Top 7 Furniture Mfg In Usa List and Guide: How To Solve Scenario …

Introduction: Navigating the Global Market for furniture mfg in usa

In the ever-evolving landscape of global commerce, sourcing high-quality furniture manufacturing in the USA presents unique challenges and opportunities for international B2B buyers. As businesses from Africa, South America, the Middle East, and Europe seek to furnish their spaces with durable and stylish products, understanding the nuances of the American furniture market becomes essential. This guide aims to navigate the complexities of furniture manufacturing in the USA by exploring various types of products, applications, and the critical process of supplier vetting.

From residential to commercial furniture solutions, the American market offers a diverse range of options tailored to meet different needs and aesthetic preferences. Buyers will benefit from insights on cost structures, production timelines, and sustainability practices that American manufacturers employ, which can significantly impact purchasing decisions.

This comprehensive resource empowers B2B buyers by providing actionable information that enhances their ability to make informed choices. With the added emphasis on quality craftsmanship and sustainable sourcing, this guide positions international buyers to build partnerships with suppliers who prioritize excellence and ethical practices. By leveraging this knowledge, businesses can confidently navigate the American furniture landscape, ensuring they select the right products that align with their brand values and customer expectations.

Top 10 Furniture Mfg In Usa Manufacturers & Suppliers List

1. Belfort Furniture – Made In the USA

2. Vermont Woods Studios – American Shaker Panel Bed

Domain: vermontwoodsstudios.com

Registered: 2005 (20 years)

Introduction: [{‘name’: ‘American Shaker Panel Bed’, ‘crafting_time’: ‘8-16 weeks’, ‘wood_types’: [‘Cherry’, ‘Maple’, ‘Walnut’], ‘vendor’: ‘Maple Corner Woodworks’, ‘price’: ‘$4,074.00’}, {‘name’: ‘Exeter Extension Dining Table’, ‘crafting_time’: ‘2-12 weeks’, ‘wood_types’: [‘Cherry’, ‘Walnut’], ‘vendor’: ‘Copeland Furniture’, ‘price’: ‘$6,596.00’}, {‘name’: ‘Quilted Vermont Cherry Rocking Chair’, ‘crafting_tim…

3. Sherrill Furniture – American-Made Sofas and Sectionals

Domain: sherrillfurniture.com

Registered: 1997 (28 years)

Introduction: Sherrill Furniture is a USA manufacturer known for high-quality American-made furniture. They offer a variety of products including sofas, loveseats, chairs, sectionals, and benches. Their collections include the 9600/9700 Design Your Own series, 9800 Sherrill Your Way, and various design choices across multiple series. The furniture is crafted with traditional American hand craftsmanship combined…

4. Vanguard Furniture – Home Furnishings

Domain: vanguardfurniture.com

Registered: 2000 (25 years)

Introduction: Vanguard Furniture offers a wide range of home furnishings categorized into various styles and rooms, including Bedroom, Dining Room, Living Room, Outdoor, and Office. Key product categories include:

– **Bedroom**: Beds, Benches and Ottomans, Dressers and Chests, Mirrors, Nightstands.

– **Dining Room**: Bar Carts and Cabinets, Bar Stools and Counter Stools, Buffets and Sideboards, Dining Chairs …

5. Bernhardt – Luxury Furniture Collections

Domain: bernhardt.com

Registered: 1995 (30 years)

Introduction: Luxury furniture collections including Bernhardt Exteriors, Bernhardt Interiors, Bernhardt Living, and Bernhardt Workspace. Product categories include Bedroom (beds, headboards, bedside pieces, dressers, chests, benches, ottomans, mirrors), Dining (dining tables, chairs, cabinets, display, bar & counter stools, mirrors), Living (fabric seating, leather seating, motion seating, accent pillows, cock…

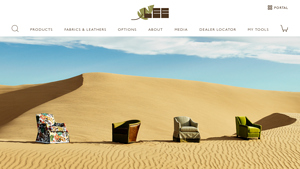

6. Lee Industries – Handcrafted Home Furnishings

Domain: leeindustries.com

Registered: 1997 (28 years)

Introduction: Lee Industries offers a wide range of handcrafted home furnishings, including: Sofas and Loveseats, Sectionals, Chairs (including Swivel and Glider Chairs), Desk Chairs, Relaxors, Sleepers (Traditional and Trundle), Ottomans and Benches, Chaises, Beds, Outdoor Dining, and Bar & Counter Stools. They also provide a variety of fabrics and leathers, including options that are stain and fade resistant,…

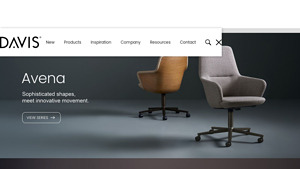

7. Davis Furniture – New Seating and Tables

Domain: davisfurniture.com

Registered: 1997 (28 years)

Introduction: New Products: Seating (Chairs, Benches, Stools, Lounge), Tables (Meeting, Cafe, Bar, Training, Occasional, Laptop), Storage (Credenza, Shelving, Wardrobe, Wall Mount), Outdoor (Chairs, Stools, Lounge, Tables), Elements (Coat Hooks + Racks, Lighting, Planters, Umbrella Stands, Side Tables, Trays, Wire Management).

