Top 7 Glass Bottles Made In Usa List and Guide: How To Solve Scen…

Introduction: Navigating the Global Market for glass bottles made in usa

In an increasingly competitive global marketplace, sourcing high-quality glass bottles made in the USA presents a unique set of challenges for international B2B buyers. Whether you’re looking to enhance your product’s appeal or ensure compliance with stringent safety standards, understanding the nuances of American-made glass packaging is crucial. This comprehensive guide delves into various aspects of the industry, including types of glass bottles, their applications across different sectors, supplier vetting processes, and cost considerations.

By leveraging insights from industry experts and data-driven analysis, this guide empowers international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Germany—to make informed purchasing decisions. You’ll discover how to identify reliable suppliers, evaluate product quality, and navigate logistical challenges, all while aligning with sustainable practices.

As consumer preferences shift towards eco-friendly packaging, investing in American-made glass bottles not only enhances your brand’s credibility but also supports local economies. This guide serves as your roadmap, equipping you with the knowledge and tools necessary to successfully navigate the complexities of sourcing glass bottles from the United States.

Top 10 Glass Bottles Made In Usa Manufacturers & Suppliers List

1. BottleStore – Glass Jars Collection

Domain: bottlestore.com

Registered: 1998 (27 years)

Introduction: Glass Jars available in various sizes and types including: 32oz Flint Glass Mayo Round Jar, 4oz Flint Paragon Round Glass Jar, 6oz Flint Paragon Round Glass Jar, 8oz Flint Glass Jelly Jam Round Glass Jar, and 8oz Flint Paragon Round Glass Jar. Each jar has specific neck sizes and closure options. Pricing examples include: 32oz jar at $1.39 per piece, 4oz jar at $0.53 per piece, 6oz jar at $0.62 pe…

2. TricorBraun – Glass Bottles & Jars

Domain: tricorbraun.com

Registered: 1998 (27 years)

Introduction: Made in the USA Containers & Packaging from TricorBraun include a variety of products such as:

– Glass Bottles & Jars:

– Beer Bottles & Growlers

– Boston Round Glass Bottles

– Glass Dropper Bottles

– Glass Liquor & Spirit Bottles

– Glass Packer Bottles

– Glass Sauce Bottles

– Glass Jars

– Glass Candle Jars

– Glass Canning Jars

– Glass Spice Jars

– Glass Straight …

3. Burch Bottle – Amber Glass Containers

Domain: burchbottle.com

Registered: 1999 (26 years)

Introduction: Made in the U.S.A, Amber glass containers, special items, sale

4. Lifefactory – 22oz Glass Water Bottle

Domain: lifefactory.com

Registered: 1999 (26 years)

Introduction: {“name”: “22oz Glass Water Bottle with Silicone Sleeve and Classic Cap”, “volume”: “22 oz (650 ml)”, “color”: “Golden Gate Orange”, “price”: “$17.99”, “item_number”: “LF230220HGC4”, “features”: [“Made in USA and Europe”, “BPA-free”, “Dishwasher safe (top rack recommended)”, “Wide-mouth access for adding ice or tea bags”, “Polypropylene screw cap for high flow”, “Protective silicone sleeve for non-…

5. Love Bottle – Love Our Waters

Domain: lovebottle.com

Registered: 2014 (11 years)

Introduction: Product Name: Love our Waters

Price: $25.00

Design: Blue ocean theme, designed by Dan Stiles

Manufacturing: Made in USA, USA manufactured reusable glass water bottle

Company: Certified B Corp, mission-driven company

Features:

– Raised heart on chest

– “You are love” message

– Handcrafted ceramic swing top lid

– 100% plastic & BPA free

– Completely nontoxic

– Made with about 40% recycled glass

– C…

6. Fillmore Container – Bottles and Jars

Domain: fillmorecontainer.com

Registered: 2002 (23 years)

Introduction: Bottles and Jars Wholesale and Bulk – Fast Shipping. Selection includes: Glass Jars, Economy Jars, Honey Jars, Glass Bottles, Sauce and Syrup Bottles, Hexagon Jars, Canning Jars, Glass Tumblers, Candle Jars, Apothecary Jars, Storage Jars, Ball Jars, Straight Sided Jars, Boston Round Bottles, Amber Glass Jars, Hot Sauce Bottles, French Square Bottles, Beverage Containers, Glass Growlers, Paragon Ja…

