Top 6 Zipper Usa List and Guide: How To Solve Scenario 1: Sourcin…

Introduction: Navigating the Global Market for zipper usa

In an increasingly competitive global market, sourcing high-quality zippers from the USA can pose significant challenges for international B2B buyers. Whether you’re in Brazil, Saudi Arabia, or elsewhere, the need for reliable, durable, and aesthetically pleasing zippers is paramount to maintaining product quality and brand reputation. This comprehensive guide on “zipper USA” addresses critical aspects of sourcing, including the diverse types of zippers available, their various applications, supplier vetting processes, and cost considerations.

Navigating the complexities of zipper procurement requires a keen understanding of market dynamics and supplier capabilities. This guide empowers you with actionable insights that will facilitate informed purchasing decisions, ensuring you select the right zippers for your specific needs. From luxury options to everyday standards, we delve into the features that distinguish suppliers, such as manufacturing practices, lead times, and customer service.

By equipping you with the knowledge to assess suppliers effectively, this guide aims to foster successful partnerships and enhance your supply chain efficiency. As you explore the vast landscape of zipper options, you’ll gain the confidence to make choices that align with your brand’s vision and operational goals, setting the stage for success in your respective markets.

Top 10 Zipper Usa Manufacturers & Suppliers List

1. Zipper Shipper – Zippers for Clothing, Bags, and More

Domain: zippershipper.com

Registered: 2012 (13 years)

Introduction: Zipper Shipper offers a wide range of zippers made in the USA, including options for clothing, bags, upholstery, and specialty uses. Key product categories include:

1. **Zippers by Use**: Clothing (jacket, jean, pocket, sportswear, coat, coveralls, leatherwear, skirt), outdoor (marine, tent, sleeping bag, Jeep), bridal/wedding, heavy-duty, and specialty zippers.

2. **Zippers by Material**: Metal …

2. UCAN Zippers – Full-Service Zipper Manufacturer

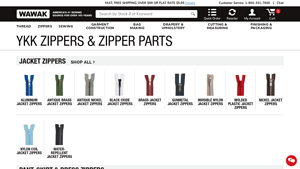

3. WAWAK – YKK Zippers & Parts

Domain: wawak.com

Registered: 2002 (23 years)

Introduction: YKK Zippers & Zipper Parts available at WAWAK. Various types of zippers include: Jacket Zippers (Aluminum, Antique Brass, Antique Nickel, Black Oxide Brass, Gunmetal, Invisible, Nylon, Molded Plastic, Nickel, Nylon Coil, Water-Repellent), Pant, Skirt & Dress Zippers (Antique Brass, Antique Silver, Black Oxide Brass, Gunmetal, Invisible, Nylon, Nickel, Nylon Coil). Parts & Accessories include Lubri…

4. Lenzip – Durable Zippers

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: American manufacturers of zippers and hardware mentioned include: 1. Lenzip – known for durable zippers, used in outdoor gear. 2. Talon – still manufactures zippers in the US. 3. Austeremfg.com – specializes in CNCed hardware, lightweight and strong. 4. YKK – a Japanese company with operations in North America, some production in the US, particularly for tactical applications. 5. Berry Amendment c…

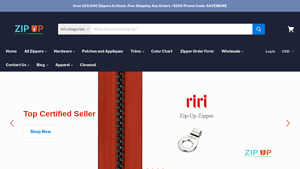

5. ZipUpZipper – Wholesale Zippers

Domain: zipupzipper.net

Registered: 2013 (12 years)

Introduction: ZipUpZipper offers a wide range of wholesale zippers including brands like YKK, Riri, Lampo, and Raccagni. They have over 100,000 zippers in stock with free shipping on orders over $100 using the promo code SAVEMORE. The product categories include various types of zippers such as glossy, metal, molded plastic, nylon, and invisible zippers, as well as hardware like buckles, buttons, and snaps. Spec…

6. Hemlock Mountain Outdoors – #3 Coil Zipper

Domain: hemlockmountainoutdoors.com

Registered: 2016 (9 years)

Introduction: #3 Coil Zipper – Made in U.S.A. – By the Foot

Understanding zipper usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metal Zippers | Durable, often polished finish, high strength | Apparel, leather goods, outdoor gear | Pros: Strong, aesthetic appeal. Cons: Heavier, may corrode in wet conditions. |

| Nylon Zippers | Lightweight, flexible, available in various colors | Fashion, home textiles, bags | Pros: Versatile, resistant to moisture. Cons: Less durable than metal options. |

| Invisible Zippers | Concealed design for seamless look | Dresses, skirts, upholstery | Pros: Aesthetic appeal, hides zipper. Cons: Requires precise sewing, less robust. |

| Waterproof Zippers | Sealed construction for moisture resistance | Outdoor gear, sportswear, luggage | Pros: Protects contents from water. Cons: Higher cost, limited color options. |

| Heavy-Duty Zippers | Reinforced construction for high-stress use | Industrial applications, heavy garments | Pros: Exceptional durability. Cons: Bulkier, may be overkill for lighter applications. |

What are the characteristics of Metal Zippers and their B2B suitability?

