Top 7 Carbon Fiber Usa List and Guide: How To Solve Scenario 1: N…

Introduction: Navigating the Global Market for carbon fiber usa

Navigating the global market for carbon fiber in the USA presents unique challenges, particularly for international B2B buyers seeking to source high-quality materials for diverse applications. With the lightweight strength of carbon fiber making it an essential component in industries such as aerospace, automotive, and marine, buyers must be equipped with the knowledge to select the right products and suppliers. This guide serves as a comprehensive resource, detailing various types of carbon fiber materials, their applications, and critical considerations for supplier vetting and cost analysis.

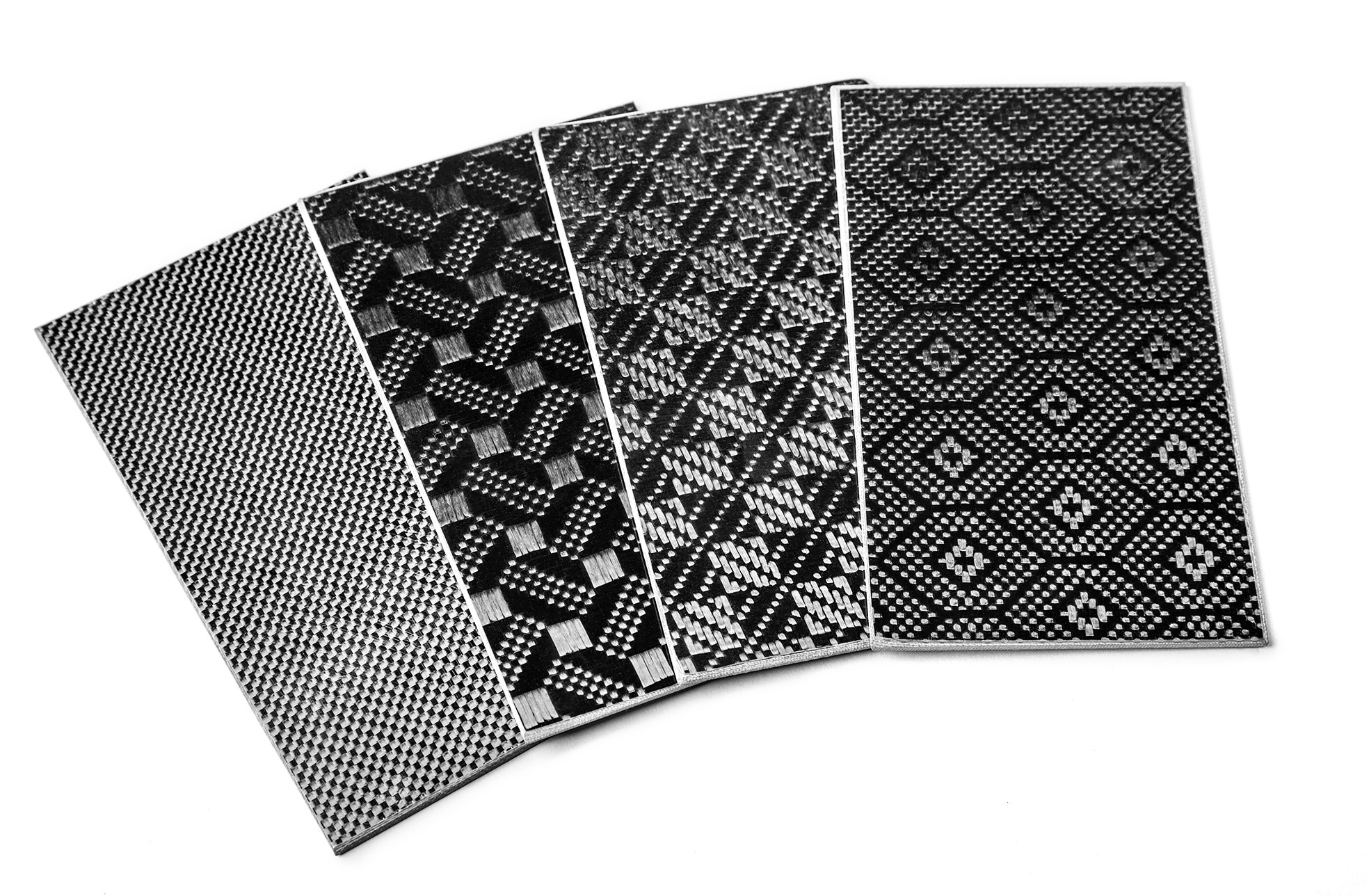

International buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Brazil, often face hurdles in ensuring that their sourcing decisions align with their specific needs and quality standards. This guide empowers these buyers by providing actionable insights on navigating the complexities of the carbon fiber market. From understanding different weave types—like plain, satin, and twill—to evaluating lead times and delivery expectations, this resource equips B2B professionals with the tools necessary for informed purchasing decisions. By leveraging this guide, international buyers can streamline their procurement processes, mitigate risks, and ultimately enhance their product offerings in a competitive landscape.

Top 10 Carbon Fiber Usa Manufacturers & Suppliers List

1. Current Inc. – Carbon Fiber Products

Domain: currentcomposites.com

Registered: 1996 (29 years)

Introduction: Current Inc. manufactures a variety of carbon fiber products including:

– Laminated Sheets

– Laminated Tubing

– Laminated Rods

– Spacers and Standoffs

– Custom Fabrication Materials

Carbon Fiber is available in different weaves:

– Plain Weave: Good stability, suited for flat panels and minimal contour radius.