Understanding furniture mfg in usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solid Wood Furniture | Crafted from high-quality hardwoods like oak, maple, and cherry; known for durability and aesthetic appeal. | Hotels, restaurants, and high-end retailers. | Pros: Long-lasting, customizable, sustainable. Cons: Higher upfront cost, longer lead times. |

| Upholstered Furniture | Features soft materials for comfort; includes sofas, chairs, and beds with various fabric options. | Offices, lounges, and residential projects. | Pros: Comfort and style, wide variety of designs. Cons: May require more maintenance, can be less durable than solid wood. |

| Modular Furniture | Designed for flexibility and adaptability; can be reconfigured for various spaces and uses. | Co-working spaces, event venues, and educational institutions. | Pros: Versatile, space-saving, easy to transport. Cons: May sacrifice sturdiness, limited customization options. |

| Eco-Friendly Furniture | Made from sustainably sourced materials, often featuring non-toxic finishes; focuses on environmental responsibility. | Eco-conscious brands, organic product retailers, and health-focused establishments. | Pros: Environmentally friendly, often unique designs. Cons: Can be more expensive, availability may vary. |

| Antique & Vintage Furniture | Restored or original pieces that reflect historical craftsmanship; unique character and stories. | Boutique hotels, specialty shops, and upscale residential projects. | Pros: Unique appeal, high resale value potential. Cons: Maintenance challenges, may require sourcing expertise. |

What Are the Characteristics of Solid Wood Furniture?

Solid wood furniture is recognized for its sturdiness and timeless aesthetic. Constructed from hardwoods such as oak, maple, and cherry, this type of furniture is ideal for B2B applications that demand durability, such as hotels and high-end retailers. Buyers should consider the higher upfront costs and longer lead times, but the investment often pays off in longevity and reduced replacement costs.

How Does Upholstered Furniture Enhance Comfort?

Upholstered furniture provides a level of comfort that solid wood cannot match, making it a popular choice for offices and lounges. With a variety of fabric options available, businesses can select styles that align with their branding. However, while upholstered pieces offer aesthetic appeal and comfort, they may require more maintenance and can be less durable than their solid wood counterparts.

Why Choose Modular Furniture for Versatile Spaces?

Modular furniture is designed for flexibility, allowing businesses to adapt their spaces quickly. This type of furniture is especially beneficial in co-working environments or event venues where configurations need to change frequently. While modular options can save space and are easy to transport, buyers should be aware that they may sacrifice some sturdiness and customization compared to traditional furniture.

What Are the Benefits of Eco-Friendly Furniture?

Eco-friendly furniture is increasingly sought after by businesses that prioritize sustainability. Made from responsibly sourced materials and often featuring non-toxic finishes, this type of furniture appeals to eco-conscious brands and health-focused establishments. While the unique designs and environmental benefits are significant advantages, buyers should note that eco-friendly options can come with a higher price tag and may have limited availability.

How Do Antique and Vintage Furniture Pieces Stand Out?

Antique and vintage furniture pieces provide unique character and historical craftsmanship that can enhance the ambiance of boutique hotels or upscale residential projects. These items often have a story, adding to their appeal. However, sourcing these pieces can be challenging, and maintenance may require additional expertise to preserve their value over time.

Key Industrial Applications of furniture mfg in usa

| Industry/Sector | Specific Application of furniture mfg in usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Custom hotel furniture and fixtures | Enhances guest experience and brand reputation | Quality craftsmanship, customization options, and lead times |

| Office & Workspace | Ergonomic office furniture | Increases employee productivity and comfort | Compliance with ergonomic standards and design flexibility |

| Education | Classroom and library furnishings | Supports learning environments and improves student engagement | Durability, safety standards, and aesthetic appeal |

| Healthcare | Patient and waiting room furniture | Improves patient comfort and facility image | Infection control materials and compliance with health regulations |

| Retail | Store fixtures and display furniture | Attracts customers and enhances product visibility | Customization for brand alignment and space optimization |

How is Furniture Manufacturing in the USA Applied in the Hospitality Sector?

In the hospitality industry, custom hotel furniture and fixtures play a crucial role in shaping guest experiences. American-made furniture is often preferred for its durability and quality craftsmanship, which not only meets aesthetic expectations but also withstands high usage. International buyers from regions like Africa or South America should seek suppliers who can provide customization options and quick turnaround times to adapt to specific design themes and cultural preferences.

What Role Does Ergonomic Furniture Play in Office and Workspace Settings?

Ergonomic office furniture manufactured in the USA is essential for enhancing employee productivity and comfort. With a growing focus on employee well-being, businesses are increasingly investing in high-quality desks, chairs, and collaborative furniture. Buyers must consider compliance with ergonomic standards and the flexibility of designs to accommodate various workspace layouts, especially when sourcing for diverse international markets.

Why is Quality Furniture Important in Educational Institutions?

Educational settings, including schools and universities, require durable classroom and library furnishings that foster engaging learning environments. American manufacturers provide products designed to meet rigorous safety standards and durability requirements, ensuring long-term use. Buyers from regions such as Europe or the Middle East should prioritize sourcing from manufacturers who understand the unique needs of educational institutions and can offer a variety of styles and configurations.

How Does Furniture in Healthcare Improve Patient Experiences?

