Industrial Manufacturing | Sealing solutions for machinery and equipment | Prevents leaks and maintains operational efficiency, reducing downtime | Material durability, compatibility with existing systems, bulk ordering options |

| Retail | Gaskets for display refrigeration units | Improves product visibility and freshness, driving customer satisfaction | Aesthetic considerations, variety of designs, ease of installation |

In the Food and Beverage sector, Reliable Gaskets USA provides custom refrigeration gaskets for commercial kitchens. These gaskets are critical for maintaining optimal temperature control in refrigerators and freezers, which helps reduce energy costs and minimizes spoilage of perishable items. B2B buyers should consider the quality of materials used, customization options available, and lead times for production to ensure they meet their operational needs efficiently.

In the Healthcare industry, Reliable Gaskets USA supplies gaskets for medical refrigeration units, essential for storing pharmaceuticals and vaccines under strict temperature conditions. This application is vital for compliance with health regulations and ensuring the efficacy of sensitive products. Buyers must prioritize suppliers that offer materials with necessary certifications and a reliable supply chain to prevent any disruptions.

The Hospitality sector utilizes gaskets in walk-in coolers and freezers to enhance food safety and operational efficiency in restaurants and hotels. These gaskets help maintain a consistent temperature, which is critical for food preservation. International buyers should seek out suppliers that provide installation support, emergency repair services, and favorable warranty terms to ensure long-term reliability.

In Industrial Manufacturing, Reliable Gaskets USA offers sealing solutions for various machinery and equipment. These gaskets prevent leaks, which can lead to costly downtime and inefficiencies in production processes. Buyers in this sector should focus on the durability of materials, compatibility with existing systems, and the possibility of bulk ordering to streamline their procurement processes.

Lastly, in the Retail sector, gaskets are used in display refrigeration units to improve product visibility and freshness, directly influencing customer satisfaction. Retailers should consider aesthetic considerations, the variety of designs available, and the ease of installation when sourcing gaskets to ensure they meet both functional and marketing needs.

3 Common User Pain Points for ‘reliable gaskets usa’ & Their Solutions

Scenario 1: Delayed Repairs Leading to Operational Downtime

The Problem: B2B buyers in industries like food service and healthcare often face urgent repair needs for refrigeration systems. A malfunctioning gasket can lead to temperature fluctuations, which may spoil perishable goods or compromise the safety of food and medicine. Delays in sourcing replacement gaskets can lead to significant operational downtime, affecting productivity and revenue. Buyers may struggle with finding a reliable supplier who can provide quick turnaround times, particularly when they are located outside of the primary service areas.

The Solution: To mitigate downtime, B2B buyers should establish a relationship with Reliable Gaskets USA, which offers rapid custom gasket fabrication and nationwide shipping. Buyers can expedite the process by proactively assessing their equipment and scheduling regular inspections. By identifying wear and tear early, they can order replacements before emergencies arise. Additionally, utilizing the company’s free inspection service can help identify potential issues, allowing for timely intervention. Buyers should also explore wholesale options, which can provide cost savings and ensure they have essential gaskets on hand, ready for installation when needed.

Scenario 2: Inconsistent Quality of Replacement Parts

The Problem: Many B2B buyers have experienced frustration with the inconsistent quality of gaskets from various suppliers. Poor-quality gaskets can lead to premature failures, requiring more frequent replacements and resulting in increased maintenance costs. This inconsistency can also hinder operational efficiency, as buyers often find themselves in a cycle of sourcing and replacing subpar products.

The Solution: Reliable Gaskets USA stands out by offering high-quality, custom-made gaskets sourced from top-grade materials manufactured in the USA. B2B buyers should emphasize the importance of quality assurance when placing orders. They can request detailed specifications and certifications for the materials used in their gaskets. Additionally, establishing a consistent ordering process with Reliable Gaskets USA can ensure that they receive products that meet their quality standards every time. By leveraging the expertise of the technicians at Reliable Gaskets, buyers can get recommendations on the right gaskets for their specific applications, thus enhancing their operational reliability.

