Top 6 Wausau Hydraulics List and Guide: How To Solve Scenario 1: …

Introduction: Navigating the Global Market for wausau hydraulics

In the ever-evolving landscape of industrial machinery, sourcing high-quality Wausau hydraulics presents a significant challenge for B2B buyers across the globe. With the demand for custom hydraulic and pneumatic solutions surging, navigating the complexities of procurement can be daunting. This guide aims to illuminate the multifaceted world of Wausau hydraulics, exploring various types, applications, and the intricacies of supplier vetting processes. From understanding the nuances of hydraulic cylinder manufacturing to assessing the cost implications of different service providers, we delve deep into critical factors that influence purchasing decisions.

International buyers from Africa, South America, the Middle East, and Europe—countries such as Brazil and Vietnam—face unique challenges in sourcing reliable hydraulic solutions. This comprehensive resource empowers you with actionable insights and expert knowledge, enabling informed choices that align with your operational needs. By addressing key considerations such as quality assurance, service capabilities, and logistical aspects, this guide serves as your roadmap to successful procurement. Gain the confidence to select the right Wausau hydraulics supplier, ensuring your projects are supported by robust and efficient hydraulic systems that meet global standards.

Top 10 Wausau Hydraulics Manufacturers & Suppliers List

1. Wausau Hydraulics – Custom Hydraulic Cylinders

Domain: wausauhydraulics.com

Registered: 2004 (21 years)

Introduction: Wausau Hydraulics and Machine, Inc. specializes in the manufacturing of custom nonstandard hydraulic and pneumatic cylinders. They also provide rebuilding services for hydraulic and pneumatic cylinders, hydraulic pumps, motors, valves, and multiport swivels.

2. Wausau Hydraulics – Hardware Store

3. Wausau Hydraulics & Machine – Hydraulic Solutions

4. Explorium – Custom Hydraulic Solutions

Domain: explorium.ai

Registered: 2018 (7 years)

Introduction: Cylinders, Fittings, Hose, Custom nonstandard hydraulic cylinders, Hydraulic pumps, Hydraulic motors

5. Names and Numbers – Hydraulic Equipment & Supplies

Domain: namesandnumbers.com

Registered: 1997 (28 years)

Introduction: Hydraulic Equipment & Supplies

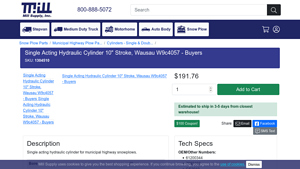

6. Wausau – Single Acting Hydraulic Cylinder 10 Stroke

Domain: millsupply.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “Single Acting Hydraulic Cylinder 10″ Stroke, Wausau W9c4057 – Buyers”, “SKU”: “1304510”, “Price”: “$191.76”, “Estimated Shipping Time”: “3-5 days”, “Bore Size”: “2””, “Stroke Length”: “10””, “Acting Type”: “Single”, “Pin Size”: “1””, “Port Size”: “1/4″ NPT”, “Port Location”: “Inline”, “Rod Flat Size”: “1-1/2″”, “Center to Center Retracted”: “17-1/4″”, “Center to Center Extended”:…

Understanding wausau hydraulics Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Hydraulic Cylinders | Tailored design, various sizes and specifications | Construction, Manufacturing | Pros: Highly specific to needs; enhanced performance. Cons: Longer lead times; potentially higher costs. |

| Pneumatic Cylinders | Utilizes compressed air, lighter weight | Automation, Packaging | Pros: Faster operation; less maintenance. Cons: Limited force compared to hydraulic options. |

| Hydraulic Pumps | Diverse types (gear, piston, vane), high efficiency | Industrial machinery, Agriculture | Pros: Reliable power source; versatile. Cons: Requires proper sizing; can be costly. |

| Multiport Swivels | Allows for fluid transfer in multiple directions | Mobile equipment, Aerospace | Pros: Flexibility in design; reduces wear. Cons: Complex installation; higher initial investment. |

| Hydraulic Valves | Controls fluid flow and pressure, various configurations | Manufacturing, Oil & Gas | Pros: Enhances system control; improves efficiency. Cons: Can be intricate to integrate; may require specialized knowledge. |

What are the Characteristics and Suitability of Custom Hydraulic Cylinders?

Custom hydraulic cylinders are designed to meet specific operational requirements, making them ideal for applications where standard solutions are inadequate. They can be manufactured in various sizes, strokes, and configurations, allowing businesses to optimize their hydraulic systems. When purchasing, B2B buyers should consider the cylinder’s material, pressure rating, and compatibility with existing systems. These cylinders are particularly suitable for construction and manufacturing industries, where precision and reliability are critical.

How Do Pneumatic Cylinders Stand Out in the Market?

Pneumatic cylinders utilize compressed air to create motion, making them a lightweight and efficient option for various applications. They are commonly used in automation and packaging industries due to their quick response times and lower maintenance needs. Buyers should evaluate factors such as the cylinder’s bore size, stroke length, and mounting options when selecting pneumatic cylinders. While they excel in speed and simplicity, their force output is generally lower than that of hydraulic systems, making them less suitable for heavy-duty applications.

