Top 7 Gehr Plastics Usa List and Guide: How To Solve Scenario 1: …

Introduction: Navigating the Global Market for gehr plastics usa

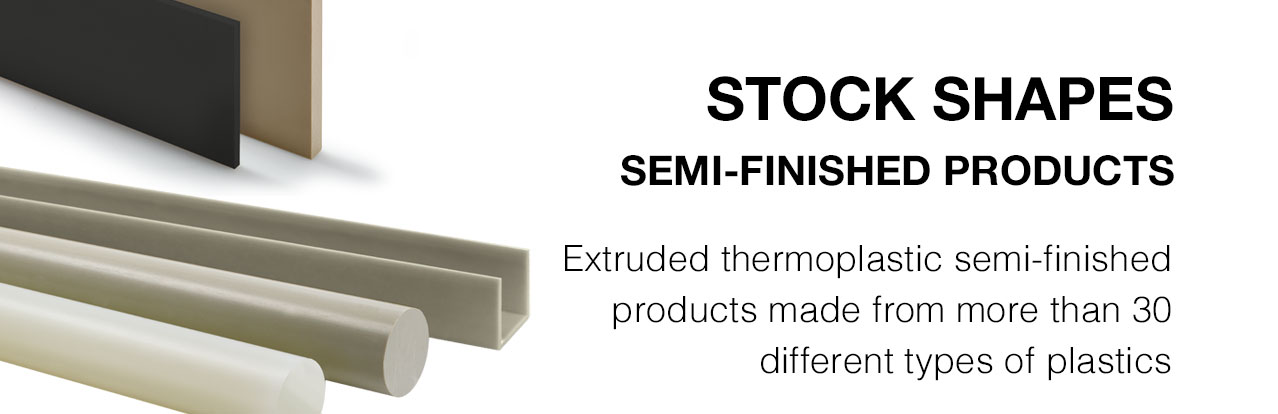

In the dynamic world of B2B sourcing, navigating the complexities of procuring high-quality materials such as those offered by GEHR Plastics USA can present significant challenges. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, often grapple with issues related to product specifications, compliance with local regulations, and ensuring supply chain reliability. This comprehensive guide to GEHR Plastics USA aims to demystify the procurement process, providing insights into the diverse range of semi-finished thermoplastic products available, including extruded rods, sheets, profiles, and tubes.

Throughout this guide, we will explore the various applications of GEHR Plastics’ offerings across industries such as food, medical, and mechanical engineering. We will also delve into effective supplier vetting strategies, helping you assess quality standards, certifications, and production capabilities. Additionally, cost considerations and pricing structures will be thoroughly analyzed, enabling you to make informed financial decisions that align with your business goals.

By leveraging the insights presented in this guide, international B2B buyers can enhance their purchasing strategies, ultimately leading to more efficient sourcing and superior product outcomes. Understanding the nuances of GEHR Plastics USA’s offerings not only empowers buyers to overcome common procurement hurdles but also positions them for success in an increasingly competitive market.

Top 10 Gehr Plastics Usa Manufacturers & Suppliers List

1. Gehr Plastics – Key Products

Domain: gehrplastics.com

Registered: 1996 (29 years)

Introduction: Key Products:

1. MEDI-GEHR®

2. ECO-GEHR®

3. FIL-A-GEHR®

Materials Offered:

– PVC Type 1

– POM-ELS

– POM-10PE

– PA 6.10

– PA 6.6

– PA 12-TR

– WPC-PP

– PPO

– PPO-30GF

– POM-C

– PEI-30GF

– PPC

– PVC TYPE II

– CPVC

– PPH

– PP-30GF

– HDPE

– ABS

– PVDF

– PSU

– PEEK

Forms Available:

– Hollow Bars

– Hexagonal Bars

– L-Angle Profiles

– Square Bars

– U-Channels

– Square Tubes

– Rectangular Tubes

– Sheets

…

2. GEHR Plastics – Semi-Finished Thermoplastics

3. Gehr Plastics – Key Plastic Materials

Domain: professionalplastics.com

Registered: 1997 (28 years)

Introduction: Gehr Plastics offers a wide range of plastic materials including sheets, rods, tubing, profiles, and parts. Key materials include: Plexiglass Sheet, PEEK Sheets & Rod, Cast Acrylic Sheet, Polycarbonate Sheets, HDPE Sheets, Acetal Sheet & Rod, UHMW Sheet & Rod, Nylon Sheet & Rod, and Vespel SP-1. The company provides various materials such as ABS, Acetal/Delrin®, Acrylic/Plexiglass, Ceramics, Compo…

4. GEHR Plastics USA – Extruded Thermoplastic Products

Domain: explorium.ai

Registered: 2018 (7 years)

Introduction: GEHR Plastics USA manufactures a wide range of extruded thermoplastic products, including rods, sheets, profiles, and tubes. They specialize in rods with larger diameters and offer custom extrusion products upon request. Key materials include Acetal, Acrylic, and Acrylonitrile Butadiene Styrene (ABS).

