Top 8 How Many Sea Port In Usa List and Guide: How To Solve Scena…

Introduction: Navigating the Global Market for how many sea port in usa

In the complex landscape of international trade, understanding the operational dynamics of U.S. sea ports is critical for businesses looking to enhance their supply chain efficiency. With approximately 360 commercial ports across the United States, including over 150 deep draft seaports, the sheer scale and diversity of these facilities present both opportunities and challenges for international B2B buyers. This guide aims to navigate the intricate world of U.S. sea ports, addressing key considerations such as types of ports, operational capacities, and the implications of recent infrastructure investments.

The U.S. port system plays a pivotal role in global commerce, contributing over $3 trillion to the economy and generating millions of jobs. For buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of port operations—including cargo volumes, shipping routes, and associated costs—can empower informed purchasing decisions. This comprehensive resource will delve into the performance metrics of major U.S. ports, supplier vetting processes, and the impact of labor dynamics on shipping schedules.

By equipping international buyers with actionable insights and strategic guidance, this guide serves as an essential tool for optimizing logistics and maximizing trade potential in the ever-evolving global market.

Top 10 How Many Sea Port In Usa Manufacturers & Suppliers List

1. Searates – US Ports & Logistics Services

Domain: searates.com

Registered: 2005 (20 years)

Introduction: United States Ports – List of Ports in United States. Services include FCL shipping, LCL shipping, bulk & break bulk, dangerous cargoes, insurance, inspection services, abandoned cargoes, pharmaceutical & healthcare logistics, certification, project cargo, customs clearance, survey services, reefer cargoes, and warehousing. Tools available: real-time freight calculator, container tracking, air tra…

2. Global Trade – U.S. Ports Impact

Domain: globaltrademag.com

Registered: 2010 (15 years)

Introduction: U.S. ports play a crucial role in local and regional economies, generating over $3 trillion in business activities related to waterborne commerce. There are approximately 360 commercial ports in the U.S., with over 150 deep draft seaports located along the Atlantic and Pacific Oceans, the Great Lakes, the Gulf of Mexico, Alaska, Hawaii, Puerto Rico, Guam, and the U.S. Virgin Islands. The Port of S…

3. Pangea Network – Top 10 Busiest Ports in the USA

Domain: pangea-network.com

Registered: 2010 (15 years)