– Satin Weave: Available in four, five, or eight harness satin; easily draped for diffic…

2. Fibreglast – Carbon Fiber Materials

Domain: fibreglast.com

Registered: 1995 (30 years)

Introduction: All Carbon Fiber Materials include a variety of products such as Carbon Fiber Tapes, Tow, & Sleeves, Carbon / KEVLAR Hybrid Fabric, Classic and Contemporary Carbon Fiber Styles, and Sample Packs. The site also offers certified and traceable products with same-day shipping for orders placed by 2:30pm ET.

3. U.S. Composites – Composite Materials & Resins

Domain: uscomposites.com

Registered: 2000 (25 years)

Introduction: U.S. Composites, Inc. offers a wide range of composite materials including: Fiberglass, Epoxy, Composites, Urethane Molding Rubbers, Carbon Fiber, and Urethane Foam. They specialize in carbon fiber, fiberglass, and KEVLAR® woven fabrics, as well as high-performance epoxy and polyester resins. Featured products include Carbon & KEVLAR® Cloth, Table Top Epoxy for clear coating, Expanding Urethane Fo…

4. Clearwater Composites – Carbon Fiber Tubes & Parts

Domain: clearwatercomposites.com

Registered: 2009 (16 years)

Introduction: Carbon Fiber Tubes: Round (Standard Modulus, High Modulus, Ultra High Modulus, Ferrule, Colored Tubing), Square (Standard Modulus, High Modulus), Rectangular (Standard Modulus, High Modulus), Hexagonal (Standard Modulus, High Modulus), Octagonal (Standard Modulus). Carbon Fiber Parts: Carbon Fiber Plates (Standard Modulus, High Modulus, Ultra High Modulus), Foam Core. Services: Manufacturing (Roll…

5. Carbon Fiber Gear – Key Products

Domain: carbonfibergear.com

Registered: 2007 (18 years)

Introduction: Made in the USA collection includes various carbon fiber products such as wallets, money clips, keychains, hats, rings, and more. Key products include:

– Carbon Fiber Valve Stem Caps: $44.95, premium aluminum with real carbon fiber inlays.

– TagArmur Frame: $149.95, genuine carbon fiber with hidden screws.

– M-Clip Money Clip: $140, real carbon fiber inlay with CNC-machined stainless steel.

– Carb…

6. Seibon Carbon – Carbon Fiber Components

Domain: seiboncarbon.com

Registered: 2003 (22 years)

Introduction: Seibon Carbon offers high-quality lightweight carbon fiber components and accessories, including products such as hoods, trunk lids, rear spoilers, front lips, and various interior and exterior trim pieces. The product categories include accessories, body pillars, bumpers, cooling panels, door panels, engine bay garnishes, fenders, mirrors, and more. They cater to popular makes and models includin…

7. Toray – Carbon Fiber Solutions

Domain: cf-composites.toray

Registered: 2021 (4 years)

Introduction: Toray Group supplies a comprehensive range of carbon fiber materials, including high-performance premium fiber for aircraft applications and affordable large tow, large volume fiber. Their capabilities include fabric, prepreg, and intermediary materials, supported by strategic investments in technology and processing. Carbon fiber is manufactured globally in Japan, Korea, France, Hungary, Mexico, …

Understanding carbon fiber usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plain Weave | Interlocked fibers in an alternating pattern, stable | Aerospace, automotive, marine panels | Pros: Good stability for flat surfaces. Cons: Limited drape for complex shapes. |

| Satin Weave | Fibers float over several intersections, flexible | Custom parts in aerospace and automotive | Pros: Excellent drape and flexibility. Cons: Slightly less stable than plain weave. |

| Twill Weave | Diagonal rib pattern, very pliable | High-performance sporting goods, automotive | Pros: Good balance of stability and flexibility. Cons: Can be heavier than plain weaves. |

| Basket Weave | Multiple warp ends interlocked, heavy fabric | Structural components in construction | Pros: High strength and durability. Cons: Bulkier, may not be suitable for lightweight applications. |

| Unidirectional | Fibers aligned in a single direction, high strength | Aerospace components, high-stress applications | Pros: Maximum strength in one direction. Cons: Limited strength in other directions. |

What Are the Characteristics of Plain Weave Carbon Fiber?

Plain weave carbon fiber features an interlocking pattern of fibers that enhances stability, making it ideal for applications requiring flat panels or minimal contouring. This type is commonly used in aerospace, automotive, and marine applications where structural integrity is paramount. Buyers should consider that while plain weave offers excellent stability, it may not drape well around complex shapes, limiting its versatility in certain designs.

How Does Satin Weave Carbon Fiber Stand Out?

Satin weave carbon fiber allows fibers to float over multiple intersections, providing superior flexibility and drapability. This characteristic makes it suitable for custom parts in both aerospace and automotive industries, where complex shapes are often required. While satin weave offers an advantage in forming around curves, its stability is somewhat less than that of plain weave, which buyers should keep in mind when selecting materials for high-stress applications.

Why Choose Twill Weave Carbon Fiber for Your Projects?

Twill weave carbon fiber is characterized by its diagonal rib pattern, providing a good balance between pliability and stability. This makes it particularly suitable for high-performance sporting goods and automotive components. While twill weave can be heavier than plain weaves, its flexibility allows for better adaptability in various applications. Buyers should evaluate the weight versus strength requirements of their projects to determine if twill weave is the right choice.

What Are the Benefits of Using Basket Weave Carbon Fiber?

Basket weave carbon fiber consists of multiple warp ends interlocked in a way that creates a heavier fabric, which is particularly strong and durable. This type is often used in structural components within construction and heavy-duty applications. While basket weave offers significant strength, its bulkiness can be a disadvantage in applications where weight reduction is critical. Buyers should assess the strength needs against the potential weight implications.

When Should You Consider Unidirectional Carbon Fiber?