Scenario 3: Difficulty in Sourcing Custom Gaskets for Unique Equipment

The Problem: B2B buyers often operate specialized equipment that requires custom gaskets not readily available on the market. The inability to find the right fit can lead to significant delays in repairs, increased energy costs due to inefficient seals, and potential damage to sensitive machinery. This challenge is particularly pronounced for businesses in niche industries such as breweries or hospitals, where standard gaskets may not suffice.

The Solution: Reliable Gaskets USA excels in providing custom gasket solutions tailored to unique requirements. B2B buyers facing this challenge should utilize the company’s expertise by submitting detailed specifications of their equipment. Engaging in a collaborative approach during the design process can result in a perfectly fitting gasket that meets operational needs. Buyers should also take advantage of the company’s free estimates and consultations, which can provide valuable insights into the best materials and designs for their specific applications. By working closely with the Reliable Gaskets team, buyers can ensure their custom gaskets not only fit perfectly but also enhance the overall efficiency of their operations.

Strategic Material Selection Guide for reliable gaskets usa

What Are the Key Materials Used in Reliable Gaskets USA?

When selecting gaskets for industrial applications, the choice of material is crucial for ensuring optimal performance and longevity. Below, we analyze four common materials used in gaskets, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of EPDM Rubber for Gaskets?

Ethylene Propylene Diene Monomer (EPDM) rubber is a popular choice for gaskets due to its excellent weather resistance and durability. It can withstand temperatures ranging from -40°F to 250°F (-40°C to 121°C) and offers good resistance to steam, water, and many chemicals.

Pros: EPDM is highly durable, cost-effective, and easy to manufacture. It is particularly suitable for outdoor applications and environments with high UV exposure.

Cons: While EPDM is resistant to many chemicals, it may not perform well with petroleum-based products. Additionally, its temperature range limits its use in high-heat applications.

Impact on Application: EPDM gaskets are ideal for refrigeration units and outdoor equipment, where moisture and UV exposure are concerns.

International Considerations: Buyers from regions such as Europe and the Middle East should ensure compliance with standards like ASTM D2000 and DIN 7728, which specify the quality and performance of EPDM materials.

How Does Silicone Compare as a Gasket Material?

Silicone gaskets are renowned for their flexibility and high-temperature resistance, making them suitable for applications ranging from -100°F to 500°F (-73°C to 260°C). They also exhibit excellent chemical resistance, particularly to water and various solvents.

Pros: Silicone gaskets are highly versatile and can maintain their integrity in extreme temperatures. They are also non-toxic, making them suitable for food processing applications.

Cons: The primary drawback of silicone is its relatively high cost compared to other materials. Additionally, silicone gaskets may not provide as strong a seal in high-pressure applications.

Impact on Application: Silicone gaskets are ideal for refrigeration, food service, and medical equipment where temperature fluctuations are common.

International Considerations: Compliance with food safety standards such as FDA and EU regulations is essential for buyers in the food industry, especially in regions like Africa and South America.

What Are the Advantages of Neoprene Gaskets?

Neoprene is another widely used material for gaskets, known for its excellent resistance to oil, ozone, and weathering. It operates effectively in temperatures ranging from -40°F to 250°F (-40°C to 121°C).

Pros: Neoprene gaskets offer good durability and flexibility, making them suitable for various industrial applications. They are also relatively cost-effective.

Cons: While neoprene has good chemical resistance, it may not perform well against certain solvents. Its performance can also degrade under high-temperature conditions.

Impact on Application: Neoprene gaskets are commonly used in refrigeration and automotive applications where oil exposure is a concern.

International Considerations: Buyers should verify compliance with ASTM standards and consider local regulations regarding chemical exposure, especially in regions with stringent environmental laws.

Why Choose PTFE for High-Performance Gaskets?

Polytetrafluoroethylene (PTFE) is known for its exceptional chemical resistance and high-temperature capabilities, functioning effectively between -450°F and 500°F (-268°C to 260°C).

Pros: PTFE gaskets are highly durable and can withstand aggressive chemicals, making them ideal for a wide range of applications.

Cons: The primary drawback is the high manufacturing complexity and cost associated with PTFE gaskets. They may also require specific installation techniques to ensure a proper seal.

Impact on Application: PTFE gaskets are particularly suited for chemical processing and high-temperature applications, where other materials may fail.