In healthcare, the right furniture can significantly enhance patient comfort and facility image. American-made patient and waiting room furniture, designed with infection control materials, is critical for maintaining hygiene standards. International buyers, particularly from regions with stringent health regulations, should focus on suppliers that offer compliant products while also ensuring aesthetic appeal to create a welcoming environment.

What Benefits Do Retail Fixtures Provide to Businesses?

Store fixtures and display furniture are vital for attracting customers and enhancing product visibility in retail settings. American manufacturers excel in creating custom solutions that align with brand identity and optimize space. Retailers looking to source furniture should consider customization options and the ability to adapt designs to different retail formats, ensuring a strong impact on customer engagement across diverse international markets.

3 Common User Pain Points for ‘furniture mfg in usa’ & Their Solutions

Scenario 1: Navigating Quality Concerns in Sourcing Furniture

The Problem: For international B2B buyers, sourcing furniture from the USA often raises concerns about quality. Many buyers have experienced inconsistencies in the quality of materials and craftsmanship when importing furniture. This issue can lead to dissatisfaction among clients, potential returns, and financial losses. Additionally, the perception that American-made furniture is synonymous with high quality can make it especially frustrating when expectations are not met.

The Solution: To mitigate quality concerns, buyers should prioritize working with established manufacturers that offer transparent sourcing and production processes. Begin by requesting samples of materials and finishes before placing bulk orders. Engage directly with manufacturers to understand their production methods and quality control measures. Utilizing third-party quality assurance services can further ensure that the products meet specified standards. Finally, consider developing a collaborative relationship with the supplier to establish clear quality benchmarks, thus fostering trust and reliability.

Scenario 2: Overcoming Long Lead Times in Furniture Manufacturing

The Problem: Long lead times are a significant pain point for B2B buyers, especially those operating in fast-paced markets. Buyers often face delays in receiving products due to the complexities of the manufacturing process and supply chain issues. These delays can disrupt business operations, leading to missed opportunities and dissatisfied customers.

The Solution: To address long lead times, B2B buyers should implement a proactive supply chain strategy. Start by assessing the production timelines of potential suppliers and consider manufacturers that have efficient processes in place. Establishing clear communication channels and setting realistic delivery expectations can help manage timelines. It may also be beneficial to negotiate flexible contracts that allow for expedited production in urgent scenarios. Additionally, consider diversifying your supplier base to include multiple manufacturers, which can provide backup options and reduce dependency on a single source.

Scenario 3: Understanding Customization Options and Their Implications

The Problem: Customization is often touted as a significant advantage of working with American furniture manufacturers. However, many international buyers find the process of customizing furniture to be complicated and opaque. They may struggle with understanding the implications of their design choices, including cost, lead time, and feasibility, leading to frustration and potential financial setbacks.

The Solution: To effectively navigate customization, buyers should engage in thorough consultations with manufacturers before finalizing designs. Prepare a clear brief detailing specific requirements, desired aesthetics, and functionality. Request detailed information about the customization process, including timelines and cost implications, to avoid surprises. Manufacturers that provide visual aids such as CAD drawings or prototypes can help buyers visualize the final product. Additionally, consider leveraging the expertise of design consultants who can bridge the gap between buyers and manufacturers, ensuring that the customization aligns with both the buyer’s vision and manufacturing capabilities.

Strategic Material Selection Guide for furniture mfg in usa

What Are the Key Materials Used in Furniture Manufacturing in the USA?

When it comes to furniture manufacturing in the USA, the choice of materials significantly influences product quality, durability, and marketability. Below, we analyze four common materials: solid wood, engineered wood, metal, and upholstery fabrics. Each material has unique properties, advantages, and considerations that international B2B buyers should be aware of.

How Does Solid Wood Perform in Furniture Manufacturing?

Key Properties: Solid wood is known for its strength and durability. It typically has a high resistance to wear and tear, making it ideal for high-use furniture like tables and chairs. However, it can be sensitive to temperature and humidity changes, which may cause warping or cracking.

Pros & Cons: The primary advantages of solid wood include its aesthetic appeal, natural variations, and longevity. It can be refinished multiple times, extending its lifespan. However, solid wood is generally more expensive than engineered alternatives and may require more complex manufacturing processes, including careful drying and treatment to prevent defects.

Impact on Application: Solid wood is compatible with a wide range of finishes and stains, allowing for customization. However, its weight can be a consideration for shipping and handling.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with international standards for wood sourcing and sustainability, such as the Forest Stewardship Council (FSC) certification. The cost of solid wood can vary significantly based on local availability and import tariffs.

What Role Does Engineered Wood Play in Furniture Manufacturing?

Key Properties: Engineered wood, including plywood and MDF (medium-density fiberboard), offers excellent dimensional stability and resistance to warping. It is typically manufactured from recycled wood fibers and can be treated for moisture resistance.

Pros & Cons: Engineered wood is generally more affordable and easier to work with than solid wood, making it a popular choice for mass production. However, it may not have the same aesthetic appeal or durability as solid wood, and it can be more susceptible to damage from water.

Impact on Application: Engineered wood is suitable for a variety of furniture applications, including cabinetry and shelving. Its surface can be easily veneered or laminated, providing a high-end look at a lower cost.