Metal zippers are recognized for their robust construction, often featuring a polished finish that enhances their aesthetic appeal. Commonly used in apparel, leather goods, and outdoor gear, they are ideal for high-stress applications where durability is paramount. When considering metal zippers, buyers should evaluate the balance between weight and strength, as these zippers can add bulk to products. Additionally, the potential for corrosion in moist environments is a critical factor, making it essential to select the right metal finish for specific applications.

How do Nylon Zippers stand out in various applications?

Nylon zippers are lightweight and flexible, making them a versatile choice for a wide range of products, including fashion items, home textiles, and bags. Their availability in multiple colors allows for creative design options, appealing to brands focused on aesthetics. However, while nylon zippers are resistant to moisture, they may not offer the same level of durability as metal zippers. Buyers should consider the specific application requirements, especially in terms of load-bearing capacity and environmental exposure, when selecting nylon zippers.

What makes Invisible Zippers a preferred choice for certain designs?

Invisible zippers are designed to be concealed within seams, providing a seamless look that is particularly favored in dresses, skirts, and upholstery. Their aesthetic appeal allows for a clean finish, making them a popular choice in high-fashion applications. However, the installation of invisible zippers requires precision and skill, which can be a drawback for manufacturers with less sewing expertise. Buyers should weigh the visual benefits against the potential challenges in production when considering invisible zippers for their designs.

What are the advantages of Waterproof Zippers for outdoor applications?

Waterproof zippers feature a sealed construction that protects contents from moisture, making them essential for outdoor gear, sportswear, and luggage. Their ability to keep items dry is a significant selling point for brands targeting adventure enthusiasts or consumers in wet climates. However, these zippers tend to come at a higher cost and may have limited color options compared to standard zippers. Buyers should assess the trade-off between functionality and budget when integrating waterproof zippers into their product lines.

How do Heavy-Duty Zippers perform in industrial settings?

Heavy-duty zippers are engineered for high-stress applications, making them ideal for industrial use and heavy garments. Their reinforced construction ensures exceptional durability, which is critical in environments where wear and tear are common. However, the bulkiness of heavy-duty zippers may not be suitable for lighter applications. When sourcing these zippers, buyers should consider the specific demands of their products and whether the added durability justifies the potential weight increase.

Key Industrial Applications of zipper usa

| Industry/Sector | Specific Application of zipper usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Apparel and Fashion | High-end clothing and accessories | Enhances product appeal and durability | Quality materials, custom designs, and competitive pricing |

| Home Textiles and Upholstery | Cushions and decorative pillows | Provides aesthetic value and functional longevity | Fabric compatibility, color options, and lead times |

| Luggage and Travel Goods | Suitcases and travel bags | Ensures reliability and ease of use in travel | Weight considerations, durability, and design flexibility |

| Automotive | Car interiors and seat covers | Improves vehicle aesthetics and user comfort | Performance under stress, resistance to wear, and customization |

| Sporting Goods | Outdoor gear and apparel | Enhances functionality and withstands extreme conditions | Weather resistance, strength, and compatibility with other materials |

How is ‘zipper usa’ Used in the Apparel and Fashion Industry?

In the apparel and fashion sector, zippers are crucial for high-end clothing and accessories. They not only serve a functional purpose but also enhance the aesthetic appeal of garments. Buyers from international markets, particularly those in Africa and Europe, often seek zippers that offer a blend of luxury and durability, such as those made from premium materials. Additionally, customization options are essential to meet diverse fashion trends and consumer preferences.

What Role Does ‘zipper usa’ Play in Home Textiles and Upholstery?

Zippers are extensively used in home textiles, particularly for cushions and decorative pillows. They provide an easy way to remove covers for cleaning while adding a polished finish to the product. International buyers should consider the compatibility of zippers with various fabrics, as well as the range of colors available to match design aesthetics. A focus on lead times is also critical to ensure timely production and delivery.

How Do ‘zipper usa’ Products Benefit Luggage and Travel Goods?

In the luggage and travel goods sector, zippers are vital for suitcases and travel bags, ensuring they can withstand the rigors of travel. Buyers prioritize zippers that offer reliability and ease of use, especially for products intended for frequent travel. Key sourcing considerations include durability and the ability to withstand the weight of packed items, as well as design flexibility to accommodate various bag styles.

In What Ways Are ‘zipper usa’ Solutions Applied in the Automotive Industry?

Zippers are increasingly used in automotive applications, particularly in car interiors and seat covers. They enhance both the aesthetic appeal and user comfort of vehicles. International buyers must consider the zippers’ performance under stress, as they should be resistant to wear and tear while providing a seamless integration with upholstery materials. Customization options can also play a significant role in meeting specific automotive design requirements.

How Does ‘zipper usa’ Contribute to the Sporting Goods Sector?

