Top 8 Glass Jars Made In Usa List and Guide: How To Solve Scenari…

Introduction: Navigating the Global Market for glass jars made in usa

In the competitive landscape of international trade, sourcing high-quality glass jars made in the USA presents unique challenges for B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe. The complexities of navigating supplier options, understanding the nuances of production standards, and ensuring cost-effectiveness can often be daunting. This comprehensive guide aims to illuminate the path for international buyers by addressing various types of glass jars, their applications across industries, and strategic insights into supplier vetting processes.

From food and beverage packaging to cosmetic containers and home decor, glass jars serve a multitude of purposes, making them essential for businesses aiming to enhance product presentation and sustainability. This guide will delve into the specifics of glass jar specifications, including sizes, closures, and finishes, while also exploring the economic factors influencing purchasing decisions, such as pricing structures and shipping considerations.

By equipping B2B buyers with actionable insights and expert knowledge, this resource empowers stakeholders to make informed purchasing decisions. Understanding the nuances of sourcing glass jars made in the USA not only enhances product quality but also supports local economies and fosters sustainable practices. As international markets continue to evolve, being well-informed about the glass jar landscape is crucial for businesses looking to thrive in a global environment.

Top 10 Glass Jars Made In Usa Manufacturers & Suppliers List

1. BottleStore – Flint Glass Mayo Round Jar

Domain: bottlestore.com

Registered: 1998 (27 years)

Introduction: [{‘capacity’: ’32oz (960ml)’, ‘type’: ‘Flint Glass Mayo Round Jar’, ‘neck_size’: ’70-470′, ‘price_per_piece’: ‘$1.39’, ‘pieces_per_carton’: 12, ‘carton_price’: ‘$16.68’, ‘special_price’: ‘$12.00’}, {‘capacity’: ‘4oz (120ml)’, ‘type’: ‘Flint (Clear) Paragon Round Glass Jar’, ‘neck_size’: ’48-485′, ‘price_per_piece’: ‘$0.53’, ‘pieces_per_carton’: 12, ‘carton_price’: ‘$6.36’}, {‘capacity’: ‘6oz (180m…

2. TricorBraun – Glass Bottles & Jars

Domain: tricorbraun.com

Registered: 1998 (27 years)

Introduction: Made in the USA Containers & Packaging from TricorBraun include a variety of products such as:

– Glass Bottles & Jars:

– Beer Bottles & Growlers

– Boston Round Glass Bottles

– Glass Dropper Bottles

– Glass Liquor & Spirit Bottles

– Glass Packer Bottles

– Glass Sauce Bottles

– Glass Jars (Candle, Canning, Spice, Straight Sided, Wide Mouth)

– Glass Carboys & Jugs

– Glass…

3. Burch Bottle – Amber Glass Containers

Domain: burchbottle.com

Registered: 1999 (26 years)

Introduction: Made in the U.S.A, Amber glass containers, special items, sale.

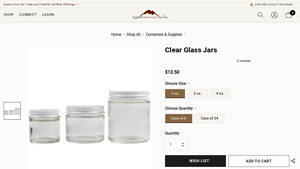

4. Mountain Rose Herbs – Clear Glass Jars

Domain: mountainroseherbs.com

Registered: 2000 (25 years)

Introduction: These quintessential clear glass jars with white metal lids are a staple for DIY enthusiasts and herbalists alike! Made in the USA, these useful and sturdy jars are great for salves, lip balms, creams, scrubs, herbal honey, and even natural wax candles. They are offered in 6 or 24 count cases; and are available in 1 oz., 2 oz., and 4 oz. sizes. The dimensions of jars with the lid on are as follows…

5. Nakpunar – Glass Jars for Canning

Domain: nakpunar.com

Registered: 2008 (17 years)

Introduction: Nakpunar offers a variety of glass jars including mason jars, hexagon jars, and unique glass jars designed for canning and preserving food. The jars are available in sizes ranging from 1.25 oz to 64 oz and come in clear, amber, or blue colors. Key products include: 4 oz Mason Glass Jar with Lid, 4 oz Glass French Square Spice Jar with Shaker, 6 oz Glass French Square Spice Jar with Shaker, 16 oz M…

6. Ball – Mason Jars

Domain: ballmasonjars.com

Registered: 2005 (20 years)

Introduction: Ball® Mason Jars include various types such as Regular Mouth Jars, Wide Mouth Jars, Vintage Jars, Keepsake Jars, and Smooth Side Jars. They are designed for canning, preserving, and storage, with options for decorative use. The jars come with accessories like jar lids and bands, pectin, and ingredients for canning. The Ball® Blue Book Guide to Preserving is available, featuring over 500 recipes an…

7. Container Store – Food Storage Solutions

Domain: containerstore.com

Registered: 1995 (30 years)

Introduction: Made in USA food storage solutions including a variety of containers designed to keep kitchens organized and ingredients fresh. The collection features airtight lids and durable materials, suitable for storing pantry staples, leftovers, grains, snacks, and meals. Options include glass jars and canisters for dry goods, offering a stylish element to kitchen decor. The product range includes brands l…

8. Ardagh Group – Glass Packaging Solutions

Domain: ardaghgroup.com

Registered: 2006 (19 years)

