Top 7 Headphones Made In The Usa List and Guide: How To Solve Sce…

Introduction: Navigating the Global Market for headphones made in the usa

In today’s competitive landscape, sourcing high-quality headphones made in the USA presents a unique challenge for international B2B buyers. With an increasing demand for premium audio products that reflect craftsmanship and innovation, businesses must navigate a market filled with various options and manufacturers. This comprehensive guide delves into the diverse types of headphones available, their applications in various industries, and essential considerations for supplier vetting. We will also explore cost implications and potential partnerships with American brands renowned for their quality and performance.

International buyers, particularly from Africa, South America, the Middle East, and Europe—including key markets like Germany and Saudi Arabia—will find valuable insights tailored to their specific needs. By addressing vital questions such as “What are the key features to consider when sourcing American-made headphones?” and “How can I assess the reliability of suppliers?”, this guide aims to empower decision-makers with the knowledge to make informed purchasing choices.

Understanding the nuances of the American headphone market will not only help you select products that meet your quality standards but also enhance your brand’s reputation by aligning with the values of craftsmanship and sustainability that come with American manufacturing. With this guide, you will be well-equipped to navigate the complexities of sourcing headphones made in the USA, ensuring a successful procurement process that meets your business objectives.

Top 10 Headphones Made In The Usa Manufacturers & Suppliers List

1. Grado – Signature S950

Domain: gradolabs.com

Registered: 1998 (27 years)

Introduction: The All New Grado Signature S950 features 52mm S Drivers, detachable cables, a Grado Gold headband assembly, and is lightweight at 395 grams. It is hand-crafted from Brazilian walnut and comes with a 2-year limited warranty. The Signature HP100 SE is a contemporary version of a classic design, featuring newly engineered drivers, detachable cables, and a fresh headband assembly, all hand-assembled …

2. Master & Dynamic – MW75 Active Noise-Cancelling Wireless Headphones

Domain: masterdynamic.com

Registered: 2011 (14 years)

Introduction: Master & Dynamic offers a range of professional headphones and luxury earphones, including:

1. **MW75 Active Noise-Cancelling Wireless Headphones** – Price: $599.00, features include active noise-cancelling technology and various color options.

2. **MH40 Wireless Over-Ear Headphones** – Price: $399.00, known for its iconic design and available in multiple colors.

3. **MG20 Wireless Gaming Head…

3. House of Marley – Little Bird True Wireless Earbuds

Domain: thehouseofmarley.com

Registered: 2010 (15 years)

Introduction: House of Marley offers a range of sustainable, eco-friendly headphones and earbuds crafted from premium, eco-conscious materials such as bamboo, FSC® certified wood, recycled plastic, aluminum, and fabrics. Key products include:

1. **Little Bird True Wireless Earbuds** – MSRP: $39.99

2. **Liberate Open-Ear True Wireless Earbuds** – MSRP: $79.99

3. **Positive Vibration Riddim Headphones** – MSRP: …

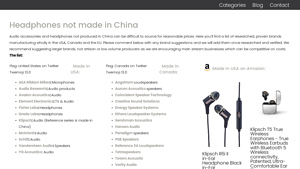

4. Fisher Labs – Headphones

Domain: chinanever.com

Registered: 2020 (5 years)

Introduction: Headphones not made in China can be sourced from various brands manufacturing in the USA, Canada, and the EU. Key brands include: Made in USA: AEA Ribbon Mikes (Microphones), Audio Research (Audio products), Avalon Acoustics (Audio), Element Electronics (TV & Audio), Fisher Labs (Headphones), Grado Labs (Headphones), Klipsch (Audio), McIntosh (Audio), Schiit (Audio), Vandersteen Audio (Speakers), …

5. Abyss – High-Performance Headphones

Domain: madeintheusamatters.com

Registered: 2022 (3 years)

Introduction: Abyss: High-performance headphones made in the USA with solid aluminum frames and lambskin leather; Audeze: Planar magnetic technology for professional musicians and studios; Bendy Head: American made headphone stand made of wood; Bose: Production facilities in Massachusetts but not exclusively made in the USA; Campfire Audio: Custom in-ear monitors made by hand in Portland, Oregon; Direct Sound: …

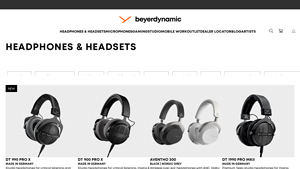

6. beyerdynamic – DT 990 PRO X

Domain: north-america.beyerdynamic.com

Registered: 1997 (28 years)

Introduction: Headphones and headsets with perfect sound from beyerdynamic, directly from the manufacturer. 2 Years Warranty and 30 Days Return policy. Key products include: DT 990 PRO X ($199.99), DT 900 PRO X ($269.99), AVENTHO 300 BLACK ($399.99), DT 1990 PRO MKII ($599.99), DT 1770 PRO MKII ($599.99), AMIRON 300 BLACK ($279.99), MMX 300 PRO ($299.99), MMX 330 PRO ($329.99), VERIO 200 ($219.99), DT 990 PRO (…

7. Creative Labs – Headphones and Audio Solutions

Domain: us.creative.com

Registered: 1999 (26 years)

Introduction: Creative Labs offers a wide range of headphones including True Wireless sweatproof earbuds, over-ear, and wireless headphones designed for high-resolution audio, comfort, and style for all-day wear. Key products include the Outlier series, Sound Blaster SXFI, and various Creative Zen models. Some products are currently out of stock.