In the sporting goods industry, zippers are essential for outdoor gear and apparel, where functionality and durability are paramount. Zippers need to withstand extreme conditions, making weather resistance and strength critical factors for buyers. International buyers should focus on sourcing zippers that can integrate well with various materials used in outdoor products, ensuring they meet the rigorous demands of sports enthusiasts.

3 Common User Pain Points for ‘zipper usa’ & Their Solutions

Scenario 1: Sourcing Quality Zippers for Diverse Applications

The Problem: International B2B buyers often struggle to find high-quality zippers that meet their specific application needs. For example, a clothing manufacturer in Brazil may require zippers that can withstand frequent use and laundering, while a luxury bag maker in Europe seeks zippers that not only perform well but also enhance the aesthetics of their products. The challenge lies in sourcing zippers that deliver both functionality and style, often leading to dissatisfaction or costly returns.

The Solution: To effectively source zippers that align with diverse application requirements, buyers should engage with reputable manufacturers like ‘Zipper USA’ that offer a wide range of products tailored for specific uses. It’s crucial to communicate the intended application clearly when placing orders. This means specifying the desired characteristics such as durability for heavy-duty use, water resistance for outdoor gear, or luxury finishes for high-end fashion items. Buyers can also request samples to evaluate the performance and aesthetics of zippers before making large orders. Additionally, understanding the manufacturing capabilities of suppliers—such as the ability to produce custom zippers—can significantly enhance the sourcing process.

Scenario 2: Managing Lead Times and Delivery Expectations

The Problem: Delays in zipper delivery can disrupt the entire production timeline for businesses, especially in industries where time-to-market is critical, such as fashion or automotive manufacturing. A company in Saudi Arabia that relies on imported zippers may experience longer lead times due to customs clearance and shipping delays, leading to missed deadlines and strained client relationships. This uncertainty can hinder planning and operational efficiency.

The Solution: To mitigate lead time issues, B2B buyers should prioritize suppliers who have robust domestic manufacturing capabilities, such as those offered by ‘Zipper USA.’ By sourcing zippers from manufacturers with local production, businesses can benefit from shorter lead times and more reliable delivery schedules. Establishing a strong relationship with suppliers can also facilitate better communication regarding production timelines and expedite order processing. Additionally, it’s advisable to maintain a buffer stock of essential zipper types to prevent production halts during unexpected delays. Implementing inventory management practices can help maintain an optimal supply while allowing flexibility in response to market demands.

Scenario 3: Navigating Customization Needs for Unique Projects

The Problem: Many B2B buyers encounter difficulties when seeking customized zipper solutions for unique projects, such as bespoke apparel or specialized equipment. For example, a manufacturer in South America may require zippers with specific color matches or unique sizes that are not readily available in standard offerings. This lack of customization options can lead to compromises in product quality and brand identity.

The Solution: To address customization challenges, buyers should work closely with manufacturers who offer personalized services. Engaging with ‘Zipper USA’ can provide access to expertise in custom zipper design and production. Buyers should prepare detailed specifications, including dimensions, colors, materials, and any special features required. It’s also beneficial to discuss minimum order quantities and turnaround times for custom orders to ensure they align with project timelines. Leveraging the manufacturer’s design capabilities can lead to innovative zipper solutions that enhance product functionality and aesthetics, ultimately supporting the brand’s unique identity in competitive markets.

By proactively addressing these common pain points, B2B buyers can streamline their sourcing processes, reduce operational risks, and enhance product offerings.

Strategic Material Selection Guide for zipper usa

What Are the Key Materials Used in Zippers for B2B Applications?

Zippers are essential components in various industries, and the choice of material significantly influences their performance, durability, and suitability for specific applications. Below are analyses of four common materials used in zippers, emphasizing their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Properties and Applications of Metal Zippers?

Metal zippers, often made from brass, aluminum, or stainless steel, are recognized for their strength and durability. They typically have a high-temperature tolerance and excellent corrosion resistance, making them suitable for heavy-duty applications, such as in outerwear, luggage, and automotive sectors.

Pros: Metal zippers offer a premium aesthetic and a robust feel, enhancing the overall quality of the product. They are highly durable and can withstand significant wear and tear.

Cons: However, metal zippers can be heavier than their plastic counterparts and may be more expensive due to manufacturing complexity. They can also be prone to rust if not properly treated, particularly in humid environments.

Impact on Application: Metal zippers are ideal for products exposed to harsh conditions, but their weight may be a concern for lightweight garments.

Considerations for International Buyers: Compliance with ASTM and ISO standards is essential. In regions like Africa and the Middle East, where humidity is high, selecting rust-resistant finishes is crucial.

How Do Plastic Zippers Compare in Terms of Versatility?

Plastic zippers, commonly made from nylon or polyester, are lightweight and versatile, making them suitable for a wide range of applications, including clothing, bags, and outdoor gear. They typically perform well under varying temperature conditions.

Pros: These zippers are resistant to corrosion and can be produced in various colors and styles, offering design flexibility. They are generally less expensive to manufacture.