5. GEHR Plastics – Semi-Finished Thermoplastics

6. Gehr Plastics Inc. – ECO-GEHR & fIL-A-GEHR

Domain: us.metoree.com

Registered: 2020 (5 years)

Introduction: Gehr Plastics Inc. manufactures thermoplastic products for various industries, including mechanical engineering, chemical apparatus, and the electrical industry. Key products include semi-finished products such as ECO-GEHR and fIL-A-GEHR, and they also offer post-processing services like centerless grinding of rods and marking with laser or inkjet printing. The company is known for its UHMWPE prod…

7. Gehr Plastics Inc. – HS Code 3916900500

Domain: panjiva.com

Registered: 2006 (19 years)

Introduction: Gehr Plastics Inc. exports products classified under HS Code 3916900500, which falls under the category of plastics and articles thereof. The shipment on 2021-12-14 had a gross weight of 5662.34 kg and a shipment quantity of 2751.24 kg. The value of goods for this shipment was $84,911 (CIF) and $20,293 (CIF) for the specific item. The shipment was sent to La Paloma Cia Metales SA Cv in Mexico.

Understanding gehr plastics usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| POM-C (Acetal) | High mechanical strength, low friction, and excellent dimensional stability | Mechanical engineering, automotive, and food industry | Pros: Durable, easy to machine. Cons: Limited chemical resistance. |

| PA12 (Nylon) | Excellent toughness, flexibility, and resistance to abrasion | Oil and gas, automotive, and aerospace industries | Pros: Good impact resistance. Cons: Moisture absorption can affect dimensions. |

| PEEK | Exceptional thermal stability, chemical resistance, and strength | Aerospace, medical devices, and electrical applications | Pros: High-performance material. Cons: Higher cost compared to other plastics. |

| PETG | Good impact resistance and clarity, easy to thermoform | Packaging, signage, and medical applications | Pros: Lightweight, recyclable. Cons: Lower heat resistance than other materials. |

| UHMW | Extremely low friction, high abrasion resistance | Material handling, food processing, and marine applications | Pros: Very durable, self-lubricating. Cons: Difficult to bond and machine. |

What are the Key Characteristics of POM-C (Acetal) and Its Applications?

POM-C, commonly known as Acetal, is recognized for its high mechanical strength and low friction properties. This makes it particularly suitable for precision components in mechanical engineering and automotive applications. Its excellent dimensional stability ensures that parts maintain their shape under varying conditions, making it a preferred choice for manufacturers looking for reliability. However, buyers should note its limited resistance to certain chemicals, which may affect its use in specific environments.

How Does PA12 (Nylon) Stand Out in Industrial Applications?

PA12, or Nylon 12, is celebrated for its excellent toughness and flexibility, along with notable resistance to abrasion. This material is widely utilized in the oil and gas sector, as well as automotive and aerospace applications, where durability is paramount. PA12’s ability to withstand impact makes it a reliable choice, though it is important for buyers to consider its propensity to absorb moisture, which can alter its dimensions and affect performance over time.

What Makes PEEK a High-Performance Material for Specialized Industries?

PEEK (Polyether Ether Ketone) is a high-performance thermoplastic known for its exceptional thermal stability and chemical resistance. This material is ideal for demanding applications in aerospace, medical devices, and electrical sectors. PEEK’s superior strength and ability to perform under extreme conditions justify its higher price point. Buyers should weigh the cost against the performance benefits, especially in applications where failure is not an option.

Why Choose PETG for Packaging and Signage Solutions?

PETG is a popular choice for applications requiring good impact resistance and clarity. Its ease of thermoforming makes it suitable for packaging, signage, and medical applications where visibility and durability are crucial. While it is lightweight and recyclable, buyers should be aware that PETG has lower heat resistance compared to other materials, which may limit its use in high-temperature environments.

What are the Benefits and Limitations of UHMW in Material Handling?

Ultra-High Molecular Weight Polyethylene (UHMW) is distinguished by its extremely low friction and high abrasion resistance. This makes it an excellent choice for material handling, food processing, and marine applications. Its self-lubricating properties enhance performance in moving applications. However, buyers must consider its challenges in bonding and machining, which may require specialized techniques for effective use in their projects.

Key Industrial Applications of gehr plastics usa

| Industry/Sector | Specific Application of gehr plastics usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mechanical Engineering | Custom extruded rods and profiles for machinery components | Enhances machinery performance and durability | Material specifications, lead times, and custom designs |

| Food Industry | Food-grade POM-C sheets for processing equipment | Ensures compliance with safety standards | Certification for food safety, chemical resistance |

| Medical Industry | Biocompatible plastics for medical device manufacturing | Facilitates innovation in healthcare solutions | Regulatory approvals, material traceability |

| Oil and Gas | PEEK materials for high-temperature applications | Improves reliability in extreme environments | Temperature resistance, chemical compatibility |

| Chemical Apparatus Engineering | High-performance thermoplastics for chemical processing | Increases efficiency and safety in chemical handling | Chemical resistance, custom fabrication capabilities |

How Does GEHR Plastics USA Serve the Mechanical Engineering Sector?

In mechanical engineering, GEHR Plastics USA provides custom extruded rods and profiles tailored for various machinery components. These products are designed to enhance machinery performance and durability, addressing common issues such as wear and tear. For international buyers, it is essential to consider material specifications and lead times, as well as the possibility of custom designs to meet specific engineering requirements.

What Are the Food Industry Applications of GEHR Plastics USA?

GEHR Plastics USA manufactures food-grade POM-C sheets that are crucial for processing equipment in the food industry. These sheets ensure compliance with safety standards, thereby safeguarding food quality and consumer health. Buyers from regions such as Africa and South America should prioritize certifications for food safety and chemical resistance to ensure that the materials meet local regulations and industry standards.

