Top 8 Mailer Usa List and Guide: How To Solve Scenario 1: Navigat…

Introduction: Navigating the Global Market for mailer usa

Navigating the complexities of sourcing high-quality mailers in the USA can be a daunting task for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. With a diverse range of mailer options available—including bubble mailers, poly mailers, and eco-friendly alternatives—selecting the right packaging solution that meets both regulatory standards and shipping requirements is crucial. This guide aims to demystify the global market for “mailer USA,” equipping buyers with the knowledge they need to make informed purchasing decisions.

Throughout this comprehensive resource, we will explore various types of mailers, their applications, and the benefits they offer for different industries. Additionally, we will provide insights into the supplier vetting process, helping you identify reliable manufacturers and distributors who can meet your specific needs. Cost considerations, including shipping fees and tariffs, will also be discussed, ensuring that you have a clear understanding of the financial implications of your choices.

By the end of this guide, B2B buyers will not only gain a deeper understanding of the mailer options available but also feel empowered to navigate the complexities of international sourcing. Armed with actionable insights, businesses can streamline their procurement processes and enhance their packaging strategies to achieve greater operational efficiency and customer satisfaction.

Top 10 Mailer Usa Manufacturers & Suppliers List

1. MailersUSA – High-Quality Bubble Mailers

Domain: mailersusa.com

Registered: 2010 (15 years)

Introduction: MailersUSA offers a variety of high-quality packaging solutions including: 1. AIRJACKET® White Poly Bubble Mailers – Starting at $33.49 USD 2. AIRJACKET® Colorful Poly Bubble Mailers – Starting at $33.08 USD 3. KRAFTAIRJACKET® Paper Bubble Mailers – Starting at $38.49 USD 4. ECOJACKET® Paper Padded Mailers – Starting at $33.43 USD 5. MAILJACKET® White Rigid Paperboard Mailers – Starting at $36.90 …

2. UsaMailers – Shipping Supplies

3. U.S. Poly Pack – Packing List Envelopes

Domain: uspolypack.com

Registered: 2012 (13 years)

Introduction: Packing Envelopes, Plastic Postal Bags, Envelope Packing In Stock. Free Shipping on Orders Over $799 (Restrictions Apply). Types of products include Packing List Envelopes and Postal Approved Mailing Bags. Packing List Envelopes are water and tear resistant with strong adhesive for permanent attachment. Postal Approved Mailing Bags meet USPS guidelines and are suitable for mailing catalogs, magazi…

4. Poly Bubble Mailers Combo – 100 Pack

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 100 Poly Bubble Mailers USA Envelopes Bags 30 #1, 30 #2, 20 #4 & 20 #5 Combo

Price: $59.95

Condition: New

Shipping: Free 2-4 day delivery

Payment Options: 4 interest-free payments of $14.99 available with Klarna.

Returns: Accepted

Popularity: 20 people are watching this.

Promotion: Buy 1, get 1 at 5% off coupon (expires August 31, 2025).

5. Crown Packaging – Shipping Mailers

Domain: shop.crownpack.com

Registered: 1997 (28 years)

Introduction: Crown Packaging offers a variety of shipping mailers including poly mailers, kraft mailers, bubble mailers, and more. Key types include: Kraft Mailers (made of durable kraft paper), Poly Mailers (made of polyethylene, waterproof and strong), Kraft Bubble Mailers (kraft paper with bubble wrap for protection), and Poly Bubble Mailers (polyethylene with bubble wrap liner for cushioning). They provide…

6. BOX USA – Clear View Poly Mailer Envelopes

7. Pratt – Custom Packaging Solutions

Domain: pratt.com

Registered: 1996 (29 years)

Introduction: Custom Pizza Box, Custom Mailer Box, Custom Shipper Box, Custom Square Mailer Box, Custom Gable Box, Custom Gift Mailer Box, Custom Document Mailer Box. Features include: 100% customized, 100% recyclable, made in the USA, low minimum order quantity of 12 boxes, free printed proof available, various shipping options (Rush, Express, Economy), and the ability to print inside the box.

8. American Paper & Packaging – Mailers and Envelopes

Domain: americanpaper.com

Registered: 1996 (29 years)

Introduction: American Paper & Packaging offers a variety of mailers and envelopes suitable for shipping smaller or flat items. Key products include: 1. Black Flat Mailers – Self-seal, stylish protection for documents and photos. 2. Express Priority Mailing Envelopes – Made from white chipboard, ensuring priority delivery. 3. Kraft Style Mailers – Inexpensive, lightweight, and durable for photos and documents. …

Understanding mailer usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Poly Mailers | Durable, waterproof polyethylene; lightweight and tear-resistant | E-commerce, apparel, and soft goods | Pros: Cost-effective, versatile. Cons: Less cushioning for fragile items. |

| Kraft Bubble Mailers | Made from kraft paper with bubble lining for added protection | Electronics, fragile items, cosmetics | Pros: Eco-friendly, strong cushioning. Cons: Heavier than poly options. |

| Poly Bubble Mailers | Waterproof outer layer with bubble wrap cushioning | Fragile items, books, and merchandise | Pros: Lightweight, excellent protection. Cons: Less sustainable than kraft. |

| Rigid Paperboard Mailers | Sturdy, flat design; ideal for documents and photos | Documents, artwork, and certificates | Pros: Professional appearance, crush-resistant. Cons: Higher shipping costs due to weight. |

| Insulated Thermal Mailers | Designed for temperature-sensitive items; includes insulation | Food, pharmaceuticals, and electronics | Pros: Protects against temperature fluctuations. Cons: Higher cost and bulkier. |

What Are Poly Mailers and When Should You Use Them?