Cons: While they are durable, plastic zippers may not withstand heavy loads as effectively as metal zippers. They can also be less aesthetically appealing for high-end products.

Impact on Application: Plastic zippers are suitable for casual wear and accessories but may not be the best choice for luxury items.

Considerations for International Buyers: Ensure that suppliers meet local compliance standards, such as REACH in Europe, particularly regarding chemical safety.

What Are the Advantages of Using Coil Zippers?

Coil zippers, made from a continuous coil of nylon or polyester, are known for their flexibility and smooth operation. They are commonly used in lightweight garments, tents, and bags.

Pros: Coil zippers are lightweight, resistant to water, and less likely to snag compared to metal zippers. They offer a smooth glide, enhancing user experience.

Cons: However, they may not be as strong as metal zippers and can be prone to damage if subjected to excessive force.

Impact on Application: Ideal for applications requiring lightweight and flexible closures, coil zippers are well-suited for outdoor gear and travel accessories.

Considerations for International Buyers: Buyers should verify the durability and weather resistance of coil zippers, especially in regions with extreme weather conditions.

How Do Specialty Zippers Enhance Product Functionality?

Specialty zippers, such as waterproof or flame-retardant zippers, are designed for specific applications where standard zippers may not suffice. These zippers are often made from advanced materials that enhance their performance under extreme conditions.

Pros: Specialty zippers provide solutions for niche markets, such as outdoor gear or safety apparel, where standard zippers may fail.

Cons: They can be more expensive and may require specialized manufacturing processes.

Impact on Application: Specialty zippers are essential for applications demanding high performance, such as in military or industrial settings.

Considerations for International Buyers: Ensure that specialty zippers comply with industry-specific regulations, particularly in sectors like aerospace or defense.

Summary Table of Zipper Materials

| Material | Typical Use Case for zipper usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Metal | Heavy-duty outerwear, luggage | High durability and aesthetic | Heavier and prone to rust | High |

| Plastic | Casual wear, bags, outdoor gear | Lightweight and versatile | Less durable under heavy loads | Medium |

| Coil | Lightweight garments, tents | Smooth operation and flexibility | Weaker than metal | Medium |

| Specialty | Outdoor gear, safety apparel | Tailored for extreme conditions | Higher cost and complexity | High |

This comprehensive analysis of zipper materials provides B2B buyers with essential insights into selecting the right zippers for their specific applications, ensuring optimal performance and compliance with industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for zipper usa

What Are the Main Stages of Zipper Manufacturing in the USA?

The manufacturing process for zippers in the USA typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical in ensuring that the final product meets high standards of quality and performance.

-

Material Preparation: The process begins with sourcing high-quality materials, such as nylon, polyester, or metal for zipper teeth and sliders. These materials undergo rigorous inspection to ensure they meet the required specifications for durability and functionality. Suppliers must provide material certifications that comply with international standards.

-

Forming: In this stage, the prepared materials are shaped into the components of the zipper. For example, nylon or polyester strips are cut and coated to form zipper tapes, while metal components are stamped and machined into the necessary shapes. Advanced techniques like injection molding are often employed for producing sliders and stops, ensuring precision and consistency.

-

Assembly: Once all components are formed, they are assembled into complete zippers. This involves threading the zipper teeth onto the tape and attaching sliders and stops. Automation plays a significant role in this stage, but skilled labor is also essential for quality assurance, particularly for luxury or custom zippers.

-

Finishing: The final stage includes a thorough inspection and finishing process. Zippers may undergo dyeing, coating, or additional treatments to enhance their aesthetic appeal and functionality. This stage also includes the application of any branding or labeling required by the client.

How is Quality Assurance Implemented in Zipper Manufacturing?

Quality assurance (QA) in zipper manufacturing is critical to ensuring that products meet international standards and customer expectations. The process typically involves several checkpoints and testing methods.

-

International Standards Compliance: Many zipper manufacturers adhere to ISO 9001 standards, which ensure that quality management systems are in place. Compliance with industry-specific standards, such as CE marking for safety and API standards for specific applications, is also essential. These certifications provide international buyers with the assurance that products meet stringent quality requirements.

-

Quality Control Checkpoints: Quality control (QC) is integrated throughout the manufacturing process. Key checkpoints include:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages helps identify defects early. This includes checking dimensions, materials, and assembly accuracy.

– Final Quality Control (FQC): Before shipping, zippers undergo a final inspection to ensure they meet all specifications and quality standards. -

Common Testing Methods: Various testing methods are employed to assess zipper performance, including:

– Pull Strength Testing: Measures the force required to separate the zipper.

– Cycle Testing: Evaluates the zipper’s functionality over repeated use.

– Corrosion Resistance Testing: Important for metal zippers, this ensures they can withstand environmental conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control systems. Audits should focus on compliance with international standards and the implementation of best practices in quality management.

-

Requesting Quality Reports: Buyers should request detailed quality reports, including IQC, IPQC, and FQC data. These reports should outline inspection results, testing methodologies, and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services can conduct random inspections and testing, ensuring that the products meet the required specifications before shipment.