How Are GEHR Plastics USA Products Used in the Medical Industry?

In the medical industry, GEHR Plastics USA specializes in providing biocompatible plastics for manufacturing medical devices. These materials enable innovation in healthcare solutions while ensuring patient safety. International buyers must pay attention to regulatory approvals and material traceability to comply with stringent medical standards, especially in regions with rigorous healthcare regulations like Europe and the Middle East.

What Role Does GEHR Plastics USA Play in the Oil and Gas Sector?

In the oil and gas industry, GEHR Plastics USA supplies PEEK materials that are designed for high-temperature applications. These materials enhance reliability in extreme environments, solving issues related to equipment failure and maintenance costs. Buyers need to consider temperature resistance and chemical compatibility to ensure that the products are suitable for their specific operational conditions.

Why Are GEHR Plastics USA’s Products Valuable for Chemical Apparatus Engineering?

GEHR Plastics USA offers high-performance thermoplastics that are essential for chemical processing applications. These materials increase efficiency and safety in chemical handling, addressing concerns related to durability and chemical exposure. Buyers should focus on chemical resistance and the ability to customize fabrication capabilities to meet the unique demands of their chemical operations, particularly in diverse markets across Africa and South America.

3 Common User Pain Points for ‘gehr plastics usa’ & Their Solutions

Scenario 1: Sourcing High-Quality Thermoplastics for Specialized Applications

The Problem: B2B buyers in industries such as aerospace, automotive, and medical often face the challenge of sourcing high-quality thermoplastics that meet stringent regulatory standards. For instance, when working on a project that requires specific materials like POM-C or PA12 for critical components, buyers may struggle to find suppliers who can provide materials with the necessary certifications and performance characteristics. This can lead to project delays, increased costs, and the risk of non-compliance with industry regulations.

The Solution: To overcome this challenge, buyers should leverage GEHR Plastics USA’s extensive product range and their commitment to quality standards, including ISO 9001:2015 certification. It’s essential to engage directly with GEHR’s technical support team to discuss specific project requirements. They can provide comprehensive technical data sheets that outline material properties, chemical resistance, and compliance certifications. Buyers should also inquire about custom extrusion options that GEHR offers, which can tailor products to meet unique specifications, ensuring they get exactly what they need without compromising on quality.

Scenario 2: Managing Supply Chain Disruptions and Lead Times

The Problem: International B2B buyers often face unpredictable supply chain disruptions, particularly when dealing with suppliers located overseas. Delays in material availability can halt production lines, leading to missed deadlines and increased operational costs. For example, a manufacturer in Brazil may experience delays when sourcing plastic sheets from Europe due to shipping issues or customs clearance, which can be particularly detrimental in time-sensitive projects.

The Solution: To mitigate supply chain risks, buyers should establish a proactive communication channel with GEHR Plastics USA. Regular updates on order status and lead times can help buyers manage their inventory better. Additionally, considering GEHR’s facilities across various locations, including a sales office in Hong Kong, buyers can explore local or regional stock options for quicker delivery. Implementing a just-in-time (JIT) inventory approach can also help maintain production flow without the burden of excess stock, while ensuring they always have the necessary materials on hand.

Scenario 3: Difficulty in Finding Technical Support for Material Selection

The Problem: Many buyers encounter challenges in selecting the right materials for their applications, particularly when the project involves complex requirements such as temperature resistance, chemical exposure, or mechanical stress. For example, a manufacturer in Saudi Arabia developing components for high-temperature environments may struggle to identify which type of thermoplastic would perform best under those conditions, leading to potential product failures and costly re-engineering.

The Solution: Buyers should take advantage of the technical expertise that GEHR Plastics USA offers. Engaging with GEHR’s knowledgeable sales representatives can provide insights into the performance of various materials under specific conditions. Buyers can also request samples to conduct in-house testing before making a larger commitment. Utilizing GEHR’s detailed material datasheets and consulting with their technical support can significantly enhance the decision-making process. Furthermore, attending industry trade shows where GEHR exhibits, such as K 2025 in Düsseldorf, can provide valuable opportunities for networking and gaining firsthand knowledge of innovative materials and applications.

Strategic Material Selection Guide for gehr plastics usa

What Are the Key Properties of Common Materials Used by GEHR Plastics USA?

GEHR Plastics USA offers a variety of thermoplastic materials, each with unique properties that cater to different industrial applications. Understanding these materials is crucial for international B2B buyers looking to make informed purchasing decisions.

Polyoxymethylene (POM-C): What Makes It a Preferred Choice?

POM-C, commonly known as acetal, is renowned for its excellent mechanical properties and dimensional stability. It has a high-temperature rating of up to 100°C (212°F) and exhibits outstanding wear resistance, making it suitable for precision parts in mechanical engineering. However, it is susceptible to hydrolysis and should be avoided in environments with high moisture.

Pros: POM-C is durable, offers low friction, and is easy to machine, making it ideal for applications such as gears and bearings.

Cons: Its cost can be higher than other plastics, and it may not perform well in humid conditions.

For buyers in regions like Brazil and Saudi Arabia, understanding local climate conditions is vital, as POM-C may require protective coatings in humid environments. Compliance with ASTM standards is also essential for ensuring product quality.