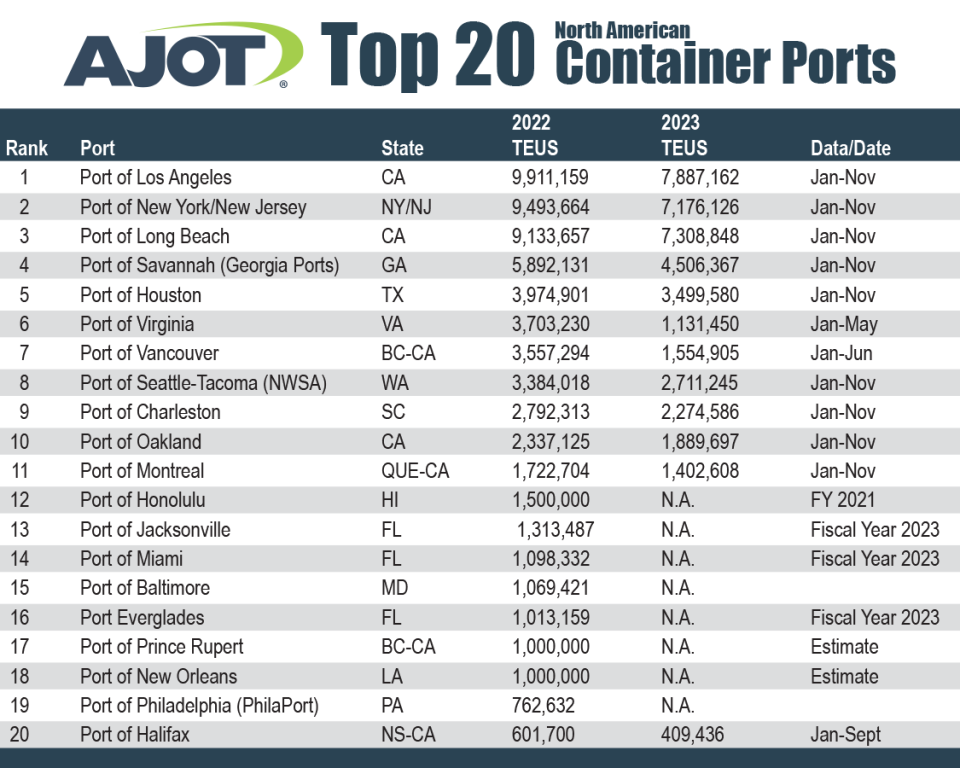

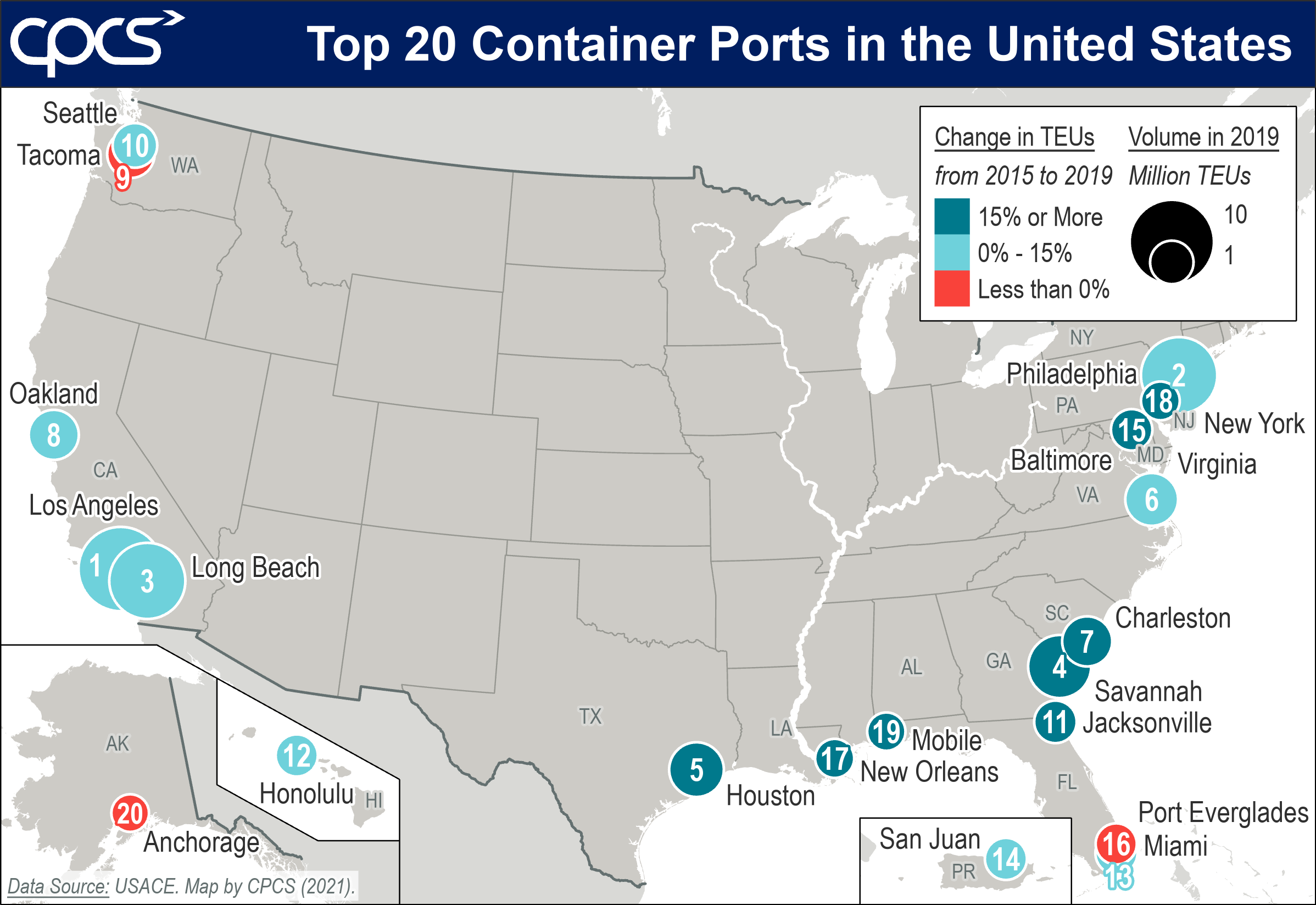

Introduction: Top 10 Busiest and Biggest Ports in the USA in 2025 based on TEUs handled in 2022: 1. Port of Los Angeles, California: 9,911,159 TEUs, -14.53% change, 5,015,315 imports, 4,895,844 exports. 2. Port of Long Beach, California: 9,133,657 TEUs, -2.67% change, 4,526,997 imports, 4,606,660 exports. 3. Port of New York and New Jersey: 9,493,664 TEUs, +5.7% change, 4,825,075 imports, 4,668,589 exports. 4. …

4. Marine Insight – US Ports Overview

5. ShipsGo – Ocean & Air Cargo Tracking Solutions

Domain: shipsgo.com

Registered: 2017 (8 years)

Introduction: List of all ports in the United States (USA) including details and location of each port. Key products include: OCEAN Container Tracking for real-time shipment tracking, Service Finder for finding service providers on routes, AIR Cargo Tracking for fast air cargo tracking, Sustainability features like Carbon Offsetting and Port Area Emission Tracker, and tools for accessing details on Ocean Ports,…

6. Cockett USA – Bulk Supply Solutions

Domain: cockettgroup.com

Registered: 2001 (24 years)

Introduction: Cockett USA offers a range of products available at various ports on the East Coast of the USA. The product availability includes different supply methods such as barge supply, packed bulk, drum pumping, ex-drum, tote tank, and tank truck. Each port has specific working days notice and minimum order quantities for product supply. For example, Baltimore, MD has a minimum order quantity of 4,000 L, …

7. Cushman Wakefield – U.S. Ports Update

Domain: cushmanwakefield.com

Registered: 1998 (27 years)

Introduction: U.S. Ports Update provides insights into the industrial real estate markets near U.S. ports and port performance. Key highlights include: 1. TEU volumes at key North American ports have risen in the first seven months of 2024, driven by increased imports. 2. Retailers expedited imports before a potential strike by the International Longshoremen Association (ILA), leading to significant shipping de…

8. Atlantic Project Cargo – Top 10 US Ports

Domain: atlanticprojectcargo.com

Registered: 2022 (3 years)

Introduction: Top 10 Biggest Ports in the USA: 1. Port of Los Angeles – 10 million TEUs, imports: furniture, auto parts, apparel, plastics, footwear; exports: paper/wastepaper, pet/animal feed, soybeans, recycled metal, fabrics/raw cotton. 2. Port of Long Beach – 8 million TEUs, imports: crude oil, electronics, plastics, furniture, clothing; exports: petroleum coke, petroleum bulk, chemicals, waste paper, foods…

Understanding how many sea port in usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Deep-Draft Seaports | Accommodate large vessels; typically found on coasts | Container shipping, bulk cargo transport | Pros: High capacity, efficiency; Cons: Higher operational costs, limited to specific locations. |

| General Cargo Ports | Handle diverse cargo types, including breakbulk | Import/export of various goods | Pros: Versatile; Cons: May lack specialized facilities for certain cargo types. |

| Bulk Ports | Specialized for bulk commodities like grain, coal | Agricultural exports, energy resources | Pros: Efficiency in handling bulk; Cons: Limited to specific cargo types. |

| Intermodal Ports | Integrate rail and truck transport with shipping | Logistics and supply chain management | Pros: Streamlined transport; Cons: Potential congestion due to multiple transport modes. |

| Regional Ports | Serve specific geographic areas; smaller in scale | Local trade and regional distribution | Pros: Accessibility; Cons: Limited capacity and range of services compared to larger ports. |

What Are Deep-Draft Seaports and Their Importance for B2B Buyers?