International Considerations: Compliance with international standards such as JIS and ASTM is critical for buyers in the chemical and pharmaceutical sectors, particularly in regions like Germany and Vietnam.

Summary of Material Selection for Reliable Gaskets USA

| Material | Typical Use Case for reliable gaskets usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| EPDM Rubber | Refrigeration units, outdoor equipment | Excellent weather resistance | Limited performance with petroleum products | Medium |

| Silicone | Food processing, medical equipment | High-temperature resistance | Higher cost, weaker seal under pressure | High |

| Neoprene | Refrigeration, automotive applications | Good durability and flexibility | Degrades under high temperatures | Medium |

| PTFE | Chemical processing, high-temperature applications | Exceptional chemical resistance | High manufacturing complexity and cost | High |

This guide provides a comprehensive overview of materials used in reliable gaskets, enabling international B2B buyers to make informed decisions based on their specific applications and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for reliable gaskets usa

What Are the Main Stages of Manufacturing Gaskets at Reliable Gaskets USA?

Reliable Gaskets USA employs a robust manufacturing process that ensures high-quality gasket production tailored to various industrial applications. The typical stages involved include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality raw materials, primarily sourced from within the USA. Reliable Gaskets USA emphasizes using durable materials that can withstand varying temperatures and environmental conditions. This step is crucial for ensuring the longevity and effectiveness of the gaskets.

-

Forming: Once the materials are prepared, they undergo forming processes. This can involve cutting, molding, or extruding the materials into the desired shapes and sizes. Advanced machinery is often used for precision cutting and shaping, ensuring that each gasket meets specific dimensional requirements. This stage is critical for achieving the perfect seal in refrigeration and other mechanical applications.

-

Assembly: After forming, gaskets may require additional components, such as adhesives or reinforcements. During the assembly phase, these components are integrated with the formed gasket. Reliable Gaskets USA often customizes this process based on client specifications, allowing for tailored solutions that meet unique operational needs.

-

Finishing: The final stage involves applying any necessary surface treatments, such as coatings or sealants, to enhance performance characteristics. This step is vital for ensuring that the gaskets can withstand environmental stressors and maintain their integrity over time. Quality control checks are integrated throughout the finishing process to guarantee compliance with specifications.

How Does Quality Assurance Work for Gaskets at Reliable Gaskets USA?

Quality assurance (QA) is a fundamental aspect of the manufacturing process at Reliable Gaskets USA. The company adheres to various international standards, including ISO 9001, to ensure that its products consistently meet customer expectations.

-

International and Industry-Specific Standards: Reliable Gaskets USA is committed to maintaining compliance with recognized standards such as ISO 9001, which focuses on quality management systems. Additionally, industry-specific standards like CE (Conformité Européenne) and API (American Petroleum Institute) certifications are also considered, especially for clients in regulated industries. These standards ensure that gaskets not only perform effectively but also adhere to safety and reliability benchmarks.

-

Quality Control Checkpoints: The quality control process at Reliable Gaskets USA includes several critical checkpoints:

– Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon receipt to verify that they meet required specifications before entering production.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections and tests are conducted to ensure that production is on track and adheres to quality standards. This includes monitoring the forming and assembly stages.

– Final Quality Control (FQC): After the gaskets are finished, a comprehensive quality assessment is performed. This involves testing for dimensions, material properties, and performance under simulated operating conditions. -

Common Testing Methods: Various testing methods are employed to assess gasket performance, including tensile strength testing, compression set testing, and thermal cycling tests. These methods help determine how well the gaskets will perform in real-world applications, ensuring that they can withstand the pressures and conditions they will face.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring reliability and compliance.

-

Supplier Audits: Conducting on-site audits is one of the most effective ways to assess a supplier’s quality assurance practices. This allows buyers to evaluate the manufacturing processes, equipment, and quality control measures firsthand. It also provides insights into the company culture regarding quality and customer service.

-

Quality Reports and Certifications: B2B buyers should request documentation, including quality reports, certifications, and inspection records. These documents provide evidence of compliance with international and industry-specific standards. Reviewing these reports can help buyers understand the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent organizations can conduct quality assessments at various stages of production, ensuring that the products meet the required specifications before they are shipped.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate several nuances when it comes to quality control in the gasket industry.

