Top 9 Lunch Box Made Usa List and Guide: How To Solve Scenario 1:…

Introduction: Navigating the Global Market for lunch box made usa

In the dynamic landscape of international trade, sourcing high-quality lunch boxes made in the USA presents a unique challenge for B2B buyers, especially in markets like Africa, South America, the Middle East, and Europe. With an increasing demand for sustainable and durable food storage solutions, businesses must navigate a complex array of products that promise both functionality and compliance with safety standards. This guide serves as a comprehensive resource, addressing critical aspects such as types of lunch boxes available, their applications across various sectors, effective supplier vetting processes, and cost considerations.

By exploring the diverse offerings in the market—from eco-friendly stainless steel options to innovative bento-style containers—international buyers will gain insights into selecting products that meet their specific needs. Additionally, this guide emphasizes the importance of understanding regulatory requirements and quality certifications, ensuring that your purchasing decisions align with both consumer preferences and legal standards.

Empowering B2B buyers with actionable insights, this guide aims to facilitate informed purchasing decisions, helping businesses in regions like Nigeria and Brazil capitalize on the growing trend of American-made lunch boxes. With a focus on quality, sustainability, and market relevance, you will be equipped to make choices that enhance your product offerings and resonate with your customer base.

Top 10 Lunch Box Made Usa Manufacturers & Suppliers List

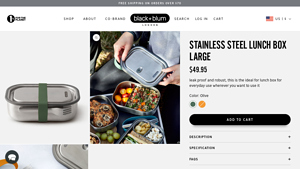

1. Black+Blum – Stainless Steel Lunch Box Large

Domain: blackblum.com

Registered: 2001 (24 years)

Introduction: Black+Blum Stainless Steel Lunch Box Large

– Price: $49.95

– Capacity: 1 litre / 34 fl oz

– Features: 100% leakproof, oven safe, freezer safe, includes fork and adjustable internal divider, plastic free

– Material: High quality stainless steel (304/18-8), silicone strap

– Dimensions: Length 7.87in, Width 5.91in, Height 2.56in

– Weight: 1 lb

– Variants: Olive, Orange (both sold out)

– Specification…

2. Bentgo – Bento Lunch Boxes and Accessories

Domain: bentgo.com

Registered: 2012 (13 years)

Introduction: Bentgo offers a variety of bento lunch boxes and accessories for kids and adults. Key products include: Bentgo Chill Kids Lunch Box ($32.99), Bentgo Kids Lunch Box ($29.99), Bentgo Kids Prints Lunch Bag ($24.99), Bentgo Chill Max Lunch Box ($39.99), Bentgo Kids Stainless Steel Lunch Box ($49.99), Bentgo Kids Water Bottle ($16.99), Bentgo Modern Lunch Box ($37.99), Bentgo Buddies Reusable Ice Packs…

3. USALoveList – Made in USA Lunch Bags and Bison Coolers

Domain: usalovelist.com

Registered: 2011 (14 years)

Introduction: Made in USA Lunch Bags and Lunch Gear for Kids and Adults: 1. Bags USA reusable lunch bags – Made in California, washable, holds sandwich, snack, and small water bottle, available in various colors. 2. Bison Coolers SoftPac line – Made in the USA, durable, leak-proof, includes Work N Play soft sided cooler and 12 can insulated cooler, comes with a 2-year warranty. 3. Cinda b. Snap Tote – Made in t…

4. Frost River – Lunch Bag Collection

Domain: frostriver.com

Registered: 2003 (22 years)

Introduction: {“name”: “Lunch Bag”, “styles”: [{“style”: “Lunch Bag”, “code”: “933”}, {“style”: “SB Lunch Bag”, “code”: “966”}, {“style”: “Lunch Tote”, “code”: “934”}], “size”: {“Lunch Bag”: “11in H x 8in W x 5in D (8.52 L)”, “Lunch Tote”: “7in H x 11in W x 4in D”}, “weight”: {“Lunch Bag”: “0.50 lbs”, “Lunch Tote”: “0.25 lbs”}, “closure”: {“Lunch Bag”: “Harness leather strap”, “Lunch Bag SB”: “Brass post with s…

5. Igloo – Playmate Elite 16-qt Cooler

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for a lunchbox/cooler made in the USA that is affordable. Currently using the ISO mini but it’s too small. Budget is under $100. Suggested options include the Igloo Playmate Elite 16-qt cooler, AO, Soft Cooler Company, and Bison (though Bison may be over $100).

6. Union Wear – Custom Insulated Lunch Bags and Coolers

Domain: unionwear.com

Registered: 1997 (28 years)

Introduction: Custom insulated lunch bags and coolers are ideal for picnics and outdoor activities. They can be personalized in various colors, styles, and sizes. Popular options include: Embroidered Insulated Lunch Bags, Printed Insulated Lunch Coolers, Insulated Lunch Cooler Tote Bags, Business Insulated Grocery Totes, and 6 Pack Coolers. Unionwear is a USA-based manufacturer, ensuring quality workmanship and…

7. Ore Originals – Mostly Mushroom Bento Box

8. Leeline Bags – Premium Made in USA Lunch Bags

Domain: leelinebags.com

Registered: 2024 (1 years)