What Benefits Do Hydraulic Pumps Provide for Industrial Applications?

Hydraulic pumps are essential components in hydraulic systems, providing the necessary power to operate machinery and equipment. They come in various types, including gear, piston, and vane pumps, each offering distinct advantages based on the application. B2B buyers should focus on factors such as flow rate, pressure output, and efficiency when selecting a hydraulic pump. These pumps are widely used in industries like agriculture and manufacturing, where reliable and robust power sources are vital for operational success.

Why Choose Multiport Swivels for Fluid Transfer?

Multiport swivels enable fluid transfer in multiple directions, offering flexibility in design and functionality. They are particularly beneficial in mobile equipment and aerospace applications, where space and movement constraints are prevalent. Buyers should consider the swivel’s design complexity and installation requirements, as they can be more intricate than standard fittings. While they provide significant advantages in reducing wear and enhancing system flexibility, the initial investment can be higher compared to simpler alternatives.

What Role Do Hydraulic Valves Play in System Efficiency?

Hydraulic valves are crucial for controlling fluid flow and pressure within hydraulic systems. They come in various configurations, allowing for tailored solutions to enhance system efficiency and performance. When purchasing hydraulic valves, B2B buyers should assess compatibility with existing systems, flow capacity, and operational reliability. These valves are widely used in sectors such as manufacturing and oil & gas, where precision control is necessary for optimal operation. However, integrating them into existing systems can be complex, requiring specialized knowledge and installation efforts.

Key Industrial Applications of wausau hydraulics

| Industry/Sector | Specific Application of Wausau Hydraulics | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Custom hydraulic cylinders for heavy machinery | Enhanced efficiency and reliability in lifting and excavation | Ensure compatibility with existing equipment; evaluate service and support options. |

| Agriculture | Hydraulic systems for farming equipment | Increased productivity and reduced downtime | Consider climate and terrain; assess the availability of local support services. |

| Manufacturing | Hydraulic pumps and valves for production lines | Improved operational efficiency and product quality | Look for customization options to fit specific production needs; check for lead times. |

| Mining | Pneumatic cylinders for drilling and excavation | Enhanced safety and performance under extreme conditions | Verify durability and resistance to harsh environments; evaluate maintenance services. |

| Transportation | Hydraulic systems for logistics and material handling | Streamlined operations and reduced labor costs | Assess the scalability of solutions; ensure compliance with local regulations. |

How is Wausau Hydraulics Applied in Construction?

In the construction sector, Wausau Hydraulics provides custom hydraulic cylinders tailored for heavy machinery such as cranes and excavators. These cylinders are crucial for lifting and moving heavy loads efficiently, which directly impacts project timelines and costs. International buyers should consider the compatibility of these cylinders with their existing equipment and the availability of local service support to ensure minimal downtime during operations.

What Role Does Wausau Hydraulics Play in Agriculture?

Wausau Hydraulics supplies hydraulic systems that enhance the performance of farming equipment, from tractors to harvesters. By optimizing power transfer and control, these systems significantly boost productivity and reduce equipment downtime, which is vital in the agricultural sector where timing can affect yield. Buyers in regions like Africa and South America should evaluate the environmental conditions of their operations to ensure that the hydraulic systems can withstand local climates.

How Does Wausau Hydraulics Improve Manufacturing Processes?

In manufacturing, Wausau Hydraulics offers hydraulic pumps and valves designed to enhance the efficiency of production lines. These components ensure smooth operation and precise control, which are essential for maintaining product quality. Buyers should focus on customization options to meet their specific production requirements and assess lead times to avoid disruptions in their manufacturing schedules.

What Benefits Does Wausau Hydraulics Bring to Mining Operations?

Mining operations utilize Wausau Hydraulics’ pneumatic cylinders for drilling and excavation tasks. These cylinders are engineered to perform reliably under extreme conditions, ensuring safety and efficiency in challenging environments. Buyers should prioritize the durability of the equipment and the availability of maintenance services, especially in remote mining locations in the Middle East and Africa.

How is Wausau Hydraulics Used in Transportation?

In the transportation sector, Wausau Hydraulics provides hydraulic systems that streamline logistics and material handling processes. These systems contribute to more efficient operations, reducing labor costs and improving overall productivity. International buyers should consider the scalability of these hydraulic solutions to accommodate future growth and ensure compliance with local transportation regulations.

3 Common User Pain Points for ‘wausau hydraulics’ & Their Solutions

Scenario 1: Custom Cylinder Requirements for Unique Applications

The Problem: Many B2B buyers face the challenge of sourcing hydraulic cylinders that meet specific operational requirements. Standard options often fall short, leading to inefficiencies or the need for costly modifications. Companies in sectors like construction and manufacturing often require nonstandard cylinders that can handle unique pressures, dimensions, or mounting configurations. This mismatch can result in production delays, increased costs, and ultimately lost revenue.