Considerations for International Buyers: Buyers should consider the standards for formaldehyde emissions, which can vary by region. Compliance with regulations like CARB (California Air Resources Board) is essential for markets in Europe and North America.

How Is Metal Utilized in Furniture Manufacturing?

Key Properties: Metals such as steel and aluminum are known for their strength and corrosion resistance. They can withstand high loads and are often used in frameworks and supports.

Pros & Cons: The main advantages of metal include its durability and modern aesthetic. It is often less expensive than solid wood and can be manufactured quickly. However, metal can be prone to scratching and may require additional coatings to prevent rust.

Impact on Application: Metal is widely used in contemporary furniture designs, particularly for office and outdoor furniture. Its compatibility with various finishes allows for creative design options.

Considerations for International Buyers: Buyers should check for compliance with international standards, such as ASTM for material properties. Shipping costs can be higher due to weight, and considerations for local sourcing should be evaluated.

What About Upholstery Fabrics in Furniture Manufacturing?

Key Properties: Upholstery fabrics vary widely in terms of durability, texture, and maintenance. Common materials include leather, cotton, polyester, and blends, each with distinct properties regarding wear resistance and cleaning.

Pros & Cons: Upholstery fabrics can significantly enhance comfort and aesthetic appeal. Leather, for example, is durable and easy to clean but can be expensive. Synthetic fabrics may offer better stain resistance but may not have the same luxurious feel.

Impact on Application: The choice of upholstery affects not only the comfort but also the overall design and marketability of furniture. Fabrics can be treated for additional durability, making them suitable for high-traffic areas.

Considerations for International Buyers: Buyers should be aware of local preferences regarding fabric types and cleaning requirements. Compliance with flammability standards (e.g., CAL 117 in the USA) is crucial for safety regulations.

Summary Table of Material Selection for Furniture Manufacturing

| Material | Typical Use Case for furniture mfg in usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Solid Wood | Tables, chairs, cabinets | Aesthetic appeal and longevity | Higher cost and manufacturing complexity | High |

| Engineered Wood | Cabinets, shelving, desks | Cost-effective and versatile | Less durable than solid wood | Medium |

| Metal | Office furniture, outdoor furniture | Strength and modern design | Prone to scratching and rust | Medium |

| Upholstery Fabrics | Sofas, chairs, cushions | Comfort and aesthetic variety | Maintenance and cleaning challenges | Medium to High |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions in sourcing furniture materials that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for furniture mfg in usa

What Are the Main Stages of Furniture Manufacturing in the USA?

The manufacturing of furniture in the USA involves several key stages that ensure the production of high-quality products. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting and preparing raw materials, primarily solid woods such as oak, maple, walnut, and cherry. The wood is typically sourced from sustainable forests and undergoes drying processes to reduce moisture content, preventing warping and cracking. Advanced technology, such as computerized cutting machines, is often employed to maximize yield and minimize waste.

-

Forming: In the forming stage, the prepared materials are shaped into components of the furniture. This may involve techniques such as milling, where wood is cut into specific dimensions, and bending or laminating for curves and intricate designs. CNC (Computer Numerical Control) machines are frequently used for precision cutting and shaping, allowing for complex designs that maintain consistency across production runs.

-

Assembly: The assembly process involves joining the formed components to create the final furniture piece. This may include methods such as doweling, mortise and tenon joints, or the use of screws and adhesives. Skilled artisans often oversee this stage to ensure structural integrity and aesthetic quality. Attention to detail is critical, as assembly impacts both the durability and visual appeal of the final product.

-

Finishing: The final stage of the manufacturing process is finishing, which enhances the furniture’s appearance and protects it from wear and tear. Techniques include staining, varnishing, and applying protective coatings. Manufacturers often emphasize eco-friendly finishes to appeal to environmentally conscious buyers. Quality control during this stage ensures that the finish is uniform and free from defects.

How Is Quality Assurance Managed in Furniture Manufacturing?

Quality assurance (QA) in furniture manufacturing is crucial for maintaining high standards and meeting customer expectations. Manufacturers adhere to both international standards, such as ISO 9001, and industry-specific regulations to ensure product quality.

-

International Standards: Compliance with ISO 9001 ensures that manufacturers maintain a quality management system that emphasizes continuous improvement and customer satisfaction. This standard covers all aspects of the manufacturing process, from design to production, ensuring that companies consistently meet customer and regulatory requirements.

-

Industry-Specific Certifications: Various certifications, such as CE marking for products sold in Europe or API for specific materials and processes, are essential for international trade. These certifications provide assurance that the products meet specific safety, health, and environmental standards.

What Are the Key Quality Control Checkpoints in Furniture Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that potential issues are identified and addressed promptly.

-

Incoming Quality Control (IQC): At this initial checkpoint, raw materials are inspected for quality and conformity to specifications before they enter the production line. This step is critical in preventing defective materials from affecting the final product.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC checks are performed to monitor critical processes. This may include measuring dimensions, evaluating joint strength, and inspecting finishes. Regular audits and checks help maintain consistency and quality.

-

Final Quality Control (FQC): Once the furniture is fully assembled and finished, a final inspection occurs. This includes checking for defects in workmanship, ensuring the finish meets standards, and verifying that the furniture meets design specifications.