Deep-draft seaports are designed to accommodate large vessels, making them ideal for container shipping and bulk cargo transport. Located primarily along the Atlantic and Pacific coasts, these ports can handle significant volumes, offering high efficiency and capacity. For B2B buyers, the primary consideration is the ability to transport large quantities of goods quickly. However, operational costs can be higher, and access may be limited to specific coastal locations.

How Do General Cargo Ports Serve Diverse Business Needs?

General cargo ports are versatile facilities that handle various cargo types, including breakbulk, containers, and roll-on/roll-off shipments. They are essential for businesses that require flexibility in their shipping operations. For international B2B buyers, these ports provide a broad range of services, though they may not have specialized facilities for specific goods. Buyers should weigh the benefits of versatility against the potential limitations in cargo handling capabilities.

Why Are Bulk Ports Critical for Specific Industries?

Bulk ports specialize in handling bulk commodities like grains, coal, and minerals, making them essential for industries reliant on these materials. They offer efficiency in loading and unloading, which is crucial for agricultural exports and energy resources. B2B buyers in these sectors benefit from lower handling costs and streamlined operations. However, the limitation to specific cargo types can restrict options for businesses looking to diversify their shipping needs.

What Advantages Do Intermodal Ports Offer for Supply Chain Management?

Intermodal ports integrate shipping with rail and truck transport, facilitating seamless logistics and supply chain management. This type of port is particularly advantageous for B2B buyers who prioritize efficiency and speed in their operations. The streamlined transport options can significantly reduce transit times. However, potential congestion due to multiple transport modes can create challenges, making it essential for buyers to plan their logistics carefully.

How Do Regional Ports Support Local Trade?

Regional ports serve specific geographic areas and are typically smaller in scale compared to their larger counterparts. They play a vital role in local trade and regional distribution, providing accessible shipping solutions for businesses within their vicinity. For B2B buyers, regional ports offer convenience and lower costs. However, their limited capacity and range of services may not meet the needs of larger operations or those requiring extensive logistics support.

Key Industrial Applications of how many sea port in usa

| Industry/Sector | Specific Application of how many sea port in usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Exporting bulk commodities (e.g., grains, soybeans) | Access to international markets, improved pricing for producers | Understanding port capacity, shipping schedules, and customs processes |

| Manufacturing | Importing raw materials and exporting finished goods | Streamlined supply chain, reduced transportation costs | Evaluating port logistics, availability of intermodal transport options |

| Energy | Transporting oil, gas, and renewable energy components | Efficient distribution, reduced transit time | Compliance with environmental regulations, capacity for specialized vessels |

| Retail | Importing consumer goods and electronics | Enhanced inventory management, faster time-to-market | Assessing port connectivity, customs clearance processes |

| Logistics and Distribution | Utilizing ports for warehousing and distribution centers | Cost savings through optimized supply chain logistics | Infrastructure availability, proximity to major trade routes |

How Do Ports Facilitate Agricultural Exports?

U.S. ports play a pivotal role in the agricultural sector by enabling the export of bulk commodities such as grains and soybeans. For international buyers, particularly from regions like Africa and South America, understanding the capacity and operational efficiency of these ports is crucial. Efficient port operations help secure better pricing for producers by ensuring timely deliveries and reducing spoilage. Buyers must consider factors like port accessibility, shipping schedules, and customs processes to optimize their export strategies.

What Benefits Do Manufacturers Gain from U.S. Ports?

Manufacturers leverage U.S. ports for importing raw materials and exporting finished goods, which enhances their supply chain efficiency. By utilizing ports, manufacturers can significantly reduce transportation costs and improve their time-to-market. For international B2B buyers, especially from Europe and the Middle East, it is essential to evaluate port logistics, including loading and unloading capabilities, to ensure seamless operations. Understanding the specific requirements for customs clearance and the availability of intermodal transport options can further streamline the manufacturing process.

How Are Energy Companies Impacted by Port Operations?

Energy companies rely on U.S. ports for the transportation of oil, gas, and renewable energy components. The efficient distribution facilitated by these ports allows for reduced transit times and better market responsiveness. For international buyers in regions like Africa and South America, compliance with environmental regulations and the capability to handle specialized vessels are critical considerations when sourcing energy products. Ports that offer robust infrastructure and capacity for energy logistics will provide significant advantages in meeting global energy demands.

What Role Do Ports Play in Retail Supply Chains?

In the retail sector, U.S. ports are essential for importing consumer goods and electronics, allowing businesses to enhance inventory management and reduce time-to-market. For international buyers, understanding the connectivity of ports to major distribution centers is vital for optimizing logistics. Fast customs clearance processes can significantly impact inventory turnover rates. Retailers must assess port capabilities to ensure efficient supply chain operations, particularly when dealing with fluctuating demand in various markets.

How Do Logistics and Distribution Companies Utilize Ports?

Logistics and distribution companies use U.S. ports as strategic hubs for warehousing and distribution centers. This utilization leads to cost savings through optimized supply chain logistics. For international buyers, especially those in regions like Europe and the Middle East, it is important to evaluate the infrastructure availability at ports and their proximity to major trade routes. Understanding the operational capacity of these ports can greatly enhance the efficiency of logistics operations, ensuring timely deliveries and customer satisfaction.

3 Common User Pain Points for ‘how many sea port in usa’ & Their Solutions

Scenario 1: Navigating Port Selection for Efficient Shipping

The Problem: For international B2B buyers, determining the optimal sea port in the U.S. for shipping can be daunting. With approximately 360 commercial ports, each varying in capacity, specialization, and geographical advantages, buyers often find it challenging to assess which port best aligns with their logistical needs. Factors such as cargo type, destination, and potential delays due to labor disputes or port congestion complicate the decision-making process. This uncertainty can lead to increased shipping costs, delayed deliveries, and ultimately, dissatisfaction among end customers.

The Solution: To effectively navigate port selection, buyers should conduct a thorough analysis of their shipping needs and the capabilities of various ports. Begin by categorizing your cargo type (e.g., bulk, containerized, perishable goods) and identifying the ports that specialize in handling such goods. Utilize port authority websites and industry reports to gather data on performance metrics like TEU capacity and average turnaround times. Additionally, establish relationships with logistics providers who have in-depth knowledge of U.S. ports. They can offer insights into recent developments, such as infrastructure improvements and labor conditions, that may affect port performance. This proactive approach will enable buyers to make informed decisions, optimizing their shipping strategy and reducing costs.