The Solution: Wausau Hydraulics specializes in the manufacturing of custom nonstandard hydraulic cylinders tailored to meet unique specifications. B2B buyers should engage directly with Wausau’s engineering team during the design phase to discuss specific requirements and constraints. Providing detailed information such as load capacity, environmental conditions, and desired materials can help streamline the process. Additionally, utilizing Wausau’s extensive experience in hydraulic design can lead to innovative solutions that enhance operational efficiency. Buyers can take advantage of Wausau’s rebuilding services to extend the life of existing cylinders, ensuring their operations remain uninterrupted while waiting for new custom orders.

Scenario 2: Maintenance and Downtime Challenges

The Problem: Equipment failure due to faulty hydraulic systems is a significant pain point for businesses across various industries. Unplanned downtime can be costly, leading to lost productivity and increased operational costs. B2B buyers often struggle with identifying reliable repair services that can quickly restore their hydraulic systems, especially for complex machinery that relies on multiple hydraulic components.

The Solution: Wausau Hydraulics offers comprehensive rebuilding services for hydraulic components, including pumps, motors, and valves. To mitigate downtime, B2B buyers should establish a proactive maintenance schedule with Wausau, ensuring regular inspections and timely repairs before issues escalate. It is essential to maintain open communication with Wausau’s service team to identify potential concerns early on. By leveraging Wausau’s expertise, companies can optimize their hydraulic systems and minimize the risk of unexpected failures. Additionally, Wausau can provide training for in-house maintenance teams, enhancing their ability to troubleshoot common issues and perform routine maintenance effectively.

Scenario 3: Sourcing Quality Components for Diverse Applications

The Problem: Sourcing high-quality hydraulic components can be challenging, particularly for international buyers who may encounter difficulties verifying suppliers’ reliability and product quality. Issues such as inconsistent standards, language barriers, and varying shipping times can complicate procurement processes, leading to frustration and delays in project timelines.

The Solution: To alleviate these concerns, B2B buyers should consider establishing a strong partnership with Wausau Hydraulics. By engaging in thorough discussions about product specifications and quality standards, buyers can ensure that Wausau’s products meet their operational needs. Furthermore, buyers should leverage Wausau’s established reputation in the industry to gain confidence in their sourcing decisions. It is advisable to request samples or prototypes before committing to larger orders, allowing for on-site testing to confirm compatibility with existing systems. Additionally, working closely with Wausau’s logistics team can streamline shipping processes, ensuring timely delivery regardless of the buyer’s location. This proactive approach can help international buyers mitigate risks associated with sourcing hydraulic components while ensuring high-quality standards are consistently met.

Strategic Material Selection Guide for wausau hydraulics

What Are the Key Materials Used in Wausau Hydraulics Products?

When selecting materials for hydraulic components, understanding their properties and suitability for specific applications is essential. Below are analyses of four common materials used in the manufacturing of hydraulic cylinders and related components at Wausau Hydraulics.

How Does Steel Perform in Hydraulic Applications?

Steel is widely used in hydraulic systems due to its strength and durability. It typically exhibits high temperature and pressure ratings, making it suitable for demanding applications. Steel also offers good corrosion resistance when treated with coatings or alloys.

Pros: Steel is robust and can withstand significant mechanical stress, making it an ideal choice for high-pressure applications. Its availability and cost-effectiveness also contribute to its widespread use.

Cons: While steel is strong, it can be susceptible to corrosion if not properly treated, which may lead to premature failure in harsh environments. Additionally, the manufacturing process can be complex, requiring specialized equipment and techniques.

Impact on Application: Steel is compatible with various hydraulic fluids, but care must be taken to ensure that the selected fluid does not contribute to corrosion.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM or ISO, to guarantee the quality of steel used in their hydraulic systems.

What Advantages Does Aluminum Offer in Hydraulic Systems?

Aluminum is another popular material, particularly for lightweight hydraulic components. It has excellent corrosion resistance and good thermal conductivity, which can enhance system efficiency.

Pros: The lightweight nature of aluminum allows for easier handling and installation, reducing overall system weight. Its corrosion resistance makes it suitable for applications in humid or corrosive environments.

Cons: Aluminum has lower tensile strength compared to steel, which may limit its use in high-pressure applications. It is also generally more expensive than steel, which can impact project budgets.

Impact on Application: Aluminum is compatible with most hydraulic fluids but should be evaluated for specific media compatibility, especially in harsh chemical environments.

Considerations for International Buyers: Buyers in Europe and the Middle East should consider compliance with DIN and JIS standards to ensure the aluminum used meets required specifications for performance and safety.

Why Is Stainless Steel a Preferred Material for Certain Applications?

Stainless steel combines the strength of steel with enhanced corrosion resistance, making it a preferred choice for hydraulic components exposed to harsh environments.