Unidirectional carbon fiber features fibers aligned in a single direction, offering maximum strength along that axis. It is commonly used in aerospace components and other high-stress applications where directional strength is crucial. However, its limitation lies in the reduced strength in perpendicular directions, which makes it less versatile than woven fabrics. B2B buyers should consider the specific load requirements of their applications when opting for unidirectional carbon fiber.

Key Industrial Applications of carbon fiber usa

| Industry/Sector | Specific Application of carbon fiber usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Aircraft components and structures | Reduces weight, enhancing fuel efficiency and performance | Compliance with FAA regulations; high-quality materials; lead times for production |

| Automotive | Performance parts and lightweight structures | Improves vehicle performance and fuel efficiency | Material certifications; compatibility with existing manufacturing processes; cost-effectiveness |

| Marine | Hulls and components for boats | Increases durability and reduces maintenance costs | Resistance to corrosion; weight-to-strength ratio; customization options |

| Sports Equipment | High-performance sporting goods | Enhances performance and reduces weight | Availability of various fabric weaves; specific resin systems for durability; market trends |

| Industrial Manufacturing | Custom tooling and fixtures | Increases precision and reduces cycle times | Custom fabrication capabilities; sourcing of raw materials; integration with existing processes |

How is Carbon Fiber Used in Aerospace Applications?

In the aerospace sector, carbon fiber is integral for manufacturing aircraft components such as wings, fuselage, and interior structures. Its lightweight nature contributes to significant fuel savings and improved performance, addressing the industry’s need for efficiency. International buyers should prioritize suppliers that comply with FAA regulations and can provide high-quality materials, as safety and performance standards are critical. Additionally, understanding lead times for production can help in planning and logistics, especially for buyers in regions with specific import regulations.

What are the Benefits of Carbon Fiber in Automotive Manufacturing?

Carbon fiber’s application in the automotive industry primarily involves performance parts like body panels, chassis, and suspension components. The material’s ability to reduce weight while maintaining strength enhances vehicle performance and fuel efficiency, making it attractive for manufacturers looking to meet stringent environmental regulations. Buyers should consider sourcing options that provide material certifications and ensure compatibility with their existing manufacturing processes. Cost-effectiveness is also essential, especially in competitive markets like South America and Africa, where price sensitivity can influence purchasing decisions.

How is Carbon Fiber Transforming Marine Applications?

In marine applications, carbon fiber is used to construct hulls and other components of boats and yachts. The material offers exceptional durability and resistance to environmental factors, significantly reducing maintenance costs over time. For international buyers, particularly in the Middle East and Africa, sourcing carbon fiber that provides a high weight-to-strength ratio is crucial for ensuring performance in demanding conditions. Customization options can also enhance the appeal of specific designs, allowing manufacturers to cater to niche markets.

Why is Carbon Fiber Essential in Sports Equipment?

Carbon fiber is widely utilized in high-performance sporting goods, including bicycles, tennis rackets, and golf clubs. Its lightweight properties improve athlete performance, while the material’s stiffness contributes to better energy transfer during use. Buyers should focus on suppliers that offer a variety of fabric weaves and resin systems tailored for durability and performance. Keeping abreast of market trends is also beneficial, as demand for advanced materials in sports equipment continues to grow, especially in competitive markets in Europe and South America.

How Can Carbon Fiber Enhance Industrial Manufacturing Processes?

In industrial manufacturing, carbon fiber is often used for creating custom tooling, fixtures, and components that require high precision and reduced cycle times. The material’s strength and lightweight nature lead to improved efficiency in production processes. Buyers should consider suppliers that offer custom fabrication capabilities and ensure a reliable sourcing of raw materials. Integration with existing manufacturing processes is also a key consideration, particularly for companies looking to innovate and improve their operations in various global markets.

3 Common User Pain Points for ‘carbon fiber usa’ & Their Solutions

Scenario 1: Navigating Complex Sourcing Challenges in Carbon Fiber

The Problem: For many B2B buyers, especially in regions like Africa and South America, sourcing high-quality carbon fiber materials can be a daunting task. The challenge often lies in identifying reliable suppliers who not only meet stringent quality standards but also offer the right specifications for unique applications. Buyers may encounter issues such as limited local availability, fluctuating prices, and lack of transparency regarding product performance and certifications. This uncertainty can lead to costly delays in production, especially when the need for quick turnaround times is critical.

The Solution: To effectively navigate these sourcing challenges, B2B buyers should prioritize developing strong relationships with established carbon fiber manufacturers in the USA. Conducting thorough research to identify suppliers that specialize in specific applications—such as aerospace or automotive—can provide insights into their product offerings. Buyers should engage directly with suppliers to discuss their specific needs and request samples or test data to evaluate material performance. Establishing clear communication about lead times and pricing structures upfront will also help mitigate risks associated with procurement. Finally, leveraging online platforms and industry networks can facilitate connections with reputable suppliers, ensuring a smoother sourcing experience.

Scenario 2: Understanding Material Specifications and Performance

The Problem: Another common pain point for B2B buyers is the complexity of understanding the various material specifications and performance characteristics of carbon fiber products. With numerous weave types, such as plain, satin, and twill, each offering different benefits, buyers may struggle to determine which type of carbon fiber is best suited for their specific applications. This confusion can lead to suboptimal purchasing decisions, resulting in materials that do not meet performance requirements or are unsuitable for intended uses.

The Solution: To overcome this knowledge gap, buyers should invest time in education and consultation with technical experts in the field. Most reputable carbon fiber manufacturers provide detailed technical resources, including data sheets and application guides, that outline the properties of different weave types and their ideal applications. Buyers should take advantage of these resources and consider attending industry webinars or workshops to gain a deeper understanding of composite materials. Additionally, consulting with engineers or product designers within their organization can help clarify the specific performance criteria required for their projects. By taking a proactive approach to education, buyers can make informed decisions that align with their project requirements.