Polyamide (PA12 GF): Why Is It Gaining Popularity?

Polyamide 12 (PA12) reinforced with glass fibers is gaining traction due to its high strength and stiffness. It can withstand temperatures up to 120°C (248°F) and has excellent chemical resistance, particularly against fuels and oils.

Pros: PA12 GF offers superior mechanical properties and is suitable for demanding applications in the automotive and aerospace sectors.

Cons: The material can be more expensive and may require specialized processing techniques.

International buyers should note that PA12 GF complies with various industry standards, making it suitable for applications in Europe and the Middle East, where regulatory compliance is stringent.

Polyetheretherketone (PEEK): What Are Its Unique Advantages?

PEEK is a high-performance thermoplastic known for its exceptional thermal stability and chemical resistance, withstanding temperatures up to 260°C (500°F). It is often used in applications requiring high strength and reliability, such as in the medical and aerospace industries.

Pros: PEEK is incredibly durable and can be sterilized, making it ideal for medical applications.

Cons: Its high cost and complex manufacturing processes can be prohibitive for some applications.

For B2B buyers, especially in regions like Africa where budget constraints may be a concern, the initial investment in PEEK may be offset by its longevity and performance in critical applications.

Polyethylene Terephthalate Glycol (PETG): Why Is It a Versatile Option?

PETG is a copolyester that combines the properties of PET with enhanced impact resistance and clarity. It is suitable for applications requiring transparency and toughness, such as in packaging and medical devices.

Pros: PETG is easy to process and can be recycled, making it an environmentally friendly choice.

Cons: While it has good chemical resistance, it may not withstand high temperatures as effectively as other materials.

International buyers should consider local recycling regulations and market preferences when selecting PETG, especially in Europe, where sustainability is increasingly prioritized.

Summary of Material Properties

| Material | Typical Use Case for GEHR Plastics USA | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| POM-C | Precision parts in mechanical engineering | Excellent mechanical properties | Susceptible to hydrolysis | Medium |

| PA12 GF | Automotive and aerospace components | High strength and stiffness | Higher cost and specialized processing | High |

| PEEK | Medical and aerospace applications | Exceptional thermal stability | High cost and complex manufacturing | High |

| PETG | Packaging and medical devices | Easy to process and recyclable | Limited high-temperature resistance | Medium |

This guide provides a comprehensive overview of the materials offered by GEHR Plastics USA, enabling international B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for gehr plastics usa

What Are the Main Stages of Manufacturing at GEHR Plastics USA?

The manufacturing process at GEHR Plastics USA is characterized by a series of well-defined stages that ensure high-quality production of semi-finished thermoplastic products. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with selecting high-grade raw materials, typically thermoplastics such as POM (Polyoxymethylene), PA (Polyamide), and PEEK (Polyether Ether Ketone). These materials are subjected to rigorous quality checks before being processed. Advanced techniques like granulation and compounding are utilized to ensure uniform material consistency, which is vital for the subsequent production phases.

Forming: The forming stage is where the raw materials are transformed into the desired shapes. GEHR employs various techniques such as extrusion, where molten plastic is forced through a die to create rods, sheets, and profiles. This method allows for the production of large diameter rods and complex profiles tailored to specific customer needs. The extrusion process is closely monitored to maintain dimensional accuracy and surface quality.

Assembly: Although GEHR primarily focuses on semi-finished products, they also offer customized solutions that may require assembly. For instance, specific applications in industries such as automotive or aerospace might necessitate combining different extruded parts. In such cases, the assembly is conducted in a controlled environment to minimize contamination and defects.

Finishing: The final stage involves finishing processes that enhance product performance and aesthetics. Techniques such as machining, surface treatment, and cutting are employed to achieve precise specifications. GEHR ensures that all finishing operations adhere to strict quality standards, preparing the products for shipment or further processing.

How Does GEHR Plastics USA Ensure Quality Control in Manufacturing?

Quality assurance is a cornerstone of GEHR Plastics USA’s operations, reflecting their commitment to delivering superior products to international B2B buyers. The company adheres to several international standards, including ISO 9001:2015, which governs their quality management systems. This certification signifies a structured approach to quality control that encompasses all manufacturing stages.

Quality Control Checkpoints: GEHR implements multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial inspection ensures that all incoming materials meet predefined specifications. Any substandard materials are rejected at this stage to prevent defects in the final products.

-

In-Process Quality Control (IPQC): During production, continuous monitoring of parameters such as temperature, pressure, and extrusion speed is conducted. This real-time oversight helps identify deviations from the standard process that could affect product quality.

-

Final Quality Control (FQC): Once production is complete, a thorough inspection of the finished products is performed. This includes dimensional checks, visual inspections, and functional testing to ensure that the products meet the required standards before they are shipped to clients.

What International Standards and Testing Methods Are Relevant for GEHR Plastics USA?

GEHR Plastics USA not only complies with ISO 9001:2015 but also adheres to industry-specific certifications such as CE marking and API (American Petroleum Institute) standards, particularly relevant for products used in sectors like food processing, chemical engineering, and oil and gas.

Common Testing Methods: To maintain high standards of quality, GEHR employs various testing methods:

-

Mechanical Testing: This includes tensile strength, impact resistance, and hardness tests, ensuring the products can withstand the demands of their intended applications.