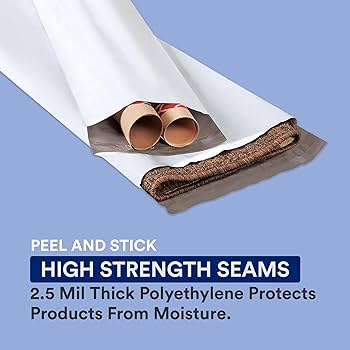

Poly mailers are made from durable polyethylene, providing a lightweight and waterproof option for shipping various items, particularly e-commerce products like clothing and accessories. Their tear-resistant nature makes them suitable for soft goods that require minimal protection. Businesses should consider the cost-effectiveness and versatility of poly mailers, especially for high-volume shipping, though they may not be ideal for fragile items that need additional cushioning.

Why Choose Kraft Bubble Mailers for Fragile Items?

Kraft bubble mailers feature a kraft paper exterior with a bubble wrap interior, delivering robust protection for fragile items during transit. They are particularly well-suited for electronics, cosmetics, and other delicate products. Businesses focused on sustainability will appreciate the eco-friendly materials, but they should be aware that these mailers tend to be heavier than poly alternatives, potentially increasing shipping costs.

How Do Poly Bubble Mailers Offer Protection?

Poly bubble mailers combine a waterproof polyethylene exterior with a cushioned bubble wrap lining, making them an excellent choice for shipping fragile items such as books and merchandise. Their lightweight design helps keep shipping costs down while providing substantial protection against impact and moisture. However, businesses should note that while poly bubble mailers offer great protection, they are less sustainable compared to kraft options.

When Should You Use Rigid Paperboard Mailers?

Rigid paperboard mailers are ideal for shipping documents, artwork, and certificates due to their sturdy, flat design that prevents bending. They provide a professional appearance and are crush-resistant, making them a preferred choice for businesses that prioritize presentation. However, buyers should consider the higher shipping costs associated with their weight and bulkiness compared to other mailer types.

What Are Insulated Thermal Mailers Best For?

Insulated thermal mailers are specifically designed to protect temperature-sensitive items, such as food, pharmaceuticals, and electronics, during transit. Their insulation helps maintain a stable temperature, making them essential for businesses in the food and healthcare sectors. While they offer critical protection, the higher cost and bulkiness can be a consideration for budget-conscious buyers.

Key Industrial Applications of mailer usa

| Industry/Sector | Specific Application of mailer usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| E-commerce & Retail | Shipping products in bubble mailers | Protects items during transit, enhances customer experience | Durability, size options, eco-friendliness, cost-effectiveness |

| Pharmaceuticals | Secure transport of medical supplies | Ensures product integrity, compliance with regulations | Tamper-evidence, moisture resistance, customization |

| Electronics | Packaging delicate electronic components | Reduces damage risk, provides insulation against shocks | Static protection, size accuracy, shipping compliance |

| Apparel & Fashion | Shipping clothing and accessories | Presents products attractively, reduces returns due to damage | Custom branding options, material quality, return policies |

| Food & Beverage | Insulated mailers for temperature-sensitive items | Maintains product quality, enhances customer satisfaction | Thermal insulation, size variety, food safety compliance |

How is ‘mailer usa’ utilized in E-commerce & Retail?

In the e-commerce and retail sector, bubble mailers are extensively used for shipping a variety of products, from small gadgets to clothing items. These mailers provide superior protection during transit, minimizing the risk of damage and enhancing the overall customer experience. For international buyers, particularly from regions like Africa and South America, sourcing durable and cost-effective mailers that comply with local shipping regulations is crucial. The ability to choose different sizes and colors also allows businesses to maintain brand consistency.

Why are mailers important in the Pharmaceuticals industry?

In the pharmaceutical industry, secure transport of medical supplies is paramount. Mailers USA offers tamper-evident and moisture-resistant options that ensure product integrity and compliance with stringent regulations. For international buyers, especially in the Middle East and Europe, it is essential to source packaging solutions that can withstand various environmental conditions while adhering to health and safety standards. This reliability not only safeguards the products but also builds trust with end-users.

How do Electronics companies benefit from mailers?

Electronics manufacturers often face challenges in shipping delicate components that are prone to damage. Mailers USA provides specialized packaging that offers cushioning and insulation against shocks, significantly reducing the likelihood of product failure upon arrival. For B2B buyers in regions like Germany and Vietnam, sourcing mailers that meet specific size and static protection requirements is vital to ensure compliance with international shipping standards and to protect valuable products during transit.

What role do mailers play in Apparel & Fashion?