Understanding headphones made in the usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Open-Back Headphones | Lightweight design, natural soundstage, breathable materials | Professional studios, audiophile listening | Pros: Excellent sound quality; Cons: Less isolation, not ideal for noisy environments. |

| Closed-Back Headphones | Sound isolation, robust design, enhanced bass response | Live sound monitoring, broadcasting | Pros: Superior noise isolation; Cons: Can be heavier and less comfortable for long wear. |

| In-Ear Monitors (IEMs) | Custom-fit options, portable, high sound fidelity | Musicians, sound engineers, mobile professionals | Pros: Compact and portable; Cons: Can be uncomfortable for prolonged use without proper fit. |

| Noise-Canceling Headphones | Active noise cancellation technology, often wireless | Corporate environments, travel, fieldwork | Pros: Reduces ambient noise significantly; Cons: Typically more expensive and may require battery. |

| Audiophile Headphones | Premium materials, high-end drivers, handcrafted craftsmanship | High-end audio production, luxury retail | Pros: Exceptional sound quality and build; Cons: High price point, may not suit casual users. |

What Are the Characteristics of Open-Back Headphones and Their Suitability for B2B Buyers?

Open-back headphones are designed to provide a natural sound experience, offering a wider soundstage that mimics live music. Their lightweight structure and breathable materials make them ideal for prolonged use in professional environments such as recording studios and audiophile listening sessions. B2B buyers should consider their application; while they excel in sound quality, the lack of sound isolation makes them unsuitable for noisy settings.

Why Choose Closed-Back Headphones for Professional Use?

Closed-back headphones feature a robust design that enhances bass response and provides excellent sound isolation. This makes them particularly suitable for live sound monitoring and broadcasting, where external noise can interfere with audio quality. Buyers in the B2B space should weigh the benefits of superior noise isolation against potential comfort issues during extended use, as these headphones can be bulkier.

How Do In-Ear Monitors (IEMs) Serve B2B Needs?

In-ear monitors are compact, often custom-fit for individual users, and deliver high sound fidelity, making them a staple for musicians and sound engineers. Their portability is a significant advantage for mobile professionals who require reliable audio quality on the go. When purchasing IEMs, B2B buyers should prioritize fit and comfort, as an improper fit can lead to discomfort during long sessions.

What Are the Benefits of Noise-Canceling Headphones in Corporate Settings?

Noise-canceling headphones utilize active technology to reduce ambient noise, making them an excellent choice for corporate environments, travel, and fieldwork. They help improve focus and productivity by minimizing distractions. However, their higher price point and reliance on battery power can be considerations for B2B buyers looking for cost-effective solutions.

Why Invest in Audiophile Headphones for High-End Audio Production?

Audiophile headphones are characterized by premium materials and high-end drivers, often handcrafted to ensure superior sound quality. These headphones are ideal for high-end audio production and luxury retail environments where sound fidelity is paramount. B2B buyers should consider the investment required, as these products can be significantly more expensive but deliver unmatched audio performance.

Key Industrial Applications of headphones made in the usa

| Industry/Sector | Specific Application of Headphones Made in the USA | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Professional Audio Production | High-fidelity monitoring in recording studios | Ensures accurate sound reproduction for mixing and mastering | Look for durability, comfort for long sessions, and sound quality. |

| Aviation and Aerospace | Communication headsets for pilots and air traffic controllers | Enhances clarity in communication in high-noise environments | Certifications for safety and reliability are crucial. |

| Medical and Healthcare | Noise-cancelling headphones for patient care and therapy | Improves patient comfort and focus during treatments | Compliance with health regulations and ease of cleaning. |

| Education and Training | Headphones for immersive learning experiences in classrooms | Facilitates better engagement and comprehension for students | Consider adjustable fit and compatibility with various devices. |

| Military and Defense | Tactical communication headsets for soldiers and operatives | Provides reliable communication in critical situations | Emphasis on ruggedness, noise isolation, and tactical features. |

How Are Headphones Made in the USA Used in Professional Audio Production?

In professional audio production, headphones made in the USA are essential for monitoring sound during recording sessions. Brands like Grado and Audeze offer high-fidelity options that provide accurate sound reproduction, crucial for mixing and mastering. These headphones help sound engineers and producers ensure that the final audio output meets industry standards. Buyers from regions like Europe and the Middle East should prioritize durability and comfort, as studio sessions can extend over long hours.

What Role Do Headphones Play in Aviation and Aerospace?

In the aviation sector, communication headsets crafted in the USA are vital for pilots and air traffic controllers. These headphones are designed to filter out ambient noise, allowing for clear communication in often chaotic environments. Buyers must consider certifications for safety and reliability, especially when sourcing for international operations in regions such as Africa and South America, where aviation standards may vary.

How Are Noise-Cancelling Headphones Utilized in Healthcare?

Noise-cancelling headphones made in the USA are increasingly employed in medical settings to enhance patient care. These headphones can improve patient comfort and focus during therapies and procedures, creating a more calming environment. International buyers should ensure compliance with health regulations and prioritize ease of cleaning, as hygiene is paramount in healthcare applications.

What Benefits Do Headphones Offer in Educational Settings?