Introduction: 10 Premium Made in USA Lunch Bag Types: 1. Titan by Arctic Zone Lunch Bags – Durable, water-resistant fabric, 9.5″ x 7″ x 6.5″, Insulated, Up to 8.2 lbs, Professionals and outdoor enthusiasts. 2. Bklyn Bento Stainless Steel Lunch Box – Stainless steel, 6.5″ x 5″ x 3.1″, Not insulated, 6.3 cups, Health-conscious consumers. 3. Hydro Flask Insulated Lunch Tote – Rigid nylon fabric, 13.5″ x 12.1″ x 5″…

9. Monbento – High-Quality Bento Boxes and Accessories

Domain: us.monbento.com

Registered: 2009 (16 years)

Introduction: monbento offers a variety of high-quality bento boxes, bottles, and accessories. Key products include: 34 floz Original Bento Box, 57.5 floz Large Size Bento Box, 27 floz Children’s Bento Box, 17 floz Children’s Bento Box (MB Foodie), 20.3 floz Snack Box (MB Gram), 11.2 floz Transparent To-Go Bottle (MB Positive S), and 12.2 floz Compact Insulated Bottle (MB Steel). The products are customizable, …

Understanding lunch box made usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel Lunch Boxes | Durable, leak-proof, vacuum-sealed, eco-friendly materials | Corporate gifting, employee lunches, catering | Pros: Long-lasting, easy to clean; Cons: Higher upfront cost. |

| Bento Boxes | Multi-compartment design, food-safe materials, customizable | School meal programs, child-focused catering | Pros: Versatile, encourages balanced meals; Cons: Limited capacity for larger portions. |

| Insulated Lunch Containers | Thermal insulation, keeps food hot/cold, durable materials | Meal prep services, outdoor catering | Pros: Temperature retention, suitable for diverse meals; Cons: Heavier and bulkier. |

| Collapsible Lunch Boxes | Space-saving design, lightweight, often made of silicone | Travel, outdoor events, emergency kits | Pros: Portable, easy storage; Cons: May not be as durable as rigid options. |

| Eco-friendly Lunch Boxes | Biodegradable or recyclable materials, sustainable production | Health-focused businesses, eco-conscious consumers | Pros: Environmentally friendly, appeals to green market; Cons: May have shorter lifespan than conventional materials. |

What are the key characteristics of stainless steel lunch boxes?

Stainless steel lunch boxes are known for their durability and eco-friendliness. They are often designed to be 100% leak-proof, thanks to innovative vacuum-sealed closures. This type is ideal for corporate gifting and employee lunches, as it reflects a commitment to sustainability. When purchasing, B2B buyers should consider the weight, size, and whether they come with additional features such as dividers or utensils.

How do bento boxes cater to diverse meal options?

Bento boxes feature multiple compartments, making them perfect for portion control and balanced meals. They are particularly popular in school meal programs and child-focused catering due to their fun designs and food-safe materials. Buyers should evaluate the size and compartment configuration to ensure they meet the specific needs of their target audience, especially when catering to children.

What advantages do insulated lunch containers offer?

Insulated lunch containers are designed to maintain food temperature, keeping meals hot or cold for extended periods. This is particularly advantageous for meal prep services and outdoor catering, where temperature control is crucial. Buyers should assess the insulation quality and capacity to ensure they can accommodate the types of meals they plan to serve.

Why choose collapsible lunch boxes for travel or outdoor events?

Collapsible lunch boxes are lightweight and designed for easy storage, making them ideal for travel and outdoor events. Their flexible nature allows them to save space when not in use, which is a significant consideration for businesses involved in outdoor catering or emergency preparedness. Buyers should look for materials that balance durability with the need for portability.

What makes eco-friendly lunch boxes appealing in today’s market?

Eco-friendly lunch boxes are made from biodegradable or recyclable materials, appealing to health-focused businesses and environmentally conscious consumers. They align with the growing trend toward sustainability, making them an attractive option for B2B buyers looking to enhance their brand image. However, it is essential to consider the longevity of these products as they may not last as long as traditional materials.

Key Industrial Applications of lunch box made usa

| Industry/Sector | Specific Application of lunch box made usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | School Meal Programs | Promotes healthy eating habits among students | Ensure compliance with food safety regulations and durability for daily use. |

| Corporate Catering | Employee Lunch Programs | Enhances employee satisfaction and productivity | Look for bulk purchasing options and customizable designs for branding. |

| Food Service | Meal Prep and Delivery Services | Streamlines packaging and reduces food waste | Prioritize leak-proof designs and materials that retain food freshness. |

| Health and Wellness | Nutrition-focused Meal Plans | Supports health initiatives and promotes balanced diets | Source eco-friendly materials and ensure ease of cleaning and maintenance. |

| Retail | Consumer Packaging for Lunch Box Products | Attracts health-conscious consumers and boosts sales | Evaluate market trends and consumer preferences for aesthetics and functionality. |

How Are Lunch Boxes Made in the USA Used in the Education Sector?

In the education sector, lunch boxes made in the USA are essential for school meal programs. They provide a practical solution for packing nutritious meals that encourage healthy eating habits among students. These lunch boxes often feature durable materials and leak-proof designs, ensuring that meals remain intact and fresh throughout the school day. For international buyers, especially from regions like Africa and South America, understanding local food safety regulations and sourcing products that can withstand daily use is crucial.

What Role Do Lunch Boxes Play in Corporate Catering?