Introduction: Ardagh Glass Packaging produces 100% and infinitely recyclable glass packaging in various shapes and sizes for major brands. They offer 15 color options and specialize in several product categories: 1. Beer Bottles: Amber glass provides 99.9% UV protection, preserving freshness and taste. 2. Beverage Bottles: Glass is considered premium packaging, impermeable and air-tight, ideal for non-alcoholic…

Understanding glass jars made in usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mason Jars | Wide mouth and regular mouth options, ideal for home canning. | Food preservation, retail packaging. | Pros: Versatile, durable, reusable. Cons: Can be bulky for shipping. |

| Paragon Round Glass Jars | Variety of sizes, flint (clear) glass, and multiple neck finishes. | Cosmetics, food, and beverage packaging. | Pros: Customizable with closures, high-quality glass. Cons: Limited color options. |

| Economy Round Glass Jars | Larger sizes available, cost-effective for bulk purchases. | Bulk storage, industrial uses. | Pros: Cost-effective, suitable for large-scale operations. Cons: May lack aesthetic appeal. |

| Specialty Jars (e.g., Cobalt Blue) | Unique colors and designs for branding and presentation. | Specialty food products, gifts. | Pros: Eye-catching, enhances product appeal. Cons: Higher price point. |

| Storage Jars | Airtight seals, available in various sizes, stackable design. | Food storage, organizational products. | Pros: Keeps contents fresh, space-saving. Cons: May not be suitable for all product types. |

What Are the Key Characteristics of Mason Jars for B2B Buyers?

Mason jars are iconic for their practicality and versatility. They typically come in wide mouth and regular mouth designs, making them ideal for a variety of food preservation methods. B2B buyers in the food industry often purchase these jars for canning and packaging products like jams, pickles, and sauces. When considering Mason jars, buyers should evaluate the shipping costs due to their bulkiness, but their durability and reusability make them a sustainable choice.

How Do Paragon Round Glass Jars Meet Diverse Packaging Needs?

Paragon round glass jars are distinguished by their flint (clear) glass and a range of neck finishes, accommodating various closures. This adaptability makes them suitable for cosmetics, food, and beverage packaging. B2B buyers should consider the customization options available, as these jars can be tailored to meet branding requirements. However, buyers may find that the limited color options do not suit all branding strategies, which could be a drawback.

Why Choose Economy Round Glass Jars for Bulk Applications?

Economy round glass jars provide a cost-effective solution for businesses looking to purchase in bulk. They are available in larger sizes, making them ideal for industrial uses or bulk storage. B2B buyers benefit from the lower price point, which is advantageous for large-scale operations. However, the aesthetic appeal may not meet the needs of brands that prioritize design, so it’s essential to assess the target market’s expectations.

What Advantages Do Specialty Jars Offer for Niche Markets?

Specialty jars, such as cobalt blue glass jars, cater to niche markets where unique design and color can enhance product visibility. These jars are perfect for specialty food products or gift items, providing an attractive packaging solution that can elevate brand appeal. While they may command a higher price point, the investment can yield significant returns in markets where presentation is key. Buyers should weigh the benefits of enhanced aesthetic appeal against the cost.

How Do Storage Jars Enhance Organizational Solutions?

Storage jars are designed with airtight seals and are often stackable, making them a practical choice for food storage and organizational products. They are particularly useful for businesses in the food industry that need to keep ingredients fresh while maximizing space. B2B buyers should consider the specific storage needs of their products, as these jars may not be appropriate for all types of items, particularly those requiring more robust protection.

Key Industrial Applications of glass jars made in usa

| Industry/Sector | Specific Application of glass jars made in usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Packaging for jams, sauces, and pickles | Enhances product shelf-life and preserves quality | Compliance with food safety regulations and standards |

| Cosmetics and Personal Care | Storage for creams, lotions, and serums | Provides an upscale look and protects product integrity | Variety in sizes and closure options for branding |

| Pharmaceuticals | Containers for medicinal products | Ensures product safety and dosage accuracy | Tamper-evident seals and regulatory compliance needed |

| Home and Garden | Decorative storage for herbs and spices | Adds aesthetic value while maintaining freshness | Customization options for branding and design |

| Crafting and DIY | Utilization in arts and crafts projects | Versatile for creative applications and reusability | Availability in various shapes and sizes |

How Are Glass Jars Made in the USA Used in the Food and Beverage Industry?

In the food and beverage sector, glass jars made in the USA are primarily used for packaging products such as jams, sauces, and pickles. These jars provide an airtight seal that extends shelf life and preserves the quality of the contents, which is crucial for maintaining flavor and safety. For international buyers, especially from regions like Africa and South America, it is essential to ensure that the jars comply with local food safety regulations. Additionally, buyers should consider sourcing jars with custom labeling options to enhance brand visibility in competitive markets.

What Role Do Glass Jars Play in the Cosmetics and Personal Care Sector?

In cosmetics and personal care, glass jars serve as elegant containers for creams, lotions, and serums. Their premium appearance not only attracts consumers but also protects the integrity of the products inside. For businesses, using glass jars can enhance brand perception and reduce the risk of contamination. International buyers should focus on sourcing jars that meet specific aesthetic requirements while also providing various sizes and closure options to accommodate different product lines, ensuring a cohesive brand identity.

How Are Glass Jars Utilized in the Pharmaceutical Industry?