Scenario 2: Understanding Infrastructure Limitations

The Problem: International buyers often encounter significant challenges related to port infrastructure limitations. Many U.S. ports are undergoing modernization efforts, which can lead to temporary disruptions in service. For example, ports like Savannah and New York/New Jersey are expanding their capacities and deepening channels to accommodate larger vessels. However, these projects can result in delays and unpredictability, causing buyers to experience supply chain disruptions if they are unaware of these changes.

The Solution: To mitigate the risks associated with infrastructure limitations, buyers should stay informed about the ongoing and planned projects at key U.S. ports. Subscribing to newsletters from port authorities and logistics publications can provide timely updates on construction timelines, expected delays, and improvements that could enhance service capacity. Additionally, incorporating flexibility into supply chain logistics can buffer against potential disruptions. For instance, consider diversifying shipping routes or selecting alternative ports that may have less congestion. By remaining vigilant and adaptable, buyers can navigate infrastructure challenges more effectively, ensuring smoother operations.

Scenario 3: Responding to Labor Disruptions

The Problem: Labor disruptions at U.S. ports pose a significant concern for international B2B buyers. Strikes and negotiations involving dockworkers can halt operations, leading to substantial delays in cargo handling. For instance, recent labor disputes on the East Coast resulted in estimated economic losses of billions during strikes. Buyers risk facing unexpected delays and increased costs if they are caught unprepared for these disruptions.

The Solution: To address potential labor-related challenges, buyers should implement a risk management strategy that includes monitoring labor relations at critical ports. Engaging with industry associations or logistics experts can provide insights into labor trends and potential strike actions. Additionally, consider developing contingency plans that include alternative shipping strategies, such as using ports on the West Coast or diversifying suppliers to reduce reliance on a single port. Establishing strong relationships with freight forwarders who are well-versed in the dynamics of U.S. ports will also enhance resilience against labor disruptions. By proactively managing labor risks, buyers can maintain supply chain continuity and avoid costly delays.

Strategic Material Selection Guide for how many sea port in usa

What Are the Key Materials Used in U.S. Sea Ports and Their Properties?

When considering the strategic material selection for U.S. sea ports, several materials stand out due to their unique properties and suitability for various applications. This analysis focuses on four common materials: steel, concrete, fiberglass, and aluminum. Each material has distinct characteristics that influence its performance, cost, and applicability, especially for international B2B buyers.

How Does Steel Perform in Sea Port Applications?

Steel is a primary material used in the construction of port infrastructure, including cranes, storage facilities, and bulkheads. Its key properties include high tensile strength and excellent durability, making it suitable for heavy loads and harsh marine environments. Steel’s corrosion resistance can be enhanced through galvanization or coatings, which is crucial given the exposure to saltwater.

Pros: Steel is durable, cost-effective, and readily available, which makes it a popular choice for large-scale construction projects.

Cons: However, it can be prone to rust and requires regular maintenance, which can increase long-term costs. Additionally, its weight can complicate transportation and installation.

For international buyers, compliance with standards such as ASTM A36 for structural steel is essential. Understanding local regulations regarding corrosion protection is also crucial, especially in regions with high humidity or salt exposure.

What Role Does Concrete Play in Port Construction?

Concrete is another fundamental material used in port development, particularly for pavements, piers, and bulkheads. Its properties include high compressive strength and excellent durability, which are essential for withstanding heavy loads and environmental stressors.

Pros: Concrete is fire-resistant, has low maintenance costs, and can be molded into various shapes, making it versatile for different applications.

Cons: On the downside, concrete is susceptible to cracking and can be less flexible than other materials. The curing process can also be time-consuming, delaying project timelines.

International buyers should consider compliance with standards like ASTM C150 for Portland cement. Additionally, understanding the local climate’s impact on concrete performance is vital, particularly in regions prone to freeze-thaw cycles.

How Does Fiberglass Compare in Port Applications?

Fiberglass is increasingly used in port applications, particularly for components like grating, handrails, and other structural elements exposed to corrosive environments. Its key properties include lightweight, high corrosion resistance, and low thermal conductivity.

Pros: Fiberglass is resistant to chemical damage and does not rust, making it ideal for marine environments. Its lightweight nature simplifies handling and installation.

Cons: However, fiberglass can be more expensive than traditional materials and may require specialized labor for installation and repairs.

For international buyers, adherence to standards such as ASTM D638 for tensile properties is crucial. Buyers should also consider the availability of skilled labor for fiberglass installation in their regions.

What Are the Benefits of Using Aluminum in Port Infrastructure?

Aluminum is often utilized for lighter structures and components in ports, such as gangways and railings. Its properties include excellent corrosion resistance and a high strength-to-weight ratio, which makes it suitable for various applications.

Pros: Aluminum is lightweight, easy to fabricate, and offers good durability, making it an attractive option for many port applications.

Cons: The primary disadvantage is its higher cost compared to steel and concrete, which can be a limiting factor for large-scale projects.

International buyers should ensure compliance with standards like ASTM B221 for aluminum extrusions. Understanding local market conditions and preferences for aluminum versus steel or concrete is also important.

Summary Table of Material Selection for U.S. Sea Ports

| Material | Typical Use Case for how many sea port in usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Cranes, storage facilities, bulkheads | High strength and durability | Prone to rust, requires maintenance | Medium |

| Concrete | Pavements, piers, bulkheads | Fire-resistant, low maintenance | Susceptible to cracking, slow curing | Medium |

| Fiberglass | Grating, handrails, structural elements | Corrosion-resistant, lightweight | Higher cost, specialized labor needed | High |

| Aluminum | Gangways, railings | Lightweight, easy to fabricate | Higher cost compared to steel | High |

This material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on the specific needs and conditions of their projects in U.S. sea ports.

In-depth Look: Manufacturing Processes and Quality Assurance for how many sea port in usa

What Are the Main Stages in Manufacturing Processes for Sea Ports in the USA?