Corporate catering services utilize lunch boxes made in the USA for employee meal programs, enhancing workplace satisfaction and productivity. By offering meals in attractive, functional packaging, businesses can promote a culture of health and wellness. Key considerations for sourcing include bulk purchasing options and the ability to customize lunch boxes with company branding. International buyers should also consider the logistics of shipping and storage, ensuring that products arrive in optimal condition.

How Are Lunch Boxes Beneficial for Food Service Providers?

Food service providers benefit significantly from using lunch boxes made in the USA for meal prep and delivery services. These containers streamline the packaging process and help reduce food waste by providing portion-controlled servings. Buyers should prioritize features like airtight seals and materials that maintain food freshness, especially in regions with varying climates, such as the Middle East and Europe. Additionally, understanding the local demand for eco-friendly options can enhance market competitiveness.

Why Are Lunch Boxes Important for Health and Wellness Initiatives?

In health and wellness sectors, lunch boxes made in the USA are pivotal for nutrition-focused meal plans. They facilitate the delivery of balanced meals designed to support health initiatives, making it easier for individuals to adhere to dietary guidelines. Buyers in this sector should focus on sourcing eco-friendly materials that align with sustainability goals, as well as ensuring that the products are easy to clean and maintain. This is particularly important for international buyers aiming to promote healthier lifestyles in their communities.

How Do Retailers Leverage Lunch Boxes for Consumer Sales?

Retailers leverage lunch boxes made in the USA as part of their product offerings, targeting health-conscious consumers. These lunch boxes often feature attractive designs and functional attributes that appeal to buyers looking for convenience and style. To maximize sales, it is essential for retailers to stay informed about market trends and consumer preferences regarding aesthetics and functionality. International buyers should consider local tastes and preferences when sourcing these products to ensure they meet consumer demands effectively.

3 Common User Pain Points for ‘lunch box made usa’ & Their Solutions

Scenario 1: Difficulty in Ensuring Food Safety and Compliance

The Problem: One of the major concerns for B2B buyers sourcing lunch boxes made in the USA is ensuring that the products meet local and international food safety regulations. Buyers from regions such as Africa and South America may face challenges in verifying that the materials used are food-safe, non-toxic, and comply with stringent safety standards. Additionally, with growing consumer awareness around health and sustainability, any lapses in compliance can lead to significant reputational damage and potential legal repercussions.

The Solution: To mitigate these risks, buyers should prioritize sourcing lunch boxes that provide transparent information regarding their materials and certifications. Look for products made from food-safe materials such as stainless steel or BPA-free plastics, and request documentation that proves compliance with FDA regulations or equivalent standards in your region. Establishing a relationship with manufacturers that offer detailed product specifications and certifications can ensure that the lunch boxes not only meet safety standards but also align with consumer expectations. Consider conducting third-party audits or inspections to verify compliance before making bulk purchases, ensuring peace of mind and protecting your brand’s integrity.

Scenario 2: Challenges with Product Durability and Longevity

The Problem: B2B buyers often find that many lunch boxes available in the market lack durability, leading to higher replacement costs and waste. This is particularly relevant for businesses in the Middle East and Europe, where extreme temperatures can impact product integrity. The need for lunch boxes that can withstand various environmental conditions while maintaining functionality is paramount for catering services, schools, and corporate clients.

The Solution: When selecting lunch boxes, prioritize those made from high-quality, robust materials that are designed for longevity. Stainless steel lunch boxes, for instance, offer superior durability compared to plastic alternatives and are less prone to cracking or warping. Additionally, consider sourcing products with features such as leak-proof seals and thermal insulation to enhance usability in diverse environments. Buyers should also inquire about the manufacturer’s warranty and return policy, as these can serve as indicators of product reliability. Investing in durable lunch boxes not only reduces long-term costs but also supports sustainability efforts by minimizing waste.

Scenario 3: Navigating Shipping and Import Regulations

The Problem: For international buyers, particularly in regions like Nigeria and Brazil, importing lunch boxes made in the USA can present logistical challenges. These challenges include navigating complex shipping regulations, dealing with customs duties, and ensuring timely delivery. Delays in shipping can disrupt supply chains, leading to lost sales opportunities and dissatisfied customers.

The Solution: To streamline the import process, buyers should work closely with logistics partners who specialize in international shipping and are familiar with the regulations governing imports in their respective countries. It’s essential to understand the tariffs and duties applicable to lunch boxes made in the USA, which can influence total costs. Establishing a clear communication channel with suppliers about shipping times and documentation requirements can help manage expectations. Additionally, consider consolidating orders to minimize shipping costs and taking advantage of bulk discounts. By proactively addressing logistical concerns, buyers can ensure a smoother procurement process and maintain a steady supply of lunch boxes for their business needs.

Strategic Material Selection Guide for lunch box made usa

What Are the Key Materials for Lunch Boxes Made in the USA?

When selecting materials for lunch boxes manufactured in the USA, it’s essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: stainless steel, plastic, glass, and silicone. Each material has unique characteristics that can significantly influence product performance and market suitability.

How Does Stainless Steel Perform for Lunch Boxes?

Stainless steel is renowned for its durability and resistance to corrosion, making it an excellent choice for lunch boxes. It can withstand high temperatures and is often rated for use in both ovens and freezers. The key properties include a high tensile strength and a temperature rating that allows it to endure extreme conditions without warping or degrading.

Pros: Stainless steel lunch boxes are robust, easy to clean, and do not retain odors or stains. They are also environmentally friendly, being recyclable and plastic-free.