What Testing Methods Are Commonly Used in Furniture Quality Control?

Several testing methods are employed to verify the durability and safety of furniture products:

-

Mechanical Testing: This involves subjecting furniture to stress tests to evaluate its strength and stability. Common tests include load testing, where weight is applied to assess structural integrity, and durability tests, where the furniture is subjected to repeated use scenarios.

-

Chemical Testing: Furniture finishes and materials may undergo chemical testing to ensure they are free from harmful substances and comply with health and safety regulations. This is especially important for products intended for children or those used in healthcare settings.

-

Environmental Testing: Given the increasing focus on sustainability, environmental testing evaluates the ecological impact of materials and finishes. This includes assessments for VOC (Volatile Organic Compounds) emissions, which can affect indoor air quality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to ensure product reliability.

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide invaluable insights into their manufacturing processes and QC practices. Buyers should look for evidence of adherence to international standards and industry-specific certifications.

-

Quality Control Reports: Requesting detailed QC reports from suppliers can help buyers understand how quality is managed throughout production. These reports should outline procedures, inspection results, and any corrective actions taken for defects.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These inspections can be conducted at various stages of production and are particularly useful for ensuring compliance with international standards.

What Are the Quality Control Nuances for International Buyers?

International buyers face unique challenges when sourcing furniture from the USA. Understanding these nuances is crucial for successful procurement:

-

Customs and Import Regulations: Familiarity with customs regulations in the buyer’s home country is vital. This includes understanding any specific requirements for importing furniture, such as compliance with safety standards.

-

Cultural Expectations: Different regions may have varying expectations for furniture design, functionality, and aesthetics. Engaging in thorough communication with suppliers about these preferences can help ensure that products meet local market demands.

-

Logistics and Transportation: Quality control does not end at the factory. Ensuring that furniture is transported safely is essential to prevent damage during shipping. Buyers should work with suppliers who have robust logistics systems in place.

In conclusion, the manufacturing processes and quality assurance practices in the USA furniture industry are designed to produce high-quality, durable products that meet international standards. By understanding these processes and implementing thorough verification methods, international B2B buyers can make informed decisions and foster successful partnerships with American manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘furniture mfg in usa’

This guide is designed to assist international B2B buyers in effectively sourcing furniture manufactured in the USA. By following these steps, you can ensure a smooth procurement process while securing high-quality products that meet your business needs.

Step 1: Define Your Technical Specifications

Start by clearly outlining the specifications for the furniture you need. This includes dimensions, materials, finishes, and any specific design elements. Having precise specifications will help you communicate effectively with potential suppliers and ensure that the products meet your requirements.

- Material Preferences: Specify whether you want solid wood, engineered wood, or upholstered options.

- Customization Needs: Determine if you require custom designs or standard products.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers in the USA. Look for companies that specialize in the type of furniture you are interested in and have a strong track record of quality and reliability.

- Online Directories and Trade Shows: Utilize platforms like ThomasNet or attend industry trade shows to discover potential partners.

- Reviews and Testimonials: Check reviews from previous buyers to gauge supplier reliability.

Step 3: Evaluate Supplier Certifications

Before proceeding with a supplier, verify their certifications and compliance with industry standards. Certifications indicate that a supplier adheres to quality control and ethical manufacturing practices.

- Sustainability Certifications: Look for certifications like FSC (Forest Stewardship Council) which ensure sustainable sourcing of materials.

- Quality Assurance: Check for ISO certifications or similar quality management systems.

Step 4: Request Samples and Catalogs

Once you have shortlisted suppliers, request samples and product catalogs. This will allow you to assess the quality and craftsmanship of the furniture before making a bulk purchase.

- Quality Assessment: Evaluate the finishes, construction quality, and materials used.

- Product Range: Ensure the supplier offers a variety of options that align with your specifications.

Step 5: Negotiate Terms and Pricing

Engage in negotiations regarding pricing, payment terms, and delivery schedules. This is crucial to ensure that you are getting the best value for your investment.

- Volume Discounts: Inquire about pricing structures for larger orders.

- Payment Flexibility: Discuss payment terms that suit your financial planning.

Step 6: Confirm Delivery and Logistics

Plan the logistics of your order, including delivery timelines and shipping methods. Understanding the logistics will help you manage your inventory and ensure timely availability of products.

- Shipping Options: Discuss whether the supplier offers direct shipping or if you need to arrange for freight forwarding.

- Lead Times: Confirm production lead times to align with your project schedules.

Step 7: Establish a Long-term Relationship

Building a long-term relationship with a supplier can lead to better pricing, priority service, and collaboration on future projects. Maintain open communication and provide feedback on their products and services.

- Regular Check-ins: Schedule periodic reviews to discuss performance and potential improvements.

- Loyalty Incentives: Ask about programs for returning customers that can benefit your business.

By following these steps, you can confidently navigate the procurement process for furniture manufactured in the USA, ensuring quality products that enhance your offerings in your respective markets.

Comprehensive Cost and Pricing Analysis for furniture mfg in usa Sourcing

What Are the Key Cost Components in Furniture Manufacturing in the USA?