What Are the Quality Control Nuances for International Buyers?

International buyers must be aware of several nuances related to quality control when sourcing zippers from the USA:

-

Understanding Certification Requirements: Different regions may have varying certification requirements. For example, CE marking is essential for products sold in the European market, while specific certifications might be necessary for Middle Eastern or African markets. Buyers should ensure that their suppliers can provide the necessary documentation.

-

Cultural and Communication Considerations: Language barriers and cultural differences can impact the quality assurance process. Establishing clear communication channels and understanding cultural nuances can facilitate better collaboration with suppliers.

-

Lead Times and Inventory Management: International buyers must consider lead times when placing orders. Suppliers with efficient QC processes can often deliver products faster, reducing the risk of delays in the supply chain. Understanding a supplier’s production capacity and inventory management practices can help buyers maintain smooth operations.

Conclusion

In-depth knowledge of the manufacturing processes and quality assurance protocols in the zipper industry is essential for B2B buyers. By understanding these processes, buyers can make informed decisions that ensure they source high-quality products that meet their specific needs. Implementing thorough verification measures and maintaining clear communication with suppliers will further enhance the likelihood of a successful partnership.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘zipper usa’

Introduction

This practical sourcing guide is designed to assist international B2B buyers in procuring zippers from USA manufacturers. Zippers are essential components in various industries, including fashion, upholstery, and technical applications. By following this step-by-step checklist, buyers can ensure they choose the right suppliers and products that meet their specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for your zipper requirements is crucial. Consider factors such as size, material (metal, plastic, or nylon), type (separating, non-separating, or invisible), and color. This detailed understanding will help streamline the selection process and avoid costly mistakes later on.

- Example Specifications:

- Type of zipper needed for each application (e.g., heavy-duty for bags, lightweight for clothing).

- Required length and puller type.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable zipper manufacturers in the USA. Look for companies with a solid track record and positive reviews from previous clients. Reliable suppliers will have a strong online presence, showcasing their product range and customer testimonials.

- Key Considerations:

- Look for manufacturers that specialize in the type of zippers you require.

- Check their history and experience in the industry.

Step 3: Evaluate Supplier Certifications

Before finalizing any agreements, verify that potential suppliers hold the necessary certifications. These may include ISO certifications, compliance with safety standards, and environmental certifications. Such credentials demonstrate a commitment to quality and sustainability.

- Why It Matters:

- Certified suppliers are more likely to adhere to industry standards, ensuring product reliability.

- Certifications can also enhance your brand’s reputation when using compliant materials.

Step 4: Request Samples

Always request samples from shortlisted suppliers to assess the quality of their zippers. This step allows you to test the durability, functionality, and overall appearance of the products before making a bulk purchase.

- What to Look For:

- Check for smooth operation, sturdiness, and finish quality.

- Ensure that the samples meet your defined specifications.

Step 5: Compare Pricing and Terms

Once you have identified potential suppliers, compare their pricing structures and payment terms. It’s essential to find a balance between cost and quality, as opting for the cheapest option may compromise performance.

- Considerations:

- Look for bulk order discounts or special pricing for long-term contracts.

- Assess lead times and minimum order quantities to align with your production schedules.

Step 6: Establish Communication Channels

Effective communication is vital throughout the sourcing process. Ensure that your chosen supplier is responsive and open to discussions regarding your needs and concerns. A supplier that prioritizes communication is more likely to provide excellent customer service.

- Tips:

- Set up regular check-ins to discuss order progress and any potential issues.

- Utilize multiple channels (email, phone, video calls) for better accessibility.

Step 7: Finalize Your Order

After thorough evaluation and communication, it’s time to finalize your order. Ensure that all terms, including delivery timelines, payment methods, and return policies, are clearly outlined in a contract. This step protects both parties and sets clear expectations.

- Final Checklist:

- Confirm all specifications and quantities.

- Ensure that both parties agree on the timeline for delivery and payment.

By following this checklist, B2B buyers can confidently navigate the procurement process for zippers in the USA, ensuring they select suppliers that align with their business needs and quality expectations.

Comprehensive Cost and Pricing Analysis for zipper usa Sourcing

What Are the Key Cost Components in Zipper USA Sourcing?

When sourcing zippers from the USA, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts cost. For instance, high-quality nylon or metal zippers typically command higher prices than standard plastic options. Suppliers like UCAN and YKK emphasize the use of premium materials, which can enhance durability and appeal, but also increase the unit price.

-

Labor: Labor costs in the USA are generally higher compared to countries with lower wage standards. However, the advantage of local sourcing includes shorter lead times and better communication, which can offset some of the higher costs through improved efficiency and reduced shipping times.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, equipment maintenance, and facility costs. US-based manufacturers often have higher overhead due to compliance with stricter regulations and standards, which can contribute to the overall pricing structure.