-

Understanding Local Standards: Different regions may have varying standards and regulations regarding gasket production. Buyers from Europe, for instance, may require CE marking, while those in the Middle East might focus on local compliance certifications. Understanding these requirements is essential for smooth transactions.

-

Communication with Suppliers: Establishing clear communication with suppliers regarding quality expectations is vital. This includes discussing specific quality standards, testing methods, and documentation requirements. Effective communication can help prevent misunderstandings and ensure that the products delivered meet the buyer’s needs.

-

Cultural Considerations: Cultural differences can impact business practices, including quality assurance. Buyers should be aware of these differences and how they may influence supplier interactions. Building strong relationships with suppliers can facilitate better cooperation and adherence to quality standards.

In conclusion, Reliable Gaskets USA employs a comprehensive manufacturing and quality assurance process that not only emphasizes high-quality production but also aligns with international standards. For B2B buyers, understanding these processes and verifying them through audits, certifications, and effective communication can lead to successful partnerships and reliable gasket solutions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘reliable gaskets usa’

Introduction

This practical sourcing guide aims to provide B2B buyers with a comprehensive checklist for procuring reliable gaskets from Reliable Gaskets USA. Whether you operate in the food service industry, hospitality, or any sector requiring robust sealing solutions, following these steps will help ensure you make informed decisions while sourcing high-quality gaskets tailored to your needs.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is crucial before reaching out to suppliers. Identify the types of gaskets needed, including dimensions, materials, and performance standards. This clarity will streamline your communication with suppliers and help them provide accurate solutions that meet your operational needs.

Step 2: Research Reliable Suppliers

Begin by compiling a list of potential suppliers, focusing on those with a strong reputation in the industry. Look for companies like Reliable Gaskets USA, which are known for their quality products and exceptional service. Utilize industry directories, trade shows, and online reviews to gather insights into supplier reliability and customer satisfaction.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify the certifications of your shortlisted suppliers. Ensuring they comply with industry standards (e.g., ISO certifications) is essential for maintaining quality and safety. This step not only protects your business from potential liabilities but also assures you that the products meet rigorous performance criteria.

Step 4: Request Samples and Prototypes

Ask suppliers for samples or prototypes of their gaskets. This allows you to assess the quality and suitability of their products firsthand. Pay attention to the material, craftsmanship, and fit, ensuring they align with your technical specifications and operational requirements.

Step 5: Inquire About Customization Options

Many businesses have unique needs that off-the-shelf products cannot meet. Discuss customization capabilities with potential suppliers, particularly for complex gasket designs. Reliable Gaskets USA, for example, offers custom-made gaskets tailored to specific applications, ensuring optimal performance and longevity.

Step 6: Assess Lead Times and Delivery Options

Understanding the lead times and delivery capabilities of your suppliers is vital for maintaining your operational timeline. Inquire about their production schedules and shipping options to ensure they can meet your demands promptly. Reliable Gaskets USA offers nationwide shipping, which is crucial for international buyers requiring timely deliveries.

Step 7: Evaluate Customer Support and After-Sales Service

Strong customer support can significantly impact your sourcing experience. Assess the responsiveness and expertise of the supplier’s customer service team. Additionally, inquire about after-sales support, including installation services, maintenance tips, and warranty options, to ensure you have ongoing assistance if needed.

By following this step-by-step checklist, you can confidently source reliable gaskets from Reliable Gaskets USA or similar suppliers, ensuring you receive high-quality products that meet your business needs.

Comprehensive Cost and Pricing Analysis for reliable gaskets usa Sourcing

What Are the Key Cost Components in Sourcing Gaskets from Reliable Gaskets USA?

When considering the procurement of gaskets from Reliable Gaskets USA, understanding the cost structure is vital. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margin.

-

Materials: Reliable Gaskets USA emphasizes the use of high-quality raw materials sourced from within the USA. The type of material selected, such as rubber or silicone, significantly affects the overall cost.

-

Labor: Skilled labor is required for the fabrication of custom gaskets. Labor costs can vary based on the complexity of the gasket design and the level of expertise needed.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help reduce overhead, which in turn can lower the pricing for buyers.