Scenario 3: Managing Production Lead Times and Inventory Challenges

The Problem: Production lead times for carbon fiber products can be a significant concern, particularly for B2B buyers working on tight schedules. Factors such as raw material shortages or production capacity constraints can result in extended lead times, causing disruptions in project timelines. This issue is especially prevalent in industries like aerospace or motorsports, where timing is critical, and delays can have cascading effects on overall project delivery.

The Solution: To mitigate risks associated with lead times, buyers should adopt a strategic approach to inventory management and order planning. Establishing a reliable forecasting system based on historical data and projected project timelines can help buyers anticipate their material needs more accurately. Additionally, maintaining open lines of communication with suppliers about potential supply chain disruptions and lead time expectations is crucial. Buyers might also consider developing a buffer stock of essential materials to cushion against unforeseen delays. Furthermore, engaging in long-term contracts with suppliers can secure better pricing and guaranteed availability, thereby reducing the uncertainty associated with lead times. By strategically managing their inventory and supplier relationships, buyers can enhance their operational efficiency and minimize disruptions in production.

Strategic Material Selection Guide for carbon fiber usa

What Are the Key Properties of Different Carbon Fiber Materials?

When selecting carbon fiber materials, understanding their properties is crucial for ensuring optimal performance in specific applications. Here, we analyze several common carbon fiber materials used in the USA, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Plain Weave Carbon Fiber

Key Properties: Plain weave carbon fiber features fibers interlocked in an alternating pattern, providing good stability and uniformity. It typically has a moderate temperature rating and decent pressure resistance, making it suitable for flat panels and applications with minimal contour.

Pros & Cons: The primary advantage of plain weave carbon fiber is its stability, which makes it easy to work with. However, it is less pliable compared to other weaves, limiting its use in complex shapes. The manufacturing complexity is moderate, which can influence production costs.

Impact on Application: This material is ideal for applications requiring flat surfaces, such as automotive panels or aerospace components. Its compatibility with various resins enhances its performance in structural applications.

Considerations for International Buyers: Buyers from regions like Africa or South America should consider compliance with local standards such as ASTM or DIN. The availability of plain weave carbon fiber may vary, so understanding local supply chains is essential.

2. Satin Weave Carbon Fiber

Key Properties: Satin weave carbon fiber is known for its excellent drapability, allowing it to conform to complex shapes. It has a high strength-to-weight ratio and performs well under varying temperature and pressure conditions.

Pros & Cons: The main advantage is its flexibility in application, making it suitable for intricate designs. However, the manufacturing process can be more complex and costly compared to plain weave options, potentially increasing the overall expense.

Impact on Application: Satin weave is particularly effective in industries like aerospace and automotive, where parts require both strength and lightweight characteristics. Its compatibility with various resin systems enhances its utility in composite applications.

Considerations for International Buyers: Buyers should be aware of the specific resin systems compatible with satin weave carbon fiber to ensure optimal performance. Compliance with international standards is also crucial, especially for aerospace applications.

3. Twill Weave Carbon Fiber

Key Properties: Twill weave carbon fiber features a diagonal rib pattern, providing excellent drape and flexibility while maintaining stability. It is often rated for higher temperatures and pressures compared to plain weave.

Pros & Cons: The flexibility of twill weave allows for a broader range of applications, but it can be more expensive due to its complex manufacturing process. Durability is a significant advantage, but this comes at a higher cost.

Impact on Application: Twill weave is commonly used in high-performance applications such as motorsports and aerospace, where both weight savings and structural integrity are critical. Its compatibility with epoxy resins further enhances its performance.

Considerations for International Buyers: International buyers should consider the availability of twill weave in their local markets and ensure that they meet the necessary compliance standards for their specific applications.

4. Unidirectional Carbon Fiber

Key Properties: Unidirectional carbon fiber consists of fibers aligned in a single direction, offering exceptional strength along the fiber axis. It is lightweight and has high tensile strength, making it ideal for load-bearing applications.

Pros & Cons: The primary advantage is its high strength-to-weight ratio, making it suitable for applications requiring significant load resistance. However, its directional strength can be a limitation in applications requiring multi-directional strength.

Impact on Application: This material is often used in aerospace and automotive applications where specific load paths are critical. Its compatibility with various resin systems allows for tailored performance in composite structures.

Considerations for International Buyers: Buyers should assess the specific load requirements of their applications and ensure that unidirectional carbon fiber meets compliance standards in their regions.

Summary Table of Carbon Fiber Materials

| Material | Typical Use Case for carbon fiber usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plain Weave | Automotive panels, aerospace components | Good stability and uniformity | Less pliable, limited to flat surfaces | Medium |

| Satin Weave | Aerospace, automotive intricate designs | Excellent drapability | Higher manufacturing complexity | High |

| Twill Weave | Motorsports, aerospace high-performance parts | Flexibility and durability | More expensive due to complex manufacturing | High |

| Unidirectional | Aerospace, automotive load-bearing applications | Exceptional strength along fiber axis | Limited multi-directional strength | Medium |

This guide provides a comprehensive overview of various carbon fiber materials, focusing on their properties and implications for international B2B buyers. Understanding these factors will enable businesses to make informed decisions when sourcing carbon fiber products.

In-depth Look: Manufacturing Processes and Quality Assurance for carbon fiber usa

What Are the Key Stages in the Manufacturing Process of Carbon Fiber in the USA?

The manufacturing process for carbon fiber involves several critical stages, each designed to enhance the material’s strength, lightweight properties, and versatility. Understanding these stages is vital for international B2B buyers looking for reliable suppliers in the USA.