Understanding the cost structure of furniture manufacturing in the USA is crucial for international B2B buyers. The primary components influencing costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the cost. Solid hardwoods like cherry, walnut, and maple are typically more expensive but offer durability and aesthetic appeal. Sustainable sourcing practices can also affect material costs, as responsibly harvested wood may carry a premium.

-

Labor: Labor costs in the USA are generally higher than in many other countries due to stringent wage laws and benefits. Skilled labor is essential for high-quality craftsmanship, particularly in custom or handcrafted furniture. This factor can add a significant markup to the final price.

-

Manufacturing Overhead: Overhead includes costs associated with utilities, rent, and equipment maintenance. In the USA, these costs can be higher than in developing countries, contributing to the overall expense of producing furniture.

-

Tooling: Investment in specialized tools and machinery for furniture production can be substantial. This expense is often amortized over the volume of products manufactured, influencing unit pricing.

-

Quality Control (QC): Ensuring high quality often requires rigorous testing and inspection processes, which can add to costs. However, strong QC practices can reduce returns and increase customer satisfaction, ultimately benefitting the bottom line.

-

Logistics: Shipping costs for both raw materials and finished products can vary widely based on distance and mode of transport. For international buyers, understanding the implications of customs duties and tariffs is also vital.

-

Margin: Manufacturers typically apply a profit margin that reflects their operational costs and market conditions. This margin can vary based on competition, brand reputation, and perceived value.

How Do Price Influencers Affect Furniture Manufacturing Costs?

Several factors can influence pricing in the furniture manufacturing sector:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly impact pricing. Higher order volumes often lead to lower per-unit costs due to economies of scale.

-

Specifications and Customization: Custom designs or unique specifications can lead to increased costs. Customization often requires additional labor, materials, and longer lead times.

-

Materials and Quality Certifications: The use of premium materials and adherence to quality certifications (like FSC for sustainable forestry) can increase costs but may also justify higher pricing due to enhanced product value.

-

Supplier Factors: The reliability and reputation of suppliers can affect pricing. Established suppliers with a history of quality may charge more, but their products often come with guarantees and consistent availability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers, as they define the responsibilities of buyers and sellers in shipping and logistics. This knowledge can help avoid unexpected costs.

What Buyer Tips Can Help Maximize Cost Efficiency?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiate Wisely: Leverage volume purchases to negotiate better pricing. Suppliers may offer discounts for larger orders or repeat business.

-

Consider Total Cost of Ownership (TCO): Evaluate the full lifecycle cost of products, including shipping, maintenance, and potential resale value. This approach often reveals more cost-effective options.

-

Understand Pricing Nuances: Prices can vary based on market demand, seasonal trends, and economic conditions. Staying informed about industry trends can empower buyers to make timely purchasing decisions.

-

Assess the Quality vs. Cost Balance: While lower-priced options may be appealing, they often come with hidden costs related to durability and maintenance. Prioritizing quality can lead to better long-term value.

-

Stay Informed About Trade Regulations: Understanding tariffs, import duties, and trade agreements can help mitigate unforeseen expenses. Engaging with logistics experts can streamline this process.

Conclusion

In summary, navigating the cost and pricing landscape of furniture manufacturing in the USA requires a comprehensive understanding of various cost components and pricing influencers. By employing strategic purchasing tactics and staying informed, international buyers can optimize their sourcing efforts, ultimately leading to more profitable business outcomes.

Alternatives Analysis: Comparing furniture mfg in usa With Other Solutions

Introduction: Exploring Alternatives in Furniture Manufacturing

In the global landscape of furniture manufacturing, B2B buyers often encounter various solutions that cater to diverse needs. While ‘furniture manufacturing in the USA’ offers distinct advantages, such as quality craftsmanship and sustainability, it’s essential to consider alternative methods or locations that may also serve international buyers effectively. This analysis compares furniture manufacturing in the USA with two viable alternatives: overseas manufacturing and modular furniture solutions, providing insights to help businesses make informed decisions.

Comparison Table

| Comparison Aspect | Furniture Mfg In USA | Overseas Manufacturing | Modular Furniture Solutions |

|---|---|---|---|

| Performance | High-quality, durable products | Variable quality, often lower | Customizable, efficient designs |

| Cost | Higher upfront investment | Lower production costs | Mid-range, depending on customization |

| Ease of Implementation | Longer lead times, local supply chains | Quick turnaround, complex logistics | Simple assembly, straightforward supply |

| Maintenance | Long-lasting, easy repairs | Potentially short lifespan | Easy to update and replace parts |

| Best Use Case | Custom, high-end projects | Budget-sensitive bulk orders | Flexible spaces, frequent reconfigurations |

Detailed Breakdown of Alternatives

Overseas Manufacturing

Overseas manufacturing, particularly in countries like China and Vietnam, provides significant cost advantages due to lower labor and material expenses. This method can deliver large quantities of furniture quickly, making it attractive for budget-sensitive businesses. However, the quality can be inconsistent, and there may be challenges with shipping times, tariffs, and import regulations. Additionally, ethical concerns regarding labor practices and environmental impacts are increasingly important for buyers focused on sustainability.