Cons: The primary drawback is the cost, as stainless steel is generally more expensive than plastic. Additionally, its weight can be a concern for consumers looking for lightweight options.

For international buyers, compliance with food safety standards such as ASTM and FDA regulations is crucial. Countries in Africa and South America may have specific import regulations that must be adhered to, particularly regarding food contact materials.

What Role Does Plastic Play in Lunch Box Manufacturing?

Plastic is widely used in lunch box production due to its versatility and low cost. Common types include polypropylene (PP) and polyethylene (PE), which offer good temperature resistance and are generally microwave-safe.

Pros: The lightweight nature of plastic makes it easy to carry, and its lower manufacturing cost allows for competitive pricing. Additionally, plastic can be molded into various shapes and designs, appealing to a broader market.

Cons: However, plastic can leach chemicals if not properly manufactured, raising concerns about food safety. It is also less durable than metal or glass, often leading to wear and tear over time.

For international buyers, it’s essential to ensure that the plastic used meets local regulations regarding food safety. Compliance with standards like DIN or JIS can vary by region, and understanding these requirements is vital for successful market entry.

How Does Glass Compare for Lunch Box Applications?

Glass lunch boxes are gaining popularity due to their aesthetic appeal and non-reactive nature. They can handle high temperatures and are dishwasher safe, making them a practical choice for consumers.

Pros: Glass is completely inert, meaning it won’t leach chemicals into food, making it a safe option for meal storage. It is also easy to clean and can be recycled.

Cons: The main disadvantage of glass is its fragility. It can break easily, which poses a risk during transport. Additionally, glass lunch boxes are typically heavier than their plastic counterparts.

International buyers should be aware of the shipping and handling requirements for glass products, as they may need special packaging to prevent breakage. Compliance with safety standards is also necessary, especially in markets that prioritize food safety.

What Advantages Does Silicone Offer for Lunch Boxes?

Silicone is increasingly used in lunch box designs due to its flexibility, durability, and heat resistance. It can withstand a wide range of temperatures, making it suitable for both hot and cold foods.

Pros: Silicone is lightweight, non-toxic, and easy to clean. It can also be folded or collapsed, making it an excellent option for space-saving designs.

Cons: However, silicone can be more expensive than plastic and may not have the same level of structural integrity as metal options. Some consumers may also have concerns about the long-term durability of silicone.

For international buyers, ensuring that silicone products meet specific food safety standards is crucial. Understanding regional preferences and regulations will help in making informed purchasing decisions.

Summary Table of Material Selection for Lunch Boxes

| Material | Typical Use Case for lunch box made usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Durable lunch boxes for adults | High durability and corrosion resistance | Higher cost and weight | High |

| Plastic | Affordable lunch boxes for kids | Lightweight and versatile | Potential chemical leaching | Low |

| Glass | Aesthetic meal storage solutions | Non-reactive and safe for food | Fragile and heavier than plastic | Medium |

| Silicone | Flexible and collapsible lunch containers | Lightweight and heat resistant | Higher cost and potential durability concerns | Medium |

This guide provides B2B buyers with crucial insights into material selection for lunch boxes made in the USA, helping them make informed decisions that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for lunch box made usa

What Are the Main Stages of Manufacturing Lunch Boxes Made in the USA?

The manufacturing of lunch boxes in the USA involves several critical stages that ensure high-quality production. Understanding these stages is essential for international B2B buyers looking to source durable and reliable lunch boxes.

Material Preparation: What Types of Materials Are Used?

The first step in the manufacturing process is the selection and preparation of materials. Common materials for lunch boxes include high-grade stainless steel, BPA-free plastics, and silicone. Stainless steel is favored for its durability, ease of cleaning, and resistance to corrosion. During this stage, suppliers must ensure that all materials meet regulatory standards for food safety, which is crucial for compliance with both domestic and international markets. For instance, materials should be tested to ensure they are free from harmful substances such as lead and phthalates.

How Are Lunch Boxes Formed?

After materials are prepared, the next phase involves forming the lunch boxes. This can be achieved through various techniques, including:

-

Injection Molding: Primarily used for plastic components, this method involves injecting molten plastic into molds to create the desired shape. It is efficient for producing large quantities with consistent quality.

-

Sheet Metal Forming: For stainless steel lunch boxes, sheet metal forming techniques like stamping and bending are employed. These techniques allow for creating intricate designs while maintaining structural integrity.

-

Vacuum Forming: This method is often used for creating lids or components that require specific shapes. A sheet of plastic is heated and then formed over a mold using vacuum pressure.

Each technique has its advantages, and the choice often depends on the design specifications and intended use of the lunch box.

What Does the Assembly Process Entail?

Once the individual components are formed, they are assembled to create the final product. This stage may involve:

-

Joining Techniques: Components are often joined using welding for metal parts or adhesive bonding for plastic and silicone components. The choice of technique affects the product’s durability and leak-proof capabilities.

-

Integration of Features: Many modern lunch boxes come with additional features such as compartments, utensils, and insulation layers. This requires careful planning during the assembly process to ensure that all elements fit and function properly.

-

Final Assembly: The last step involves attaching lids, seals, and any additional components. This stage is crucial for ensuring that the lunch box is functional and meets the design specifications.

What Quality Control Measures Are Essential for Lunch Box Manufacturing?