-

Chemical Resistance Testing: Given the diverse applications of their thermoplastics, GEHR conducts tests to evaluate resistance against various chemicals, a critical factor for clients in the chemical processing industry.

-

Thermal Testing: Products are subjected to heat resistance evaluations to ensure stability under high temperatures, which is especially important in industries like aerospace and automotive.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is crucial for ensuring reliability and compliance with local regulations.

Audits and Reports: Buyers should request access to quality audit reports from GEHR Plastics USA. These reports provide insights into the company’s adherence to quality management practices and can outline any corrective actions taken in response to past issues.

Third-Party Inspections: Engaging third-party inspection services can further validate the quality of products before shipment. These independent evaluations can provide an objective assessment of compliance with international standards.

Certification Verification: Buyers should also verify the validity of certifications such as ISO 9001 and CE. This can often be done through online databases or by directly contacting the certifying bodies.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various quality control nuances when sourcing from GEHR Plastics USA. Understanding the specific requirements of their local markets is essential, especially in regions with strict import regulations.

Cultural and Regulatory Considerations: Different countries may have unique standards regarding product safety and quality. For instance, products destined for the food industry may require additional certifications, such as FDA approval in the USA or specific food safety standards in the EU. Buyers should ensure that the supplier is equipped to provide necessary certifications that align with their local regulations.

Communication and Support: Establishing clear lines of communication with GEHR is vital. B2B buyers should feel comfortable discussing their quality expectations and any specific testing or documentation they may require. GEHR’s customer service teams can offer tailored support to help facilitate smooth transactions.

By leveraging these insights into GEHR Plastics USA’s manufacturing processes and quality assurance protocols, international buyers can make informed decisions, ensuring their sourcing strategies align with their operational standards and market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gehr plastics usa’

Introduction

This practical sourcing guide is designed for B2B buyers interested in procuring products from GEHR Plastics USA, a leading manufacturer of semi-finished thermoplastics. By following this checklist, you will ensure that you make informed decisions when sourcing materials that meet your specifications and operational needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the materials you need from GEHR Plastics. This includes dimensions, material types, and any industry-specific standards that must be adhered to. Having well-defined specifications helps streamline the sourcing process and ensures that suppliers understand your needs accurately.

- Considerations: Identify whether you need custom extrusions or standard products.

- Documentation: Prepare detailed drawings or specifications to share with potential suppliers.

Step 2: Conduct Market Research

Investigate the range of products and services offered by GEHR Plastics USA. Understanding their offerings will help you determine whether they can meet your specific needs. Review product catalogs and technical data sheets to gauge the suitability of their materials for your application.

- Resources: Utilize GEHR Plastics’ website and download their product brochures for comprehensive insights.

- Comparative Analysis: Compare their products with competitors to assess market positioning and unique selling points.

Step 3: Verify Supplier Certifications

Before proceeding with any order, verify that GEHR Plastics USA holds the necessary certifications, such as ISO 9001:2015. Certifications are indicators of quality management systems and ensure that products are manufactured to high standards.

- Documentation: Request copies of relevant certifications and quality assurance documentation.

- Compliance: Check for compliance with industry standards relevant to your specific sector, such as FDA approvals for food-related applications.

Step 4: Request Samples

Always request samples of the materials you intend to purchase. This allows you to evaluate the quality and suitability of the products firsthand. Sampling is crucial, especially for specialized materials that must meet rigorous performance criteria.

- Testing: Conduct tests under your operational conditions to ensure compatibility.

- Feedback Loop: Use this opportunity to provide feedback to GEHR Plastics regarding any adjustments needed for your application.

Step 5: Evaluate Pricing and Payment Terms

Assess the pricing structure offered by GEHR Plastics USA, along with their payment terms. Understanding the cost implications and payment conditions is essential for budgeting and financial planning.

- Quote Comparison: Obtain quotes from multiple suppliers to ensure competitive pricing.

- Negotiation: Be prepared to negotiate terms that fit your financial strategy and timelines.

Step 6: Assess Delivery Capabilities

Investigate GEHR Plastics’ delivery capabilities, including lead times and shipping options. Timely delivery is crucial for maintaining production schedules and minimizing downtime.

- Logistics: Understand their logistics network and how it aligns with your operational requirements.

- Flexibility: Check for options regarding expedited shipping if needed.

Step 7: Establish Communication Channels

Finally, set up clear communication channels with GEHR Plastics USA. Establishing a reliable point of contact can facilitate smoother transactions and quick resolution of any issues that may arise.

- Regular Updates: Schedule regular updates to discuss order progress and any potential concerns.

- Feedback Mechanism: Implement a feedback mechanism to ensure continuous improvement in your sourcing experience.

By following these steps, you can effectively source from GEHR Plastics USA, ensuring that you secure quality materials tailored to your business needs.

Comprehensive Cost and Pricing Analysis for gehr plastics usa Sourcing

What Are the Key Cost Components in Sourcing from GEHR Plastics USA?

When considering a partnership with GEHR Plastics USA, it’s essential to understand the cost structure involved in sourcing their products. The primary cost components include:

-

Materials: The type of thermoplastic materials selected significantly impacts pricing. GEHR offers a diverse range of materials such as POM, PA12, and PEEK, each with varying costs based on quality and availability.

-

Labor: Labor costs are influenced by the complexity of the manufacturing process and the expertise required. Custom extrusion and specialized machining will typically incur higher labor costs compared to standard offerings.