-

Tooling: Custom tooling for specific zipper designs or functionalities can be a significant upfront investment. This cost is usually amortized over larger order quantities, making it crucial for buyers to consider their volume needs when negotiating prices.

-

Quality Control (QC): Implementing stringent quality control measures ensures product reliability, especially for high-performance applications. This can add to the cost but is essential for maintaining brand reputation and reducing returns.

-

Logistics: Shipping costs can vary based on the mode of transport, distance, and volume. Domestic shipping may be more straightforward, but international buyers must consider import duties, taxes, and potential delays, which can add to the total cost.

-

Margin: Supplier margins will vary based on the competitive landscape and the uniqueness of the products offered. Established brands may have higher margins due to their reputation for quality and service.

How Do Price Influencers Affect Zipper Sourcing Costs?

Several factors influence pricing in the zipper market, particularly for international buyers from regions such as Africa, South America, the Middle East, and Europe.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk pricing discounts. Buyers should assess their inventory needs and negotiate MOQs that allow them to benefit from reduced per-unit costs.

-

Specifications and Customization: Custom zippers tailored to specific applications can lead to higher prices. Buyers should weigh the importance of customization against the potential cost savings of standard options.

-

Material Choices: Selecting premium materials can elevate costs but may also enhance product value and longevity. It’s essential to balance quality with budget constraints.

-

Quality and Certifications: Zippers that meet specific quality standards or certifications (e.g., ISO, ASTM) may come at a premium. Buyers must evaluate the necessity of these certifications based on their market requirements.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more but often provide greater assurance of quality and service.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define responsibilities regarding shipping costs, insurance, and risk, impacting the total cost of ownership.

What Tips Can Help Buyers Optimize Zipper Sourcing Costs?

-

Negotiation: Engage in discussions with suppliers about pricing flexibility, especially for larger orders. Establishing a long-term relationship can lead to better terms and discounts.

-

Cost-Efficiency: Consider the total cost of ownership rather than just the purchase price. This includes logistics, potential returns, and the expected lifespan of the zippers.

-

Pricing Nuances for International Buyers: Be aware of fluctuating exchange rates and their impact on pricing. Additionally, factor in customs duties and taxes when calculating total costs.

-

Research and Comparison: Conduct thorough research and compare multiple suppliers to understand the market price range. This knowledge empowers buyers during negotiations.

-

Request Samples: Before committing to large orders, request samples to assess quality and performance. This can prevent costly mistakes and ensure that the chosen zippers meet specific application needs.

By understanding the cost structure, price influencers, and employing strategic sourcing tips, international buyers can make informed decisions that enhance their supply chain efficiency and product quality.

Alternatives Analysis: Comparing zipper usa With Other Solutions

Exploring Alternative Zipper Solutions for B2B Buyers

In the competitive landscape of zipper manufacturing, businesses often find themselves evaluating various options to meet their unique needs. While ‘Zipper USA’ offers a range of products, it’s beneficial to consider alternative solutions that may align better with specific requirements, such as budget constraints, performance expectations, and application types. Below, we compare ‘Zipper USA’ against two notable alternatives: UCAN and YKK.

| Comparison Aspect | Zipper USA | UCAN | YKK |

|---|---|---|---|

| Performance | Reliable and durable; suitable for various applications | High-quality luxury and standard options, known for performance | Industry leader, recognized for durability and strength |

| Cost | Competitive pricing, especially for bulk orders | Generally offers good value, but luxury options can be pricier | Varies widely; premium products may be costlier |

| Ease of Implementation | Straightforward ordering process, with solid customer support | Personalized service with hands-on guidance | Well-established distribution, but may require more navigation |

| Maintenance | Low-maintenance; designed for durability | Requires standard care; luxury lines may need special handling | Robust designs that withstand wear; minimal maintenance required |

| Best Use Case | General applications across various industries | Fashion and luxury items needing a touch of elegance | Heavy-duty applications, technical gear, and high-volume production |

Understanding the Pros and Cons of Alternative Zipper Solutions

UCAN

UCAN specializes in both luxury and standard zippers, making it an appealing choice for businesses looking to elevate their product offerings. Their luxury lines, such as G2 Luxury and Alpha One, are designed to add character and sophistication to designs. The downside is that while their standard options are competitively priced, the luxury zippers can be significantly more expensive, which may not suit every budget. Additionally, UCAN prides itself on personalized service, ensuring that clients receive tailored advice, which can be particularly advantageous for new businesses or those entering the luxury market.

YKK

As one of the largest zipper manufacturers globally, YKK is synonymous with quality and reliability. Their products are widely used across numerous sectors, including fashion, upholstery, and outdoor gear. The strength of YKK zippers is a significant advantage, especially for heavy-duty applications. However, YKK’s extensive product range can be overwhelming, and their premium lines may come with a higher price tag. This could deter smaller businesses or those with tight budgets. Nevertheless, YKK’s reputation for durability often justifies the investment for high-volume producers or brands seeking long-lasting performance.