In the apparel and fashion industry, shipping clothing and accessories in attractive, branded mailers can greatly enhance the customer experience. Mailers USA offers customizable options that not only protect the items but also serve as a marketing tool. For international buyers, considerations such as material quality and return policies are critical, as they impact both customer satisfaction and the overall brand image. Ensuring that the mailers are both visually appealing and functional is key to minimizing returns due to damage.

How do mailers support the Food & Beverage sector?

For the food and beverage industry, insulated mailers are essential for transporting temperature-sensitive items safely. Mailers USA provides solutions that maintain product quality during transit, which is crucial for customer satisfaction. B2B buyers, particularly from regions with diverse climates, need to consider thermal insulation capabilities and size variety when sourcing these mailers. Compliance with food safety standards is also a significant factor, ensuring that the products arrive fresh and intact.

3 Common User Pain Points for ‘mailer usa’ & Their Solutions

Scenario 1: Navigating Compliance and Shipping Regulations

The Problem:

B2B buyers, particularly those in regions like Africa and South America, often struggle with understanding the complex compliance and shipping regulations associated with international shipping. For instance, a company in Brazil may find it challenging to comply with both local and U.S. regulations when importing packaging materials. This can lead to delays, additional costs, or even confiscation of shipments, creating significant disruptions in their supply chain.

The Solution:

To effectively navigate these challenges, it’s crucial to partner with a supplier like MailersUSA that not only provides high-quality packaging solutions but also offers guidance on compliance. Buyers should inquire about the certifications and compliance standards that MailersUSA adheres to. For instance, using postal-approved mailing bags can ensure that the packaging meets the necessary regulations. Additionally, establishing a direct line of communication with MailersUSA’s customer service team can help clarify any specific requirements for your country. Consider using their resources and documentation to stay informed about changes in regulations, thus avoiding unnecessary hurdles in your shipping process.

Scenario 2: Ensuring Product Protection During Transit

The Problem:

A common pain point for businesses is ensuring that their products remain safe and intact during transit. For instance, a European e-commerce retailer shipping fragile items like glassware may be concerned about damage during shipping. Without the right protective packaging, they risk returns, negative customer feedback, and financial losses.

The Solution:

To mitigate this risk, B2B buyers should select the right type of mailers for their products from MailersUSA’s extensive range. Utilizing products like the AIRJACKET® White Poly Bubble Mailers can provide superior cushioning against impacts while also being lightweight, which helps reduce shipping costs. It’s advisable to conduct a thorough analysis of the products being shipped and match them with the appropriate mailers that offer the necessary protection. Furthermore, incorporating additional protective materials, such as packing peanuts or bubble wrap, can enhance product safety. Documenting your shipping processes and regularly reviewing the condition of items upon arrival can also help identify any persistent issues and refine your packaging strategy.

Scenario 3: Managing Inventory and Order Fulfillment Efficiency

The Problem:

B2B buyers often face challenges in managing their inventory and ensuring efficient order fulfillment, particularly when dealing with a wide variety of packaging materials. For example, a distributor in the Middle East may find it overwhelming to stock different sizes and types of mailers, leading to inefficiencies and delays in shipping orders to clients.

The Solution:

To improve inventory management and order fulfillment, businesses should consider adopting a streamlined approach when sourcing mailers from MailersUSA. Implementing a just-in-time inventory system can reduce excess stock and storage costs while ensuring that the necessary mailers are available when needed. Buyers should assess their sales data to determine the most frequently used mailers and establish minimum stock levels for those items. Utilizing MailersUSA’s bulk purchasing options can also lead to cost savings and ensure that you always have the right packaging materials on hand. Additionally, integrating inventory management software can help track usage patterns and predict future needs, allowing for a more responsive and efficient operation. This approach not only enhances operational efficiency but also improves customer satisfaction by ensuring timely deliveries.

Strategic Material Selection Guide for mailer usa

What Are the Key Properties of Common Materials Used in Mailers?

In the realm of packaging, selecting the right material for mailers is crucial for ensuring product protection, compliance with international standards, and cost-effectiveness. Here, we analyze four common materials used in mailers: Kraft paper, Polyethylene (Poly) film, Bubble wrap, and Recycled paper. Each material has distinct properties that cater to different shipping needs.

How Does Kraft Paper Perform as a Mailer Material?

Kraft paper is renowned for its strength and durability, making it a popular choice for mailers. It is made from wood pulp and has a natural brown color, which is often associated with eco-friendliness. Kraft paper mailers can withstand moderate pressure and are resistant to tearing, making them suitable for shipping various products, including clothing and books.

Pros: Kraft paper is biodegradable and recyclable, appealing to environmentally conscious businesses. It is also cost-effective and readily available, which reduces manufacturing complexity.

Cons: While it offers decent protection, it is not waterproof, which can be a limitation in humid or wet environments. Additionally, it may not be suitable for heavy or fragile items without additional cushioning.

Impact on Application: Kraft paper mailers are ideal for items that do not require extensive moisture protection. Businesses shipping to regions with high humidity, such as parts of Africa and South America, may need to consider additional protective measures.

What Advantages Does Polyethylene Offer for Mailers?