Quality assurance is a vital aspect of the manufacturing process, particularly for products intended for food use. Implementing robust quality control measures ensures that the final product is safe and meets customer expectations.

What International Standards Should Be Considered?

Manufacturers of lunch boxes in the USA often adhere to various international standards to maintain quality. The ISO 9001 standard for quality management systems is widely recognized and helps organizations ensure consistent quality in their products. Additionally, compliance with food safety standards such as those set by the FDA is crucial for any product intended for food storage.

Industry-specific certifications, such as CE marking for European markets or the American National Standards Institute (ANSI) certifications, can also enhance credibility in international markets. B2B buyers should look for suppliers with these certifications to ensure compliance and quality assurance.

What Are the Key Quality Control Checkpoints?

Quality control in manufacturing typically involves several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This is the first checkpoint where raw materials are inspected upon arrival. Quality assurance teams verify that materials meet specified standards before they enter the production line.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor the quality of components and assembly. This helps identify and rectify any issues before the final product is completed.

-

Final Quality Control (FQC): Once the lunch boxes are fully assembled, they undergo final inspections. This includes checking for defects, ensuring proper sealing, and verifying that all features function as intended.

What Testing Methods Are Commonly Used?

To ensure the quality and safety of lunch boxes, manufacturers employ various testing methods, including:

-

Leak Testing: For lunch boxes designed to be leak-proof, rigorous testing is conducted to ensure that seals and closures function correctly under different conditions.

-

Material Testing: Tests are performed to verify that materials can withstand temperature changes and are free from harmful substances.

-

Durability Testing: This includes drop tests and stress tests to ensure the lunch box can withstand everyday use without breaking or deforming.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, ensuring that suppliers adhere to stringent quality control measures is critical. Here are some effective strategies:

What Audit Processes Should Be Followed?

Conducting regular audits of potential suppliers can provide insight into their quality control processes. Buyers should request documentation related to their quality management systems and any relevant certifications. On-site audits can also help verify compliance with international standards and assess the manufacturing environment.

How Important Are Reports and Documentation?

Suppliers should provide detailed reports on their quality control processes, including results from inspections and tests. This documentation can help buyers understand the reliability of the supplier and the quality of the products being manufactured.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can add an extra layer of assurance. These independent organizations can conduct audits, perform product testing, and verify compliance with international standards, giving buyers peace of mind when sourcing lunch boxes from USA manufacturers.

What Are the Nuances of Quality Control for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control. Different markets may have varying regulatory requirements, and understanding these can aid in selecting the right supplier. For instance, the EU has stringent regulations concerning food safety and material compliance, which may differ from standards in other regions.

Understanding cultural expectations regarding quality and safety can also influence purchasing decisions. Buyers should ensure that suppliers are capable of meeting their specific market needs, which may require additional certifications or testing.

By comprehensively understanding the manufacturing processes and quality assurance measures in place for lunch boxes made in the USA, international B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their quality standards and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lunch box made usa’

In today’s global market, sourcing quality lunch boxes made in the USA presents unique opportunities and challenges for international B2B buyers. This checklist will guide you through the essential steps to ensure a successful procurement process, focusing on quality, compliance, and supplier reliability.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it is vital to establish clear technical specifications for the lunch boxes you intend to procure. Consider factors such as materials (e.g., stainless steel, BPA-free plastic), size, weight, and features like leak-proof or microwave-safe capabilities. Having detailed specifications will help you communicate your needs effectively to suppliers and ensure that you receive products that meet your quality standards.

Step 2: Research Reputable Suppliers

Identifying reliable suppliers is crucial in ensuring product quality and consistency. Look for manufacturers with a proven track record in producing lunch boxes, preferably those with experience in exporting to international markets. Utilize resources such as trade directories, industry associations, and trade shows to gather information about potential suppliers.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for certifications that demonstrate compliance with safety and quality standards, such as FDA approval for food-safe materials or ISO certifications for manufacturing processes.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted potential suppliers, request product samples to evaluate quality firsthand. Inspect the lunch boxes for durability, design, and safety features. This step is vital to ensure that the products meet your specifications and can withstand the demands of your target market.

Step 5: Verify Supplier Certifications and Compliance

Ensure that the suppliers you are considering comply with relevant regulations and standards. This includes checking for certifications related to food safety, environmental impact, and labor practices. A supplier’s commitment to compliance not only protects your business but also enhances your brand’s reputation in international markets.

Step 6: Discuss Pricing and Payment Terms

Engage in discussions about pricing structures and payment terms with your chosen suppliers. Consider factors such as minimum order quantities, shipping costs, and lead times. Understanding the financial implications will help you budget appropriately and avoid unexpected costs during the procurement process.

Step 7: Establish Clear Communication Channels

Effective communication is essential for a successful sourcing relationship. Establish clear channels for regular updates and feedback throughout the procurement process. This can include setting up a dedicated point of contact and utilizing project management tools to track progress and address any issues that may arise.

By following this checklist, B2B buyers can streamline their sourcing process for lunch boxes made in the USA, ensuring they secure high-quality products that meet their operational needs and market demands.

Comprehensive Cost and Pricing Analysis for lunch box made usa Sourcing

What Are the Key Cost Components for Sourcing Lunch Boxes Made in the USA?

When considering the sourcing of lunch boxes made in the USA, it is essential to understand the various cost components that contribute to the final pricing. The primary factors include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and desired profit margins.