In educational environments, headphones manufactured in the USA facilitate immersive learning experiences. They are used in classrooms to enhance engagement and comprehension, particularly in language learning and multimedia presentations. Buyers should look for adjustable fit and compatibility with various educational technologies to ensure that they meet the diverse needs of students.

Why Are Tactical Communication Headsets Important in Military Applications?

In military and defense sectors, tactical communication headsets are crucial for soldiers and operatives, providing reliable communication in critical situations. These headphones must be rugged, offer noise isolation, and include tactical features that enhance operational effectiveness. Buyers from international markets should focus on sourcing products that meet stringent military specifications to ensure optimal performance in diverse and challenging environments.

3 Common User Pain Points for ‘headphones made in the usa’ & Their Solutions

Scenario 1: High Import Costs and Shipping Delays

The Problem:

B2B buyers often face significant challenges related to high import costs and shipping delays when sourcing headphones made in the USA for their businesses. For international buyers from regions like Africa and South America, these issues can be exacerbated by local customs regulations and tariffs. This can lead to inflated costs that can erode profit margins, particularly for businesses that require bulk purchases. Additionally, unexpected delays in shipping can disrupt timelines for product launches or marketing campaigns, causing further complications in customer satisfaction and brand reputation.

The Solution:

To mitigate these challenges, B2B buyers should establish direct relationships with American manufacturers or distributors to negotiate better shipping terms and lower costs. Engaging with manufacturers who have streamlined logistics and established partnerships with shipping companies can reduce lead times and costs. Additionally, consider utilizing freight forwarders who specialize in international shipping for electronics, as they can provide insights into the most cost-effective shipping routes and practices. Buyers can also explore purchasing in larger volumes to benefit from bulk pricing, which can help offset shipping costs. Lastly, staying informed about local customs regulations and working with local trade experts can help navigate any potential barriers in the importing process.

Scenario 2: Limited Product Variety for Professional Use

The Problem:

Another common pain point is the limited variety of headphones made in the USA that cater specifically to professional use cases, such as audio engineering, live sound, or studio monitoring. Many international buyers may find that available options do not meet their specific audio quality or ergonomic requirements. This is particularly true for businesses in the music and entertainment industries, where high fidelity and comfort during extended use are paramount.

The Solution:

To address this issue, B2B buyers should conduct thorough market research to identify manufacturers that specialize in professional-grade audio equipment. It’s beneficial to engage with manufacturers that offer customizable options, allowing businesses to specify features such as sound profiles, comfort designs, and materials. Buyers can also participate in industry trade shows or audio expos, such as CanJam or the Florida Audio Expo, to directly test products and establish connections with brands that may not be widely advertised. Collaborating with audio consultants can provide valuable insights into selecting the right headphones that meet professional standards, ensuring that businesses invest in quality products that enhance their operational effectiveness.

Scenario 3: Quality Assurance and Warranty Concerns

The Problem:

Quality assurance is a significant concern for B2B buyers, particularly when sourcing products from international markets. Many buyers worry about the reliability and durability of headphones made in the USA, especially when investing in high-ticket items. This concern is compounded when manufacturers do not offer comprehensive warranties or clear quality assurance processes, leading to potential losses if products fail to meet expectations.

The Solution:

To alleviate these concerns, B2B buyers should prioritize sourcing headphones from reputable manufacturers that provide clear warranty terms and quality assurance protocols. Researching the manufacturer’s track record for product durability and customer service can provide peace of mind. Additionally, buyers should request samples before making bulk purchases to evaluate the product’s performance and comfort firsthand. Establishing clear communication with the manufacturer regarding warranty coverage and repair services can also ensure that buyers have support in case of defects or issues. Utilizing platforms that aggregate customer reviews and testimonials can help buyers make informed decisions and select manufacturers known for their commitment to quality and customer satisfaction.

Strategic Material Selection Guide for headphones made in the usa

What Are the Key Materials Used in Headphones Made in the USA?

When selecting materials for headphones manufactured in the USA, several factors come into play, including performance, durability, and cost. Here, we analyze four common materials: aluminum, plastic, wood, and leather, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Aluminum Enhance Headphone Performance?

Aluminum is a popular choice for headphone frames and components due to its lightweight nature and strength. It typically has a high corrosion resistance and can withstand a range of temperatures, making it suitable for various environments.

Pros: Aluminum offers excellent durability and a premium feel, which can enhance the overall aesthetic appeal of the product. Its manufacturing process is relatively straightforward, allowing for precise machining and finishing.

Cons: While aluminum is not the most expensive material, it is costlier than some plastics. Additionally, it can be prone to scratches and dents if not properly treated, which may affect the product’s long-term appearance.

Impact on Application: Aluminum is compatible with various audio components and can effectively dampen vibrations, leading to improved sound quality.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with international standards such as ASTM for material specifications, as well as consider the availability of aluminum in their local markets.

Why Is Plastic a Common Choice for Headphone Components?

Plastic is often used in headphone manufacturing due to its versatility and cost-effectiveness. It can be molded into complex shapes and is generally resistant to impact.

Pros: The primary advantage of plastic is its low cost, making it an attractive option for budget-conscious buyers. It also allows for a wide range of colors and finishes, enhancing branding opportunities.

Cons: Plastic may not offer the same level of durability as metals, and it can be susceptible to wear and tear over time. Additionally, some plastics may not be environmentally friendly, which could be a consideration for eco-conscious markets.