Polyethylene (Poly) film is a synthetic material known for its excellent moisture resistance and durability. It is lightweight, which can help reduce shipping costs, and it provides a barrier against dirt and moisture, making it a preferred choice for shipping textiles and non-perishable goods.

Pros: Poly mailers are tear-resistant and often come with self-sealing adhesives, simplifying the packing process. They are also available in various sizes and thicknesses, allowing for customization based on specific shipping needs.

Cons: The main drawback is that polyethylene is not biodegradable, which may not align with sustainability goals. Additionally, it can be less protective against sharp objects compared to padded alternatives.

Impact on Application: Poly mailers are particularly effective for shipping items that require moisture protection. For international buyers, compliance with local regulations regarding plastic waste is essential, especially in European markets where sustainability standards are stringent.

How Effective Is Bubble Wrap in Providing Protection for Mailers?

Bubble wrap is a cushioning material that offers excellent protection for fragile items. It is typically used as an inner lining for mailers, providing a layer of shock absorption. The air-filled bubbles help to prevent damage during transit, making it suitable for electronics, glassware, and other delicate products.

Pros: The cushioning effect of bubble wrap significantly reduces the risk of damage, making it ideal for high-value items. It is also lightweight, which helps keep shipping costs down.

Cons: Bubble wrap is made from plastic, which raises environmental concerns. Additionally, it can add complexity to the packaging process, as it requires an outer mailer to contain the product.

Impact on Application: Businesses shipping fragile items to international markets must consider the additional weight and cost of using bubble wrap. Compliance with international shipping standards, such as ISPM 15 for wooden packaging, may also be necessary.

What Are the Benefits of Using Recycled Paper for Mailers?

Recycled paper is an eco-friendly alternative that combines the benefits of traditional paper with sustainability. It is made from post-consumer waste and offers decent strength and durability for various shipping applications.

Pros: Using recycled paper aligns with global sustainability initiatives, appealing to environmentally conscious consumers. It is also cost-effective and can be printed with branding, enhancing marketing efforts.

Cons: Recycled paper may not be as strong as virgin Kraft paper, and its moisture resistance is limited, which can be a concern for certain products.

Impact on Application: International buyers should be aware of the varying standards for recycled materials in their markets. For instance, European countries often have stringent requirements for recycled content in packaging.

Summary Table of Material Selection for Mailers

| Material | Typical Use Case for mailer usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Kraft Paper | Shipping clothing and books | Biodegradable and recyclable | Not waterproof | Low |

| Polyethylene | Shipping textiles and non-perishables | Moisture resistant and durable | Not biodegradable | Medium |

| Bubble Wrap | Shipping fragile items like electronics | Excellent cushioning protection | Environmental concerns | Medium |

| Recycled Paper | Eco-friendly shipping for various goods | Aligns with sustainability goals | Limited moisture resistance | Low |

This analysis provides a comprehensive overview of the materials used in mailers, enabling international B2B buyers to make informed decisions based on their specific shipping needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for mailer usa

What Are the Main Stages of Manufacturing Mailers in the USA?

The manufacturing process for mailers in the USA involves several critical stages that ensure the final product meets the high standards expected by international B2B buyers. Understanding these stages can help buyers make informed decisions when sourcing packaging solutions.

Material Preparation: What Materials Are Used in Mailer Manufacturing?

The first step in the manufacturing process is material preparation. Mailers are typically made from various materials such as polyethylene for poly mailers and kraft paper for kraft mailers. Each material is chosen for its specific properties—polyethylene is known for its moisture resistance and durability, while kraft paper offers strength and eco-friendliness. Suppliers often source these materials from certified vendors to ensure quality and compliance with international standards.

How Are Mailers Formed and Shaped?

After material preparation, the next stage is forming. This involves cutting the raw materials into specific sizes and shapes according to the design specifications. Advanced cutting technologies, such as die-cutting and laser cutting, are employed to achieve precision. This stage also includes the application of adhesives and other components, particularly in bubble mailers, where a layer of cushioning material is added to protect the contents during transit.

What Is Involved in the Assembly of Mailers?

The assembly stage combines the formed components into a finished product. For example, in the case of bubble mailers, the outer layer of polyethylene or kraft paper is bonded with the inner bubble cushioning. This is typically done using heat sealing or adhesive bonding techniques, which provide strong, long-lasting seams. Automation plays a significant role in this stage, increasing efficiency and reducing production times.

How Are Mailers Finished to Ensure Quality?

The finishing stage involves several processes, including printing and packaging. Many manufacturers offer customization options, allowing businesses to print their branding on the mailers. This is often achieved through flexographic or digital printing methods. Finally, the finished mailers are packaged for shipment, ensuring they are protected during transit to the end user.

What Quality Assurance Measures Are Employed in Mailer Manufacturing?

Quality assurance (QA) is a crucial aspect of the mailer manufacturing process. International B2B buyers should be aware of the standards and practices that manufacturers implement to ensure their products meet the required quality levels.

Which International Standards Are Relevant for Mailer Quality?

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with ISO standards signifies that a manufacturer has a structured approach to managing quality and continual improvement. Additionally, industry-specific certifications like CE marking or API certification may be relevant depending on the mailer’s intended use and market.