-

Tooling: For custom gaskets, tooling costs are crucial. These are one-time expenses incurred for creating molds or dies specific to the gasket design.

-

Quality Control (QC): Ensuring the gaskets meet industry standards and customer specifications requires stringent QC measures, which add to the overall cost.

-

Logistics: Shipping costs can fluctuate based on location and shipping method. Reliable Gaskets USA offers nationwide shipping, which can be a cost-effective solution for buyers.

-

Margin: The profit margin for Reliable Gaskets USA reflects the company’s commitment to quality and service. Understanding this can provide insights into potential price negotiations.

How Do Price Influencers Affect Gasket Sourcing Decisions?

Several factors influence the pricing of gaskets, particularly for international buyers from regions such as Africa, South America, the Middle East, and Europe.

-

Volume/MOQ: Purchasing in bulk often leads to reduced pricing per unit. Reliable Gaskets USA offers wholesale pricing options, which can be beneficial for businesses with significant needs.

-

Specifications and Customization: Custom gaskets tailored to specific applications may incur higher costs due to the additional labor and tooling involved. Buyers should clearly define their requirements to receive accurate quotes.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (e.g., ISO standards) can significantly influence prices. Higher quality often comes at a premium, but it can lead to lower Total Cost of Ownership (TCO) in the long run.

-

Supplier Factors: Reliable Gaskets USA prides itself on exceptional customer service and quick turnaround times. The reputation and reliability of the supplier can affect perceived value and pricing.

-

Incoterms: Understanding the terms of shipment and delivery is crucial for international buyers. Incoterms dictate who bears the cost and risk at various points in the shipping process, which can impact overall pricing.

What Are the Best Buyer Tips for Sourcing Gaskets Internationally?

For international B2B buyers, particularly those from diverse markets, here are some actionable tips:

-

Negotiate Wisely: Building a relationship with the supplier can lead to better pricing and terms. Don’t hesitate to discuss volume discounts or long-term contracts that could lower costs.

-

Focus on Total Cost of Ownership (TCO): While the initial purchase price is important, consider the long-term costs associated with maintenance, energy efficiency, and replacement frequency. Quality gaskets can minimize energy loss and extend equipment life, providing savings over time.

-

Be Aware of Pricing Nuances: Understand that international shipping can add unexpected costs. Be prepared for customs duties and taxes, which vary by country. Engaging in thorough market research about local regulations can prevent unforeseen expenses.

-

Request Detailed Quotes: Ensure that quotes are itemized to clarify the breakdown of costs, including materials, labor, and shipping. This transparency allows for better comparisons and informed decision-making.

By considering these factors and tips, international buyers can navigate the complexities of sourcing reliable gaskets from Reliable Gaskets USA more effectively, ensuring both quality and cost-efficiency in their procurement processes.

Alternatives Analysis: Comparing reliable gaskets usa With Other Solutions

Exploring Alternative Solutions to Reliable Gaskets USA

In the competitive landscape of gasket manufacturing and sealing solutions, businesses often seek alternatives that can match or exceed the offerings of Reliable Gaskets USA. Understanding the strengths and weaknesses of various options is crucial for B2B buyers looking to make informed decisions. Below, we compare Reliable Gaskets USA against two viable alternatives: Gasket Solutions Inc. and Custom Gasket Mfg. This analysis focuses on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Reliable Gaskets USA | Gasket Solutions Inc. | Custom Gasket Mfg. |

|---|---|---|---|

| Performance | High-quality custom gaskets with fast delivery. | Good quality but longer lead times. | Excellent performance, tailored solutions. |

| Cost | Competitive pricing with wholesale options. | Generally higher due to premium materials. | Mid-range pricing, dependent on customization. |

| Ease of Implementation | Quick installation services available. | Moderate complexity, requires professional installation. | Varies; some products are DIY-friendly. |

| Maintenance | Regular inspections and cleaning services offered. | Limited maintenance support. | Maintenance guidance provided, but no hands-on service. |

| Best Use Case | Ideal for restaurants, hospitals, and breweries needing fast service. | Suitable for industrial applications with less urgency. | Best for specialized projects requiring unique designs. |

In-depth Analysis of Alternatives

Gasket Solutions Inc.