-

Manufacturing Overhead: This encompasses utilities, rent, and equipment maintenance. GEHR’s commitment to quality and sustainability may contribute to higher overhead costs, which can be reflected in pricing.

-

Tooling: Custom tooling for unique specifications adds to the initial cost. Buyers should consider whether the tooling can be amortized over larger production runs to mitigate costs.

-

Quality Control (QC): GEHR maintains stringent quality standards, which may result in additional QC costs. Certifications and compliance with ISO standards may also influence pricing.

-

Logistics: Shipping and handling, especially for international orders, can significantly affect the total cost. The choice of Incoterms will dictate who bears these costs and can affect the final pricing structure.

-

Margin: GEHR Plastics, being a family-owned enterprise with a focus on quality, typically incorporates a reasonable profit margin that reflects their commitment to customer satisfaction and product excellence.

How Do Price Influencers Affect Costs for B2B Buyers?

Several factors can influence the pricing of products sourced from GEHR Plastics USA:

-

Volume/MOQ: Bulk orders often lead to lower per-unit costs. Understanding the minimum order quantities (MOQ) can help buyers optimize their purchasing strategy for cost-effectiveness.

-

Specifications and Customization: Customized products will generally incur additional costs. Clearly defining specifications during the initial discussions can help in receiving accurate quotes.

-

Material Selection: The choice of material plays a crucial role in determining price. Specialty materials with high-performance characteristics will naturally be more expensive than standard options.

-

Quality and Certifications: Products that meet specific industry standards or certifications may command a premium. Buyers should weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of GEHR Plastics as a supplier can affect pricing. Established suppliers with proven track records may charge more due to their perceived value and reliability.

-

Incoterms: Understanding the chosen Incoterms is crucial for international buyers. They determine the responsibilities of both buyer and seller regarding shipping costs, insurance, and risk.

What Tips Can Help Buyers Negotiate Better Prices?

To navigate the complexities of pricing when sourcing from GEHR Plastics USA, international buyers can leverage several strategies:

-

Negotiate Volume Discounts: Engage in discussions about potential discounts for larger orders. Establishing a long-term relationship with GEHR may also yield more favorable pricing over time.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the upfront costs but also the long-term expenses associated with sourcing. This includes maintenance, replacement, and operational efficiency of the materials.

-

Understand Pricing Nuances for International Transactions: Be aware of exchange rates, tariffs, and import duties that may impact the final cost. Buyers from regions like Africa, South America, and the Middle East should factor these into their budgeting.

-

Conduct Market Research: Stay informed about market trends and competitor pricing. This knowledge can empower buyers during negotiations and ensure they are receiving a fair price.

-

Clarify Specifications Early: Clearly defined product specifications can prevent costly misunderstandings and ensure that the quoted price reflects the buyer’s exact needs.

In summary, understanding the cost components, price influencers, and strategic negotiation tips can empower international B2B buyers to make informed purchasing decisions when sourcing from GEHR Plastics USA.

Alternatives Analysis: Comparing gehr plastics usa With Other Solutions

When considering solutions for thermoplastic needs, it’s essential to evaluate various alternatives to ensure the best fit for your business requirements. This analysis will compare GEHR Plastics USA with two viable alternatives in the semi-finished thermoplastics market, enabling international B2B buyers to make informed decisions.

| Comparison Aspect | Gehr Plastics USA | Alternative 1: Professional Plastics | Alternative 2: Ensinger |

|---|---|---|---|

| Performance | High-quality thermoplastics, ISO 9001 certified, wide range of products | Extensive product range, robust performance in various applications | Excellent thermal and chemical resistance, specialized in engineering plastics |

| Cost | Competitive pricing but varies by customization | Generally lower cost, especially for standard items | Higher price point due to premium materials and specialization |

| Ease of Implementation | User-friendly online ordering system, customer support available | Easy online ordering, quick shipping options | More complex ordering process, requires more technical input |

| Maintenance | Low maintenance; durable materials | Low maintenance; wide availability of replacements | Moderate maintenance; some products may require specific handling |

| Best Use Case | Custom applications in various industries, including food and medical | General-purpose applications, ideal for bulk orders | High-performance applications in aerospace, automotive, and medical fields |

What Are the Pros and Cons of Professional Plastics?

Professional Plastics offers a broad selection of thermoplastic materials and is well-regarded for its affordability. The company’s extensive inventory and quick shipping capabilities make it an attractive option for businesses needing standard plastic sheets, rods, or tubes. However, while the pricing is often lower, the performance may not match the quality and customization options available at GEHR Plastics USA. Additionally, Professional Plastics may not provide the same level of technical support for specialized applications.

How Does Ensinger Stand Out Among Alternatives?

Ensinger is recognized for its premium engineering plastics that deliver exceptional thermal and chemical resistance. This makes it an excellent choice for industries requiring high-performance materials, such as aerospace and automotive. While Ensinger’s products are generally of superior quality, they tend to come at a higher cost. Furthermore, the ordering process can be more complex, necessitating a more technical understanding of material specifications, which may be a barrier for some buyers.

How Can B2B Buyers Choose the Right Solution?

Selecting the right thermoplastic solution depends on various factors, including application requirements, budget constraints, and the necessary level of customization. For businesses seeking high-quality, customized products for specialized applications, GEHR Plastics USA stands out with its extensive range and commitment to quality. Conversely, if cost is a primary concern and the application is more general, Professional Plastics may be a more suitable choice. For those in need of high-performance materials where budget allows for it, Ensinger could provide the necessary specifications and durability.