What Are the Key Quality Control Checkpoints in Mailer Production?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. The three primary checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet quality specifications.

- In-Process Quality Control (IPQC): Ongoing checks during production monitor the process and materials to catch any defects early.

- Final Quality Control (FQC): The final product undergoes rigorous testing to ensure it meets all quality standards before shipping.

What Common Testing Methods Are Used to Ensure Mailer Quality?

Testing methods for mailers vary based on the material and intended use. Common tests include:

- Tensile Strength Testing: Measures the strength of the material under stress.

- Water Resistance Testing: Ensures that the mailer can withstand exposure to moisture.

- Drop Tests: Simulate the shipping process to evaluate the mailer’s ability to protect contents during transit.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to verify the quality control processes of their suppliers. This can include:

What Should B2B Buyers Look for in Supplier Audits and Reports?

Requesting detailed audits and quality control reports from suppliers can provide insights into their manufacturing practices. Buyers should look for:

- Certification Details: Ensure that the supplier holds relevant certifications and complies with international standards.

- Quality Control Documentation: Review reports that outline testing results and any corrective actions taken.

How Important Are Third-Party Inspections for Quality Assurance?

Engaging third-party inspection services can add an additional layer of assurance. These independent entities can conduct audits and tests, providing unbiased evaluations of a supplier’s quality control processes. This is especially important for international buyers who may not be able to visit the manufacturing facility.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be mindful of specific nuances in quality control that may affect their procurement decisions.

How Do Regulatory Differences Impact Quality Assurance?

Different countries have varying regulations regarding packaging and shipping materials. Buyers should familiarize themselves with local requirements in their respective regions to ensure compliance. This includes understanding customs regulations, which may require specific certifications for imported goods.

What Role Does Cultural Understanding Play in Quality Expectations?

Cultural differences can also influence expectations around quality. For instance, buyers from Germany may have different quality benchmarks compared to those from South America. Understanding these cultural nuances can facilitate better communication and expectations between buyers and suppliers.

Conclusion

In summary, the manufacturing processes and quality assurance measures for mailers in the USA are multifaceted and designed to meet high international standards. By understanding these processes and the relevant quality control practices, international B2B buyers can make informed decisions when sourcing packaging solutions. Engaging with suppliers who prioritize quality and compliance not only ensures product integrity but also fosters long-term business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mailer usa’

To ensure a smooth and successful procurement process for mailers from the USA, this guide provides a step-by-step checklist for international B2B buyers. By following these actionable steps, you can secure the best products and establish reliable supplier relationships.

Step 1: Identify Your Packaging Needs

Before reaching out to suppliers, clearly define what types of mailers you require. Consider factors such as the nature of the items being shipped, weight, fragility, and environmental conditions during transit.

– Types of mailers: Decide between bubble mailers, poly mailers, or kraft mailers based on your product specifications.

– Size and volume: Estimate the quantities and sizes you need to optimize shipping costs and storage space.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers in the USA who specialize in the types of mailers you need. Look for companies with a strong track record and positive reviews.

– Supplier reliability: Check online reviews and testimonials from other international buyers.

– Industry experience: Favor suppliers that have experience servicing businesses in your region or industry, as they may better understand your specific requirements.

Step 3: Request Samples

Once you’ve narrowed down potential suppliers, request samples of the mailers you are interested in. This step is crucial to assess the quality and suitability of the products for your needs.

– Quality assessment: Evaluate the materials used, durability, and overall design.

– Fit for purpose: Ensure that the samples align with your packaging specifications and protect your products effectively.

Step 4: Verify Supplier Certifications

Confirm that the suppliers comply with relevant industry standards and certifications. This not only ensures product quality but also demonstrates their commitment to sustainable practices.

– Sustainability certifications: Look for certifications indicating eco-friendly materials and practices.

– Compliance: Ensure that the mailers meet postal and shipping regulations applicable in your destination country.

Step 5: Negotiate Terms and Pricing

Engage in discussions with potential suppliers about pricing, minimum order quantities, and payment terms. Effective negotiation can lead to better pricing and favorable contract conditions.

– Bulk discounts: Inquire about discounts for larger orders to optimize your budget.

– Payment terms: Establish clear terms that align with your cash flow and procurement cycles.

Step 6: Assess Shipping and Delivery Options

Understand the logistics involved in getting the mailers delivered to your location. Efficient shipping is essential to maintain your supply chain.

– Shipping methods: Discuss available shipping options, transit times, and costs.

– Customs considerations: Be aware of any import duties or regulations that could affect delivery times and costs.

Step 7: Establish a Long-term Relationship

After successfully sourcing your mailers, focus on building a strong relationship with your supplier. A reliable partnership can lead to better service and pricing in the future.

– Communication: Maintain regular communication for feedback and updates on your orders.

– Future needs: Keep your supplier informed about your future packaging requirements to facilitate smoother transactions.

By following this checklist, international B2B buyers can effectively navigate the sourcing process for mailers in the USA, ensuring quality products and strong supplier relationships.

Comprehensive Cost and Pricing Analysis for mailer usa Sourcing

What Are the Key Cost Components for Sourcing Mailers in the USA?