The pharmaceutical industry utilizes glass jars for storing medicinal products, ensuring both safety and dosage accuracy. These jars are often equipped with tamper-evident seals, which are vital for maintaining product integrity and consumer trust. For international B2B buyers, particularly from the Middle East and Europe, it is crucial to ensure that sourced jars comply with stringent health regulations and standards. Additionally, buyers should prioritize suppliers who can provide documentation of compliance with relevant pharmaceutical packaging guidelines.

Why Are Glass Jars Important for Home and Garden Applications?

In the home and garden sector, glass jars are commonly used for decorative storage of herbs and spices. They not only provide an aesthetic appeal but also help maintain the freshness of the contents. For businesses, offering customized glass jars can create a unique selling proposition that resonates with eco-conscious consumers. International buyers should consider sourcing jars that offer customization options to enhance brand identity while ensuring that the glass is durable and suitable for various environmental conditions.

How Do Glass Jars Fit into Crafting and DIY Projects?

Glass jars are versatile tools in the crafting and DIY space, serving as containers for various projects. They can be repurposed for storage, decoration, or even as part of creative displays. For businesses catering to this market, it’s important to offer a range of jar shapes and sizes to meet diverse customer needs. International buyers should ensure that the jars are readily available in bulk and consider options that allow for easy customization, enabling them to cater to local crafting trends and preferences.

3 Common User Pain Points for ‘glass jars made in usa’ & Their Solutions

Scenario 1: Limited Availability of Custom Sizes and Styles

The Problem: B2B buyers often encounter challenges when sourcing glass jars in specific sizes or designs that align with their branding or product needs. For instance, a food manufacturer may require unique jar sizes for sauces or jams that aren’t commonly available. This limitation can lead to delays in production, increased costs due to custom orders, or even the need to compromise on product presentation, which can negatively impact market appeal.

The Solution: To address this issue, buyers should engage with suppliers who specialize in custom glass jar manufacturing. When initiating discussions, it’s essential to provide detailed specifications, including dimensions, neck sizes, and desired finishes. Establish a collaborative relationship with the supplier to explore potential mold creation for unique jar shapes or sizes. Additionally, consider suppliers based in the USA who can provide quicker turnaround times and lower shipping costs, thereby improving supply chain efficiency. Utilizing platforms that showcase a variety of suppliers can also help buyers find the perfect match for their specific needs.

Scenario 2: Concerns About Product Safety and Quality Standards

The Problem: International buyers, especially those from regions with varying regulatory standards, may worry about the safety and quality of glass jars made in the USA. There is often uncertainty regarding whether these jars meet food safety regulations, which can deter businesses from making significant purchases. This is particularly critical for industries such as food and beverage, where compliance with health standards is non-negotiable.

The Solution: To mitigate these concerns, buyers should request certifications and compliance documentation from suppliers to verify that their glass jars meet the necessary safety standards, such as FDA regulations for food contact materials. Establishing a clear communication channel with the supplier about their quality assurance processes is crucial. Additionally, consider conducting independent testing on a sample batch to ensure that the jars perform as expected under various conditions. Building a relationship with suppliers who are transparent about their manufacturing practices can also foster trust and confidence in the products.

Scenario 3: High Shipping Costs and Long Lead Times

The Problem: B2B buyers often face inflated shipping costs and lengthy lead times when importing glass jars from the USA to their respective markets. This situation can strain budgets and disrupt timelines, especially for businesses that rely on just-in-time inventory models. For instance, a company in Brazil may find that high freight fees significantly increase the total cost of procurement, making it difficult to maintain competitive pricing.

The Solution: To alleviate these issues, buyers should consider consolidating orders to maximize shipping efficiency. By collaborating with other businesses to place bulk orders, companies can share shipping costs and reduce per-unit expenses. Additionally, exploring different shipping methods, such as sea freight instead of air freight, can lead to substantial savings, albeit with longer lead times. Another strategy is to identify local distributors or warehousing solutions that allow for reduced shipping distances and faster delivery. Engaging with a logistics partner familiar with international shipping can also streamline the process and help negotiate better rates, ultimately improving the bottom line.

Strategic Material Selection Guide for glass jars made in usa

What Are the Key Materials Used in Glass Jars Made in the USA?

When selecting glass jars made in the USA, understanding the materials used is crucial for international B2B buyers. The choice of material directly influences the jar’s performance, durability, and suitability for various applications. Below are analyses of four common materials used in the manufacturing of glass jars.

What Are the Key Properties of Flint Glass?

Flint glass, also known as clear glass, is the most commonly used material for glass jars. It boasts excellent transparency, making it ideal for showcasing products. Key properties include a high melting point, making it suitable for hot-fill applications, and good chemical resistance, which protects the contents from contamination.

Pros and Cons: Flint glass is highly durable and offers a premium look, enhancing brand perception. However, it can be more expensive than other glass types and is heavier, which may increase shipping costs. Additionally, its brittleness can pose challenges during handling and transportation.

Impact on Application: Flint glass is compatible with a wide range of media, including food, beverages, and cosmetics. It is particularly favored in the food industry for canning and preservation due to its non-reactive nature.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local food safety standards, which may vary. Familiarity with ASTM standards can facilitate smoother import processes.

How Does Amber Glass Differ from Other Glass Types?

Amber glass is characterized by its distinctive brown hue, which provides UV protection, making it suitable for light-sensitive products like oils and pharmaceuticals. It has similar thermal properties to flint glass but offers additional benefits.