-

Materials: The choice of materials significantly affects the cost. Options like stainless steel, which is durable and eco-friendly, are often more expensive than plastic alternatives. For instance, a premium stainless steel lunch box could retail around $49.95, reflecting the quality of materials used.

-

Labor: Labor costs in the USA are generally higher than in many other countries. This includes wages, benefits, and associated costs for skilled workers who handle manufacturing and assembly.

-

Manufacturing Overhead: This encompasses costs related to the facility, utilities, and equipment maintenance. Given the push for sustainable practices, manufacturers may also incur additional costs for eco-friendly practices.

-

Tooling: Initial tooling costs for custom designs or molds can be significant, especially for lunch boxes with unique features or branding requirements. These costs are typically spread over the production volume.

-

Quality Control (QC): Ensuring that products meet safety and quality standards is crucial. This may involve testing materials and finished products, which can add to costs but is essential for maintaining a reputable brand.

-

Logistics: Shipping and handling fees vary based on the destination. International buyers should be aware of potential tariffs and customs duties that could impact the overall price.

-

Margin: Finally, the manufacturer’s profit margin will be factored into the final pricing. This can vary based on competition, market demand, and the perceived value of the product.

How Do Price Influencers Impact B2B Sourcing Decisions for Lunch Boxes?

Several factors influence the pricing of lunch boxes made in the USA, which international buyers should consider:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Higher volumes usually yield lower per-unit costs due to economies of scale.

-

Specifications and Customization: Custom designs or specific features can lead to increased costs. Buyers should clarify their requirements upfront to receive accurate quotes.

-

Materials and Quality Certifications: Products made with higher-quality materials or those that meet specific certifications (like food safety standards) will command higher prices.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established manufacturers may charge more due to their experience and quality assurance practices.

-

Incoterms: Understanding the Incoterms used in the contract is crucial. They define the responsibilities of buyers and sellers regarding shipping, which can impact overall costs.

What Buyer Tips Can Help Navigate the Sourcing Process for Lunch Boxes?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider several strategies to optimize their sourcing process:

-

Negotiation: Engage in discussions with suppliers to negotiate better terms, especially regarding volume discounts or payment terms. Building a good relationship can lead to more favorable pricing.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes all costs associated with the purchase, such as shipping, customs, and storage, not just the unit price.

-

Pricing Nuances: Be aware of fluctuations in material costs and labor rates, as these can change based on market conditions and regulations.

-

Research Local Market Trends: Understanding local market demands can help buyers identify which products are likely to sell well, allowing for more strategic ordering and pricing.

By comprehensively analyzing the cost structure and pricing influencers, international B2B buyers can make informed decisions when sourcing lunch boxes made in the USA. Always remember that indicative prices can fluctuate based on numerous factors, including market demand and raw material availability.

Alternatives Analysis: Comparing lunch box made usa With Other Solutions

Exploring Alternatives for Lunch Boxes: A Comparative Analysis

When considering the purchase of lunch boxes, especially those made in the USA, it’s essential to evaluate alternative solutions. This analysis provides insights into various options available in the market, focusing on their performance, cost, ease of implementation, maintenance, and best use cases. By understanding these alternatives, international B2B buyers can make informed decisions that align with their needs and preferences.

| Comparison Aspect | Lunch Box Made USA | Stainless Steel Lunch Box | Bentgo® Bento Lunch Box |

|---|---|---|---|

| Performance | High durability, 100% leakproof | Excellent insulation, robust design | Versatile compartments, keeps food fresh |

| Cost | Premium pricing | $49.95 | $32.99 – $49.99 |

| Ease of Implementation | Readily available, multiple designs | Requires proper sealing to ensure leakproof | User-friendly, easy to clean |

| Maintenance | Minimal; dishwasher safe | Hand wash lid and strap; dishwasher safe for body | Dishwasher safe; easy to clean |

| Best Use Case | Ideal for adults, office use | Best for meal preppers, outdoor activities | Designed for kids, school lunches |

In-Depth Analysis of Alternatives

Stainless Steel Lunch Box

This option is known for its robustness and leakproof capabilities, making it a reliable choice for transporting meals. The vacuum-sealed design ensures food freshness, which is crucial for business settings where meal quality matters. Although priced at $49.95, this lunch box is a worthy investment for those who prioritize durability and eco-friendliness. However, it requires careful handling to ensure it remains leakproof, and users should avoid using it in the microwave.

Bentgo® Bento Lunch Box

The Bentgo® brand focuses on versatility and user-friendliness, making it an excellent choice for families and individuals on the go. Priced between $32.99 and $49.99, these lunch boxes come with multiple compartments, making them perfect for portion control and variety. They are easy to clean and dishwasher safe, which enhances convenience. However, while they perform well for everyday use, they may not offer the same level of durability as stainless steel options.

Making the Right Choice for Your Business Needs

For international B2B buyers, selecting the right lunch box solution depends on specific needs. If durability and a premium design are paramount, a lunch box made in the USA could be the best fit. Alternatively, for buyers looking for versatility and ease of use, the Bentgo® Bento Lunch Box offers appealing features at a competitive price. Finally, if sustainability and robust performance are priorities, the stainless steel option stands out as a reliable choice.

In summary, each alternative presents unique benefits and trade-offs. Assessing the specific requirements of your target audience—be it for corporate gifts, employee lunches, or family meal prep—will ultimately guide you to the most suitable solution.