7. Bormioli Luigi – Glassmaking Excellence

Understanding glass bottles made in usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Glass Bottles | Available in various sizes, typically clear or amber | Beverage packaging, food storage | Pros: Versatile, recyclable; Cons: Heavier than plastic, fragile. |

| Specialty Glass Jars | Unique shapes and designs, often with decorative features | Gourmet foods, cosmetics, artisan products | Pros: Attractive presentation; Cons: Higher costs, limited volume. |

| Milk Bottles | Classic design, often with a wide mouth for easy pouring | Dairy products, smoothies | Pros: Durable, eco-friendly; Cons: May require specific closures. |

| Canning Jars | Designed for home canning, often with metal lids | Preserving fruits, sauces, pickles | Pros: Airtight seal, reusable; Cons: Limited to specific applications. |

| Water Bottles | Typically BPA-free, often with silicone sleeves for grip | Health and wellness, promotional items | Pros: Reusable, stylish; Cons: Higher price point than plastic. |

What are the Characteristics and Applications of Standard Glass Bottles?

Standard glass bottles are versatile and come in a range of sizes, commonly in clear or amber glass. They are widely used in the beverage and food industry for products such as juices, sauces, and oils. When considering B2B purchases, buyers should evaluate factors such as volume requirements, closure compatibility, and shipping logistics, as these bottles can be heavier and more fragile than their plastic counterparts.

How Do Specialty Glass Jars Stand Out in the Market?

Specialty glass jars are characterized by their unique shapes and decorative elements, making them ideal for gourmet foods, cosmetics, and artisan products. Their aesthetic appeal can enhance brand perception and attract consumers. B2B buyers should consider the target market’s preferences and the product’s positioning when selecting these jars, as they often come at a premium price point but provide significant branding opportunities.

What are the Key Features of Milk Bottles for B2B Buyers?

Milk bottles feature a classic design, typically equipped with a wide mouth for easy pouring. They are commonly used for dairy products and smoothies, emphasizing durability and eco-friendliness. When sourcing milk bottles, businesses should assess the compatibility of closures and the potential need for customized designs, especially if they aim to differentiate their products in a competitive market.

Why are Canning Jars Popular Among B2B Buyers?

Canning jars are specifically designed for home canning, featuring airtight seals and often coming with metal lids. They are popular in the food industry for preserving fruits, sauces, and pickles. B2B buyers should consider the jar’s size and sealing mechanism to ensure it meets their production needs, as well as the market trends toward homemade and organic products, which can drive demand for these jars.

What Makes Water Bottles an Attractive Option for B2B Purchases?

Water bottles made from glass often include BPA-free materials and are designed with silicone sleeves for better grip and protection against breakage. They are increasingly popular in health and wellness sectors, as well as for promotional items. B2B buyers should weigh the advantages of reusability and aesthetic appeal against the higher price point compared to plastic alternatives, especially in markets focused on sustainability.

Key Industrial Applications of glass bottles made in usa

| Industry/Sector | Specific Application of glass bottles made in usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Packaging for sauces, jams, and condiments | Enhances product shelf life while maintaining taste; recyclable and eco-friendly packaging | Compliance with food safety standards; durability and design for branding |

| Pharmaceuticals | Bottles for liquid medications | Ensures product integrity and safety; glass is inert and does not leach chemicals | Regulatory compliance; specific neck sizes for closures; tamper-evident features |

| Cosmetics & Personal Care | Containers for lotions, oils, and serums | Provides an upscale look; preserves product quality and extends shelf life | Customization options; compatibility with various closures; aesthetic appeal |

| Beverage Industry | Bottles for craft beers and spirits | Supports brand differentiation; glass maintains beverage flavor and quality | Sourcing local materials for sustainability; varied sizes and designs to meet market trends |

| Dairy Products | Milk and cream bottles | Retains freshness and flavor; glass is reusable, promoting sustainability | Specific sizes for different product lines; compliance with health regulations; logistical considerations for shipping |

How Are Glass Bottles Made in the USA Used in the Food & Beverage Sector?

In the food and beverage industry, glass bottles are widely used for packaging sauces, jams, and condiments. Their ability to preserve the taste and quality of products while extending shelf life makes them a preferred choice. B2B buyers from regions like Africa and South America should consider the durability and eco-friendly nature of glass, which aligns with growing consumer demand for sustainable products. Compliance with food safety standards is crucial, as is the ability to customize designs for branding purposes.

What Role Do Glass Bottles Play in Pharmaceuticals?

Glass bottles are essential in the pharmaceutical sector for packaging liquid medications. Their inert properties ensure that no harmful chemicals leach into the products, maintaining integrity and safety. International buyers, especially from Europe and the Middle East, must ensure that their sourcing complies with stringent regulatory standards. Specific neck sizes for closures and tamper-evident features are vital considerations to prevent contamination and ensure user safety.