Pros and Cons: The primary advantage of amber glass is its ability to protect contents from UV light, thus extending shelf life. The downside includes a higher cost due to its specialized manufacturing process and limited visibility of the contents.

Impact on Application: Amber glass jars are ideal for packaging essential oils, herbal products, and certain food items that require protection from light.

Considerations for International Buyers: Compliance with international standards such as DIN and JIS is essential when exporting amber glass products. Buyers should also consider the environmental impact and recycling capabilities of amber glass in their regions.

What Are the Benefits of Green Glass for Packaging?

Green glass jars are often used for beverages and specialty foods. They offer a unique aesthetic and also provide some UV protection, although not as effectively as amber glass.

Pros and Cons: Green glass is visually appealing and can enhance brand differentiation. However, it is generally less effective in blocking UV light compared to amber glass. Additionally, its production can be more complex, leading to higher costs.

Impact on Application: Green glass is suitable for products like wines, spirits, and gourmet foods that benefit from a distinctive appearance.

Considerations for International Buyers: Buyers should be aware of local preferences for packaging colors, which can vary significantly between regions. Understanding cultural perceptions of color can inform better marketing strategies.

Why Choose Recycled Glass for Sustainability?

Recycled glass is increasingly popular due to its lower environmental impact. It retains many of the properties of new glass while reducing energy consumption during production.

Pros and Cons: The use of recycled glass can lower costs and enhance sustainability credentials, appealing to eco-conscious consumers. However, the quality may vary depending on the source of the recycled material, which can affect the final product’s durability.

Impact on Application: Recycled glass jars are suitable for a wide range of products, including food and cosmetics, but may not be ideal for high-end packaging due to potential imperfections.

Considerations for International Buyers: Buyers should ensure that recycled glass meets local regulations regarding food safety and packaging standards. Familiarity with recycling practices in their regions can also enhance supply chain efficiency.

Summary Table of Material Selection for Glass Jars Made in the USA

| Material | Typical Use Case for glass jars made in usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flint Glass | Food, beverages, cosmetics | High durability and transparency | Heavier and more expensive | Medium |

| Amber Glass | Essential oils, pharmaceuticals | UV protection for sensitive products | Higher cost, limited visibility | High |

| Green Glass | Wines, gourmet foods | Unique aesthetic and brand differentiation | Less UV protection than amber glass | Medium |

| Recycled Glass | General food, cosmetics | Lower environmental impact | Quality may vary, potential durability issues | Low |

This guide provides actionable insights for international B2B buyers, ensuring they make informed decisions when selecting glass jars made in the USA.

In-depth Look: Manufacturing Processes and Quality Assurance for glass jars made in usa

What Are the Key Stages in the Manufacturing Process of Glass Jars Made in the USA?

The manufacturing of glass jars in the USA involves several critical stages, each essential to ensuring high-quality products that meet international standards. Understanding these stages helps B2B buyers assess potential suppliers effectively.

Material Preparation: What Raw Materials Are Used in Glass Jar Production?

The process begins with the preparation of raw materials. The primary components used to manufacture glass jars are silica sand, soda ash, and limestone, with additional materials such as colorants or recycled glass (cullet) often included to enhance specific properties. The selection of high-quality raw materials is crucial, as impurities can lead to defects in the final product. Suppliers often maintain stringent sourcing guidelines and quality checks to ensure the consistency of materials used.

How Are Glass Jars Formed Through Various Techniques?

The forming stage utilizes several techniques, with the most common being blow molding and press molding. In blow molding, air is injected into a molten glass parison, expanding it to fit the mold, which allows for intricate shapes and designs. Press molding involves pushing molten glass into a mold, making it ideal for thicker jars. The choice of technique can affect the jar’s strength, weight, and aesthetic appeal, impacting the overall user experience.

What Finishing Techniques Are Applied to Glass Jars?

Once formed, glass jars undergo finishing processes that enhance their functionality and appearance. This includes annealing, where jars are slowly cooled to relieve internal stresses, ensuring durability. Additional treatments may include surface coatings for improved scratch resistance or decorative finishes like labeling and etching. Each of these finishing touches can significantly impact the product’s marketability, making it essential for B2B buyers to communicate their specific needs to manufacturers.

How Is Quality Assurance Implemented During Glass Jar Production?

Quality assurance (QA) is a fundamental aspect of glass jar manufacturing, ensuring that products meet established standards for safety and performance. B2B buyers should be aware of various QA methods and certifications that indicate a manufacturer’s commitment to quality.

What International Standards and Certifications Are Relevant to Glass Jar Quality?

International standards such as ISO 9001 are critical for manufacturers aiming to demonstrate a commitment to quality management systems. This certification ensures that a company consistently meets customer and regulatory requirements. Additionally, industry-specific certifications like CE marking for compliance with European safety standards and API standards for pharmaceutical packaging can further validate a manufacturer’s capabilities.

What Are the Key Quality Control Checkpoints in Glass Jar Production?

Quality control (QC) in glass jar manufacturing typically includes several checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC). IQC involves inspecting raw materials upon arrival to ensure they meet specifications. During IPQC, ongoing assessments are made throughout the production process to identify and rectify defects early. Finally, FQC checks the finished jars for consistency, labeling accuracy, and adherence to dimensional standards.