In conclusion, international B2B buyers should carefully assess their specific needs and priorities when comparing GEHR Plastics USA with alternatives like Professional Plastics and Ensinger. By understanding the strengths and limitations of each option, businesses can make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for gehr plastics usa

What Are the Essential Technical Properties of GEHR Plastics USA Products?

Understanding the critical specifications of GEHR Plastics’ products is vital for B2B buyers looking to make informed purchasing decisions. Here are some of the key technical properties:

-

Material Grade

Material grade refers to the specific classification of the plastic used in manufacturing. GEHR offers various grades, including POM (Polyoxymethylene), PA (Polyamide), and PEEK (Polyether Ether Ketone). Each grade has unique properties such as mechanical strength, chemical resistance, and thermal stability. Selecting the correct material grade is crucial for ensuring product performance in specific applications, particularly in industries like automotive, medical, and chemical processing. -

Tolerance

Tolerance defines the allowable deviation from specified dimensions in a manufactured part. GEHR Plastics adheres to strict tolerances, ensuring that products fit precisely into applications. This precision is vital for industries where component reliability is paramount, such as aerospace and medical devices, where even slight variations can lead to failures. -

Thickness

The thickness of sheets and rods is another critical property that influences the strength and application suitability of the material. GEHR offers a range of thicknesses, allowing customers to select the optimal size for their specific needs. For instance, thicker sheets may be required for high-load applications, while thinner sheets may be more suited for lightweight uses. -

Chemical Resistance

This property indicates how well a material can withstand exposure to various chemicals without degrading. GEHR Plastics provides detailed chemical resistance data for its products, which is crucial for industries such as food processing, pharmaceuticals, and oil and gas. Buyers must consider chemical exposure when selecting materials to ensure longevity and performance. -

Temperature Resistance

Temperature resistance is the range of temperatures within which a material can maintain its properties without failure. GEHR’s materials, such as PEEK, are known for their high-temperature resistance, making them suitable for applications in extreme environments. Understanding this property helps buyers choose the right material for applications that involve heat, such as automotive engines or industrial machinery.

What Are Common Trade Terms Used in the Plastic Industry?

Familiarity with industry jargon can enhance communication and streamline purchasing processes. Here are some common trade terms used in the plastics industry:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of GEHR Plastics, OEM clients may require custom extrusions or specific grades of materials to integrate into their products, making understanding OEM needs essential for tailored solutions. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. GEHR Plastics may have an MOQ for certain products to ensure cost-effectiveness in production. Understanding MOQ helps buyers plan their orders and manage inventory efficiently. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. It is an essential part of the procurement process, enabling buyers to compare costs and negotiate terms effectively. Buyers should provide detailed specifications in their RFQs to receive accurate quotes. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international trade. These terms clarify who is responsible for shipping, insurance, and tariffs. For global buyers sourcing from GEHR Plastics, understanding Incoterms is crucial for managing costs and logistics effectively. -

Lead Time

Lead time is the period from order placement to delivery. In the plastics industry, lead times can vary based on product availability and customization requirements. Knowing the lead time helps buyers plan their production schedules and manage project timelines. -

Custom Extrusion

Custom extrusion involves producing plastic shapes and profiles tailored to specific customer requirements. GEHR Plastics specializes in custom extrusion, allowing clients to obtain unique dimensions and material properties that meet their operational needs. This flexibility is particularly valuable for specialized applications across various industries.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing from GEHR Plastics USA, ensuring they select the right materials for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the gehr plastics usa Sector

What Are the Current Market Dynamics and Key Trends Influencing Gehr Plastics USA?

The global thermoplastics market is experiencing notable growth driven by increasing demand across various industries, including automotive, aerospace, and healthcare. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is critical. The rise of advanced manufacturing technologies, such as 3D printing and automated extrusion processes, is reshaping sourcing strategies. Companies are increasingly looking for suppliers that offer customizable products and quick turnaround times to meet market demands.

Additionally, the trend towards digital transformation is significant. B2B buyers are gravitating toward suppliers that utilize online platforms for ordering, tracking shipments, and accessing product information seamlessly. Gehr Plastics USA has embraced this shift, offering a customer portal that enhances the buyer experience. As the market evolves, a focus on quality certifications such as ISO 9001:2015 is essential for buyers seeking reliable suppliers. The emphasis on innovation, particularly in specialty materials like PEEK and PA12, is also a growing trend that can provide competitive advantages.

How Is Sustainability Shaping B2B Sourcing in the Gehr Plastics USA Sector?

Sustainability is no longer a mere trend but a crucial consideration in B2B sourcing. The environmental impact of plastic production is under scrutiny, prompting buyers to seek out suppliers that prioritize eco-friendly practices. Gehr Plastics USA demonstrates a commitment to sustainability through its recognition in the ECOVADIS Sustainability Rating, which reflects its adherence to responsible sourcing and production methods.

For international buyers, the importance of ethical supply chains cannot be overstated. They are increasingly inclined to partner with manufacturers who can provide transparency in their sourcing and production processes. Certifications for “green” materials are particularly important, as they assure buyers of the minimal environmental impact of their purchases. Gehr Plastics offers a range of certified products, including food-approved POM-C sheets, which align with the stringent requirements of various industries. This focus on sustainability not only enhances brand reputation but also meets the growing consumer demand for environmentally responsible products.