Gasket Solutions Inc. offers a wide range of gaskets primarily for industrial applications. Their products are known for high quality and durability, making them a good choice for heavy machinery. However, their lead times can be longer compared to Reliable Gaskets USA, which might be a drawback for businesses requiring immediate solutions. Additionally, their pricing tends to be on the higher end due to the use of premium materials, which may not be feasible for smaller operations.

Custom Gasket Mfg.

Custom Gasket Mfg. specializes in tailored gasket solutions, making them an excellent choice for projects that require unique specifications. Their gaskets often provide superior performance in niche applications. However, their pricing is mid-range and can escalate based on the level of customization required. While they do offer maintenance guidance, they lack the hands-on service that Reliable Gaskets USA provides, potentially leaving customers to handle maintenance on their own.

Making the Right Choice for Your Business

Choosing the right gasket solution depends on several factors, including urgency, budget, and specific application requirements. If your business operates in a fast-paced environment where downtime can be costly, Reliable Gaskets USA’s quick turnaround and installation services may be the best fit. Conversely, for industries that prioritize durability and can afford longer lead times, Gasket Solutions Inc. may provide the necessary quality. For specialized projects requiring unique designs, Custom Gasket Mfg. could be the ideal choice, though you should weigh the costs and support services against your operational needs.

In conclusion, B2B buyers should assess their specific requirements, including performance expectations, budget constraints, and the importance of service and support, to select the most suitable gasket solution for their operations.

Essential Technical Properties and Trade Terminology for reliable gaskets usa

What Are the Essential Technical Properties of Gaskets?

When evaluating gaskets, especially in the context of Reliable Gaskets USA, understanding the technical properties is crucial for B2B buyers to ensure they are making informed purchasing decisions. Below are some key specifications that define gasket quality and suitability for various applications:

1. Material Grade

The material used in gaskets is a primary determinant of performance. Common materials include rubber, silicone, and thermoplastics. Each material has specific characteristics, such as temperature resistance and chemical compatibility. For instance, EPDM rubber is suitable for outdoor applications due to its UV resistance, while silicone is ideal for high-temperature environments. Choosing the right material is vital to ensure durability and longevity in demanding applications.

2. Tolerance

Tolerance refers to the allowable deviation in the dimensions of the gasket. Precise tolerances are essential in ensuring a proper fit within the mechanical assembly, preventing leaks and ensuring optimal performance. In B2B settings, maintaining tight tolerances can significantly reduce maintenance costs and increase operational efficiency, especially in industries like food service and refrigeration where leaks can lead to significant product loss.

3. Durometer Hardness

Durometer hardness measures the softness or firmness of the gasket material, impacting its compressibility and sealing ability. Measured on a scale (often Shore A), a lower durometer indicates a softer material, which can conform better to uneven surfaces. Understanding the durometer is crucial for applications where a perfect seal is essential, such as in refrigeration units, where temperature and pressure fluctuations can affect gasket performance.

4. Compression Set

Compression set is a measure of a gasket’s ability to return to its original thickness after being compressed. A low compression set indicates that the gasket will maintain its sealing properties over time, even under constant pressure. This property is particularly important in environments with extreme temperatures or fluctuating pressures, as it ensures long-term reliability and reduces the need for frequent replacements.

5. Chemical Resistance

Gaskets are often exposed to various chemicals, including cleaning agents and food substances. Understanding the chemical resistance of the gasket material is essential for preventing degradation and ensuring safety in food service applications. For example, gaskets used in breweries must withstand various acids and cleaning chemicals, making material selection critical for compliance and operational efficiency.

What Common Trade Terms Should B2B Buyers Know?

Navigating the world of gaskets also involves understanding industry terminology. Here are several key terms that are frequently encountered in B2B transactions related to gaskets:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the gasket industry, OEMs supply gaskets that are specifically designed to fit original machinery. Understanding OEM relationships can help buyers ensure compatibility and quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and costs. Knowing the MOQ helps in budgeting and planning for procurement, especially for companies that may not require large quantities.