Material Preparation: How Are Carbon Fibers Made?

The journey of carbon fiber begins with the selection of precursor materials, often polyacrylonitrile (PAN) or pitch. The chosen precursor undergoes a series of treatments, which typically include spinning, stabilization, and carbonization.

- Spinning: The precursor is spun into fibers, creating long, thin strands.

- Stabilization: These fibers are then chemically treated and heated to stabilize their structure, preventing them from melting during subsequent processing.

- Carbonization: The stabilized fibers are subjected to high temperatures (up to 3,000°C) in an inert atmosphere, resulting in the formation of carbon fibers. This step is crucial, as it significantly enhances the tensile strength and modulus of the fibers.

Forming: What Techniques Are Used to Shape Carbon Fiber?

Once the carbon fibers are prepared, the next stage is forming them into usable shapes. This can be achieved through various techniques, including:

- Weaving: Carbon fibers are woven into fabrics using different patterns such as plain, satin, or twill. Each weave provides unique properties, such as flexibility and strength, suitable for specific applications.

- Lay-Up: In this process, layers of carbon fiber fabric are arranged and bonded together using resin systems, often epoxy. This method is widely used in aerospace and automotive industries to create lightweight, high-strength components.

- Molding: Carbon fiber can also be molded into complex shapes using techniques such as resin transfer molding (RTM) and vacuum infusion. These methods allow for precise control over the fiber orientation and resin distribution, ensuring optimal performance.

Assembly: How Are Carbon Fiber Components Joined Together?

Once individual parts are formed, they need to be assembled. This can involve various bonding techniques, including:

- Adhesive Bonding: Epoxy or other adhesives are used to bond carbon fiber parts together, providing a strong and lightweight joint.

- Mechanical Fastening: In some cases, mechanical fasteners may be employed, especially in applications where disassembly is necessary.

What Are the Finishing Processes for Carbon Fiber Products?

The finishing stage involves refining the carbon fiber components to meet specific standards and aesthetic requirements. This includes:

- Trimming and Machining: Parts are trimmed to size and may undergo machining to achieve precise dimensions.

- Surface Treatment: Various treatments may be applied to enhance the surface finish, such as sanding or coating, which can improve aesthetics and corrosion resistance.

What Quality Assurance Measures Are Implemented in Carbon Fiber Manufacturing?

Quality assurance (QA) is critical in the carbon fiber manufacturing process to ensure that products meet international standards and customer expectations.

What International Standards Govern Carbon Fiber Production?

Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for quality management systems. For specific industries, additional certifications may be necessary:

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with safety, health, and environmental protection standards.

- API Certification: Relevant for carbon fiber products used in the oil and gas industry, ensuring that materials meet stringent performance criteria.

How Are Quality Control Checkpoints Structured?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to monitor and verify product quality:

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Continuous monitoring is performed during the production stages to identify and rectify any deviations from quality standards.

- Final Quality Control (FQC): Finished products undergo rigorous testing and inspection before shipment to ensure they meet all specifications.

What Common Testing Methods Are Used to Validate Carbon Fiber Quality?

Several testing methods are employed to validate the quality of carbon fiber products:

- Tensile Testing: Measures the strength and elasticity of the fibers.

- Flexural Testing: Evaluates the material’s resistance to bending.

- Impact Testing: Assesses the durability and toughness of the final product.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, ensuring that suppliers maintain rigorous quality control practices is paramount. Here are some effective strategies:

- Supplier Audits: Conducting on-site audits can provide insight into the manufacturing processes and quality assurance systems in place.

- Quality Reports: Requesting detailed quality reports and certifications can help verify compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control measures.

What Nuances Should International Buyers Consider Regarding Quality Control?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of several nuances when dealing with quality control:

- Cultural Differences: Understanding regional practices and standards can enhance communication with suppliers and ensure alignment on quality expectations.

- Logistical Considerations: Shipping and handling can affect product quality. Buyers should inquire about how suppliers manage these logistics to mitigate risks.

Conclusion

Understanding the manufacturing processes and quality assurance measures for carbon fiber in the USA is essential for international B2B buyers. By familiarizing themselves with the stages of production, relevant standards, and verification methods, buyers can make informed decisions and establish reliable partnerships with suppliers in the USA. This knowledge not only enhances procurement strategies but also contributes to the overall success of projects utilizing carbon fiber materials.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘carbon fiber usa’

To assist international B2B buyers in procuring carbon fiber products from the USA, this practical sourcing guide offers a structured checklist. By following these steps, you can ensure that your procurement process is efficient, cost-effective, and meets your technical requirements.

Step 1: Define Your Technical Specifications

Before approaching suppliers, clearly outline your technical requirements for carbon fiber products. This includes understanding the type of carbon fiber (e.g., sheets, tubes, rods) and the specific weave patterns (plain, satin, twill) that suit your application. Precise specifications will not only streamline your search but also ensure compatibility with your project needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers in the USA. Look for companies that specialize in carbon fiber products and have a proven track record in your industry. Utilize online resources, trade shows, and industry networks to compile a list of potential suppliers. This step is essential to ensure you engage with manufacturers that can meet your quality standards and delivery timelines.

Step 3: Evaluate Supplier Certifications

Verify the certifications and industry standards that suppliers adhere to. Look for ISO certifications, compliance with ASTM standards, and any other relevant quality assurances. Certifications demonstrate a supplier’s commitment to quality and can significantly mitigate risks associated with material defects.

Step 4: Request Samples and Technical Data

Before making a bulk purchase, request samples of the carbon fiber products you intend to order. Evaluate the quality, weight, and performance characteristics of the samples. Additionally, ask for technical data sheets (TDS) that provide detailed information about the product’s specifications, including tensile strength and thermal properties, to ensure they meet your project requirements.