Impact on Application: Plastic components can be effective in reducing weight, making headphones more comfortable for extended use. However, they may not provide the same acoustic performance as metal components.

Considerations for International Buyers: Buyers should be aware of local regulations regarding plastic use, particularly in Europe, where environmental standards are stringent.

How Does Wood Influence the Sound Quality of Headphones?

Wood is increasingly used in high-end headphone designs due to its unique acoustic properties. It is often employed in ear cups to enhance sound quality.

Pros: Wood provides natural sound dampening, resulting in a warmer audio profile. It also adds an aesthetic appeal that can differentiate products in a crowded market.

Cons: The main drawback of wood is its higher cost and the complexity involved in the manufacturing process. Wood is also more sensitive to humidity and temperature changes, which can affect its longevity.

Impact on Application: Wood is particularly suited for audiophile-grade headphones, where sound quality is paramount. However, it may not be ideal for all applications, especially where durability is a concern.

Considerations for International Buyers: Buyers should consider the source of the wood to ensure it complies with sustainability practices, especially in regions like Europe where eco-certifications are valued.

What Role Does Leather Play in Headphone Comfort and Aesthetics?

Leather is often used for ear pads and headbands due to its comfort and luxurious appearance.

Pros: Leather offers excellent comfort, which is crucial for long listening sessions. It also conveys a premium feel, enhancing the product’s marketability.

Cons: The primary disadvantage of leather is its cost, as it tends to be more expensive than synthetic alternatives. Additionally, it requires maintenance to prevent wear and tear.

Impact on Application: Leather contributes to a high-quality user experience, making it suitable for luxury headphone brands. However, it may not be suitable for all markets, particularly where vegan or cruelty-free products are preferred.

Considerations for International Buyers: Buyers should be aware of cultural preferences regarding leather use, especially in regions like the Middle East, where there may be sensitivities around animal products.

Summary Table of Material Selection for Headphones Made in the USA

| Material | Typical Use Case for headphones made in the usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Headphone frames and components | Lightweight and durable | Prone to scratches | Medium |

| Plastic | Budget headphones and components | Cost-effective and versatile | Less durable than metals | Low |

| Wood | High-end audiophile headphones | Natural sound dampening | Higher cost and sensitive to humidity | High |

| Leather | Ear pads and headbands | Excellent comfort and luxury feel | Expensive and requires maintenance | High |

This analysis provides valuable insights for international B2B buyers looking to source headphones made in the USA, emphasizing the importance of material selection in product performance and market suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for headphones made in the usa

What Are the Key Stages in the Manufacturing Process for Headphones Made in the USA?

The manufacturing process for headphones made in the USA involves several critical stages that ensure the final product meets high standards of quality and performance. These stages can be broadly categorized into material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Sourced and Processed?

The first step in headphone manufacturing is material preparation. This stage involves sourcing high-quality materials, which can include metals, plastics, and various types of foam. Companies often prioritize local suppliers to support domestic manufacturing, which can enhance supply chain reliability and reduce lead times.

Materials are inspected for quality and consistency before being processed. For instance, metals used in headphone drivers must meet specific specifications for weight and acoustic properties. This initial quality check is crucial, as it lays the foundation for the entire manufacturing process.

Forming: What Techniques Are Used to Shape Headphone Components?

Once materials are prepared, the next step is forming. This stage involves shaping components such as ear cups, headbands, and driver housings. Common techniques include injection molding for plastics and CNC machining for metals.

In some cases, advanced techniques such as 3D printing are employed to create intricate designs that enhance comfort and performance. The choice of technique can significantly impact the product’s durability and sound quality, making it essential for manufacturers to choose the right processes based on their design specifications.

Assembly: How Are Components Put Together to Create the Final Product?

The assembly stage involves combining all the formed components into a complete headphone unit. This is typically done in a clean room environment to minimize dust and debris, which can affect performance. Skilled technicians often hand-assemble components to ensure precision, especially in high-end models where acoustic performance is paramount.

During assembly, manufacturers may also incorporate features such as detachable cables or custom driver placements, which can enhance the user experience. Quality control checkpoints are established throughout this stage to monitor for defects and ensure that components fit together seamlessly.

Finishing: What Processes Enhance the Aesthetic and Functional Quality of Headphones?

The finishing stage includes painting, polishing, and final inspections. This stage not only enhances the aesthetic appeal of the headphones but also protects them from wear and tear. For instance, coatings may be applied to prevent scratches and improve durability.

Final inspections during this phase involve checking for visual defects, ensuring that all components are functioning correctly, and verifying that the headphones meet the specified acoustic performance standards. This attention to detail is crucial for maintaining brand reputation and customer satisfaction.

What Quality Assurance Standards Are Relevant for Headphones Made in the USA?

Quality assurance is a vital aspect of manufacturing headphones in the USA, particularly for B2B buyers who demand reliability and consistency. Several international and industry-specific standards are essential for ensuring quality.

Which International Standards Should Buyers Be Aware Of?

The ISO 9001 standard is one of the most recognized quality management systems globally. It provides a framework for improving processes, ensuring product quality, and enhancing customer satisfaction. Manufacturers adhering to ISO 9001 demonstrate a commitment to continuous improvement, which is crucial for meeting the evolving needs of B2B buyers.

Additionally, specific certifications such as CE mark and API (American Petroleum Institute) may apply depending on the headphone’s intended use, especially in sectors like telecommunications or medical devices. Understanding these certifications can help buyers gauge the reliability of their suppliers.