The manufacturing processes involved in the construction and operation of sea ports in the USA encompass several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring that port facilities can handle the complexities of modern shipping demands.

-

Material Preparation: This initial stage involves sourcing high-quality materials essential for building port infrastructure. Common materials include steel for cranes and loading equipment, concrete for dock surfaces, and specialized coatings to protect against corrosion. Suppliers should be vetted for their ability to provide materials that meet specific industry standards, ensuring durability and safety.

-

Forming: Once materials are prepared, they undergo forming processes. Techniques like welding, casting, and machining are employed to create components such as piers, container cranes, and cargo handling equipment. Advanced technologies, including CNC machining and robotic welding, can enhance precision and efficiency, critical for meeting the high demands of port operations.

-

Assembly: The assembly stage combines the formed components into functional units. This process often takes place on-site, where skilled laborers fit together massive structures like gantry cranes or container stacks. Coordination with logistics is essential here to ensure that the assembly process aligns with the port’s operational timelines.

-

Finishing: The finishing stage involves applying protective coatings, painting, and conducting final inspections. This step is crucial for ensuring that all structures can withstand the harsh marine environment. Quality assurance checks during this stage may include surface testing for coatings and structural integrity assessments.

Which Key Techniques Are Used in Sea Port Manufacturing?

Manufacturing processes in sea ports leverage several advanced techniques to enhance efficiency and safety. Key techniques include:

- Modular Construction: This approach allows for prefabrication of components off-site, reducing on-site construction time and minimizing disruption to port operations.

- 3D Printing: Emerging in the maritime sector, 3D printing can produce complex parts that would be difficult or costly to manufacture using traditional methods.

- Digital Twin Technology: By creating a virtual model of port infrastructure, operators can simulate operations and identify potential issues before they arise, optimizing maintenance and operational efficiency.

What International Standards Apply to Quality Assurance in Sea Ports?

Quality assurance in the manufacturing processes of sea ports is governed by various international standards. The most significant include:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is applicable to any organization, including port authorities and suppliers. Compliance with ISO 9001 ensures that processes are consistent and continuously improved.

- ISO 14001: Focused on environmental management, this standard is crucial for ports aiming to minimize their ecological footprint and comply with environmental regulations.

- CE Marking: For equipment used in European ports, CE marking indicates conformity with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints in Port Manufacturing?

Quality control (QC) is essential at various checkpoints throughout the manufacturing process. These checkpoints include:

- Incoming Quality Control (IQC): This initial inspection verifies that materials meet specified standards before they enter the manufacturing process.

- In-Process Quality Control (IPQC): Conducted during the manufacturing stages, IPQC ensures that each step adheres to quality standards, reducing the risk of defects.

- Final Quality Control (FQC): The final inspection occurs after assembly and finishing, confirming that the completed structures and equipment meet all regulatory and operational standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is crucial. Here are several methods to ensure supplier compliance:

- Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and adherence to quality standards. Audits should assess compliance with ISO certifications and other relevant standards.

- Quality Reports: Requesting detailed quality reports can help buyers understand the QC measures implemented by suppliers. These reports should include data on defect rates, inspection results, and corrective actions taken.

- Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased evaluation of a supplier’s manufacturing and quality assurance processes. This is particularly important for international transactions where direct oversight may be challenging.

What Are Common Testing Methods for Ensuring Quality in Port Manufacturing?

Testing methods employed in the manufacturing of port facilities and equipment can vary depending on the specific components but typically include:

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle inspection assess the integrity of materials without causing damage.

- Load Testing: For cranes and lifting equipment, load testing ensures that they can handle specified weights safely and effectively.

- Environmental Testing: This testing evaluates how materials and structures will perform under various environmental conditions, including exposure to saltwater, temperature fluctuations, and heavy winds.

How Do QC and Certification Nuances Affect International B2B Buyers?

International B2B buyers need to be aware of the nuances in QC and certification processes that may vary by region. For example:

- Regulatory Differences: Different countries have varying regulations regarding safety and environmental standards. Buyers must ensure that suppliers comply with both local and international standards.

- Cultural Factors: Understanding cultural approaches to quality assurance can help buyers communicate effectively with suppliers and ensure mutual understanding of quality expectations.

- Documentation Requirements: Buyers should familiarize themselves with the documentation required for importing port-related equipment and materials, which may include certificates of compliance, quality reports, and customs documentation.

Conclusion

Navigating the complexities of manufacturing processes and quality assurance for sea ports in the USA requires a comprehensive understanding of various stages, techniques, and standards. For B2B buyers, particularly those from international markets, ensuring that suppliers meet rigorous quality standards is essential for successful partnerships and operational efficiency. By leveraging audits, quality reports, and third-party inspections, buyers can effectively verify supplier quality control processes and mitigate risks associated with international procurement.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how many sea port in usa’

In the dynamic landscape of global trade, understanding the number and capabilities of seaports in the United States is essential for international buyers. This guide provides a systematic approach to sourcing information about U.S. seaports, enabling you to make informed decisions for your logistics and supply chain needs.

Step 1: Identify Your Shipping Needs

Establish the specific requirements for your shipments, including cargo type, volume, and delivery timelines. Knowing whether you need a port capable of handling bulk, container, or specialized cargo will help narrow down suitable options. Consider the geographical proximity of ports to your suppliers and markets, as this can significantly affect shipping times and costs.

Step 2: Research the Number of Ports

The U.S. has approximately 360 commercial ports, with over 150 deep-draft ports located along its coasts and waterways. Understanding this landscape is vital for identifying potential ports for your logistics operations. Utilize resources such as the U.S. Coast Guard and the American Association of Port Authorities for up-to-date statistics and port directories.

Step 3: Evaluate Port Capacities and Infrastructure

Analyze the capacity and infrastructure of the ports you’re considering. Focus on metrics such as TEU (twenty-foot equivalent unit) handling capabilities, available facilities for loading/unloading, and intermodal connections (e.g., rail and road access). Ports with robust infrastructure can enhance your supply chain efficiency and reduce delays.

- Example Ports:

- Port of Los Angeles: 10.3 million TEUs in 2024.