Which Testing Methods Are Commonly Used to Ensure Glass Jar Quality?

Various testing methods are employed to validate the quality of glass jars. Common tests include:

- Visual Inspection: Ensures there are no visible defects such as bubbles, cracks, or chips.

- Dimensional Testing: Verifies that jars meet specified size and shape requirements.

- Strength Testing: Assesses the jars’ resistance to breakage and thermal shock.

- Leak Testing: Particularly important for jars intended for food or liquid storage.

These tests help ensure that the final products are safe for their intended use, meeting both customer expectations and regulatory requirements.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital. Here are several actionable strategies:

What Steps Should Buyers Take to Conduct Supplier Audits?

Conducting on-site audits is one of the most effective ways to assess a supplier’s quality control processes. Buyers should evaluate the manufacturing facility’s cleanliness, organization, and adherence to safety protocols. During audits, buyers can also review documentation related to quality management systems and past inspection reports.

How Can Buyers Leverage Third-Party Inspections?

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services often include comprehensive inspections of raw materials, in-process checks, and final product evaluations. Engaging a reputable third-party inspector can offer additional assurance of quality, particularly for buyers unfamiliar with local manufacturing practices.

What Documentation Should Buyers Request to Assess Quality?

Buyers should request detailed quality assurance documentation, including:

- Quality Control Reports: Outlining the results of various tests and inspections conducted during the manufacturing process.

- Certificates of Compliance: Demonstrating adherence to international standards and certifications.

- Traceability Records: Ensuring that all materials used in production can be traced back to their source.

These documents can provide insights into a supplier’s commitment to quality and help mitigate risks associated with purchasing glass jars.

Conclusion: Why Quality Assurance is Essential for B2B Buyers of Glass Jars

Understanding the manufacturing processes and quality assurance measures for glass jars made in the USA is essential for B2B buyers. By focusing on the stages of production, relevant standards, and effective verification methods, buyers can make informed decisions that ensure the procurement of high-quality glass jars suitable for their specific needs. This knowledge not only enhances product integrity but also fosters long-term partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘glass jars made in usa’

This practical sourcing guide serves as a comprehensive checklist for international B2B buyers looking to procure glass jars made in the USA. By following these steps, you can ensure that your sourcing process is efficient, compliant, and aligned with your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for the glass jars you need is crucial. Consider factors such as size, shape, color, and closure type, as these will affect both functionality and aesthetics. Identify your product’s requirements, such as whether the jars need to be food-safe, reusable, or suitable for specific contents like liquids or solids.

- Size & Capacity: Determine the volume of jars needed (e.g., 4oz, 12oz, etc.).

- Material & Finish: Choose between flint, green, or amber glass based on the product’s requirements.

Step 2: Research Suppliers and Manufacturers

Conduct thorough research to identify potential suppliers of glass jars made in the USA. Look for manufacturers who specialize in glass products and have a solid reputation for quality and reliability. Supplier directories, trade shows, and industry associations can provide valuable leads.

- Local vs. National Suppliers: Consider the benefits of sourcing from local manufacturers for quicker shipping and lower transportation costs.

- Online Marketplaces: Utilize platforms that specialize in American-made products to find reputable suppliers.

Step 3: Verify Supplier Certifications

Before engaging with a supplier, it’s important to verify their certifications and compliance with industry standards. Look for certifications like ISO, FDA, or others relevant to your product type. This step ensures that the jars meet safety and quality requirements.

- Quality Assurance: Ask for documentation that proves their compliance with industry standards.

- Sustainability Practices: Inquire about their environmental policies, especially if sustainability is a priority for your brand.

Step 4: Request Samples

Once you have shortlisted potential suppliers, request samples of the glass jars. Evaluating samples allows you to assess the quality, design, and functionality of the jars before placing a bulk order. This step is critical for ensuring that the jars meet your specifications.

- Quality Check: Inspect the samples for any defects, such as cracks or inconsistencies.

- Fit and Finish: Ensure that the jars work well with your intended closures and packaging.

Step 5: Evaluate Pricing and Terms

After evaluating the samples, compare pricing among your shortlisted suppliers. Consider the total cost of ownership, including shipping, taxes, and any potential tariffs. Be sure to understand the payment terms and conditions, including any minimum order quantities.

- Bulk Discounts: Inquire about pricing tiers based on order volume.

- Shipping Costs: Factor in logistics costs to determine the most cost-effective supplier.

Step 6: Negotiate and Finalize the Contract

Once you select a supplier, negotiate the contract terms to ensure they align with your business objectives. Pay close attention to lead times, payment terms, and return policies. A well-negotiated contract can safeguard your interests and help avoid future disputes.

- Clear Terms: Ensure that all specifications, delivery schedules, and payment terms are clearly outlined.

- Performance Clauses: Consider including clauses that address quality assurance and delivery timelines.

Step 7: Establish a Communication Plan

Finally, establish a communication plan with your chosen supplier. Effective communication is key to a successful partnership, especially if issues arise during production or shipping. Regular check-ins can help you stay informed about the status of your order.

- Point of Contact: Identify a reliable contact person within the supplier’s organization for streamlined communication.

- Feedback Loop: Create a system for providing feedback on quality and delivery to ensure continuous improvement.

By following this checklist, you can effectively navigate the complexities of sourcing glass jars made in the USA, ensuring that you make informed decisions that benefit your business.