3. RFQ (Request for Quotation)

An RFQ is a formal request to suppliers to provide pricing and terms for specific products or services. When seeking gaskets, submitting an RFQ can streamline the procurement process and ensure that buyers receive competitive pricing and detailed specifications.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps B2B buyers understand shipping costs, risk management, and delivery obligations. For instance, “FOB” (Free on Board) indicates that the seller is responsible for costs until the goods are loaded onto the shipping vessel.

5. Custom Gasket

A custom gasket is tailored to specific dimensions and requirements of the customer. This is particularly important for businesses that need gaskets to fit unique equipment or machinery. Understanding the benefits of custom gaskets can lead to improved efficiency and reduced maintenance costs.

In conclusion, grasping these technical properties and trade terms equips B2B buyers with the knowledge necessary to make informed decisions when sourcing gaskets. This understanding not only facilitates smoother transactions but also enhances operational efficiency across various industries.

Navigating Market Dynamics and Sourcing Trends in the reliable gaskets usa Sector

What Are the Current Market Dynamics and Key Trends Affecting the Reliable Gaskets USA Sector?

The reliable gaskets market is influenced by several global drivers, including the increasing demand for refrigeration and HVAC systems, particularly in the food service and healthcare sectors. As industries strive for operational efficiency and cost-effectiveness, the demand for high-quality sealing solutions that prevent energy loss has surged. Emerging technologies such as advanced manufacturing processes, automation, and digital supply chain management are reshaping how gaskets are produced and sourced. These advancements allow companies like Reliable Gaskets USA to offer customized solutions quickly, catering to diverse client needs across various regions, including Africa, South America, the Middle East, and Europe.

International B2B buyers are increasingly prioritizing suppliers that can deliver not only quality products but also timely service. The rise of e-commerce platforms and digital marketplaces is facilitating cross-border transactions, enabling buyers to easily access suppliers from different regions. Furthermore, the focus on cost-effectiveness has led to a trend toward wholesale purchasing, where maintenance teams or DIY operators seek to procure gaskets directly from manufacturers at reduced prices. This trend is particularly relevant for markets in Africa and South America, where cost sensitivity remains high.

How Is Sustainability and Ethical Sourcing Shaping the Gaskets Industry?

Sustainability is becoming a critical consideration for B2B buyers in the gasket sector. The environmental impact of manufacturing processes and the materials used in gaskets are under increasing scrutiny. Companies are now expected to demonstrate commitment to sustainable practices, including the use of eco-friendly materials and efficient production methods. Reliable Gaskets USA, for example, sources its raw materials from local suppliers, ensuring a lower carbon footprint associated with transportation.

Ethical sourcing is also gaining traction, as buyers demand transparency in supply chains. The importance of ‘green’ certifications, such as ISO 14001, is growing, as they signal a company’s commitment to environmental management. Buyers from regions like Europe are particularly attuned to these certifications, influencing their purchasing decisions. By prioritizing suppliers who adhere to sustainable practices, international B2B buyers can not only fulfill their corporate social responsibility goals but also enhance their brand reputation in increasingly eco-conscious markets.

What Is the Brief Evolution of Reliable Gaskets USA and Its Relevance to B2B Buyers?

Reliable Gaskets USA has evolved significantly since its inception in 2005, establishing itself as a key player in the gasket manufacturing sector. Initially serving Southern California, the company has expanded its reach to several other states, including Arizona and North Carolina, enhancing its service offerings. This growth reflects the company’s commitment to quality and customer service, positioning it as a trusted partner for various industries, including food service, healthcare, and hospitality.

The company’s history of innovation and responsiveness to market demands makes it a reliable choice for international B2B buyers seeking custom solutions. By leveraging its extensive industry experience and local manufacturing capabilities, Reliable Gaskets USA can provide tailored products that meet specific operational needs while maintaining high standards of quality and sustainability. This evolution underscores the importance of choosing suppliers with a proven track record, especially in a competitive global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of reliable gaskets usa

-

1. How do I solve gasket leakage issues in refrigeration units?

To address gasket leakage in refrigeration units, first inspect the gaskets for visible wear or damage. If they are worn, replacing them with high-quality, custom-made gaskets from Reliable Gaskets USA is recommended. Ensure proper installation to maintain an effective seal. Regular maintenance checks can also help identify potential issues early, preventing costly downtime. Additionally, consider scheduling routine inspections and cleaning of condenser coils, as dirty coils can exacerbate sealing problems. -