Pros: The corrosion-resistant properties of stainless steel make it ideal for applications involving water, chemicals, or saline environments. It also maintains strength at higher temperatures.

Cons: Stainless steel is more expensive than both carbon steel and aluminum, which can be a limiting factor for budget-conscious projects. Additionally, its manufacturing can be more complex, requiring specialized techniques.

Impact on Application: Stainless steel is compatible with a wide range of hydraulic fluids and is particularly suitable for applications where cleanliness is paramount, such as in food processing or pharmaceuticals.

Considerations for International Buyers: Buyers from regions like Brazil and Vietnam should ensure that their suppliers adhere to international standards, such as ASTM A276, to guarantee the quality and performance of stainless steel components.

How Does Composite Material Enhance Hydraulic Systems?

Composite materials, such as carbon fiber reinforced polymers, are increasingly being used in hydraulic applications due to their lightweight and high-strength properties.

Pros: Composites offer excellent strength-to-weight ratios and are resistant to corrosion, making them suitable for specialized applications where weight reduction is crucial.

Cons: The cost of composite materials can be significantly higher than traditional metals, which may deter some buyers. Additionally, the manufacturing processes for composites can be complex and require specialized knowledge.

Impact on Application: Composites can be tailored for specific media compatibility, making them versatile for various hydraulic fluids.

Considerations for International Buyers: Buyers should be aware of the evolving standards for composite materials and ensure compliance with relevant regulations in their region.

Summary Table of Material Selection for Wausau Hydraulics

| Material | Typical Use Case for Wausau Hydraulics | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-pressure hydraulic cylinders | High strength and durability | Susceptible to corrosion if untreated | Medium |

| Aluminum | Lightweight hydraulic components | Corrosion resistance and lightweight | Lower strength compared to steel | High |

| Stainless Steel | Corrosive environment applications | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Composite | Specialized lightweight applications | High strength-to-weight ratio | High cost and complex manufacturing | High |

This guide aims to provide B2B buyers with actionable insights into material selection for hydraulic applications, ensuring informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for wausau hydraulics

What Are the Key Stages in the Manufacturing Process for Wausau Hydraulics?

Wausau Hydraulics specializes in the production of custom nonstandard hydraulic and pneumatic cylinders, emphasizing precision and quality throughout their manufacturing process. The stages involved typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Hydraulic Component Manufacturing?

The first step in the manufacturing process is material preparation. Wausau Hydraulics utilizes high-quality raw materials such as steel and aluminum, which are selected based on the specific requirements of the hydraulic components. This phase includes cutting, machining, and treating materials to ensure they meet the necessary specifications and tolerances. Advanced CNC machining techniques are often employed to achieve precise dimensions, which are critical for the performance of hydraulic systems.

What Forming Techniques Are Used in Hydraulic Cylinder Production?

Once materials are prepared, the next stage is forming. This process may involve techniques such as extrusion, forging, and welding, depending on the design of the hydraulic cylinders. Wausau Hydraulics may use advanced forming technologies to create complex shapes and configurations that meet customer specifications. For instance, hydraulic cylinders often require intricate designs that can withstand high pressures, necessitating specialized forming techniques to ensure structural integrity.

How Does Assembly Work in Hydraulic Manufacturing?

The assembly stage involves bringing together various components to create the final product. Wausau Hydraulics employs skilled technicians who meticulously assemble hydraulic cylinders, ensuring that each part fits perfectly and operates smoothly. This stage often includes the installation of seals, rods, and other internal components. Attention to detail during assembly is crucial, as any misalignment can lead to performance issues or failures in the hydraulic system.

What Finishing Processes Are Important for Quality?

After assembly, the finishing processes enhance the durability and functionality of the hydraulic components. This may involve surface treatments such as anodizing or painting, which protect against corrosion and wear. Additionally, hydraulic cylinders may undergo pressure testing and other quality checks to ensure they meet the necessary performance standards before being shipped to clients.

How Does Wausau Hydraulics Ensure Quality Control in Manufacturing?

Quality assurance is integral to the manufacturing process at Wausau Hydraulics. The company adheres to international standards such as ISO 9001, which outlines requirements for a quality management system. This commitment to quality ensures that every product meets both regulatory and customer expectations.

What Are the Key Quality Control Checkpoints?

Wausau Hydraulics implements several quality control checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards before processing begins.

- In-Process Quality Control (IPQC): During production, regular checks are performed to monitor the quality of components at various stages. This proactive approach allows for the early detection of issues, minimizing waste and rework.

- Final Quality Control (FQC): Once the manufacturing process is complete, each hydraulic cylinder undergoes final inspections. This includes functional testing and dimensional checks to confirm that the product meets all specifications.

What Testing Methods Are Commonly Used?

Various testing methods are employed to validate the quality and functionality of hydraulic components. Common techniques include:

- Hydraulic Pressure Testing: This method checks for leaks and ensures that the cylinder can withstand specified pressure levels.