Comprehensive Cost and Pricing Analysis for glass jars made in usa Sourcing

What Are the Key Cost Components for Sourcing Glass Jars Made in the USA?

When evaluating the cost structure of glass jars made in the USA, several key components come into play. Materials constitute a significant portion of the cost, with high-quality glass and closures often driving prices higher. Labor costs in the U.S. are typically higher than in many other countries, reflecting skilled craftsmanship and compliance with labor laws. Manufacturing overhead includes utilities, equipment maintenance, and rent, which can vary based on location and scale of production. Additionally, tooling costs can be substantial, especially for custom designs, as specialized molds are required for different jar shapes and sizes.

Quality Control (QC) is another critical expense, ensuring that products meet safety and quality standards, which is particularly important for food-related packaging. Lastly, logistics costs involve warehousing, transportation, and distribution, which can fluctuate based on the distance to the buyer’s location and the chosen shipping method.

How Do Pricing Influencers Affect the Cost of Glass Jars?

Several factors influence the pricing of glass jars sourced from the USA. The volume of the order or Minimum Order Quantity (MOQ) can significantly impact pricing; larger orders typically lead to lower per-unit costs due to economies of scale. Specifications and customization—such as neck size, color, and design—can also alter pricing. Higher quality materials or certifications (e.g., FDA compliance for food safety) will increase costs but may be necessary for certain markets.

Supplier factors play a role as well; established manufacturers may charge a premium due to brand reputation and reliability. Lastly, Incoterms (International Commercial Terms) dictate who bears the cost and risk during shipping, affecting the overall pricing structure.

What Buyer Tips Can Help Achieve Cost Efficiency in Glass Jar Sourcing?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, negotiating pricing effectively is crucial. Understanding the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, customs duties, and potential tariffs, can lead to more informed decisions.

Buyers should be proactive in negotiating terms, especially regarding payment terms and delivery schedules, which can provide flexibility and reduce upfront costs. It’s also wise to conduct a thorough market analysis to compare prices from different suppliers and understand regional price variations, particularly for buyers from Brazil or Saudi Arabia, where import costs may differ.

Pricing nuances are especially important for international transactions. Variations in currency exchange rates can affect the final cost, so locking in prices when favorable can be advantageous. Additionally, consider bulk purchasing agreements or long-term contracts with suppliers to secure better rates.

What Are the Important Disclaimers Regarding Pricing?

It’s essential to note that the prices for glass jars sourced from the USA can fluctuate based on market conditions, changes in raw material costs, and supplier pricing strategies. The indicative prices provided by suppliers often reflect base costs without including potential tariffs, shipping fees, and other logistical expenses. Buyers should always request detailed quotes that encompass all aspects of pricing to avoid unexpected costs.

Alternatives Analysis: Comparing glass jars made in usa With Other Solutions

Exploring Alternatives to Glass Jars Made in the USA

When considering packaging solutions for products, particularly in the food and beverage sector, glass jars made in the USA are often a popular choice. However, businesses should also explore alternative packaging options that may better suit their specific needs regarding performance, cost, and usability. This analysis compares glass jars made in the USA with two viable alternatives: plastic containers and metal tins.

| Comparison Aspect | Glass Jars Made In USA | Plastic Containers | Metal Tins |

|---|---|---|---|

| Performance | Excellent barrier properties; preserves flavor and freshness | Moderate barrier; may leach chemicals | Good barrier; resistant to moisture and oxygen |

| Cost | Moderate to high ($0.50 – $2.55 per jar) | Low to moderate ($0.10 – $1.00 per container) | Moderate ($0.30 – $1.50 per tin) |

| Ease of Implementation | Requires careful handling; heavier | Lightweight and easy to stack | Moderate; requires sealing methods |

| Maintenance | Reusable and recyclable; easy to clean | Single-use often; recyclable | Reusable; may require cleaning |

| Best Use Case | Premium products, preserves, and artisan foods | Bulk goods, snacks, and non-perishable items | Dry goods, oils, and specialty items |

What are the Pros and Cons of Plastic Containers?

Plastic containers are a popular alternative due to their lightweight nature and low cost. They are widely used for packaging everything from snacks to liquid products. The primary advantage of plastic is its affordability and versatility, making it suitable for bulk products. However, the potential for chemical leaching, especially with certain types of food, raises health concerns. Additionally, while many plastics are recyclable, they are often single-use, which may not align with sustainability goals.

How Do Metal Tins Compare?

Metal tins present another viable option, particularly for dry goods and specialty items. They offer good protection against moisture and oxygen, which can help preserve product integrity. Tins are often perceived as a premium packaging solution, enhancing brand perception. However, they can be heavier than plastic and may require additional sealing methods to ensure freshness. While they are recyclable, the initial cost can be higher than plastic, but they provide a reusable option, appealing to eco-conscious consumers.

Conclusion: How Should B2B Buyers Choose the Right Packaging Solution?

For B2B buyers, the choice between glass jars made in the USA, plastic containers, and metal tins depends on various factors, including the type of product, target market, and brand positioning. Glass jars are ideal for premium products that benefit from enhanced presentation and preservation, while plastic containers may be more suitable for cost-sensitive bulk products. Metal tins can serve niche markets effectively but may require consideration regarding sealing and weight. Ultimately, assessing product requirements, cost constraints, and environmental impact will guide buyers in selecting the most suitable packaging solution for their business needs.