- Port of New York and New Jersey: 8.7 million TEUs in 2024.

Step 4: Assess Proximity to Major Trade Routes

Look into the strategic location of ports concerning major shipping lanes and trade routes. Ports that are well-positioned can facilitate faster transit times and lower shipping costs. Consider how these routes align with your supply chain strategy and the potential for direct shipping options.

Step 5: Investigate Port Services and Support

Understand the range of services offered by each port, including customs clearance, warehousing, and specialized handling for certain types of cargo. Ports that provide comprehensive support can streamline your operations and mitigate potential disruptions. Check for any additional services that could benefit your logistics strategy.

Step 6: Consider Recent Developments and Investments

Stay informed about ongoing infrastructure projects and investments at various ports. Many U.S. ports are undergoing expansions and upgrades to enhance their capabilities. This can impact their future performance and your long-term logistics planning. Look for reports and news articles detailing recent developments, such as new terminal constructions or technological advancements.

Step 7: Connect with Port Authorities and Stakeholders

Engage directly with port authorities and logistics providers to gather firsthand insights. Building relationships with port representatives can provide valuable information about port operations, upcoming changes, and potential partnership opportunities. Attend trade shows or industry events to network with stakeholders in the maritime and logistics sectors.

By following these steps, B2B buyers can effectively navigate the complexities of U.S. seaports, ensuring that their logistics operations are efficient, cost-effective, and aligned with their business goals.

Comprehensive Cost and Pricing Analysis for how many sea port in usa Sourcing

What are the Key Cost Components in Sea Port Sourcing in the USA?

When considering sourcing through U.S. sea ports, it is essential to understand the cost structure involved. The primary cost components include:

-

Materials: This encompasses the cost of raw materials needed for goods being imported or exported. Prices can vary significantly based on the type of goods, market conditions, and availability.

-

Labor: Labor costs at ports can fluctuate due to factors such as union agreements and regional wage standards. Recent labor disruptions have highlighted the impact of labor negotiations on operational efficiency.

-

Manufacturing Overhead: This includes indirect costs related to the production of goods, such as utilities, rent, and administrative expenses. Understanding these costs is crucial for accurately assessing the total cost of port sourcing.

-

Tooling: Costs associated with the tools and equipment needed for production and handling at the port. These can vary depending on the complexity of the goods being shipped.

-

Quality Control (QC): Ensuring that products meet specified standards can incur additional costs, particularly for international shipments that may require certifications or inspections.

-

Logistics: This is a significant cost driver, encompassing transportation from the port to the final destination. Factors such as distance, mode of transport, and volume can affect logistics costs.

-

Margin: This refers to the profit margin expected by suppliers and intermediaries. Understanding the margin expectations can aid in negotiating better pricing.

How Do Price Influencers Affect Sea Port Sourcing Costs?

Several factors can influence pricing when sourcing through U.S. sea ports:

-

Volume/MOQ: Larger order volumes often lead to lower per-unit costs. Buyers should consider minimum order quantities (MOQs) to negotiate better terms.

-

Specifications/Customization: Customized goods typically come with higher costs due to the additional resources needed for design and production. Clear specifications can help avoid unexpected expenses.

-

Materials: The choice of materials directly impacts pricing. Buyers should evaluate alternative materials that may offer cost savings without sacrificing quality.

-

Quality/Certifications: Goods requiring certifications or compliance with international standards can incur additional costs. Understanding these requirements early in the sourcing process can prevent delays and unexpected expenses.

-

Supplier Factors: The reliability and reputation of suppliers can affect pricing. Established suppliers may charge a premium for their services due to their proven track record.

-

Incoterms: The terms of shipping (Incoterms) determine the responsibilities of buyers and sellers during transportation. Understanding these terms is crucial for calculating total costs.

What Buyer Tips Can Help in Navigating Sea Port Sourcing?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can leverage several strategies to optimize costs:

-

Negotiation: Engage in active negotiations with suppliers. Discussing pricing structures, volume discounts, and payment terms can yield substantial savings.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the purchase price. This approach considers long-term costs associated with logistics, maintenance, and operational efficiencies.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that can significantly impact final costs. Understanding these nuances can aid in budgeting and pricing strategies.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing and terms over time. Trust can foster collaboration and improve negotiation outcomes.

-

Market Research: Stay informed about market trends and pricing fluctuations in the U.S. port sector. This knowledge can empower buyers to make more informed decisions.

Conclusion

While sourcing through U.S. sea ports presents various costs and pricing considerations, understanding the key components and influencers can significantly enhance decision-making for international B2B buyers. By leveraging effective negotiation strategies and focusing on the total cost of ownership, buyers can optimize their sourcing processes and achieve competitive advantages in their markets. Always consult with experts and conduct thorough research to navigate the complexities of international trade effectively.

Alternatives Analysis: Comparing how many sea port in usa With Other Solutions

Exploring Alternatives to Understanding Sea Port Capacity in the USA

In the complex landscape of international trade, understanding the capabilities and limitations of sea ports is crucial for B2B buyers. While assessing the number of sea ports in the USA provides valuable insights into maritime logistics, several alternative methods and technologies can also aid in understanding and optimizing shipping routes and capacity. This section compares the traditional approach of counting sea ports against two viable alternatives: utilizing port management software and leveraging intermodal transportation systems.

| Comparison Aspect | How Many Sea Port In USA | Port Management Software | Intermodal Transportation Systems |

|---|---|---|---|

| Performance | Provides a quantitative overview of port capacity and location. | Offers real-time analytics and data visualization for operational efficiency. | Facilitates seamless cargo movement across multiple transportation modes. |

| Cost | Generally low-cost; mainly involves data collection and reporting. | Moderate to high; depending on software features and subscription models. | Varies widely based on infrastructure and service providers involved. |

| Ease of Implementation | Straightforward; relies on existing port data and government resources. | Requires training and integration with existing logistics systems. | Can be complex; involves coordination among multiple carriers and modes. |

| Maintenance | Minimal ongoing effort; data needs updating periodically. | Ongoing software support and updates required. | Requires continuous relationship management with various carriers. |

| Best Use Case | Ideal for understanding the static capacity and geographical distribution of ports. | Best for companies needing real-time data for operational decision-making. | Suitable for businesses looking to optimize logistics across different transport modes. |

Analyzing Port Management Software as an Alternative

Port management software provides a robust alternative to simply counting sea ports in the USA. This technology offers real-time data analytics, enabling businesses to track cargo movement, optimize supply chain operations, and enhance decision-making processes. The primary advantage of this approach lies in its ability to provide actionable insights that can lead to cost savings and increased efficiency. However, the implementation cost can be significant, and companies may require training to maximize the software’s potential.