When considering sourcing mailers from the USA, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts pricing. For instance, poly mailers are often cheaper than kraft or bubble mailers due to the lower cost of polyethylene compared to paper-based materials. Eco-friendly options may come at a premium, reflecting the growing demand for sustainable products.

-

Labor: Labor costs vary by region and can influence the overall price. In areas with higher wage standards, the production costs may be elevated, impacting the pricing structure.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and other indirect costs that are allocated across production. Efficient operations can reduce these costs, which can be passed on to buyers.

-

Tooling: Custom tooling for specific designs or sizes can add significant upfront costs. Buyers should consider whether they need customized mailers and how that might affect their overall budget.

-

Quality Control (QC): Ensuring product quality is essential, especially for businesses that rely on brand reputation. More rigorous QC processes can increase costs, but they also minimize the risk of returns and dissatisfaction.

-

Logistics: Shipping costs are another critical component. These can vary based on order size, shipping method, and distance. Understanding Incoterms is essential, as they dictate who is responsible for shipping costs and risks.

-

Margin: Suppliers typically add a profit margin on top of the production costs. This margin can vary widely depending on market conditions and supplier negotiation.

How Do Price Influencers Affect Mailer Costs for International Buyers?

Several factors can influence the pricing of mailers, especially for international buyers from regions such as Africa, South America, the Middle East, and Europe.

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQs). Larger orders can lead to volume discounts, making it more cost-effective for buyers who can meet these thresholds.

-

Specifications/Customization: Custom designs or specifications will usually incur additional costs. Buyers should evaluate if the benefits of customization outweigh the higher prices.

-

Materials and Quality Certifications: High-quality materials or certified eco-friendly products can command higher prices. Buyers should assess their target market’s expectations regarding quality and sustainability.

-

Supplier Factors: The reputation and reliability of suppliers can also influence pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: Understanding shipping terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers better anticipate total costs. These terms define responsibilities and costs related to shipping, which can significantly impact the total purchase price.

What Are the Best Practices for Negotiating Mailer Pricing?

For international buyers, effective negotiation and cost management can lead to significant savings. Here are some actionable tips:

-

Negotiate Based on Volume: Leverage larger orders to negotiate better pricing or favorable payment terms.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also shipping costs, potential tariffs, and the cost of returns due to low-quality products.

-

Understand Pricing Nuances: Familiarize yourself with the pricing dynamics in the USA, including seasonal price fluctuations and market trends, to time your purchases effectively.

-

Build Relationships with Suppliers: Establishing a good relationship can lead to better deals, priority service, and access to exclusive products.

-

Request Samples: Before committing to large orders, ask for samples to evaluate quality, ensuring that the products meet your standards without incurring unnecessary costs.

Conclusion: How Can International Buyers Navigate Mailer Sourcing in the USA?

Sourcing mailers from the USA can be advantageous due to quality and variety, but international buyers must navigate a complex cost structure and pricing influencers. By understanding the key components of pricing, leveraging volume for discounts, and strategically negotiating terms, buyers can optimize their purchasing strategies and reduce overall costs. Always remember that prices can vary significantly based on market conditions and supplier relationships, so it’s essential to perform due diligence before making purchasing decisions.

Alternatives Analysis: Comparing mailer usa With Other Solutions

Exploring Alternatives to Mailers USA: A Comparative Analysis

When it comes to selecting packaging solutions, businesses must consider various alternatives that can meet their operational requirements. Mailers USA offers a range of high-quality mailers, but several other options can also provide effective solutions for shipping and packaging needs. Below, we compare Mailers USA with two viable alternatives: USA Mailers and PAC Worldwide.

| Comparison Aspect | Mailers USA | USA Mailers | PAC Worldwide |

|---|---|---|---|

| Performance | High-quality, durable mailers | Good quality, but less variety | Customizable, with eco-friendly options |

| Cost | Competitive pricing starting from $28 | Competitive pricing with free shipping | Higher price point for custom solutions |

| Ease of Implementation | Easy to order with straightforward sizes | User-friendly website; free shipping simplifies logistics | More complex due to customization options |

| Maintenance | Minimal maintenance required | No maintenance; disposable use | Requires awareness of recycling policies |

| Best Use Case | Ideal for e-commerce and retail | Suitable for bulk orders with budget constraints | Great for brands focused on sustainability |

In-Depth Analysis of Alternatives

What are the Key Benefits and Drawbacks of USA Mailers?

USA Mailers is a solid alternative that offers a variety of poly and kraft mailers. Its main advantage lies in its straightforward pricing model, including free shipping within the continental U.S. This can significantly reduce overall shipping costs for businesses, especially those making bulk orders. However, the selection may not be as diverse as Mailers USA, potentially limiting businesses that require specific types of mailers for different applications.

How Does PAC Worldwide Stand Out Among Packaging Solutions?

PAC Worldwide excels in providing customizable mailers that cater to specific business needs, including eco-friendly options. This is particularly advantageous for companies looking to align their packaging with sustainability goals. However, the higher price point associated with PAC Worldwide’s products may deter budget-conscious buyers. Additionally, the customization process can complicate ordering, making it less appealing for businesses seeking quick and straightforward solutions.