Essential Technical Properties and Trade Terminology for glass jars made in usa

What Are the Essential Technical Properties of Glass Jars Made in the USA?

When sourcing glass jars made in the USA, understanding key technical properties is vital for ensuring product quality and compliance with industry standards. Here are some essential specifications:

-

Material Grade

Glass jars are typically made from soda-lime glass, known for its durability and clarity. The material grade affects the jar’s resistance to thermal shock, chemical compatibility, and overall strength. For B2B buyers, selecting the right material grade is crucial for ensuring product integrity during storage and transport. -

Neck Finish and Closure Compatibility

The neck finish refers to the diameter and design of the jar’s opening, which is essential for closure compatibility. Common neck finishes include 400, 405, 450, 470, and 485. Understanding these specifications helps buyers choose the correct lids or closures, preventing leakage and ensuring product safety. -

Capacity and Volume

Glass jars come in various sizes, typically ranging from 4 oz to 64 oz. The capacity impacts packaging, shipping costs, and shelf space. Buyers must consider their product’s volume requirements to optimize storage and logistics. -

Tolerance

Tolerance specifications define the allowable deviation in dimensions during manufacturing. For glass jars, tight tolerances are crucial for ensuring that jars fit properly with closures and can be efficiently packed. Poor tolerances can lead to increased breakage and wasted materials. -

Thermal Shock Resistance

This property measures how well the glass can withstand rapid temperature changes. Jars with high thermal shock resistance are essential for products that may undergo canning or high-temperature processing. For B2B buyers, selecting jars with this property can reduce the risk of breakage during filling and storage. -

Color and Transparency

The color of glass jars can vary from clear to amber or green, impacting light exposure and product preservation. Clear jars are ideal for visibility, while colored jars can protect light-sensitive products. Buyers should consider the implications of color on product quality and branding.

Which Trade Terms Should B2B Buyers Understand When Purchasing Glass Jars?

Navigating the procurement process involves understanding key trade terminology that can affect negotiations and transactions. Here are several terms that are essential for B2B buyers:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces products that are sold under another company’s brand. In the context of glass jars, buyers might source jars from an OEM to package their products, ensuring brand consistency while leveraging manufacturing expertise. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ helps buyers plan their purchasing strategy and manage inventory effectively. It can also impact pricing, as larger orders often qualify for discounts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This is an essential step in the procurement process, allowing buyers to compare offers and negotiate better deals. Clearly defined RFQs can streamline purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping responsibilities, risk management, and delivery timelines, which are crucial for smooth logistics. -

Lead Time

Lead time is the duration from placing an order to receiving the product. Understanding lead times helps buyers plan their inventory and production schedules effectively. It is particularly important in industries where timely delivery impacts sales and operations. -

Sustainability Certifications

Many buyers are increasingly focused on sustainability. Certifications such as ISO 14001 indicate that a manufacturer adheres to environmental management standards. Knowing about these certifications can enhance a buyer’s brand reputation and appeal to environmentally conscious consumers.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when purchasing glass jars made in the USA, ensuring quality, compliance, and optimal supply chain management.

Navigating Market Dynamics and Sourcing Trends in the glass jars made in usa Sector

What Are the Key Market Dynamics and Trends in the Glass Jars Made in USA Sector?

The global market for glass jars, particularly those made in the USA, is experiencing significant growth, driven by rising consumer demand for sustainable packaging solutions. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly prioritizing products that reflect environmentally conscious practices. This trend aligns with a broader shift towards sustainability, where glass packaging is favored for its recyclability and minimal environmental impact compared to plastic alternatives.

Emerging technologies are reshaping sourcing strategies within the glass jar sector. Automation in manufacturing processes and advancements in supply chain management are enhancing operational efficiencies, reducing lead times, and ultimately lowering costs. Additionally, platforms that facilitate direct sourcing from manufacturers are becoming more popular among B2B buyers, allowing them to negotiate better terms and ensure product quality. International buyers are also utilizing data analytics to assess market trends, enabling them to make informed purchasing decisions that align with consumer preferences.

Furthermore, the demand for customized glass jars is on the rise, as businesses seek to differentiate their products in competitive markets. This customization can range from unique designs to specific sizes and closure options, catering to niche markets and enhancing brand identity.

How Is Sustainability and Ethical Sourcing Influencing the Glass Jars Market?

Sustainability is a critical consideration for international B2B buyers in the glass jar sector. The environmental impact of packaging materials is under scrutiny, prompting companies to seek ethically sourced products that minimize their carbon footprint. Glass, being a recyclable material, presents a favorable option, as it can be recycled indefinitely without losing quality.

Ethical sourcing practices are becoming a standard expectation among consumers and businesses alike. Companies are increasingly looking for suppliers who can demonstrate commitment to sustainable practices, including responsible sourcing of raw materials, waste reduction in manufacturing, and transparent supply chains. Certifications such as ISO 14001 for environmental management and partnerships with organizations promoting sustainability add value and credibility to suppliers.

Moreover, using ‘green’ materials, such as recycled glass and eco-friendly packaging, is gaining traction. B2B buyers are more inclined to partner with manufacturers who prioritize sustainability, as this reflects positively on their own brand reputation and aligns with consumer values.

What Is the Historical Context of Glass Jar Manufacturing in the USA?