Evaluating Intermodal Transportation Systems as an Alternative

Intermodal transportation systems represent another alternative for understanding and optimizing cargo movement beyond just focusing on sea ports. This method integrates various modes of transportation—such as rail, truck, and sea—allowing for more flexible logistics solutions. The best use case for intermodal systems arises when companies need to navigate complex supply chains or address capacity limitations at specific ports. However, coordinating logistics across multiple carriers can introduce complexities and variable costs, making it essential for businesses to weigh these factors against their operational needs.

Making an Informed Choice: Selecting the Right Solution for Your Needs

When evaluating how to approach maritime logistics, B2B buyers must consider their specific operational requirements and the trade-offs associated with each method. While understanding the number of sea ports in the USA offers foundational insights, leveraging advanced technologies like port management software and intermodal transportation systems can provide enhanced capabilities for optimizing supply chains. Ultimately, the choice should be driven by factors such as budget, operational complexity, and the need for real-time data. By carefully assessing these alternatives, businesses can position themselves for success in the global marketplace.

Essential Technical Properties and Trade Terminology for how many sea port in usa

What Are the Key Technical Properties of U.S. Sea Ports?

Understanding the technical specifications of U.S. sea ports is essential for international B2B buyers seeking efficient trade routes and logistics solutions. Here are some critical specifications that define the operational capabilities of these ports:

-

TEU Capacity

TEU (Twenty-foot Equivalent Unit) is a standard measure used to quantify cargo capacity in container shipping. It represents the capacity of a shipping container that is 20 feet long. Knowing the TEU capacity of a port is crucial for buyers as it helps in assessing the port’s ability to handle shipping volumes, which directly affects supply chain efficiency. -

Draft Depth

Draft depth refers to the vertical distance between the waterline and the bottom of the ship’s hull (keel). It is a vital specification for determining which vessels can dock at a port. Ports with deeper drafts can accommodate larger vessels, enabling the handling of more cargo and reducing shipping costs. For B2B buyers, understanding draft depth aids in selecting ports that can handle their specific shipping needs. -

Berth Length

Berth length is the linear space available for vessels to dock. Longer berths allow for the simultaneous docking of multiple vessels, improving turnaround times and overall port efficiency. For businesses that rely on just-in-time shipping, this is a significant factor in minimizing delays and optimizing logistics. -

Cargo Handling Equipment

This includes cranes, forklifts, and other machinery used to load and unload cargo. The type and efficiency of cargo handling equipment can impact the speed and cost of operations at a port. Buyers should consider ports equipped with modern, efficient machinery to ensure quick turnaround times and lower operational costs. -

Intermodal Connectivity

Intermodal connectivity refers to how well a port integrates with other transportation modes, such as rail, road, and air. Ports with robust intermodal facilities can facilitate seamless transfers between different transport methods, enhancing supply chain efficiency. For B2B buyers, evaluating intermodal connectivity is crucial for optimizing logistics and reducing shipping times.

What Are the Common Trade Terms Related to U.S. Sea Ports?

Familiarity with industry terminology is essential for B2B buyers to navigate contracts, negotiations, and logistics effectively. Here are some common trade terms you should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of sea ports, OEMs might be relevant for companies sourcing equipment or machinery for their shipping needs. Understanding this term helps buyers identify reliable suppliers and manufacturers. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers to understand as it influences purchasing decisions and inventory management. Knowing the MOQ can help companies negotiate better terms and manage supply costs effectively. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a company solicits price quotes from suppliers for specific products or services. In maritime trade, an RFQ may be used to request shipping rates from different ports or carriers. This process is vital for ensuring competitive pricing and informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that outline the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers to clarify shipping responsibilities, costs, and risks involved in importing or exporting goods. -

Port Authority

A port authority is a public or private authority responsible for managing and overseeing port operations. They play a critical role in infrastructure development, security, and regulatory compliance. For businesses, knowing the port authority’s role can aid in understanding the operational framework and potential regulatory hurdles.

By familiarizing yourself with these technical properties and trade terms, you can make informed decisions that optimize logistics, reduce costs, and improve your overall supply chain strategy when utilizing U.S. sea ports.

Navigating Market Dynamics and Sourcing Trends in the how many sea port in usa Sector

What Are the Key Market Dynamics and Trends in the U.S. Seaport Sector?

The U.S. seaport sector plays a crucial role in global trade, with approximately 360 commercial ports facilitating diverse shipping activities. As of 2024, significant growth has been observed, with major ports like Los Angeles, New York/New Jersey, and Savannah achieving record container throughput. This surge is driven by various global factors, including the post-pandemic recovery of supply chains, rising consumer demand, and increased freight volumes, particularly from emerging markets in Africa, South America, and the Middle East.

International B2B buyers should also be aware of the growing emphasis on digitization in the sector. Technologies such as blockchain, IoT, and AI are revolutionizing logistics, enhancing transparency, and improving operational efficiency. For instance, port authorities are increasingly adopting automated systems to streamline cargo handling and reduce turnaround times. This trend presents opportunities for B2B buyers to leverage efficient logistics and minimize costs in their supply chains.

Another critical aspect is the ongoing infrastructure investments, with billions allocated to modernize facilities and expand capacity. Ports like Savannah and Los Angeles are leading the way with projects that aim to accommodate larger vessels and enhance intermodal connections. Buyers should monitor these developments closely, as they may influence shipping costs, delivery times, and overall market accessibility.

How Are Sustainability and Ethical Sourcing Impacting the U.S. Seaport Sector?