2. What is the best gasket material for refrigeration applications?

The best gasket material for refrigeration applications is typically made from high-quality rubber or silicone, as these materials provide excellent sealing properties and temperature resistance. Reliable Gaskets USA offers custom gaskets tailored to specific equipment needs, ensuring optimal performance. When selecting a gasket, consider the operating temperatures and any chemical exposure to ensure longevity and reliability. For specialized needs, consulting with a gasket expert can help determine the most suitable material. -

3. How can I ensure the quality of gaskets sourced from Reliable Gaskets USA?

To ensure the quality of gaskets from Reliable Gaskets USA, check for certifications and the sourcing of raw materials. All gaskets are manufactured in the USA, which guarantees adherence to strict quality standards. Inquire about the production process and quality assurance protocols in place. Additionally, request samples if possible, and consider customer reviews or case studies to assess the reliability of their products in real-world applications. -

4. What are the minimum order quantities (MOQ) for gaskets?

Minimum order quantities (MOQ) for gaskets at Reliable Gaskets USA can vary based on the type and customization required. Generally, larger orders may benefit from lower per-unit pricing. For international B2B buyers, discussing specific needs with the sales team can provide clarity on MOQs and potential discounts for bulk orders. Always confirm these details before placing an order to ensure alignment with your procurement strategy. -

5. What payment terms are available for international orders?

Reliable Gaskets USA offers various payment terms for international orders, including credit terms, wire transfers, and payment through letters of credit. It’s important to discuss your preferred payment method with the sales team to ensure compliance with both parties’ financial policies. For larger orders, negotiating payment terms can provide flexibility and facilitate smoother transactions. Always confirm currency exchange rates and potential fees when dealing with international payments. -

6. How does Reliable Gaskets USA handle logistics for international shipping?

Reliable Gaskets USA collaborates with reputable logistics partners to ensure timely and safe delivery of products worldwide. They provide options for different shipping methods based on urgency and budget considerations. When placing an order, discuss shipping timelines, costs, and customs documentation to avoid delays. Additionally, obtaining tracking information can help you monitor your shipment’s progress during transit. -

7. Can I customize gaskets for specific equipment needs?

Yes, Reliable Gaskets USA specializes in creating custom gaskets tailored to specific equipment and operational requirements. When requesting a custom gasket, provide detailed specifications, including dimensions, material preferences, and any unique features needed for optimal performance. Their experienced team will work closely with you to ensure that the final product meets your exact requirements, ensuring a perfect fit and reliable sealing. -

8. What are the common signs that gaskets need replacement?

Common signs that gaskets may need replacement include visible wear, cracks, or discoloration. Additionally, if you notice temperature fluctuations, increased energy costs, or condensation around refrigeration units, it may indicate a failed gasket. Regular inspections every 1-2 years can help identify these issues early. Addressing gasket wear promptly can prevent further equipment damage and maintain operational efficiency in your facility.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for reliable gaskets usa

In the ever-evolving landscape of industrial needs, the importance of strategic sourcing for reliable gaskets cannot be overstated. Reliable Gaskets USA stands out as a premier supplier, offering high-quality, custom-made gaskets that cater to diverse sectors, including hospitality, healthcare, and food service. Their commitment to quality, coupled with extensive service offerings such as free inspections and emergency repairs, positions them as a trusted partner for businesses seeking to enhance operational efficiency.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe (including Germany and Vietnam) explore sourcing options, the value of aligning with a supplier that guarantees local manufacturing and rapid service becomes increasingly apparent. Reliable Gaskets USA not only ensures that products are made from top-quality materials sourced domestically but also supports clients with tailored solutions to meet specific requirements.

Looking ahead, companies should prioritize establishing relationships with suppliers that demonstrate reliability and responsiveness. By choosing Reliable Gaskets USA, businesses can secure the essential sealing solutions needed to maintain optimal performance and competitiveness in their respective markets. Engage with Reliable Gaskets USA today to explore how their offerings can support your operational goals and drive success.