How Are Glass Bottles Beneficial in Cosmetics & Personal Care?

In the cosmetics and personal care industry, glass bottles are used for lotions, oils, and serums, offering an upscale aesthetic that appeals to consumers. The inert nature of glass preserves product quality, preventing chemical reactions that can compromise efficacy. B2B buyers should focus on customization options to enhance brand identity and consider compatibility with various closure types. Aesthetic appeal remains a key factor in attracting consumers in competitive markets.

Why Are Glass Bottles Important for the Beverage Industry?

Craft breweries and spirit manufacturers utilize glass bottles to differentiate their products in a crowded market. Glass not only maintains the flavor and quality of beverages but also offers a premium appearance that attracts discerning customers. Buyers from regions like Brazil should prioritize sourcing local materials to enhance sustainability efforts. Additionally, offering varied sizes and designs can help brands meet evolving consumer preferences and market trends.

How Do Glass Bottles Serve the Dairy Industry?

In the dairy sector, glass bottles are primarily used for milk and cream packaging, providing a sustainable and reusable option. They help retain freshness and flavor, appealing to environmentally conscious consumers. B2B buyers must consider specific sizes that cater to different product lines, as well as compliance with health regulations to ensure safety. Logistical considerations for shipping and distribution are also essential in maintaining product integrity during transport.

3 Common User Pain Points for ‘glass bottles made in usa’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance for Glass Bottles Made in the USA

The Problem: B2B buyers often face complex regulatory requirements when importing or purchasing glass bottles made in the USA. Different countries have varying standards regarding materials, safety, and environmental impact. This can lead to confusion and potential delays in getting products to market, especially if the bottles need to comply with specific health regulations or labeling requirements in the buyer’s home country. Failing to adhere to these regulations can result in fines, product recalls, or damage to brand reputation.

The Solution: To effectively navigate regulatory compliance, B2B buyers should conduct thorough research on the regulations applicable in their target markets. Collaborating with suppliers who are well-versed in international shipping and compliance can streamline this process. Buyers should request documentation confirming that the glass bottles meet relevant safety and quality standards, such as FDA approval for food and beverage containers. Additionally, investing in a compliance consultant or using third-party auditing services can further ensure that all aspects of the supply chain adhere to the necessary regulations, minimizing risks and facilitating smoother market entry.

Scenario 2: Managing Supply Chain and Delivery Challenges

The Problem: Supply chain disruptions can severely impact the availability of glass bottles made in the USA, especially given the global nature of logistics and the increased demand for sustainable packaging solutions. B2B buyers may encounter issues such as delays in production, shipping bottlenecks, or increased freight costs, which can affect their ability to deliver products to customers on time. This uncertainty can lead to lost sales and strained relationships with clients who expect timely deliveries.

The Solution: To mitigate supply chain challenges, buyers should establish strong relationships with multiple suppliers of glass bottles to create a diversified sourcing strategy. This allows for greater flexibility and the ability to switch suppliers in case of disruptions. Additionally, implementing a robust inventory management system can help track stock levels and forecast demand more accurately, enabling proactive ordering and reducing the risk of stockouts. Leveraging local suppliers for certain bottle types can also shorten lead times and enhance reliability. Finally, regular communication with suppliers about their production schedules and potential challenges can help buyers stay informed and make necessary adjustments in advance.

Scenario 3: Overcoming Cost Concerns with American-Made Glass Bottles

The Problem: While sourcing glass bottles made in the USA offers many benefits, including quality assurance and supporting local economies, the associated costs can be higher than importing cheaper alternatives. B2B buyers, particularly in competitive markets, may struggle with budget constraints and fear that higher packaging costs will eat into their profit margins. This can lead to difficult decisions about whether to prioritize quality and sustainability or to opt for lower-cost options.

The Solution: Buyers can effectively manage costs by focusing on the total cost of ownership rather than just the initial purchase price. This includes considering the durability and reusability of glass bottles, which can lead to lower long-term costs. Additionally, negotiating bulk purchase agreements or long-term contracts with suppliers can lead to significant discounts. Exploring co-packing solutions or partnerships with other companies can also help distribute costs while benefiting from shared resources. Finally, educating end-users on the benefits of American-made products, such as sustainability and quality, can justify the premium pricing and help in maintaining competitive positioning in the market.

Strategic Material Selection Guide for glass bottles made in usa

When selecting materials for glass bottles manufactured in the USA, international B2B buyers must consider various factors that influence product performance, durability, and compliance with regional standards. The following analysis covers common glass materials used in bottle production, highlighting their properties, advantages, disadvantages, and specific considerations for global markets.