Conclusion: Which Packaging Solution Should B2B Buyers Choose?

In choosing the right packaging solution, B2B buyers should carefully evaluate their specific needs, including budget, shipping frequency, and environmental impact. Mailers USA is a robust option for companies seeking variety and reliability, while USA Mailers provides an attractive pricing structure for bulk orders. For businesses prioritizing sustainability and customization, PAC Worldwide stands out despite its higher costs. By assessing these factors, buyers can make an informed decision that aligns with their operational strategies and customer expectations.

Essential Technical Properties and Trade Terminology for mailer usa

What Are the Key Technical Properties of Mailers in the B2B Market?

Understanding the technical properties of mailers is crucial for international B2B buyers seeking reliable packaging solutions. Here are some of the essential specifications to consider:

1. Material Grade

Mailers are typically made from various materials, including polyethylene (poly) and kraft paper. Poly mailers are known for their durability and moisture resistance, making them suitable for shipping items that require protection from environmental factors. Kraft paper mailers, on the other hand, offer a more eco-friendly option with a robust design. Choosing the right material grade is vital for ensuring the mailer’s performance aligns with the shipping requirements.

2. Size and Dimensions

Mailers come in various sizes, which are critical for accommodating different products. For instance, oversized items may require jumbo mailers, while small or flat items can be shipped in standard-sized poly or bubble mailers. Selecting the appropriate dimensions not only ensures that products fit securely but also helps minimize shipping costs by reducing excess space.

3. Weight Capacity

Different mailers have varying weight capacities, which are essential for determining what can be shipped. Poly mailers generally support heavier items due to their stronger material. In contrast, kraft bubble mailers provide cushioning but may have lower weight thresholds. Understanding weight capacity helps businesses avoid potential damages during transport.

4. Seal Strength

The sealing mechanism of a mailer—whether it be a self-adhesive strip or a pressure-sensitive seal—plays a crucial role in ensuring that items remain secure during transit. A strong seal prevents tampering and accidental openings, which is particularly important for high-value shipments. Evaluating seal strength is essential for maintaining product integrity and customer satisfaction.

5. Eco-Friendliness

With increasing emphasis on sustainability, many manufacturers now offer eco-friendly mailers made from recyclable materials. These products not only help businesses meet environmental regulations but also appeal to eco-conscious consumers. Understanding the eco-properties of mailers can enhance a company’s brand image and align with global sustainability goals.

What Are Common Trade Terms Used in the Mailer Industry?

Navigating the B2B mailer market requires familiarity with industry jargon. Here are some essential terms that international buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are then marketed by another company. In the mailer industry, this can apply to manufacturers who create custom mailers for brands to use under their own label. Understanding OEM relationships can help businesses leverage partnerships for better pricing and product customization.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. In the mailer sector, this can affect inventory management and cost efficiency. Buyers should negotiate MOQ terms to ensure they can acquire enough product without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. This is particularly relevant for bulk orders or custom mailers, enabling businesses to compare offers and negotiate better deals. Understanding how to craft an RFQ can lead to more favorable purchasing terms.

4. Incoterms (International Commercial Terms)

Incoterms are predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for international transactions, as they help mitigate risks associated with cross-border shipping.

5. SKU (Stock Keeping Unit)

An SKU is a unique identifier for each distinct product and service that can be purchased. In the mailer industry, SKUs help businesses track inventory and streamline order fulfillment. Understanding SKU implications can enhance inventory management practices.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing mailers, ultimately enhancing their shipping processes and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the mailer usa Sector

What Are the Key Market Dynamics and Trends in the Mailer USA Sector?

The mailer sector in the USA has experienced a dynamic evolution driven by several global factors. With the rapid growth of e-commerce, international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking reliable packaging solutions. Key trends shaping the market include the rising demand for customized packaging, advanced materials, and innovative designs that enhance product protection while promoting brand identity. Notably, there is a growing inclination towards lightweight yet durable packaging options, such as poly bubble mailers and kraft mailers, which reduce shipping costs and environmental impact.

Additionally, technology is transforming sourcing practices. The integration of automation and digital platforms allows businesses to streamline their procurement processes, enabling faster order fulfillment and improved inventory management. International buyers are also leveraging data analytics to optimize their supply chains, ensuring that they can respond promptly to market demands. With the growing emphasis on direct-to-consumer shipping, businesses are adapting their packaging strategies to cater to this trend, ensuring that products arrive safely and attractively.

How Is Sustainability Influencing Sourcing Decisions in the Mailer USA Market?

Sustainability is becoming a pivotal consideration for B2B buyers in the mailer sector. As environmental concerns rise, companies are increasingly prioritizing ethical sourcing and sustainable materials in their packaging solutions. The use of recyclable and biodegradable materials, such as eco-friendly kraft paper and recyclable poly mailers, is gaining traction among suppliers. This shift is not just a trend but a necessity, as consumers and regulatory bodies alike demand greater accountability in packaging waste management.

Moreover, third-party certifications for sustainability are becoming essential for suppliers to distinguish themselves in a competitive market. Certifications such as FSC (Forest Stewardship Council) and Cradle to Cradle signify a commitment to environmentally responsible practices, making these suppliers more attractive to international buyers. As the push for greener practices intensifies, companies that invest in sustainable packaging solutions are likely to gain a competitive edge, fostering loyalty among eco-conscious customers and partners.