Concluding Thoughts: Choosing the Right Zipper Solution for Your Business

When selecting a zipper supplier, B2B buyers should evaluate their specific needs against the strengths and weaknesses of each option. If your business focuses on high-end products that require a touch of luxury, UCAN may be the ideal choice. Conversely, for robust applications that demand reliability, YKK stands out as a trusted leader. Zipper USA offers a balanced approach with competitive pricing and versatility, making it suitable for various applications. Ultimately, understanding your business requirements, budget constraints, and target market will guide you in making the most informed decision for your zipper sourcing needs.

Essential Technical Properties and Trade Terminology for zipper usa

What Are the Key Technical Properties of Zippers in the USA Market?

Understanding the technical properties of zippers is crucial for B2B buyers, especially when making decisions that impact product quality, functionality, and ultimately, customer satisfaction. Here are some essential specifications to consider:

-

Material Grade

Zippers are made from various materials, including nylon, polyester, and metal. Each material has its advantages: nylon zippers are lightweight and flexible, while metal zippers offer superior strength and durability. Understanding the material grade helps buyers select zippers that align with the intended application, ensuring performance and longevity. -

Tolerance

Tolerance refers to the acceptable range of variation in dimensions during manufacturing. For zippers, maintaining strict tolerances is essential to ensure smooth operation and proper fit in garments or other products. A tight tolerance reduces the likelihood of malfunctions, thereby enhancing customer satisfaction and reducing returns. -

Slider Type

The slider is a critical component of the zipper, responsible for opening and closing. Different slider types, such as auto-lock, non-lock, and semi-auto-lock, offer varying levels of security and ease of use. B2B buyers should consider the intended use of the zipper; for instance, auto-lock sliders may be preferable in high-traffic applications like bags or jackets. -

Load Capacity

This specification indicates the amount of force a zipper can withstand before failing. Load capacity is particularly important in industrial applications or heavy-duty garments. Buyers should ensure that the zippers they select can handle the demands of their products to avoid costly failures and ensure customer safety. -

Water Resistance

With the increasing demand for outdoor gear, water-resistant zippers have become essential. These zippers feature special coatings or designs that prevent water from penetrating. Buyers in regions with high rainfall or for products exposed to moisture should prioritize water-resistant options to enhance product reliability. -

Color and Finish Options

The aesthetic appeal of zippers can significantly impact the overall design of a product. Zippers come in various colors and finishes, allowing brands to match their products’ styles. Offering a range of options can help businesses differentiate themselves in competitive markets.

What Trade Terms Are Important for B2B Zipper Purchases?

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the zipper industry, OEMs often provide customized solutions tailored to the specific needs of brands, making it essential for buyers to engage with reliable OEM partners. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for managing inventory and production costs. Buyers should negotiate MOQs that align with their production schedules to avoid excess inventory or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document that buyers use to invite suppliers to submit price quotes for specific products or services. Creating a detailed RFQ helps ensure that suppliers understand the buyer’s requirements, leading to more accurate and competitive pricing. -

Incoterms

Incoterms, or International Commercial Terms, are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and responsibilities, facilitating smoother international trade. -

Lead Time

Lead time is the amount of time from placing an order to its delivery. Understanding lead times is critical for inventory management and production planning. Buyers should seek suppliers with competitive lead times to ensure timely product launches and maintain customer satisfaction. -

Customization

Customization refers to the ability to modify products to meet specific customer needs. Many zipper manufacturers offer customization options, allowing businesses to differentiate their products in the market. Engaging with suppliers who can provide tailored solutions can enhance a brand’s competitive edge.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring they source zippers that meet their specific needs while fostering successful supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the zipper usa Sector

What Are the Current Market Dynamics and Key Trends in the Zipper Sector?

The zipper industry is currently experiencing a transformation driven by several global factors. Increased demand for sustainable and ethically produced materials is reshaping sourcing strategies, particularly among international B2B buyers from Africa, South America, the Middle East, and Europe. As consumers become more environmentally conscious, brands are under pressure to adopt sustainable practices, prompting suppliers to innovate with eco-friendly materials and production methods. The rise of e-commerce has also changed the landscape, enabling buyers to source zippers more efficiently from global suppliers, thus expanding their options beyond local markets.

Emerging B2B technologies, such as AI and data analytics, are enhancing supply chain transparency and efficiency. Suppliers are leveraging these tools to optimize inventory management and forecast demand more accurately, allowing them to offer competitive pricing and shorter lead times—critical factors for buyers looking to maintain agility in their operations. Additionally, customization is becoming a key trend, with brands seeking unique zippers that align with their design ethos. This trend is particularly prevalent in the fashion and luxury sectors, where the aesthetics of zippers play a significant role in product appeal.

How Are Sustainability and Ethical Sourcing Influencing the Zipper Market?

Sustainability has become a focal point in the zipper industry, with environmental impact considerations influencing sourcing decisions. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, from material selection to production processes. This shift is not just about compliance; it has become a competitive advantage as brands strive to align with consumer values.