The history of glass jar manufacturing in the USA dates back to the 19th century, with the introduction of the Mason jar by John Landis Mason in 1858. This innovation revolutionized food preservation and canning, making it easier for households to store and enjoy seasonal produce year-round. Over the years, the glass jar industry has evolved, adapting to changing consumer needs and technological advancements.

In the 20th century, the mass production of glass jars became widespread, driven by the food and beverage industry’s growth. Today, brands like Ball® continue to lead in the market, emphasizing quality and sustainability. The historical significance of glass jars extends beyond mere functionality; they are now seen as a symbol of nostalgia and a return to homegrown, artisanal practices.

International B2B buyers can leverage this rich history by sourcing glass jars made in the USA, which not only supports local economies but also aligns with consumer preferences for authentic, high-quality packaging.

Frequently Asked Questions (FAQs) for B2B Buyers of glass jars made in usa

-

How do I solve challenges related to sourcing glass jars made in the USA?

To effectively address sourcing challenges, first identify reputable suppliers specializing in glass jars made in the USA. Conduct thorough research, including reading reviews and checking industry certifications. Engage in direct communication to discuss your specific needs, such as customization options and lead times. Utilize trade platforms or industry-specific trade shows to connect with manufacturers. Additionally, consider establishing a local representative to facilitate communication and logistics, ensuring that any issues are addressed promptly. -

What are the advantages of using glass jars made in the USA for my products?

Choosing glass jars made in the USA offers several benefits, including enhanced quality assurance, compliance with local regulations, and support for domestic manufacturing. American-made products often have a reputation for higher durability and safety standards, which can enhance your brand image. Additionally, sourcing locally can reduce lead times and shipping costs, making it easier to manage inventory and respond to market demands quickly. This aligns with consumer preferences for locally sourced products, potentially increasing your market appeal. -

What should I consider when vetting suppliers for glass jars?

When vetting suppliers, evaluate their manufacturing capabilities, quality control processes, and certifications. Request samples to assess the quality of their glass jars and ensure they meet your specifications. It’s also crucial to investigate their production lead times, minimum order quantities (MOQs), and responsiveness to inquiries. Look for suppliers with a proven track record of reliability and customer satisfaction. Additionally, consider their ability to handle international shipping and customs processes, especially if you’re importing to regions like Africa or South America. -

Can I customize glass jars to fit my branding needs?

Yes, many manufacturers of glass jars made in the USA offer customization options, including size, shape, color, and labeling. Customization allows you to align the packaging with your brand identity and product requirements. Discuss your specific needs with potential suppliers and inquire about their design capabilities, minimum order quantities for custom orders, and associated costs. Providing clear design specifications and examples will help ensure that the final product meets your expectations. -

What are the common minimum order quantities (MOQs) for glass jars?

Minimum order quantities can vary significantly based on the supplier, type of glass jar, and customization requirements. Typically, MOQs for standard glass jars range from 500 to 5,000 units, while custom designs may require higher quantities. It’s essential to confirm the MOQ with each supplier you consider and assess whether it aligns with your production needs. If your order volume is lower, some suppliers may offer flexibility or alternative options, such as mixed product orders. -

What payment terms should I expect when sourcing glass jars?

Payment terms for international B2B transactions can vary widely among suppliers. Common practices include a deposit upfront (usually 30-50%) with the balance due upon shipment or delivery. Some suppliers may also offer net payment terms, allowing you to pay within a specified period after receiving the goods. It’s important to negotiate payment terms that work for both parties and to ensure that they are clearly documented in the purchase agreement to avoid any misunderstandings. -

How do I ensure quality assurance for imported glass jars?

To ensure quality assurance for imported glass jars, implement a multi-step approach. Start by requesting detailed product specifications and quality certifications from your supplier. Consider conducting pre-shipment inspections, either through third-party services or by visiting the manufacturing facility. Additionally, establish a clear return policy for defective products and maintain open communication with your supplier throughout the production process. Regularly monitoring the quality of incoming shipments can help you address any issues promptly. -

What logistics considerations should I keep in mind when importing glass jars?

When importing glass jars, it’s crucial to consider logistics aspects such as shipping methods, customs regulations, and transportation costs. Choose a reliable freight forwarder with experience in handling fragile goods to ensure safe transport. Familiarize yourself with the customs clearance process in your country to avoid delays and unexpected fees. It’s also wise to factor in lead times for production and shipping to align with your inventory management strategies, especially when sourcing from regions like the USA for markets in Africa or South America.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for glass jars made in usa

The strategic sourcing of glass jars made in the USA offers a unique opportunity for international B2B buyers to enhance their product offerings while supporting local economies. Key takeaways include the importance of quality assurance, compliance with international standards, and the ability to customize packaging solutions that align with specific market needs. By sourcing domestically, businesses can benefit from shorter lead times, reduced transportation costs, and a more reliable supply chain.

As global markets continue to evolve, the demand for sustainable and innovative packaging solutions is on the rise. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the advantages of American-made glass jars, including their durability and aesthetic appeal, which can significantly enhance product positioning.

Looking ahead, now is the opportune moment to explore partnerships with American manufacturers. By integrating these high-quality glass jars into your supply chain, you can meet growing consumer expectations for sustainability and craftsmanship. Engage with U.S. suppliers today to capitalize on this trend and elevate your brand in the competitive global marketplace.