Step 5: Compare Pricing and Lead Times

Gather quotes from multiple suppliers and compare not just the pricing but also the lead times for delivery. Understanding the cost implications and delivery schedules will help you make an informed decision. Be cautious of prices that seem too low; they may indicate lower quality or hidden costs.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a preferred supplier, engage in negotiations regarding payment terms, shipping costs, and return policies. Clear agreements on these aspects will help prevent misunderstandings and ensure a smooth transaction. Look for flexibility in terms that can accommodate your project’s cash flow and timelines.

Step 7: Establish a Communication Plan

After finalizing your supplier, establish a communication plan to facilitate ongoing dialogue. Regular updates on production progress, shipping schedules, and any potential issues are crucial for maintaining a strong relationship. Effective communication will help you address any concerns promptly and ensure that your project remains on track.

By following these steps, you can confidently navigate the procurement process for carbon fiber products in the USA, ensuring that you select the best suppliers and materials for your business needs.

Comprehensive Cost and Pricing Analysis for carbon fiber usa Sourcing

What Are the Key Cost Components in Carbon Fiber Sourcing from the USA?

When sourcing carbon fiber products from the USA, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type of carbon fiber (e.g., plain weave, twill weave, or satin weave) significantly influences the cost. Higher quality fibers, such as 12K or 6K fabrics, generally command a premium due to their superior strength and performance characteristics.

-

Labor: Skilled labor is essential for the production of high-quality carbon fiber products. The complexity of the manufacturing processes, including weaving and fabricating, can lead to variations in labor costs.

-

Manufacturing Overhead: This includes costs related to facility operations, utilities, and equipment maintenance. Manufacturers may pass these costs onto buyers, particularly in regions with higher operational expenses.

-

Tooling: Specialized tooling may be required for custom fabrications or unique product specifications. This can represent a significant upfront investment, which is often amortized over production runs.

-

Quality Control (QC): Rigorous QC processes ensure that products meet specific standards and certifications, which can add to the overall cost. Compliance with industry standards, particularly for aerospace and automotive applications, is vital.

-

Logistics: Shipping costs can vary significantly based on the destination, shipping method, and volume of the order. For international buyers, it’s essential to factor in import duties and tariffs, which can affect the final price.

-

Margin: The profit margin for suppliers can vary based on market conditions, competition, and the unique value proposition of their products.

How Do Price Influencers Affect Carbon Fiber Sourcing Decisions?

Several factors can influence pricing when sourcing carbon fiber from the USA:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer discounts for larger orders. Understanding the MOQ can help buyers negotiate better terms, particularly for bulk purchases.

-

Specifications and Customization: Custom specifications may incur additional costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Products with recognized certifications (e.g., ISO, ASTM) may have higher prices due to the added assurance of quality and performance.

-

Supplier Factors: The reputation and experience of the supplier can impact pricing. Established manufacturers may charge more for their expertise and reliability.

-

Incoterms: The terms of shipment (e.g., FOB, CIF) significantly influence costs. It’s crucial for buyers to understand these terms to accurately assess their total costs.

What Buyer Tips Can Enhance Cost-Efficiency in Carbon Fiber Procurement?

-

Effective Negotiation: Engage in open discussions with suppliers about pricing structures, volume discounts, and potential cost-saving alternatives. Establishing a good relationship can also lead to more favorable terms.

-

Understanding Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational costs, and potential savings over the product’s life cycle. This broader perspective can inform more strategic purchasing decisions.

-

Pricing Nuances for International Buyers: For B2B buyers in regions like Africa, South America, the Middle East, and Europe, it’s vital to account for currency fluctuations and geopolitical factors that may affect pricing and availability.

-

Research and Comparison: Conduct thorough research on various suppliers and products. Comparing quotes and terms can help identify the best value for your specific needs.

-

Stay Informed on Market Trends: The carbon fiber market is influenced by global supply chain dynamics. Regularly monitoring industry news can help buyers anticipate price changes and make informed purchasing decisions.

Disclaimer for Indicative Prices

Prices for carbon fiber products can vary widely based on specifications, order size, and supplier terms. Therefore, it is advisable for buyers to obtain detailed quotes from multiple suppliers to understand the current market pricing accurately.

Alternatives Analysis: Comparing carbon fiber usa With Other Solutions

When considering the materials available for high-performance applications, it is essential to evaluate the alternatives to carbon fiber. Understanding the strengths and weaknesses of these alternatives can help B2B buyers make informed decisions based on their specific requirements.

| Comparison Aspect | Carbon Fiber USA | Alternative 1: Fiberglass | Alternative 2: Aluminum |

|---|---|---|---|

| Performance | High strength-to-weight ratio; excellent stiffness and durability | Moderate strength; heavier than carbon fiber, but good flexibility | Good strength and stiffness; heavier than carbon fiber but highly durable |

| Cost | Higher initial investment | Lower cost, widely available | Moderate cost, depends on alloy quality |

| Ease of Implementation | Requires specialized handling and fabrication techniques | Easier to work with; can be molded and shaped easily | Readily available; standard machining processes applicable |

| Maintenance | Low maintenance; resistant to corrosion | Moderate maintenance; can absorb moisture | Requires regular maintenance to prevent corrosion |

| Best Use Case | Aerospace, automotive, high-end sports equipment | Marine applications, automotive parts | Structural components, transportation, and aerospace |

What Are the Advantages and Disadvantages of Fiberglass Compared to Carbon Fiber USA?