What Are the Key Quality Control Checkpoints in Headphone Manufacturing?

Quality control (QC) is integrated into various stages of the manufacturing process, with several key checkpoints identified:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During assembly, manufacturers conduct inspections to monitor the quality of the assembly process, ensuring that no defects occur as components are combined.

-

Final Quality Control (FQC): This final checkpoint occurs after assembly and finishing, where the entire product undergoes thorough testing for performance, durability, and aesthetic quality.

These checkpoints are designed to catch potential issues at various stages, reducing the likelihood of defective products reaching the market.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is crucial. Buyers can employ several strategies to ensure their suppliers maintain high standards.

What Methods Can Buyers Use to Conduct Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess quality control practices. Buyers can request to visit manufacturing facilities to observe processes, review quality management systems, and evaluate compliance with international standards like ISO 9001.

Additionally, suppliers should be willing to provide quality assurance documentation, such as inspection reports and certificates of compliance, which verify adherence to relevant standards.

How Do Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These services can conduct independent audits, performance testing, and compliance checks, offering buyers peace of mind regarding the reliability of their suppliers.

What Nuances Should International Buyers Consider Regarding QC and Certification?

International buyers should be aware of specific nuances regarding quality assurance and certification that can vary by region. For instance, some countries may have stricter import regulations, which necessitate compliance with local standards beyond those required in the USA.

Understanding these regional differences can help buyers navigate the complexities of international trade and ensure that the products they source meet both local and international expectations for quality and performance.

By prioritizing thorough due diligence in manufacturing processes and quality assurance, B2B buyers can establish long-term partnerships with reliable suppliers of headphones made in the USA, ensuring they receive products that meet their high standards for quality and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘headphones made in the usa’

Introduction

Navigating the procurement of headphones made in the USA requires a strategic approach to ensure quality, compliance, and supplier reliability. This step-by-step checklist is designed to guide international B2B buyers through the essential actions needed to successfully source American-made headphones, particularly for markets in Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing headphones that meet your needs. Consider factors such as sound quality, type (wired or wireless), design preferences, and target user demographics. Detailed specifications will help you communicate effectively with suppliers and ensure that the products align with your market expectations.

Step 2: Identify Reputable Manufacturers

Research and compile a list of reputable manufacturers known for producing headphones in the USA. Look for brands with a strong history of quality and innovation, such as Grado Labs and Audeze. This step is crucial as it sets the foundation for reliable sourcing, ensuring that the products meet your quality standards.

Step 3: Evaluate Potential Suppliers

Before committing, it’s essential to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Key aspects to investigate include:

– Production Capacity: Ensure they can meet your demand.

– Quality Assurance Processes: Look for certifications such as ISO or adherence to industry standards.

Step 4: Request Samples for Testing

Always request samples of the headphones before finalizing any orders. Testing samples allows you to assess the sound quality, comfort, and durability firsthand. Use this opportunity to evaluate how well the product meets your technical specifications and gather feedback from potential users.

Step 5: Verify Compliance with Regulations

Ensure that the headphones comply with both local and international regulations, including safety and environmental standards. Check for certifications such as CE marking for European markets or FCC compliance for U.S. standards. Compliance is critical to avoid legal issues and ensure market acceptance.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, it’s time to negotiate terms. Discuss pricing, payment terms, lead times, and shipping arrangements. Clear agreements on these aspects can prevent misunderstandings and ensure a smoother procurement process.

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor the production and delivery of your headphone orders. This may include regular communication with the supplier, on-site inspections, or third-party audits. A robust quality control system is essential to maintain the standards expected by your customers and to ensure ongoing supplier accountability.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing headphones made in the USA, ensuring that they secure high-quality products that meet their specific requirements.

Comprehensive Cost and Pricing Analysis for headphones made in the usa Sourcing

Understanding the cost structure and pricing dynamics for sourcing headphones made in the USA is essential for international B2B buyers seeking quality audio products. This analysis delves into the key cost components, price influencers, and practical tips for negotiating favorable terms.

What are the Key Cost Components for Headphones Made in the USA?

-

Materials: The choice of materials significantly impacts the overall cost. Premium components such as high-grade metals, natural woods, and advanced speaker drivers enhance audio quality but also increase expenses. For instance, brands like Grado utilize Brazilian walnut, which not only elevates the product but also adds to the cost.

-

Labor: Manufacturing headphones in the USA often involves higher labor costs compared to countries with lower wage standards. Skilled labor is crucial for the precision required in high-fidelity audio products. Handcrafting techniques, as seen in brands like Audeze and Campfire Audio, further contribute to labor costs.

-

Manufacturing Overhead: This encompasses costs related to facilities, utilities, and maintenance. American manufacturers may face higher overhead costs due to regulatory compliance and quality standards.

-

Tooling: Initial investment in specialized equipment for manufacturing processes can be significant, especially for custom designs or specialized headphone types.

-

Quality Control (QC): Rigorous QC processes are vital to ensure product reliability and performance, which can add to the cost but is essential for maintaining brand reputation.

-

Logistics: Shipping and handling costs can be higher for international buyers due to tariffs, shipping times, and customs duties. Understanding Incoterms can help mitigate some of these costs.

-

Margin: Manufacturers typically add a margin to cover their costs and profit. This margin can vary based on brand positioning and market demand.

How Do Price Influencers Affect Headphone Sourcing?