Sustainability is becoming a key consideration for B2B buyers operating in the U.S. seaport sector. Environmental concerns, driven by climate change and regulatory pressures, are prompting ports to adopt greener practices. Initiatives such as clean energy use, emissions reduction, and waste management are gaining traction. For instance, ports are investing in electrification of operations and transitioning to renewable energy sources to minimize their carbon footprint.

Moreover, ethical sourcing is becoming integral to supply chain strategies. Buyers are increasingly prioritizing suppliers who demonstrate commitment to sustainable practices. This includes sourcing materials from certified green suppliers and ensuring that their supply chains are free from exploitation and environmental degradation. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming essential for businesses aiming to align with sustainability goals.

For international buyers from regions like Africa, South America, and Europe, partnering with U.S. ports that prioritize sustainability can enhance brand reputation and market competitiveness. This trend not only supports compliance with growing regulations but also meets the expectations of environmentally conscious consumers.

What Is the Historical Context of U.S. Seaports Relevant to B2B Buyers?

The evolution of U.S. seaports dates back to the early colonial period when they served as crucial nodes for trade and commerce. Over centuries, these ports have adapted to changing economic landscapes, technological advancements, and shifts in global trade patterns. The establishment of the Interstate Highway System and advancements in containerization in the mid-20th century significantly transformed port operations, enabling faster and more efficient cargo movement.

In recent decades, U.S. ports have faced new challenges, including globalization and increased competition from international ports. This has led to a concerted effort to modernize infrastructure and enhance operational capabilities. For B2B buyers, understanding this historical context is vital, as it highlights the resilience and adaptability of U.S. ports, which continue to be pivotal in global trade dynamics. By leveraging these insights, buyers can make informed decisions when sourcing from or partnering with U.S. ports.

Frequently Asked Questions (FAQs) for B2B Buyers of how many sea port in usa

-

How many commercial sea ports are there in the USA?

The United States has approximately 360 commercial ports, according to the U.S. Coast Guard. These ports accommodate various types of vessels, including ocean-going cargo ships, barges, and ferries. Among these, more than 150 are classified as deep draft seaports located along the Atlantic and Pacific Oceans, the Great Lakes, the Gulf of Mexico, and other regions. This extensive network supports significant trade activities, contributing to the U.S. economy and facilitating international commerce. -

What are the largest ports in the United States for international trade?

The largest ports in the U.S. for international trade include the Port of Los Angeles, Port of New York and New Jersey, and Port of Houston. The Port of Los Angeles leads in container volume, handling over 10 million TEUs (Twenty-foot Equivalent Units) annually. These ports are critical for B2B buyers as they serve as major gateways for imports and exports, providing vital logistics and transportation infrastructure for global trade. -

How can I vet suppliers using U.S. sea ports?

To vet suppliers effectively, consider requesting their shipping history and trade compliance records. Check if they regularly utilize major U.S. ports, as established supply chains are often linked to reputable carriers. Additionally, using platforms like the U.S. Customs and Border Protection’s trade database can help verify the legitimacy of suppliers. Engage in direct communication to assess their reliability, payment terms, and capacity to meet your specific needs. -

What are the typical payment terms for B2B transactions involving U.S. ports?

Payment terms can vary widely depending on the supplier and the nature of the transaction. Common practices include letters of credit, which provide security for both parties, and payment in advance, especially for first-time transactions. Net 30 or Net 60 terms are also prevalent, allowing buyers time to manage cash flow. Always clarify payment expectations upfront to avoid misunderstandings and ensure smoother transactions. -

What should I know about minimum order quantities (MOQ) when sourcing from U.S. ports?

Minimum order quantities (MOQ) can differ significantly between suppliers and are influenced by factors such as product type and production costs. When sourcing from U.S. ports, it’s essential to discuss MOQ with potential suppliers upfront. Some suppliers may have flexible MOQs for initial orders, while others may require larger quantities to optimize shipping and production efficiency. Understanding these terms can help you plan your inventory and reduce costs. -

How do logistics and transportation work with U.S. sea ports for international shipments?

Logistics involving U.S. sea ports typically include a multi-step process: goods are loaded onto vessels, transported to the designated port, and then unloaded for distribution. International shipments often involve freight forwarders who coordinate the movement of goods, ensuring compliance with customs regulations and documentation. Understanding the logistics framework is crucial for B2B buyers, as it affects delivery times, costs, and overall supply chain efficiency. -

What quality assurance practices should I consider when sourcing through U.S. ports?

Quality assurance is vital when sourcing products through U.S. ports. Implementing a robust QA process involves conducting inspections at various stages of production and shipment. Consider working with third-party inspection services to verify product quality before shipping. Additionally, reviewing supplier certifications and compliance with industry standards can help mitigate risks associated with product quality and ensure that you receive goods that meet your specifications. -

How do environmental regulations impact shipping through U.S. sea ports?

Environmental regulations play a significant role in shipping through U.S. ports, influencing operational practices and costs. Ports must comply with federal and state regulations aimed at reducing emissions and protecting marine environments. These regulations may lead to increased costs for shipping providers, which can affect pricing for B2B buyers. Staying informed about these regulations can help you anticipate potential changes in logistics and sourcing costs, allowing for better planning and decision-making.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for how many sea port in usa

The United States boasts approximately 360 commercial ports, with over 150 deep-draft seaports strategically located along its coastlines and inland waterways. This extensive network is vital for global trade, facilitating billions of dollars in cargo movements annually. Key ports like Los Angeles, New York/New Jersey, and Savannah are not only handling record volumes but also undergoing significant infrastructure upgrades, ensuring their competitiveness in an evolving maritime landscape.

For international B2B buyers, understanding the capabilities and growth potential of U.S. ports is essential for strategic sourcing. The ongoing investments in port infrastructure, such as rail enhancements and terminal expansions, promise to streamline logistics and reduce costs. Moreover, the resilience shown by these ports amidst labor challenges highlights their crucial role in maintaining supply chain stability.

As you consider your sourcing strategies, leveraging the strengths of U.S. ports can enhance your operational efficiency and market reach. Engage with U.S. port authorities and logistics providers to explore tailored solutions that align with your business objectives. The future of global trade is being shaped at these ports—position your business to benefit from this dynamic environment.