What Is the Historical Context That Has Shaped Gehr Plastics USA’s B2B Landscape?

Founded in 1932, Gehr Plastics has evolved from a small family-owned business to a leading global manufacturer of semi-finished thermoplastic products. The company’s commitment to innovation and quality has been pivotal in its success. Initially focusing on the German market, Gehr Plastics expanded its operations to the United States and other international markets, establishing a strong presence in Boothwyn, PA.

Over the years, the company has adapted to changing market demands by diversifying its product offerings and embracing advanced manufacturing technologies. This adaptability has allowed Gehr Plastics to maintain its leadership position in the industry. The emphasis on quality management, evidenced by its ISO 9001:2015 certification, ensures that international B2B buyers can rely on Gehr Plastics for high-quality, durable materials that meet their specific needs. As the company looks to the future, its rich history and ongoing commitment to excellence will continue to influence its B2B relationships worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of gehr plastics usa

-

How do I ensure the quality of GEHR Plastics products before purchasing?

To guarantee the quality of GEHR Plastics products, request certifications such as ISO 9001:2015, which indicates adherence to quality management standards. Additionally, you can ask for samples to evaluate material properties and compliance with industry specifications. Engaging in direct communication with sales representatives can also clarify product details, manufacturing processes, and quality assurance measures in place. Furthermore, consider reviewing testimonials or case studies from other businesses in your industry that have successfully sourced materials from GEHR. -

What is the best type of thermoplastic for my application?

The ideal thermoplastic for your application depends on various factors such as temperature resistance, chemical exposure, and mechanical properties. GEHR offers a wide range of materials, including POM, PA12, and PEEK, each suited for different environments. For example, POM is excellent for precision engineering, while PEEK is ideal for high-temperature applications. Assess your specific requirements and consult with GEHR’s technical team to identify the most suitable material that meets your operational needs. -

What are the minimum order quantities (MOQ) for GEHR Plastics products?

Minimum order quantities can vary based on the type of product and customization requirements. Typically, standard products have lower MOQs, while custom extrusions may require larger orders to justify production costs. It is advisable to directly contact GEHR’s sales team for specific MOQs related to your desired products. This information will help you plan your procurement strategy effectively while ensuring that your needs are met without excessive inventory. -

How can I customize GEHR Plastics products for my specific needs?

GEHR Plastics offers a range of customization options, including specific dimensions, colors, and material formulations. To initiate a custom order, reach out to their sales or engineering team with your specifications. They can provide insights into feasibility, lead times, and pricing. Be prepared to discuss your application requirements in detail to ensure the end product meets your expectations and industry standards. -

What payment terms does GEHR Plastics offer for international orders?

Payment terms for international orders may vary based on the buyer’s location and credit history. Common terms include advance payment, letters of credit, or net payment terms based on established relationships. It is crucial to clarify payment options during the negotiation phase. Engaging in open discussions with GEHR’s finance department can provide insights into possible terms that align with your financial practices and risk management strategies. -

How does GEHR Plastics handle logistics for international shipments?

GEHR Plastics collaborates with reliable logistics partners to facilitate international shipments. They typically offer various shipping options, including air and sea freight, depending on urgency and cost considerations. It is advisable to discuss logistics arrangements early in the ordering process, including delivery timelines, customs documentation, and any additional fees. This proactive approach will help mitigate potential delays and ensure smooth delivery to your location. -

What industries does GEHR Plastics cater to, and how can I find industry-specific solutions?

GEHR Plastics serves a diverse range of industries, including automotive, medical, food processing, and oil and gas. To find industry-specific solutions, visit their website or contact their sales team for tailored recommendations. They can provide insights into materials and products that have been successfully used in similar applications, helping you make informed choices that align with industry standards and requirements. -

How can I stay updated on new products and innovations from GEHR Plastics?

To stay informed about new products and innovations, consider subscribing to GEHR Plastics’ newsletter or following them on social media platforms. Additionally, attending industry trade shows, such as K 2025 in Düsseldorf, can provide firsthand exposure to their latest offerings and technologies. Engaging with their sales team can also keep you updated on product developments that may benefit your business operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for gehr plastics usa

In the competitive landscape of thermoplastic manufacturing, GEHR Plastics USA stands out as a premier supplier committed to quality and innovation. Their extensive product range, including extruded rods, sheets, and custom extrusion solutions, aligns perfectly with the diverse needs of industries such as food processing, medical, and oil and gas. By prioritizing ISO 9001:2015 standards, GEHR ensures that international B2B buyers can rely on their products for both performance and compliance.

Strategic sourcing from GEHR Plastics not only provides access to high-quality materials but also fosters long-term partnerships that can drive business growth. Their established presence in key global markets, including a network of sales offices across Europe and Asia, facilitates efficient communication and logistics for buyers from Africa, South America, and the Middle East.

Looking ahead, as industries continue to evolve and demand sustainable solutions, GEHR Plastics is poised to meet these challenges with innovative products. International buyers are encouraged to engage with GEHR to explore tailored solutions that can enhance operational efficiency and sustainability in their supply chains. Partnering with GEHR not only empowers businesses but also positions them at the forefront of their respective markets.