Fiberglass is a well-established alternative to carbon fiber that offers several advantages, particularly in terms of cost. It is generally less expensive and easier to work with, making it a popular choice for a wide range of applications, including marine and automotive sectors. However, fiberglass does not match the strength-to-weight ratio of carbon fiber, which can limit its use in high-performance applications. Additionally, fiberglass can absorb moisture, leading to potential structural degradation over time.

How Does Aluminum Compare to Carbon Fiber USA in Performance and Cost?

Aluminum is another common alternative that provides good strength and durability at a moderate cost. It is widely used in structural applications and can be easily machined to fit various designs. While aluminum offers decent performance, it is significantly heavier than carbon fiber, which can be a disadvantage in applications where weight is a critical factor. Furthermore, aluminum components may require regular maintenance to prevent corrosion, especially in harsh environments, making them less suitable for low-maintenance applications.

Conclusion: How Can B2B Buyers Determine the Right Material for Their Needs?

When selecting the right material for a specific application, B2B buyers should consider various factors such as performance requirements, budget constraints, ease of implementation, and maintenance needs. Carbon fiber USA excels in high-performance scenarios where weight and strength are paramount, while fiberglass presents a cost-effective solution for less demanding applications. Aluminum serves as a robust alternative for structural needs but may require more maintenance. By carefully evaluating these aspects, buyers can align their material choice with the operational demands and financial considerations of their projects, ensuring they achieve optimal performance and value.

Essential Technical Properties and Trade Terminology for carbon fiber usa

What Are the Key Technical Properties of Carbon Fiber in the USA?

When considering carbon fiber for industrial applications, several critical specifications define its performance and suitability for various projects. Understanding these properties can significantly impact decision-making for B2B buyers.

-

Material Grade

Material grade refers to the quality and type of carbon fiber used, which can range from standard to high-modulus fibers. Higher-grade fibers exhibit superior tensile strength and stiffness, making them ideal for aerospace and automotive applications. For buyers, selecting the appropriate material grade ensures the end product meets performance requirements while optimizing costs. -

Tensile Strength

This property measures the maximum amount of tensile (pulling) stress that a material can withstand before failure. Carbon fiber typically boasts a tensile strength of 500 to 700 MPa, which is significantly higher than many metals. For B2B buyers, high tensile strength is crucial in applications where lightweight components must endure substantial forces, such as in aircraft and motorsport. -

Weight-to-Strength Ratio

The weight-to-strength ratio is a defining characteristic of carbon fiber, often cited as one of its most significant advantages. This ratio highlights how much strength a material provides per unit of weight, making carbon fiber a preferred choice in industries where reducing weight while maintaining strength is critical. This property is particularly relevant in the automotive sector, where fuel efficiency can be enhanced through lightweight materials. -

Thermal Conductivity

Carbon fiber exhibits varying levels of thermal conductivity depending on its composition and weave. This property is essential for applications that require heat dissipation, such as in electronic housings or automotive components. Understanding thermal conductivity helps B2B buyers select the right type of carbon fiber for specific thermal management needs. -

Moisture Absorption

Carbon fiber’s resistance to moisture absorption is a vital property for applications in humid environments, like marine and outdoor industries. Low moisture absorption ensures dimensional stability and prevents degradation of the material over time, which is critical for long-term performance. Buyers should consider this property when selecting carbon fiber for environments where exposure to moisture is a concern.

What Are Common Trade Terms Used in the Carbon Fiber Industry?

Familiarity with industry jargon can enhance communication and streamline the procurement process for carbon fiber products.

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the carbon fiber industry, OEMs often require specific materials to meet their design and performance criteria. Understanding OEM relationships is vital for B2B buyers looking to source components for manufacturing. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. In the carbon fiber sector, MOQs can vary significantly based on the type of material and supplier. For international buyers, knowing the MOQ is essential for budgeting and inventory management, as it impacts the overall cost of acquisition. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. In the context of carbon fiber, issuing an RFQ allows buyers to compare costs and terms from different suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs. For B2B buyers in regions such as Africa or South America, understanding Incoterms is crucial for navigating cross-border purchases effectively. -

Composite Material

This term refers to a material made from two or more constituent materials with significantly different physical or chemical properties. Carbon fiber is often used in composites with resins to enhance strength and flexibility. Buyers should recognize the benefits of composite materials in achieving desired performance characteristics in their applications. -

Layup

Layup is the process of stacking layers of carbon fiber fabric and resin to create a composite structure. Understanding the layup process helps buyers assess the complexity and potential costs associated with manufacturing carbon fiber components, ensuring they can effectively plan their projects.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing carbon fiber products, ensuring they meet both performance expectations and business requirements.

Navigating Market Dynamics and Sourcing Trends in the carbon fiber usa Sector

What Are the Current Market Dynamics and Key Trends in the Carbon Fiber USA Sector?

The carbon fiber market in the USA is undergoing significant transformation driven by global demand for lightweight, high-strength materials across various industries, including aerospace, automotive, and marine. This demand is largely fueled by the growing emphasis on fuel efficiency and performance enhancement, which necessitates the adoption of advanced materials. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is essential. Notably, the shift towards automation and digitalization in manufacturing processes is creating opportunities for more efficient sourcing and production methods, such as 3D printing and automated layup techniques.

Emerging trends indicate a rising preference for specialized carbon fiber products, such as pre-impregnated (pre-preg) fabrics and custom-engineered composites tailored to specific applications. This trend is particularly relevant for B2B buyers seeking to differentiate their offerings in competitive markets. Additionally, the industry is witnessing a gradual shift towards local sourcing as companies aim to mitigate supply chain disruptions caused by global events. Buyers are encouraged to assess suppliers based on their ability to provide rapid response times, inventory availability, and technical support, which are critical for maintaining production schedules.

How Is Sustainability and Ethical Sourcing Addressed in the Carbon Fiber USA Sector?