- Dimensional Inspection: Using tools like calipers and gauges, technicians verify that all dimensions conform to the design specifications.

- Functional Testing: This assesses the operational performance of the hydraulic cylinder in real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is critical. Here are some actionable steps:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed quality control reports and audit results from Wausau Hydraulics. These documents should outline the manufacturing process, quality checks, and compliance with international standards. A thorough understanding of the supplier’s quality management system is essential.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and quality assurance measures in place. This is especially valuable for buyers who may not have the resources to conduct on-site audits themselves. Third-party inspectors can verify compliance with industry standards such as CE and API, further assuring product quality.

What Are the Quality Certification Nuances for International B2B Buyers?

International buyers must also consider the specific certification requirements relevant to their regions. For instance, while ISO 9001 is widely recognized, certain industries may require additional certifications. Understanding these nuances helps buyers ensure that the products they procure are compliant with local regulations and standards.

In conclusion, Wausau Hydraulics emphasizes a rigorous manufacturing process and a robust quality control system, making them a reliable supplier for international B2B buyers. By understanding the intricacies of their manufacturing processes and quality assurance practices, buyers can make informed decisions that align with their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wausau hydraulics’

This guide serves as a comprehensive checklist for B2B buyers looking to procure hydraulic solutions from Wausau Hydraulics and Machine, Inc. With a focus on custom hydraulic and pneumatic cylinders, along with repair services, it’s essential to follow a systematic approach to ensure the best outcomes for your business needs.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the foundation of a successful procurement process. Clearly outline the type of hydraulic or pneumatic cylinders you need, including dimensions, materials, and performance criteria. This step ensures that potential suppliers can meet your expectations and provide tailored solutions.

Step 2: Conduct Market Research

Before engaging suppliers, research the market to understand the range of options available. Identify competitors and compare their offerings, pricing, and customer reviews. This knowledge will empower you to negotiate better terms and make informed decisions.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for:

– Industry Reputation: Investigate their history and track record in the market.

– Client Testimonials: Ensure they have satisfied customers who can vouch for their reliability.

Step 4: Verify Supplier Certifications

Confirm that the supplier holds relevant certifications and adheres to industry standards. This is essential to ensure product quality and compliance with safety regulations. Check for certifications like ISO, which indicate a commitment to quality management systems.

Step 5: Request Detailed Quotes

Once you have identified potential suppliers, request detailed quotes that include pricing, lead times, and terms of service. A comprehensive quote should also cover any additional costs such as shipping and installation. Evaluate these quotes carefully to identify the best value for your investment.

Step 6: Assess After-Sales Support

Consider the level of support you will receive after the purchase. This includes warranty terms, repair services, and customer service responsiveness. A supplier that offers robust after-sales support can significantly reduce downtime and enhance your operational efficiency.

Step 7: Negotiate Terms and Finalize the Agreement

Once you have selected a supplier, engage in negotiations to finalize the terms of your agreement. Discuss payment terms, delivery schedules, and any contingencies for unforeseen circumstances. A well-defined contract protects both parties and ensures clarity throughout the transaction.

By following this step-by-step checklist, B2B buyers can make informed decisions when sourcing hydraulic solutions from Wausau Hydraulics and Machine, Inc. This structured approach not only mitigates risks but also enhances the likelihood of securing high-quality products that meet your business needs.

Comprehensive Cost and Pricing Analysis for wausau hydraulics Sourcing

What Are the Key Cost Components for Sourcing Wausau Hydraulics Products?

When considering sourcing from Wausau Hydraulics and Machine, Inc., understanding the key cost components is essential for international B2B buyers. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type and quality of raw materials significantly impact the overall cost. Wausau specializes in custom nonstandard hydraulic and pneumatic cylinders, which may require specific materials based on customer specifications.

-

Labor: Skilled labor is necessary for both the manufacturing and rebuilding processes. Labor costs can vary based on the complexity of the components and the region where production occurs. In Schofield, Wisconsin, labor rates are influenced by local market conditions.

-

Manufacturing Overhead: This encompasses costs related to facility maintenance, utilities, and administrative expenses. Given Wausau’s focus on high-quality products, overhead costs may be higher to ensure optimal production conditions.

-

Tooling: Custom tooling may be necessary for the production of specialized hydraulic components. Tooling costs can vary widely depending on the design and complexity of the product.

-

Quality Control (QC): Ensuring product quality is crucial, especially for hydraulic systems. This involves costs related to testing and certification, which can affect pricing, particularly for international buyers who may require specific certifications.

-

Logistics: Shipping costs can be significant, especially for international shipments. Factors such as distance, shipping methods, and import/export regulations can all impact logistics costs.

-

Margin: Wausau’s pricing structure will also include a profit margin, which can vary based on market competition and the specific customer relationship.

What Influences the Pricing of Wausau Hydraulics Products?