Essential Technical Properties and Trade Terminology for lunch box made usa

What Are the Key Technical Properties of Lunch Boxes Made in the USA?

When considering lunch boxes made in the USA, several technical properties are crucial for B2B buyers. Understanding these specifications can enhance product quality and consumer satisfaction.

1. Material Grade: What Grade of Stainless Steel is Used?

Stainless steel lunch boxes often use 304-grade stainless steel (also known as 18-8). This grade is highly resistant to corrosion and rust, making it ideal for food storage. The durability of this material ensures that the lunch boxes can withstand daily use without degrading. For B2B buyers, selecting products made from high-grade materials can lead to longer-lasting items, reducing replacement costs.

2. Leak-Proof Design: How is Leak Resistance Achieved?

A significant property of quality lunch boxes is their leak-proof design. Many products feature a vacuum-sealed closure and silicone seals that create an airtight environment. This design is essential for preventing spills and maintaining food freshness. For businesses, offering leak-proof lunch boxes can enhance customer satisfaction, particularly in markets where portability and cleanliness are paramount.

3. Capacity: What Volume Should You Expect?

Lunch boxes vary in capacity, typically ranging from 1 liter (34 fl oz) to larger sizes. Understanding the volume is vital for buyers targeting specific market segments, such as schools or corporate offices. A well-sized lunch box can cater to different consumer needs, from adults seeking healthy meal options to children needing smaller portions.

4. Temperature Resistance: Can It Withstand Extreme Conditions?

Temperature resistance is another critical property, especially for lunch boxes designed for both hot and cold foods. Many high-quality options are oven and freezer-safe, allowing for versatile usage. For B2B buyers, selecting lunch boxes that can withstand various temperatures increases the product’s appeal in diverse markets, enhancing its usability.

5. Ease of Cleaning: What Maintenance is Required?

Ease of cleaning is an essential feature for lunch boxes. Many designs are dishwasher-safe, while others require hand washing for certain components. The choice of materials can affect this property; for example, stainless steel is often easier to clean than plastic. Buyers should prioritize lunch boxes that facilitate easy maintenance, as this is a strong selling point for consumers.

What Trade Terminology Should B2B Buyers Understand?

Navigating the B2B landscape requires familiarity with specific trade terms that can influence purchasing decisions.

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of lunch boxes, an OEM might design and manufacture products that are then branded and sold by a different company. Understanding OEM relationships can help buyers identify potential partners for custom products.

2. MOQ (Minimum Order Quantity): Why Is It Important?

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers, as it affects inventory management and cash flow. Knowing the MOQ helps businesses assess their purchasing capabilities and negotiate better terms with suppliers.

3. RFQ (Request for Quotation): How Is It Used?

An RFQ is a document sent by a buyer to suppliers requesting price quotes for specific products. It is a critical step in the procurement process, enabling buyers to compare costs and make informed decisions. Crafting a clear RFQ can lead to better pricing and terms from suppliers.

4. Incoterms: What Are They and Why Do They Matter?

Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of sellers and buyers in international transactions. They clarify who is responsible for shipping costs, insurance, and risk during transport. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings and unexpected costs in global trade.

5. Lead Time: What Is It and How Does It Affect Orders?

Lead time refers to the amount of time it takes from placing an order to receiving it. For lunch box suppliers, understanding lead times is crucial for inventory planning and meeting customer demands. Buyers should consider lead times when placing orders to ensure timely delivery and maintain their supply chain efficiency.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring they select the best lunch boxes made in the USA for their market needs.

Navigating Market Dynamics and Sourcing Trends in the lunch box made usa Sector

What Are the Key Trends Influencing the Lunch Box Made in USA Market?

The lunch box market, particularly products made in the USA, is witnessing significant growth driven by various global factors. Increased health consciousness among consumers, particularly in regions like Africa, South America, the Middle East, and Europe, is pushing demand for eco-friendly and reusable lunch solutions. In addition, the rise of remote work and flexible dining options has led to a surge in demand for portable food containers, catering to professionals and families alike.

Emerging technologies in materials science are also reshaping the market landscape. Innovations in stainless steel and BPA-free plastics have resulted in durable, lightweight, and leak-proof products that appeal to international buyers. Furthermore, the integration of smart features, such as temperature control and built-in compartments, is attracting tech-savvy consumers who prioritize functionality.

For international B2B buyers, understanding these dynamics is crucial. The market is increasingly competitive, with brands focusing on unique selling propositions (USPs) like sustainability, design, and functionality. Buyers are encouraged to evaluate suppliers based on these trends and seek partnerships that align with their market demands.

How Is Sustainability and Ethical Sourcing Impacting the Lunch Box Made in USA Sector?

Sustainability is a pivotal concern in the lunch box market. With growing awareness of environmental issues, consumers are gravitating towards products that minimize ecological footprints. For international B2B buyers, sourcing lunch boxes made in the USA often translates to higher standards in manufacturing processes, including the use of recyclable materials and reduced emissions.

Ethical sourcing is equally vital, as it reflects a commitment to social responsibility and fair labor practices. Many US manufacturers are obtaining certifications like Fair Trade and Green Seal, which reassure buyers about the integrity of their supply chains. The emphasis on sustainable materials, such as stainless steel and organic cotton, is not only appealing to eco-conscious consumers but also helps brands differentiate themselves in a crowded market.