Modular Furniture Solutions

Modular furniture offers flexibility and adaptability, making it suitable for businesses that require versatile spaces. These products are often designed for easy assembly and reconfiguration, which can be a significant advantage for companies that frequently change their office layouts. While modular solutions can be cost-effective, their quality may vary, and they may not provide the same level of durability as traditional, handcrafted furniture. This option works best for businesses that prioritize functionality over long-term aesthetics.

Conclusion: Choosing the Right Furniture Manufacturing Solution

When selecting a furniture manufacturing solution, B2B buyers must carefully evaluate their specific requirements, including budget, quality expectations, and the intended use of the furniture. ‘Furniture manufacturing in the USA’ stands out for its commitment to quality and sustainability, making it ideal for high-end, custom projects. Conversely, overseas manufacturing may appeal to those needing cost-effective, large-scale production, while modular solutions offer flexibility for dynamic workspaces. Ultimately, the right choice hinges on aligning the solution with the buyer’s operational goals and values, ensuring a successful investment in furniture that meets their needs.

Essential Technical Properties and Trade Terminology for furniture mfg in usa

What Are the Critical Technical Properties in Furniture Manufacturing?

In the realm of furniture manufacturing in the USA, understanding the technical properties of products is essential for B2B buyers. Here are some key specifications that influence quality, durability, and overall value:

-

Material Grade

Material grade refers to the quality of wood or other materials used in furniture production. Common grades include select, #1 common, and #2 common for wood. Higher-grade materials offer better aesthetics and durability, which can significantly impact customer satisfaction and product longevity. Buyers should prioritize higher grades for long-term investments. -

Tolerance

Tolerance indicates the allowable variation in dimensions during production. For example, a tolerance of ±1/16 inch is common in furniture. Tight tolerances ensure better fit and finish, which is crucial for both functionality and visual appeal. Buyers should inquire about tolerances to ensure the final product meets their specifications. -

Finish Quality

This property encompasses the type of finish applied to the furniture, such as lacquer, oil, or varnish. The quality of the finish affects both the appearance and durability of the piece. A high-quality finish can enhance resistance to scratches and moisture, making it essential for products aimed at commercial use. -

Sustainability Certifications

Certifications such as FSC (Forest Stewardship Council) and SFI (Sustainable Forestry Initiative) indicate that the materials used are sourced sustainably. These certifications not only appeal to environmentally conscious consumers but also ensure compliance with increasing regulations regarding sustainable practices. Buyers should consider these certifications as part of their procurement strategy. -

Load Capacity

This specification defines the maximum weight a piece of furniture can support safely. For example, a dining table should have a higher load capacity than a side table. Understanding load capacity is crucial for ensuring safety and functionality, particularly in commercial settings.

What Are Common Trade Terms in the Furniture Manufacturing Industry?

Familiarity with industry jargon can greatly enhance communication and efficiency in B2B transactions. Here are some essential terms to know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products that are sold under another company’s brand name. In the furniture industry, this term is vital for identifying suppliers who can produce custom designs or branded products. Establishing relationships with reliable OEMs can streamline production and enhance brand value. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell in a single order. Understanding MOQs is essential for B2B buyers to manage inventory levels and cash flow. Suppliers with lower MOQs can be advantageous for smaller businesses or startups. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specified products. This process is crucial for comparing multiple suppliers and ensuring competitive pricing. Buyers should clearly outline their requirements in RFQs to obtain accurate quotes. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) specify who bears the costs and risks at various stages of shipping. Understanding Incoterms is vital for managing logistics and ensuring compliance with international trade laws. -

Lead Time

Lead time is the period between placing an order and receiving the product. In the furniture manufacturing sector, lead times can vary significantly based on customization and production capacity. Buyers should factor in lead times when planning inventory and sales strategies.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring they procure high-quality furniture that meets their specific needs.

Navigating Market Dynamics and Sourcing Trends in the furniture mfg in usa Sector

What Are the Current Market Dynamics and Key Trends in Furniture Manufacturing in the USA?

The furniture manufacturing sector in the USA is witnessing a resurgence, driven by a combination of domestic demand for high-quality products and a shift toward local sourcing. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly interested in American-made furniture due to its reputation for quality and craftsmanship. Key trends include the adoption of digital technologies like AI and automation in production processes, which enhance efficiency and customization capabilities. The rise of e-commerce platforms has also transformed how furniture is marketed and sold, allowing international buyers to access a wider range of products directly from manufacturers.

Additionally, there is a growing emphasis on sustainability and ethical sourcing. Buyers are increasingly seeking products made from responsibly sourced materials, reflecting a broader global trend towards environmental consciousness. This shift is not only about compliance with regulations but also about meeting consumer expectations for sustainability. As a result, manufacturers that integrate sustainable practices into their operations are likely to gain a competitive edge in the global market.

How Is Sustainability Impacting the Furniture Manufacturing Sector in the USA?

Sustainability has become a crucial consideration for international B2B buyers in the furniture manufacturing sector. The environmental impact of furniture production is significant, contributing to deforestation, waste, and carbon emissions. To mitigate these effects, many manufacturers are adopting ethical sourcing practices, utilizing sustainably harvested woods, and minimizing waste through efficient production processes. Certifications such as Forest Stewardship Council (FSC) and Sustainable Forestry Initiative (SFI) are becoming essential for businesses looking to establish credibility in the marketplace.