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs, making it advantageous for buyers to negotiate bulk purchases. However, brands may impose MOQs that can impact smaller buyers.

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers should be clear about their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: The level of certification (e.g., CE, RoHS) can influence pricing. Products made from sustainable or premium materials often command higher prices.

-

Supplier Factors: The reputation and reliability of the supplier can impact both pricing and service levels. Established brands may charge more due to their market position and perceived value.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is crucial. Incoterms dictate who bears the cost at various stages of shipping, which can affect the final landed cost of the products.

What Negotiation Tips Can Help International B2B Buyers?

-

Establish Relationships: Building a rapport with suppliers can facilitate better pricing and terms. Long-term relationships often yield more favorable outcomes.

-

Focus on Total Cost of Ownership (TCO): Rather than just the initial purchase price, consider the TCO, which includes maintenance, warranty, and potential resale value. This holistic view can justify higher upfront costs if they lead to better long-term value.

-

Be Aware of Pricing Nuances: Different markets may have varying pricing structures due to local demand, competition, and economic conditions. For buyers from Africa or South America, understanding these nuances can provide leverage in negotiations.

-

Request Samples: Before committing to larger orders, requesting samples can help assess quality and suitability, reducing the risk of costly mistakes.

-

Negotiate Terms: Don’t hesitate to negotiate payment terms, delivery schedules, and other contractual elements. Flexibility in these areas can lead to more favorable pricing structures.

Conclusion

Sourcing headphones made in the USA involves navigating a complex landscape of costs and pricing influencers. By understanding these components and employing strategic negotiation tactics, international B2B buyers can secure high-quality products that meet their specific needs while optimizing their costs. Keep in mind that indicative prices can vary significantly based on the factors discussed, so thorough research and due diligence are essential.

Alternatives Analysis: Comparing headphones made in the usa With Other Solutions

Exploring Alternatives for Headphones: A Comparative Analysis

When evaluating headphones made in the USA, it’s essential to consider viable alternatives that may meet your audio needs. Understanding the strengths and weaknesses of each option can help international B2B buyers make informed purchasing decisions. Below, we compare headphones made in the USA with two notable alternatives: imported headphones and custom in-ear monitors (CIEMs).

Comparison Table

| Comparison Aspect | Headphones Made In The USA | Imported Headphones | Custom In-Ear Monitors (CIEMs) |

|---|---|---|---|

| Performance | High-quality sound, often handcrafted | Variable quality; depends on brand | Tailored sound profile, superior isolation |

| Cost | Generally higher due to craftsmanship | More affordable options available | Premium pricing due to custom design |

| Ease of Implementation | Ready to use; limited models | Wide variety; easy to procure | Requires fitting and longer lead time |

| Maintenance | Durable, often with good warranty | Variable; some may have limited support | Careful handling necessary; typically durable |

| Best Use Case | Professional audio, audiophiles | General consumer, casual listening | Musicians, audiophiles seeking unique fit |

What Advantages Do Headphones Made in the USA Offer?

Headphones made in the USA, such as those from Grado Labs or Audeze, are known for their exceptional performance and craftsmanship. These headphones often feature high-quality materials and are assembled by skilled artisans, which can result in superior sound quality. However, they come at a premium price point, which may not be suitable for all budgets. Moreover, the limited variety can pose challenges for businesses needing a broad selection.

How Do Imported Headphones Compare?

Imported headphones, such as those from brands like Sony or Bose, typically offer a wide range of choices at various price points. This variety makes them accessible for businesses looking for cost-effective solutions. However, the performance can vary significantly based on the manufacturer, with some offering excellent sound quality while others may not meet professional standards. For B2B buyers, the ease of procurement and lower costs can be appealing, but it’s crucial to assess the quality and reliability of the specific brands being considered.

What Are the Benefits of Custom In-Ear Monitors (CIEMs)?

Custom in-ear monitors provide a unique solution tailored to individual listening preferences, particularly for musicians and audio professionals. They are designed to fit the user’s ears perfectly, offering exceptional sound isolation and a personalized audio experience. However, the downside is the higher cost associated with the custom fitting process and the longer lead times for delivery. For businesses focused on professional audio quality and unique sound characteristics, CIEMs can be an excellent investment.

Conclusion: How to Choose the Right Headphone Solution

In determining the best headphone solution for your organization, consider your specific audio needs, budget constraints, and the intended use case. If high-quality performance and craftsmanship are paramount, headphones made in the USA may be the best fit. For those prioritizing cost-effectiveness and variety, imported headphones could be more appropriate. Meanwhile, businesses seeking tailored audio experiences might find value in custom in-ear monitors. Ultimately, aligning the headphone choice with your organization’s goals will ensure optimal satisfaction and performance.

Essential Technical Properties and Trade Terminology for headphones made in the usa

What Are the Key Technical Properties of Headphones Made in the USA?