The carbon fiber industry is increasingly recognizing the importance of sustainability and ethical sourcing. The environmental impact of carbon fiber production, which involves energy-intensive processes, has prompted manufacturers to explore greener alternatives. This includes the development of bio-based resins and recycling initiatives aimed at minimizing waste and reducing carbon footprints.

For B2B buyers, the significance of ethical supply chains cannot be overstated. Suppliers that prioritize sustainable practices are more likely to gain a competitive edge and build trust with environmentally-conscious clients. Certifications such as ISO 14001 for environmental management and the use of recycled carbon fiber materials are becoming critical factors in supplier selection. Buyers should actively seek out suppliers who can demonstrate their commitment to sustainability through transparency in their production processes and sourcing practices.

What Is the Brief Evolution and History of Carbon Fiber in the USA?

The evolution of carbon fiber in the USA can be traced back to the 1960s when it was initially developed for aerospace applications. The material’s unique properties—high strength-to-weight ratio and resistance to thermal expansion—made it ideal for use in high-performance environments. Over the decades, advancements in manufacturing techniques and an increase in applications across various industries, including automotive and sporting goods, have propelled carbon fiber into mainstream use.

Today, the USA stands as a leader in carbon fiber innovation, with numerous manufacturers investing in research and development to enhance product performance and sustainability. This evolution reflects not only technological advancements but also a growing awareness of the material’s potential to meet the demands of modern engineering and design challenges. As the industry continues to grow, international B2B buyers can leverage this rich history to inform their sourcing strategies and partnerships.

Frequently Asked Questions (FAQs) for B2B Buyers of carbon fiber usa

-

How do I solve challenges in sourcing carbon fiber from the USA?

To address sourcing challenges, start by identifying reputable suppliers with proven track records in carbon fiber manufacturing. Conduct thorough research on potential partners, focusing on their certifications, product range, and customer reviews. Engage in direct communication to discuss your specific needs and request samples to evaluate quality. Additionally, consider utilizing trade platforms and industry networks to gain insights into reliable suppliers and market trends. -

What is the best type of carbon fiber for aerospace applications?

For aerospace applications, unidirectional carbon fiber is often the best choice due to its high strength-to-weight ratio and stiffness. This type of carbon fiber is engineered to provide superior performance where load-bearing and structural integrity are critical. Additionally, twill and satin weaves are also popular for their excellent drape and flexibility, making them suitable for complex shapes in aerospace components. -

What customization options are available when ordering carbon fiber products?

Most manufacturers offer a variety of customization options for carbon fiber products, including different weaves (plain, satin, twill), thicknesses, and dimensions. You can also request specific finishes or treatments to enhance the material’s performance in your application. Discuss your project requirements with the supplier to explore available customization options, which can include tailored shapes and sizes to fit unique specifications. -

What are the minimum order quantities (MOQs) for carbon fiber products?

Minimum order quantities can vary significantly among suppliers, often depending on the type of carbon fiber and the manufacturing process involved. Generally, MOQs can range from a few meters of fabric to larger quantities for custom fabrication. It’s essential to clarify MOQs with potential suppliers early in the negotiation process to ensure they align with your project needs and budget constraints. -

What payment terms should I expect when sourcing carbon fiber from the USA?

Payment terms for international orders typically include options like wire transfers, letters of credit, or payment upon delivery. Many suppliers may require a deposit upfront, especially for custom orders. It’s advisable to discuss and negotiate payment terms during the initial discussions to ensure clarity and alignment with your cash flow requirements. Understanding currency exchange rates and potential additional fees is also crucial for international transactions. -

How can I ensure quality assurance (QA) for my carbon fiber orders?

To guarantee quality, request detailed information on the supplier’s QA processes, including certifications (ISO, ASTM) and testing protocols. Ask for samples to evaluate material quality firsthand and inquire about their return policy for defective products. Establishing a clear communication channel with the supplier for ongoing updates and quality checks during production can also help mitigate risks associated with quality assurance. -

What logistics considerations should I keep in mind when importing carbon fiber?

When importing carbon fiber, consider shipping methods, customs regulations, and potential tariffs that may apply to your order. Choose a reliable logistics partner experienced in handling composite materials to ensure timely and safe delivery. Additionally, factor in lead times for production and shipping, and communicate with your supplier about any specific delivery requirements to avoid delays. -

How do I assess the reliability of a carbon fiber supplier?

To evaluate a supplier’s reliability, start by reviewing their industry experience and customer testimonials. Request references from previous clients and check for any certifications that demonstrate compliance with industry standards. Conduct site visits, if possible, to inspect their manufacturing facilities and processes. Engaging in open dialogue about their production capabilities and lead times can also provide valuable insights into their reliability as a supplier.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for carbon fiber usa

As the global demand for carbon fiber continues to rise, strategic sourcing has become essential for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Key takeaways from this guide underscore the versatility of carbon fiber, which is not only lightweight and strong but also adaptable across various industries, from aerospace to automotive and beyond. Buyers should prioritize suppliers who offer diverse fabric weaves and custom fabrication capabilities, ensuring that they meet specific project requirements effectively.

The importance of establishing robust relationships with U.S. manufacturers cannot be overstated. Reliable suppliers can navigate the complexities of lead times and material availability, especially in the context of fluctuating global supply chains. Leveraging these relationships can enhance your competitive edge in your respective markets.

Looking ahead, the carbon fiber landscape is poised for innovation and growth. International buyers are encouraged to engage with U.S. manufacturers to explore cutting-edge applications and sustainable practices. By prioritizing strategic sourcing now, companies can position themselves at the forefront of this evolving industry and drive substantial value for their operations. Reach out today to start transforming your projects with high-quality carbon fiber solutions.