Furthermore, the demand for eco-friendly materials is rising, with buyers seeking furniture made from recycled or reclaimed materials. This trend not only aligns with the values of environmentally conscious consumers but also helps manufacturers differentiate their offerings in a crowded marketplace. By prioritizing sustainability and ethical sourcing, companies can enhance their brand reputation and appeal to a growing segment of international buyers who prioritize green practices.

What Is the Historical Context of the Furniture Manufacturing Industry in the USA?

The history of furniture manufacturing in the USA is marked by a rich tradition of craftsmanship and innovation. Once dominated by local artisans, the industry experienced significant shifts in the late 20th century as many manufacturers moved production overseas in search of lower costs. This transition led to a decline in American jobs and the quality of imported goods often fell short of domestic standards.

In recent years, however, there has been a notable revival of interest in American-made products. Factors such as rising shipping costs, supply chain vulnerabilities highlighted by global events, and a renewed focus on quality have encouraged many companies to bring manufacturing back to the USA. This evolution not only supports local economies but also aligns with the increasing demand for sustainable and ethically produced furniture, positioning American manufacturers favorably in the global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of furniture mfg in usa

-

How do I ensure the quality of furniture sourced from manufacturers in the USA?

To ensure quality, conduct thorough research on potential suppliers. Look for manufacturers with a solid reputation and positive customer reviews. Request samples to assess craftsmanship, materials, and finishes. Additionally, inquire about their quality assurance processes, warranties, and certifications. Establishing clear communication regarding your quality expectations and inspection protocols will further safeguard your interests. -

What are the typical minimum order quantities (MOQs) for furniture manufacturers in the USA?

MOQs can vary significantly based on the manufacturer and the type of furniture. Generally, American manufacturers may require MOQs ranging from 50 to 200 units per order. However, some companies may accommodate smaller orders, especially for custom or specialized items. It’s advisable to discuss your specific needs with the supplier to negotiate terms that suit your business model. -

What payment terms should I expect when sourcing furniture from USA manufacturers?

Payment terms can vary widely among manufacturers. Common practices include a deposit of 30-50% upfront, with the balance due upon completion or delivery. Some suppliers may offer credit terms for established clients. Always clarify payment methods (e.g., wire transfer, credit card) and any potential fees associated with international transactions. Ensure that the terms are documented in your purchase agreement for transparency. -

How do I manage logistics and shipping for furniture sourced from the USA?

Managing logistics involves coordinating with freight forwarders or shipping companies experienced in handling furniture. Discuss shipping options, including sea freight or air freight, depending on your budget and urgency. Confirm the supplier’s ability to package items securely to prevent damage during transit. Consider customs regulations and duties in your country to avoid unexpected costs and delays. -

What customization options are available when ordering furniture from US manufacturers?

Many US furniture manufacturers offer extensive customization options, including sizes, colors, materials, and finishes. When discussing your order, clearly communicate your specific requirements. Some manufacturers may have design teams to assist in creating tailored solutions. Ensure that you receive samples or prototypes for approval before final production to align with your expectations. -

How can I verify the credibility of a furniture manufacturer in the USA?

To verify a manufacturer’s credibility, research their business history, customer reviews, and industry reputation. Check for memberships in relevant trade organizations, certifications (e.g., ISO), and compliance with industry standards. Request references from past clients and review case studies or portfolios of completed projects. Engaging in direct communication with the manufacturer can also provide insight into their professionalism and reliability. -

What are the environmental considerations when sourcing furniture from the USA?

Sourcing from US manufacturers often aligns with sustainable practices, such as using responsibly sourced materials and environmentally friendly manufacturing processes. Inquire about the supplier’s sustainability initiatives, such as certifications like FSC (Forest Stewardship Council) or participation in programs like 1% for the Planet. Understanding these aspects will help you make informed choices that align with your company’s values and social responsibility goals. -

What quality assurance processes should I expect from a US furniture manufacturer?

Reputable US furniture manufacturers typically implement rigorous quality assurance processes throughout production. This may include initial material inspections, in-process checks, and final product evaluations. Ask about their specific QA protocols, including any third-party inspections or certifications. Understanding their commitment to quality will give you confidence in the durability and craftsmanship of the furniture you source.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for furniture mfg in usa

In navigating the dynamic landscape of furniture manufacturing in the USA, international B2B buyers can leverage strategic sourcing to enhance their purchasing decisions. The resurgence of American-made furniture, characterized by superior craftsmanship, sustainable practices, and local economic benefits, presents a compelling case for sourcing from U.S. manufacturers. By prioritizing quality materials like solid wood and embracing ethical production processes, businesses not only improve their product offerings but also align with increasing consumer demand for sustainability and responsibility.

As buyers from regions such as Africa, South America, the Middle East, and Europe consider their supply chain strategies, the value of establishing partnerships with U.S. manufacturers becomes evident. These relationships can lead to reduced lead times, improved quality control, and a reliable supply of innovative designs tailored to diverse markets.

Looking ahead, the furniture industry in the USA is poised for growth, driven by a commitment to sustainability and excellence. International buyers are encouraged to explore the rich offerings of American manufacturers, tapping into this opportunity to strengthen their own market positions while contributing to a more sustainable global economy. Engage with U.S. suppliers today to discover the unique advantages they can bring to your business.