Several factors can influence the pricing of products sourced from Wausau Hydraulics, making it crucial for buyers to be aware of these variables:

-

Volume/MOQ: The minimum order quantity (MOQ) can affect pricing. Larger orders often lead to lower per-unit costs due to economies of scale.

-

Specifications/Customization: Custom products typically come at a premium. Buyers should clearly communicate their specifications to receive accurate quotes.

-

Materials: The choice of materials significantly impacts the final cost. Higher-grade materials may be necessary for specific applications, leading to increased pricing.

-

Quality and Certifications: Compliance with international quality standards can affect costs. Products with certifications may command higher prices, reflecting the added assurance of quality.

-

Supplier Factors: The reputation and reliability of Wausau as a supplier can influence pricing. Established suppliers may charge more for their expertise and reliability.

-

Incoterms: Understanding the terms of trade (Incoterms) is vital. These terms define the responsibilities of buyers and sellers in the shipping process, which can significantly affect total costs.

What Tips Can Help International Buyers Negotiate Better Prices?

For international buyers, especially those from Africa, South America, the Middle East, and Europe, there are several strategies to consider for cost-efficient sourcing:

-

Negotiate Effectively: Leverage volume purchases or long-term contracts to negotiate better pricing. Establishing a strong relationship with the supplier can also lead to favorable terms.

-

Consider Total Cost of Ownership: Evaluate not just the purchase price but also the total cost of ownership, including maintenance, logistics, and potential downtime. A higher initial cost may lead to lower overall expenses if the product is more reliable.

-

Understand Pricing Nuances: Be aware that international buyers may face additional costs related to tariffs, taxes, and logistics. Factor these into your budget to avoid surprises.

-

Research Market Conditions: Keep abreast of market conditions and trends in hydraulic equipment. Understanding the competitive landscape can provide leverage during negotiations.

-

Request Detailed Quotes: Ask for comprehensive quotes that break down costs. This transparency can help identify areas for negotiation and clarify what influences the pricing.

Disclaimer on Indicative Prices

It is essential to note that prices can vary based on specific project requirements, market fluctuations, and other factors. Therefore, always seek updated quotes directly from Wausau Hydraulics and Machine, Inc. to ensure accurate pricing for your specific needs.

Alternatives Analysis: Comparing wausau hydraulics With Other Solutions

Understanding Alternatives in Hydraulic Solutions

When considering hydraulic solutions for industrial applications, it is essential for buyers to evaluate various options available in the market. Wausau Hydraulics specializes in custom hydraulic and pneumatic cylinders, providing tailored solutions and comprehensive repair services. However, several alternatives exist that may also meet the needs of B2B buyers, each with unique strengths and weaknesses. This analysis will compare Wausau Hydraulics with two viable alternatives: Parker Hannifin and Bosch Rexroth.

Comparison Table

| Comparison Aspect | Wausau Hydraulics | Parker Hannifin | Bosch Rexroth |

|---|---|---|---|

| Performance | High customization for niche applications | High reliability, extensive product range | Robust solutions for diverse industries |

| Cost | Moderate; varies with customization | Competitive; value for broad applications | Higher initial investment, but offers long-term savings |

| Ease of Implementation | Moderate; requires specific knowledge for custom solutions | Easy; widely used with extensive support | Moderate; requires training for advanced systems |

| Maintenance | Regular maintenance needed for custom parts | Low; standardized parts available | Moderate; requires specialized knowledge |

| Best Use Case | Specialized industries needing custom solutions | General industrial applications | Complex systems requiring integration |

Detailed Breakdown of Alternatives

Parker Hannifin

Parker Hannifin is a leading global supplier of motion and control technologies. The company’s extensive product range includes hydraulic components that are known for their reliability and performance. One of the significant advantages of Parker is the availability of standardized parts, which simplifies maintenance and reduces downtime. This can lead to lower overall operational costs. However, the downside is that while Parker offers customization, it may not match the level of bespoke solutions that Wausau provides for specialized applications.

Bosch Rexroth

Bosch Rexroth is recognized for its innovative hydraulic solutions, particularly in complex industrial environments. Their products are designed for high efficiency and adaptability, making them suitable for a wide range of applications, from manufacturing to mobile machinery. The initial investment in Bosch Rexroth systems can be higher than Wausau Hydraulics, but the long-term efficiency gains and potential for reduced maintenance costs can offset this. A drawback is that implementation may require specialized training, particularly for their advanced systems, which could increase the time and cost of setup.

Conclusion: How to Choose the Right Hydraulic Solution

When selecting a hydraulic solution, B2B buyers must consider their specific operational needs, budget constraints, and the level of customization required. Wausau Hydraulics is ideal for organizations seeking highly tailored solutions and specialized repair services. In contrast, Parker Hannifin may be the best choice for those looking for reliable, standardized components that minimize maintenance. Bosch Rexroth offers advanced technologies that may be worth the higher investment for businesses that require integrated systems capable of handling complex tasks. Ultimately, the right choice will depend on the balance between immediate needs and long-term operational goals.