What are the Key Properties of Soda-Lime Glass in Glass Bottles?

Soda-lime glass is the most widely used material for glass bottles due to its favorable properties. It typically withstands temperatures up to 500°F (260°C) and offers good resistance to corrosion from acids and bases. This glass type is also relatively easy to mold and shape during manufacturing.

Pros: Soda-lime glass is durable, cost-effective, and widely available. Its clarity makes it suitable for various applications, including food and beverage packaging.

Cons: While it is resistant to many chemicals, soda-lime glass can be susceptible to thermal shock if not handled properly. Additionally, it may not be suitable for high-pressure applications.

Impact on Application: Soda-lime glass is ideal for beverages, sauces, and other liquids due to its inert nature, which does not leach chemicals into contents.

International Considerations: Buyers from regions like Africa and South America should ensure compliance with local food safety standards, such as those set by the FDA or equivalent organizations.

How Does Borosilicate Glass Enhance Performance in Specific Applications?

Borosilicate glass is known for its excellent thermal resistance, withstanding temperatures from -40°F to 600°F (-40°C to 315°C). This material is highly resistant to thermal shock, making it suitable for laboratory and high-temperature applications.

Pros: Its durability and resistance to chemical corrosion make borosilicate glass ideal for pharmaceuticals and laboratory use.

Cons: The manufacturing process for borosilicate glass is more complex and costly compared to soda-lime glass, which may increase the final product price.

Impact on Application: Borosilicate glass is perfect for applications requiring high thermal stability, such as laboratory glassware and high-end beverage containers.

International Considerations: Compliance with ASTM standards is crucial for buyers in Europe and the Middle East, where specific regulations govern laboratory equipment and food safety.

What Role Does Recycled Glass Play in Sustainable Bottle Production?

Recycled glass, often sourced from post-consumer products, is increasingly popular in bottle manufacturing. It retains many properties of virgin glass but has a lower carbon footprint due to reduced energy consumption during production.

Pros: Using recycled glass can significantly lower production costs and environmental impact, appealing to eco-conscious brands.

Cons: The quality of recycled glass can vary, potentially affecting the final product’s clarity and strength. Additionally, it may require more stringent quality control measures during production.

Impact on Application: Recycled glass is suitable for various applications, including food and beverage packaging, as long as it meets safety standards.

International Considerations: Buyers should be aware of local recycling regulations and standards, such as those enforced by the European Union, to ensure compliance.

Why is Specialty Glass Important for Niche Markets?

Specialty glass, including colored or UV-filtering glass, serves specific market needs, such as protecting light-sensitive products or enhancing aesthetic appeal.

Pros: Specialty glasses can provide unique branding opportunities and better product preservation.

Cons: These glasses often come at a higher cost and may require specialized manufacturing processes, affecting lead times.

Impact on Application: Ideal for cosmetics and premium beverages, specialty glass can enhance product visibility and protect contents from degradation.

International Considerations: Buyers should check for compliance with local regulations regarding packaging materials, especially in the cosmetics and food sectors.

Summary Table of Material Selection for Glass Bottles Made in the USA

| Material | Typical Use Case for glass bottles made in usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Soda-Lime Glass | Beverages, sauces, food packaging | Cost-effective and durable | Susceptible to thermal shock | Low |

| Borosilicate Glass | Laboratory, high-temperature applications | Excellent thermal resistance | Higher manufacturing complexity | High |

| Recycled Glass | Eco-friendly food and beverage packaging | Lower carbon footprint | Variable quality | Medium |

| Specialty Glass | Cosmetics, premium beverages | Unique branding opportunities | Higher cost and specialized processes | High |

This guide provides essential insights into material selection for glass bottles made in the USA, helping international B2B buyers make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for glass bottles made in usa

What Are the Key Stages in the Manufacturing Process of Glass Bottles Made in the USA?

The manufacturing of glass bottles in the USA involves several critical stages, each designed to ensure quality and consistency. Understanding these processes is essential for international B2B buyers looking to source high-quality glass bottles.

Material Preparation: What Materials Are Used in Glass Bottle Production?

The first step in manufacturing glass bottles is material preparation, which primarily involves the use of silica sand, soda ash, and limestone. These raw materials are carefully measured and mixed to form a homogeneous batch. The quality of the raw materials significantly impacts the final product, as impurities can lead to defects in the glass. Therefore, suppliers often source materials from reputable suppliers and conduct rigorous testing before use.

How Are Glass Bottles Formed?