When sourcing headphones manufactured in the USA, understanding key technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

-

Driver Size and Type

Headphone drivers convert electrical signals into sound. The size of the driver, typically measured in millimeters (mm), affects sound quality and bass response. For instance, a 52mm driver, like that used in the Grado Signature S950, can deliver a richer sound experience. In a B2B context, larger drivers often indicate a higher-end product suitable for professional audio applications. -

Material Composition

The materials used in headphones significantly impact durability, comfort, and audio quality. Common materials include lightweight metals, high-grade plastics, and natural woods, such as Brazilian walnut in some Grado models. Understanding material properties can help businesses ensure they are purchasing products that meet their quality standards and can withstand intensive use. -

Impedance

Measured in ohms (Ω), impedance affects how much power a headphone requires to produce sound. Lower impedance headphones (16-32Ω) are suitable for portable devices, while higher impedance models (above 50Ω) typically require dedicated amplifiers. B2B buyers need to consider impedance to ensure compatibility with their audio equipment and intended use, such as studio mixing or casual listening. -

Frequency Response

This specification indicates the range of frequencies a headphone can reproduce, typically measured in Hertz (Hz). A wider frequency response (e.g., 20 Hz to 20 kHz) allows for a more detailed sound profile. For professional applications, understanding frequency response is critical for ensuring that headphones meet the audio fidelity required for tasks like music production or sound engineering. -

Weight and Comfort Features

The weight of headphones, often expressed in grams, plays a vital role in user comfort, especially during extended use. Features such as padded ear cups and adjustable headbands can enhance comfort. B2B buyers should prioritize these factors to ensure their products are suitable for long-term use in professional settings. -

Warranty and Support

A robust warranty reflects the manufacturer’s confidence in their product quality. For example, Grado offers a 2-year limited warranty, which provides peace of mind for B2B purchasers. Understanding warranty terms can help businesses assess the long-term viability of their investment.

What Are Common Trade Terms Related to Headphones Manufacturing?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some commonly used terms in the headphones manufacturing sector:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of headphones, businesses may source components from OEMs to assemble their own branded products. Understanding OEM relationships can help buyers navigate supply chains effectively. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it impacts inventory costs and purchasing strategies. Knowing the MOQ can help businesses plan their orders to meet demand without overextending their budgets. -

RFQ (Request for Quotation)

An RFQ is a document that companies use to solicit price quotes from suppliers. When sourcing headphones, submitting an RFQ allows buyers to compare prices and terms from different manufacturers. This process is essential for ensuring cost-effectiveness in procurement. -

Incoterms

These are international commercial terms that define the responsibilities of sellers and buyers in international transactions. Understanding Incoterms is critical for B2B buyers to clarify shipping responsibilities, risks, and costs when importing headphones from the USA. -

Lead Time

Lead time refers to the duration from placing an order to receiving the product. It is a key factor in supply chain management, especially for businesses that require timely delivery of headphones for events or launches. Being aware of lead times can help buyers plan their inventory and marketing strategies effectively. -

Quality Assurance (QA)

QA encompasses the processes and procedures to ensure that products meet specified quality standards. For headphones made in the USA, QA practices are crucial in maintaining brand reputation and customer satisfaction. B2B buyers should inquire about QA protocols to ensure product reliability.

Understanding these technical properties and trade terms will empower international B2B buyers to make well-informed decisions when sourcing headphones made in the USA, ensuring quality, compatibility, and value in their purchases.

Navigating Market Dynamics and Sourcing Trends in the headphones made in the usa Sector

What Are the Current Market Dynamics and Key Trends in the Headphones Made in the USA Sector?

The global market for headphones is experiencing robust growth, driven by rising demand for high-quality audio experiences across various sectors, including entertainment, gaming, and professional audio. International B2B buyers are increasingly looking for products that combine quality with cultural relevance, particularly in regions such as Africa, South America, the Middle East, and Europe. As competition intensifies, manufacturers of headphones made in the USA are leveraging technological advancements and artisanal craftsmanship to differentiate themselves.

Emerging trends include the integration of smart technology, such as noise-cancellation features and wireless connectivity, which are essential for meeting the needs of today’s tech-savvy consumers. Moreover, the growing popularity of remote work and online learning has spurred demand for high-quality audio solutions, leading companies to explore partnerships with American brands that specialize in professional and consumer audio products.

Buyers are also becoming more discerning, seeking not only superior sound quality but also brands with a rich heritage and commitment to craftsmanship. This trend aligns with the increasing preference for locally-made products that resonate with consumers’ values and lifestyles. Brands like Grado Labs and Master & Dynamic exemplify this approach, blending traditional manufacturing techniques with modern design and technology.

How Important Are Sustainability and Ethical Sourcing in the Headphones Made in the USA Sector?

Sustainability and ethical sourcing are no longer optional considerations for B2B buyers; they are essential components of a comprehensive purchasing strategy. The environmental impact of electronics manufacturing is significant, and headphones made in the USA often benefit from shorter supply chains and more stringent regulations governing labor and environmental practices. This makes them an attractive option for international buyers who prioritize sustainability in their sourcing decisions.

American manufacturers are increasingly utilizing eco-friendly materials and processes, such as biodegradable plastics, recycled metals, and sustainable wood sources. Certifications like FSC (Forest Stewardship Council) for wood products and ISO standards for manufacturing processes are becoming important benchmarks for discerning buyers. These certifications not only enhance product credibility but also align with the growing consumer demand for transparency and responsibility in production practices.

Moreover, brands that emphasize ethical labor practices and local sourcing can attract clients looking to enhance their corporate social responsibility (CSR) profiles. By choosing headphones made in the USA, buyers can support local economies and ensure that their purchases contribute to a more sustainable future.

What Is the Brief Evolution and History of Headphones Made in the USA?