Essential Technical Properties and Trade Terminology for wausau hydraulics

What Are the Key Technical Properties of Wausau Hydraulics?

When evaluating hydraulic systems and components, understanding their technical properties is crucial for ensuring performance, reliability, and compatibility. Here are some essential specifications:

-

Material Grade

Hydraulic components are often made from high-strength materials such as steel or aluminum alloys. The choice of material affects the durability, weight, and resistance to corrosion. For instance, using high-grade steel can enhance the lifespan of hydraulic cylinders, making them suitable for heavy-duty applications. -

Tolerance Levels

Tolerance refers to the permissible limit of variation in a physical dimension. In hydraulic systems, tight tolerances (e.g., +/- 0.001 inches) are critical for ensuring proper fit and function. Components that do not meet specified tolerances can lead to inefficiencies, leaks, or system failures, impacting operational reliability. -

Pressure Rating

The pressure rating indicates the maximum pressure a hydraulic component can safely handle. This specification is vital for selecting the appropriate components for specific applications. Exceeding pressure ratings can cause catastrophic failures, posing risks to equipment and personnel. -

Stroke Length

Stroke length is the distance a hydraulic cylinder can extend or retract. This property is essential for determining the range of motion required in applications such as construction machinery or industrial automation. Selecting the right stroke length ensures that the hydraulic system meets operational needs without compromise. -

Flow Rate

Flow rate, typically measured in gallons per minute (GPM), indicates how much fluid can pass through a hydraulic system. This specification directly impacts the efficiency and speed of hydraulic operations. A higher flow rate can lead to faster system responses but requires careful consideration of the system design to avoid cavitation and other issues. -

Temperature Range

Hydraulic fluids operate effectively within specified temperature ranges. Understanding the temperature limits is crucial for maintaining system performance and preventing fluid degradation. Selecting components that can withstand the operational temperature range is vital for ensuring long-term reliability.

What Are Common Trade Terms in the Hydraulic Industry?

Familiarity with industry jargon can significantly enhance communication and negotiation with suppliers. Here are some critical terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the hydraulic industry, sourcing from OEMs ensures that components meet specific standards and compatibility requirements, providing assurance of quality and performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is essential for B2B buyers to manage inventory and cash flow effectively. This term can impact purchasing decisions, especially for smaller businesses or when testing new products. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. This process is crucial for comparing costs and ensuring budget alignment. A well-prepared RFQ can lead to better pricing and terms, making it a valuable tool in procurement. -

Incoterms

International Commercial Terms (Incoterms) are standard trade terms used in international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is vital for mitigating risks and ensuring smooth logistics in global trade. -

Hydraulic Fluids

Hydraulic fluids are specialized liquids used to transmit power in hydraulic systems. Their properties, such as viscosity and temperature stability, are essential for maintaining system performance. Selecting the right hydraulic fluid can enhance efficiency and extend equipment life. -

Actuator

An actuator is a device that converts energy into motion, often used in hydraulic systems to control machinery. Understanding the types of actuators and their applications is essential for designing efficient hydraulic systems that meet specific operational needs.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing hydraulic components from Wausau Hydraulics and similar manufacturers. This knowledge not only facilitates better negotiations but also ensures that the selected solutions align with operational requirements and industry standards.

Navigating Market Dynamics and Sourcing Trends in the wausau hydraulics Sector

What Are the Key Market Dynamics and Trends in the Wausau Hydraulics Sector?

The global hydraulics market is experiencing significant transformation, driven by technological advancements, increasing automation, and a growing emphasis on efficiency. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. Emerging trends include the rise of smart hydraulics, integrating IoT technologies for predictive maintenance and enhanced performance monitoring. This shift not only optimizes equipment lifespan but also reduces downtime, a critical factor for industries reliant on hydraulic systems.

Moreover, the demand for custom solutions is on the rise, with companies like Wausau Hydraulics leading the charge in manufacturing nonstandard hydraulic and pneumatic cylinders tailored to specific applications. This trend reflects a broader movement towards customization in manufacturing, allowing businesses to meet unique operational needs. Additionally, as sustainability becomes increasingly prioritized across industries, hydraulics companies are responding with eco-friendly designs and energy-efficient systems, appealing to environmentally conscious buyers.

How Are Sustainability and Ethical Sourcing Affecting the Wausau Hydraulics Market?

Sustainability is no longer an option but a necessity in the hydraulic sector. The environmental impact of hydraulic systems, particularly concerning fluid leaks and energy consumption, has prompted a shift towards more sustainable practices. For B2B buyers, this means seeking suppliers who prioritize eco-friendly materials and processes. Wausau Hydraulics, for instance, is focusing on developing hydraulic solutions that minimize environmental impact, such as using biodegradable fluids and recyclable materials.