What Is the Historical Context Behind the Mailer USA Sector’s Growth?

The mailer industry in the USA has evolved significantly over the past few decades. Initially dominated by traditional paper envelopes, the sector began to embrace innovation with the introduction of bubble mailers in the late 20th century, which provided enhanced protection for fragile items. The advent of e-commerce in the 2000s marked a turning point, propelling demand for more diverse and resilient packaging solutions to accommodate a variety of products shipped directly to consumers.

As businesses adapted to changing consumer behaviors, the focus shifted towards optimizing packaging for efficiency, cost-effectiveness, and branding. This evolution has paved the way for the current landscape, where international B2B buyers seek not only functionality in packaging but also sustainability and compliance with global standards. The continuous advancement in materials and technology ensures that the mailer sector remains responsive to the evolving needs of businesses worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of mailer usa

-

How do I determine the right size mailer for my products?

Choosing the correct size mailer is crucial for ensuring your products are adequately protected during transit. Measure the dimensions of your items, including any additional packaging, and select a mailer that provides a snug fit without excessive space. Consider using mailers with cushioning, like bubble mailers, for fragile items. Many suppliers offer size guides or recommendations based on common product dimensions, making it easier to find the right match. -

What are the benefits of using poly mailers versus kraft mailers?

Poly mailers are lightweight, waterproof, and tear-resistant, making them ideal for shipping soft goods like clothing. They offer robust protection against moisture and environmental factors, ensuring that the contents arrive in pristine condition. On the other hand, kraft mailers are biodegradable and made from recycled materials, appealing to eco-conscious businesses. The choice between them should be based on your product type, branding, and sustainability goals. -

What customization options are available for mailers?

Many suppliers offer customization options for mailers, including printing your company logo, brand colors, or specific designs. Custom mailers can enhance brand visibility and create a cohesive unboxing experience for your customers. Additionally, you can choose mailers with specific features like self-sealing strips, tear-resistant materials, or unique sizes tailored to your products. Discuss your branding requirements with your supplier to explore available options. -

What is the minimum order quantity (MOQ) for mailers from US suppliers?

The MOQ for mailers can vary significantly by supplier and product type. Some suppliers may allow small orders, while others may have higher minimums, especially for custom designs. It’s essential to clarify the MOQ with your supplier before placing an order. If you’re a smaller business, consider looking for suppliers that cater to startups or offer bulk purchasing options to maximize cost-efficiency. -

What payment terms should I expect when sourcing mailers from the USA?

Payment terms can vary among suppliers, but many offer flexible options such as net 30, 60, or even 90 days for established businesses. Newer companies may need to pay upfront or provide a deposit. It’s crucial to discuss payment methods accepted, such as credit cards, bank transfers, or letters of credit, especially for international transactions. Understanding these terms can help you manage cash flow and budgeting for your business. -

How can I vet suppliers to ensure quality mailers?

To vet suppliers effectively, check their reputation through online reviews, testimonials, and case studies. Request samples to evaluate the quality of materials and construction. It’s also beneficial to inquire about certifications related to sustainability and product safety. Engage in direct communication with the supplier to assess their responsiveness and willingness to address your concerns. Building a relationship with suppliers who prioritize quality can lead to long-term partnerships. -

What logistics considerations should I keep in mind when importing mailers?

When importing mailers, consider shipping costs, transit times, and customs duties. Research the most efficient shipping methods, whether by air or sea, based on your urgency and budget. Ensure that your supplier provides necessary documentation for customs clearance, such as invoices and packing lists. Additionally, stay informed about any trade regulations or tariffs that may affect your imports, especially if you’re sourcing from the USA to regions like Africa or South America. -

What quality assurance processes should I look for in a mailer supplier?

Quality assurance processes are vital for ensuring that your mailers meet industry standards. Look for suppliers that implement rigorous testing of materials and conduct inspections during production. Certifications from recognized bodies can also indicate adherence to quality standards. Inquire about their return and replacement policies in case of defective products. A supplier with a solid QA process is more likely to deliver consistent and reliable products that meet your expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for mailer usa

In the competitive landscape of international trade, the strategic sourcing of mailers from the USA presents significant advantages for B2B buyers. High-quality packaging solutions, such as poly and kraft mailers, offer durability and protection for goods during transit, which is crucial for maintaining product integrity. By choosing reputable suppliers like MailersUSA, businesses can benefit from a diverse range of products tailored to their specific shipping needs, ensuring that they meet customer expectations while optimizing costs.

Additionally, sourcing from U.S. manufacturers not only supports local economies but also mitigates potential tariff implications that can arise from overseas sourcing. This strategic approach can enhance supply chain efficiency and reliability, allowing businesses to respond swiftly to market demands.

As we look ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe should consider leveraging the advantages of U.S. mailers. Investing in high-quality packaging solutions will not only elevate your brand’s presentation but also enhance customer satisfaction. Explore partnerships with trusted suppliers today to secure a competitive edge in your market.