For B2B buyers, partnering with suppliers who prioritize sustainability can enhance their brand image and meet the increasing consumer demand for ethical products. This focus can also lead to potential cost savings in the long run, as sustainable practices often yield efficiencies in production and waste management.

What Is the Historical Context of the Lunch Box Made in USA Market?

The lunch box sector in the USA has evolved significantly over the decades. Initially, lunch boxes were primarily utilitarian, designed for school children and workers. However, as consumer preferences shifted towards personalization and aesthetic appeal, manufacturers began to introduce innovative designs, materials, and functionalities.

The 21st century has seen a remarkable transformation, with an increasing focus on sustainability and health consciousness. The rise of eco-friendly materials and the decline of single-use plastics have prompted manufacturers to rethink their product offerings. This evolution has made the “lunch box made in USA” an attractive option for international B2B buyers, as these products often embody quality craftsmanship and responsible manufacturing practices.

Understanding this historical context allows buyers to appreciate the growth trajectory of the market and make informed sourcing decisions that align with current trends and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of lunch box made usa

-

How do I ensure the lunch boxes I source are of high quality?

To ensure high-quality lunch boxes, conduct thorough supplier vetting. Request product samples to evaluate materials, design, and functionality. Check for certifications such as FDA approval or BPA-free labels, which indicate safety and compliance with international standards. Additionally, seek out reviews or testimonials from other B2B buyers and inquire about the supplier’s quality assurance processes. Regular audits of the manufacturing process can also help maintain quality standards. -

What customization options are available for lunch boxes made in the USA?

Many manufacturers offer customization options, including branding with logos, color choices, and material variations. Inquire about the minimum order quantities (MOQ) for customized products, as these can vary by supplier. Some manufacturers may also provide design services to help create unique lunch box styles that align with your brand. Make sure to clarify the lead times for customization, as they can impact your overall supply chain schedule. -

What are the typical minimum order quantities (MOQ) for lunch boxes sourced from the USA?

MOQs for lunch boxes can vary widely depending on the supplier and the product’s complexity. Generally, expect MOQs to range from 100 to 1,000 units. However, some suppliers may offer lower MOQs for standard products while requiring higher quantities for customized options. Discuss your needs with potential suppliers to negotiate favorable terms that align with your business model and budget. -

What payment terms should I expect when sourcing lunch boxes from the USA?

Payment terms can differ among suppliers, but common practices include a 30% deposit upon order confirmation with the balance due before shipment. Some suppliers might offer net payment terms, such as net 30 or net 60 days, especially for established business relationships. Always clarify payment methods accepted (e.g., bank transfer, credit card) and ensure all terms are documented in the purchase agreement to avoid disputes. -

How can I assess the reliability of a supplier for lunch boxes?

To assess a supplier’s reliability, evaluate their business history, production capacity, and client references. Request documentation of their certifications and adherence to international quality standards. Conducting a factory visit or third-party audit can provide insight into their operations. Additionally, check their responsiveness to inquiries and willingness to accommodate your needs, as these factors often indicate a supplier’s commitment to customer satisfaction. -

What are the logistics considerations for importing lunch boxes from the USA?

Logistics considerations include shipping methods (air vs. sea), customs clearance, and freight forwarding services. Determine the best shipping option based on cost, urgency, and the nature of the product. Understand the customs regulations in your country to avoid delays and additional charges. Partnering with a reliable freight forwarder can help navigate these complexities and ensure timely delivery. -

What are the common materials used in lunch boxes manufactured in the USA?

Lunch boxes are typically made from materials such as stainless steel, plastic, glass, and silicone. Stainless steel is favored for its durability and safety, while BPA-free plastics offer lightweight options. Glass containers provide an eco-friendly alternative but can be heavier. Consider the intended use and market preferences when selecting materials, as they can affect functionality, safety, and consumer appeal. -

How can I ensure compliance with international trade regulations when sourcing lunch boxes?

To ensure compliance with international trade regulations, familiarize yourself with both U.S. export laws and your country’s import regulations. Obtain necessary certifications for food safety, such as FDA compliance for materials in contact with food. Work with a customs broker who can guide you through the import process and help ensure all documentation, such as bills of lading and certificates of origin, is complete and accurate. Staying informed about tariffs and trade agreements can also benefit your sourcing strategy.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for lunch box made usa

In conclusion, the strategic sourcing of lunch boxes made in the USA presents a unique opportunity for international B2B buyers. The emphasis on high-quality materials, such as stainless steel, not only enhances product durability but also aligns with growing consumer preferences for sustainable and health-conscious options. Additionally, the innovative designs that prioritize leak-proof functionality and ease of use cater to a diverse range of customer needs, from busy professionals to families seeking practical meal solutions.

As you consider sourcing lunch boxes from the USA, it is crucial to evaluate suppliers based on their commitment to quality, sustainability, and customer satisfaction. Engaging with reputable manufacturers will not only ensure that you receive premium products but also foster long-term partnerships that can adapt to evolving market demands.

Looking ahead, the market for lunch boxes is poised for growth, driven by increasing health consciousness and a shift towards eco-friendly solutions. We encourage international buyers from regions such as Africa, South America, the Middle East, and Europe to explore this promising sector. By prioritizing strategic sourcing of lunch boxes made in the USA, you can position your business at the forefront of this expanding market, meeting consumer needs while enhancing your competitive edge.