Ethical sourcing is equally important. Buyers are increasingly looking for suppliers who adhere to ethical labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can serve as indicators of a company’s commitment to sustainability. By partnering with manufacturers that prioritize these aspects, international buyers can enhance their own sustainability credentials while ensuring compliance with local regulations and expectations in their respective markets.

What Is the Evolution of the Wausau Hydraulics Sector?

Wausau Hydraulics has evolved from a traditional hydraulic component manufacturer to a leader in customized hydraulic solutions. Founded in the mid-20th century, the company initially focused on standard hydraulic cylinder production. Over the years, it adapted to market needs, expanding its offerings to include specialized services such as the rebuilding of hydraulic and pneumatic cylinders, pumps, and valves. This evolution reflects broader trends in the manufacturing sector, where customization and repair services are increasingly valued.

By embracing innovation and responding to changing market demands, Wausau Hydraulics has positioned itself as a pivotal player in the global hydraulics landscape, catering to a diverse clientele across various industries. As the market continues to evolve, the company’s commitment to quality and customer-centric solutions will likely remain integral to its success, making it a reliable partner for international B2B buyers seeking tailored hydraulic solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of wausau hydraulics

-

How can I ensure the quality of Wausau hydraulics products?

To ensure quality, request detailed specifications and certifications for the hydraulic components you’re considering. Wausau Hydraulics emphasizes quality through rigorous testing and adherence to industry standards. Additionally, ask for samples or references from previous clients who have sourced similar products. Establishing a quality assurance agreement can also help maintain standards throughout your procurement process. -

What customization options are available for hydraulic cylinders from Wausau?

Wausau Hydraulics specializes in custom nonstandard hydraulic and pneumatic cylinders tailored to specific applications. When inquiring, provide detailed specifications including dimensions, pressure requirements, and environmental conditions. Their engineering team can collaborate with you to design a solution that meets your operational needs, ensuring optimal performance in your equipment. -

What are the minimum order quantities (MOQ) for Wausau hydraulics products?

Minimum order quantities can vary based on the product type and customization level. Generally, Wausau Hydraulics is flexible and aims to accommodate clients’ needs, particularly for bulk orders or long-term partnerships. It is advisable to discuss your requirements directly with their sales team to understand the MOQ applicable to your specific order. -

What payment terms does Wausau Hydraulics offer for international buyers?

Wausau Hydraulics typically offers a range of payment terms, which may include upfront payments, net 30, or 60-day terms depending on the order size and buyer’s creditworthiness. For international transactions, consider discussing letters of credit or other secure payment methods to mitigate risk. Always confirm payment terms in writing before finalizing your order. -

How does Wausau Hydraulics handle logistics for international shipping?

Wausau Hydraulics has experience with international logistics and can assist in arranging shipping to various destinations. They usually work with trusted freight forwarders to ensure timely delivery. It’s essential to discuss shipping options, costs, and estimated delivery times during the ordering process to align with your project timelines. -

What is the warranty policy for Wausau hydraulics products?

Wausau Hydraulics offers a warranty on their products, which typically covers defects in materials and workmanship. The warranty duration may vary based on the product type and specific agreements made at the time of purchase. Review the warranty terms carefully and ensure they are documented in your purchase agreement to avoid potential disputes. -

What are the key factors to consider when vetting Wausau Hydraulics as a supplier?

When vetting Wausau Hydraulics, consider their industry experience, product quality, customer reviews, and their capacity for customization. Evaluate their manufacturing processes and quality control measures. Additionally, assess their responsiveness and ability to meet delivery timelines, which are crucial for maintaining your operational efficiency. -

How can I stay updated on new products and innovations from Wausau Hydraulics?

To stay informed about new products and innovations, subscribe to Wausau Hydraulics’ newsletter or follow them on social media platforms. Engaging directly with their sales team can also provide insights into upcoming product launches. Attending industry trade shows where Wausau showcases their offerings can further enhance your understanding of their latest solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for wausau hydraulics

How Can Strategic Sourcing Enhance Your Business with Wausau Hydraulics?

In conclusion, partnering with Wausau Hydraulics offers a strategic advantage for B2B buyers seeking custom hydraulic solutions. Their specialization in nonstandard hydraulic and pneumatic cylinder manufacturing, along with advanced rebuilding services, ensures that clients can access tailored products that meet specific operational needs. This focus on customization not only enhances efficiency but also extends the lifespan of hydraulic systems, providing significant long-term cost savings.

Strategic sourcing from Wausau Hydraulics also fosters reliability in supply chains, crucial for businesses operating in diverse markets across Africa, South America, the Middle East, and Europe. As international buyers increasingly prioritize quality and adaptability, engaging with a company that understands the nuances of global sourcing can lead to competitive differentiation.

Looking ahead, companies are encouraged to explore collaborative opportunities with Wausau Hydraulics. By investing in these partnerships, businesses can secure innovative hydraulic solutions that drive operational excellence. Don’t miss out on the chance to elevate your hydraulic applications—reach out today to discover how Wausau Hydraulics can support your business growth and sustainability goals.