Ethical sourcing is equally important, as it encompasses fair labor practices and responsible supply chain management. B2B buyers are now looking for suppliers that can provide certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX, which assure them of the environmental and social standards met during production. Many suppliers are also adopting recycled materials, such as PET zippers, which reduce waste and minimize the carbon footprint. By prioritizing suppliers with green certifications and ethical practices, international buyers can enhance their brand reputation and meet the growing consumer demand for sustainable products.

What Is the Brief Evolution of the Zipper Industry?

The zipper has evolved significantly since its invention in the late 19th century. Initially designed for functionality, zippers have transformed into essential design elements in various industries, including fashion, automotive, and outdoor gear. The introduction of brands like YKK in the mid-20th century revolutionized zipper manufacturing, emphasizing quality and reliability.

Over the decades, the focus has shifted from merely functional to incorporating aesthetics and sustainability. Innovations such as water-resistant and eco-friendly zippers have emerged, catering to the growing demand for performance and environmental responsibility. Today, the zipper industry stands at the intersection of technology, design, and sustainability, making it a dynamic sector for B2B buyers looking to source high-quality products that align with modern consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of zipper usa

-

How do I choose the right zipper for my product line?

Choosing the right zipper depends on the specific application and desired aesthetics of your products. For high-end fashion items, luxury zippers like YKK’s Excella® offer a polished look and durability. For everyday applications, standard nylon or metal zippers may suffice. Consider factors such as material, size, color, and functionality to ensure the zipper complements your product design and meets performance requirements. -

What are the common minimum order quantities (MOQs) for zippers in the USA?

Minimum order quantities can vary significantly depending on the supplier and type of zipper. Generally, MOQs for custom or specialized zippers can range from 500 to 1,000 units, while standard zippers may have lower MOQs. It’s advisable to discuss your specific needs with suppliers to find options that fit your production scale and budget. -

What customization options are available for zippers?

Many suppliers offer a range of customization options, including size, color, material, and branding features such as custom pulls or tape. Depending on the supplier, you may also be able to request specific finishes or additional functionalities, such as water resistance or eco-friendly materials. Engaging with suppliers early in the design process will help you identify the best customization options for your product. -

How can I ensure the quality of zippers before placing a large order?

To ensure quality, request samples from potential suppliers before making a bulk purchase. Conduct thorough inspections to assess the zippers’ durability, functionality, and aesthetic appeal. Additionally, inquire about the supplier’s quality assurance processes, certifications, and manufacturing practices. Establishing clear quality standards and communication with your supplier can mitigate risks associated with product defects. -

What payment terms should I expect when sourcing zippers from the USA?

Payment terms can vary widely among suppliers. Common options include upfront payment, a percentage deposit with the balance upon delivery, or net payment terms (e.g., net 30 or net 60 days). It’s essential to clarify payment conditions during negotiations to ensure they align with your cash flow needs and business practices. Also, consider using secure payment methods to protect your financial transactions. -

How do I manage logistics and shipping for my zipper orders from the USA?

Managing logistics involves coordinating with your supplier regarding shipping methods and timelines. Discuss options such as air freight for faster delivery or sea freight for cost savings. Be aware of customs regulations in your country to avoid delays. Engaging a freight forwarder can streamline the shipping process and ensure compliance with international trade regulations. -

What should I consider when vetting zipper suppliers?

When vetting suppliers, evaluate their manufacturing capabilities, product range, and reputation in the industry. Look for established companies with a track record of reliability and quality. Request references or testimonials from previous clients, and consider their responsiveness and willingness to accommodate your specific needs. Certifications related to quality and sustainability can also enhance a supplier’s credibility. -

How do I handle potential disputes with zipper suppliers?

To minimize disputes, establish clear contracts that outline terms, conditions, and expectations regarding product quality, delivery timelines, and payment. Maintain open communication throughout the transaction process. If issues arise, address them promptly with the supplier to find a resolution. If necessary, consider mediation or arbitration as alternatives to litigation to resolve disputes efficiently.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for zipper usa

In today’s competitive market, strategic sourcing of zippers from the USA offers significant advantages for international B2B buyers. By prioritizing quality, buyers can ensure that their products not only meet customer expectations but also enhance their brand reputation. American manufacturers like UCAN and YKK provide a diverse range of zippers, from luxury options to durable everyday choices, all while maintaining competitive pricing and industry-leading lead times.

Moreover, establishing partnerships with U.S.-based suppliers fosters personalized service and support, which can be crucial for navigating the complexities of international trade. This relationship-oriented approach allows businesses to leverage the expertise of manufacturers who have a deep understanding of their products and the markets they serve.

Looking ahead, as global supply chains continue to evolve, investing in U.S. zippers can provide a strategic edge. By aligning with reliable suppliers, businesses in Africa, South America, the Middle East, and Europe can enhance their operational efficiency and product quality. Now is the time to explore these opportunities—reach out to American zipper manufacturers to discuss how they can meet your sourcing needs and help your brand stand out in the marketplace.