The evolution of headphones made in the USA can be traced back to the mid-20th century, when audio innovation began to take off. Companies like Grado Labs, founded in 1953, pioneered the development of high-fidelity audio equipment, including headphones that have since become synonymous with quality and craftsmanship. Over the decades, American manufacturers have maintained a focus on artisanal production techniques, which have helped to establish a reputation for excellence.

As the market has expanded, brands have adapted to changing consumer preferences and technological advancements, leading to the introduction of wireless and noise-cancelling models. Despite these advancements, the commitment to quality and the “Made in the USA” label remains a significant selling point, particularly for B2B buyers looking to invest in reliable and ethically produced audio equipment. This heritage of innovation and craftsmanship continues to shape the landscape of the headphones market, making American-made products a compelling choice for international buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of headphones made in the usa

-

How do I ensure the quality of headphones made in the USA?

To ensure quality when sourcing headphones made in the USA, consider conducting thorough supplier vetting. This includes reviewing certifications, customer testimonials, and product samples. Engage in direct communication with manufacturers to understand their quality assurance processes and production standards. It’s also beneficial to visit manufacturing facilities, if possible, to observe operations and quality control measures firsthand. Establishing a clear quality assurance agreement can help protect your interests and ensure that the products meet your specifications. -

What are the key features to look for in B2B headphones?

When sourcing headphones for B2B purposes, prioritize durability, sound quality, and comfort. Look for features such as noise cancellation, wireless connectivity, and customizable designs. Assess whether the headphones can accommodate various environments, such as offices or outdoor settings. Additionally, consider the warranty and customer service support offered by the manufacturer. These features will ensure that the headphones meet the demands of your business and provide a satisfactory user experience. -

What is the minimum order quantity (MOQ) for headphones made in the USA?

Minimum order quantities (MOQs) for headphones made in the USA can vary significantly by manufacturer. Typically, MOQs range from 50 to 500 units, depending on the brand and customization options. For custom designs or specialized features, the MOQ may be higher. It’s advisable to discuss your specific needs directly with suppliers to negotiate favorable terms. Understanding the MOQ is crucial for budgeting and inventory planning as you scale your business. -

How can I customize headphones for my brand?

Customizing headphones typically involves selecting colors, materials, and branding options such as logo placement. Many manufacturers offer tailored services, allowing you to create a unique product that aligns with your brand identity. To begin the process, communicate your requirements clearly to potential suppliers and request samples of previous custom work. Discuss timelines and costs associated with customization to ensure your project stays within budget and schedule. -

What payment terms should I expect when ordering headphones from the USA?

Payment terms can vary by supplier but generally include options such as upfront deposits, net 30 or net 60 terms, and letters of credit for larger orders. It’s essential to clarify payment terms during initial discussions to avoid misunderstandings. Consider establishing a secure payment method, such as escrow services, to protect both parties. Additionally, ensure that the terms are documented in the purchase agreement to safeguard your interests. -

How do I handle logistics and shipping for headphones made in the USA?

Logistics for shipping headphones internationally can be complex. Work with suppliers who have experience in exporting goods to your region. Confirm that they can provide all necessary documentation, including customs paperwork. It’s advisable to partner with a reliable freight forwarder to navigate shipping regulations and ensure timely delivery. Discuss shipping costs upfront and consider whether your supplier offers options for bulk shipping to reduce costs. -

What certifications should I look for when sourcing headphones made in the USA?

Look for certifications that indicate compliance with industry standards, such as CE, FCC, and RoHS. These certifications ensure that the headphones meet safety, environmental, and performance requirements. Additionally, inquire about ISO certifications, which reflect a manufacturer’s commitment to quality management systems. Understanding these certifications will help you assess the reliability and safety of the products you plan to source. -

How can I assess the reputation of a headphone manufacturer in the USA?

To assess a manufacturer’s reputation, start by researching customer reviews and testimonials online. Check industry forums and social media platforms for discussions about their products and services. Networking with other businesses in your industry can provide valuable insights into their experiences. Additionally, consider requesting references from the manufacturer and contacting previous clients to gain a firsthand account of their service and product quality. This comprehensive approach will help you make an informed decision.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for headphones made in the usa

What Are the Key Advantages of Sourcing Headphones Made in the USA?

In conclusion, the strategic sourcing of headphones made in the USA presents a unique opportunity for international B2B buyers seeking high-quality audio products. American-made headphones, such as those from Grado Labs and Audeze, are renowned for their craftsmanship and superior sound quality, catering primarily to professional markets. This focus on quality over quantity not only enhances brand reputation but also aligns with growing consumer demand for ethically produced goods.

Furthermore, sourcing from the USA can mitigate supply chain risks and ensure compliance with stringent manufacturing standards. As global markets increasingly prioritize sustainability and local production, American-made headphones offer a compelling value proposition.

How Can International Buyers Leverage This Market Trend?

As you explore partnerships with American headphone manufacturers, consider the long-term benefits of integrating these products into your offerings. The demand for premium audio equipment is on the rise across diverse markets, including Africa, South America, the Middle East, and Europe. Engaging with US-based companies can provide your business with a competitive edge, ensuring you meet the expectations of discerning customers.

What’s Next for Your Sourcing Strategy?

Now is the time to act. By investing in American-made headphones, you not only enhance your product line but also contribute to a sustainable manufacturing ecosystem. Reach out to manufacturers to discuss potential partnerships and explore innovative solutions that will elevate your brand’s presence in the global audio market.