Once the materials are prepared, they are melted in a furnace at temperatures reaching approximately 1,600 degrees Celsius (2,912 degrees Fahrenheit). This molten glass is then shaped using various forming techniques, including:

-

Blow Molding: This method involves blowing air into a molten glass parison to form the desired bottle shape. It is widely used for producing lightweight bottles.

-

Pressing: In this method, a plunger presses the molten glass into a mold. This technique is suitable for producing thicker-walled bottles and jars.

-

Extrusion: Molten glass is forced through a die to create a continuous shape, which is then cut to size. This method is less common for bottles but can be used for specific applications.

Each technique requires specialized machinery and skilled operators to ensure precision and consistency.

What Finishing Processes Are Involved?

After forming, the glass bottles undergo various finishing processes. These may include annealing, where bottles are slowly cooled in a controlled environment to relieve internal stresses, and surface treatment, which may involve polishing or applying coatings to enhance appearance and durability. The final step often includes decorating the bottles through methods such as screen printing or labeling, which are essential for branding and consumer appeal.

What Quality Assurance Measures Are Essential for Glass Bottle Production?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the final products meet both international standards and customer expectations. For B2B buyers, understanding these measures can help in evaluating suppliers.

Which International Standards Should B2B Buyers Be Aware Of?

Manufacturers of glass bottles in the USA often adhere to international quality standards such as ISO 9001, which focuses on effective quality management systems. Compliance with these standards indicates a commitment to quality and continuous improvement. Additionally, industry-specific standards may include CE marking for products sold in Europe and API standards for pharmaceutical packaging.

What Are the Key Quality Control Checkpoints in Glass Bottle Manufacturing?

Quality control (QC) checkpoints are established throughout the manufacturing process to monitor and ensure product quality. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection verifies the quality of raw materials before production begins. It ensures that only the best materials are used in the manufacturing process.

-

In-Process Quality Control (IPQC): During the production process, periodic inspections are conducted to identify any deviations from the required specifications. This can involve measuring dimensions, checking for defects, and ensuring the machinery is functioning correctly.

-

Final Quality Control (FQC): After production, finished products undergo a thorough inspection to ensure they meet all specifications and standards before they are packaged and shipped.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to assess the quality and safety of glass bottles. Common methods include:

-

Visual Inspection: Manual checks for defects, such as cracks, chips, or bubbles in the glass.

-

Dimensional Testing: Ensuring that bottles meet specific size and shape requirements using calipers and gauges.

-

Thermal Shock Testing: Evaluating the glass’s resistance to sudden temperature changes, which is crucial for products intended for hot or cold liquids.

-

Chemical Resistance Testing: Ensuring that the glass does not react adversely with the contents it will hold, particularly for food and beverage applications.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, ensuring supplier quality is vital. Here are some effective strategies:

What Auditing Practices Should Be Considered?

Conducting supplier audits is a reliable way to assess manufacturing practices and quality control measures. Buyers should request access to audit reports and certifications that demonstrate compliance with international standards.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality assurance practices. These inspections often include a comprehensive review of production processes, quality control measures, and compliance with relevant standards.

What Documentation Should Buyers Request?

B2B buyers should request detailed documentation, including:

-

Certificates of Compliance: Verification that products meet specific standards.

-

Quality Control Reports: Documentation of quality checks performed during production.

-

Test Reports: Results from testing methods used to ensure product quality.

What Are the Quality Control Nuances for International Buyers?

When sourcing glass bottles from the USA, international buyers must consider various nuances. For instance, understanding regional regulations regarding packaging materials is essential, as compliance varies by country. Additionally, cultural differences may influence expectations regarding quality and service.

By being informed about manufacturing processes and quality assurance measures, international B2B buyers can make educated decisions when selecting suppliers for glass bottles made in the USA. This knowledge not only ensures the procurement of high-quality products but also fosters strong, reliable business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘glass bottles made in usa’

Introduction

Sourcing glass bottles made in the USA requires careful consideration and strategic planning. This guide provides a step-by-step checklist designed for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe. By following these steps, you can ensure a smooth procurement process that meets your quality, compliance, and budgetary needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to clearly outline your technical specifications. This includes determining the type of glass bottles required—such as size, shape, color, and neck finish. Establishing these parameters helps streamline your search and ensures that suppliers can meet your specific needs.

- Consider the intended use: Different applications may require different glass types, such as flint glass for beverages or amber glass for light-sensitive products.

- Assess volume requirements: Estimate the quantity needed to facilitate discussions with suppliers about lead times and pricing.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of American-made glass bottles. Look for manufacturers with a strong reputation and proven track records in quality and reliability.

- Utilize industry directories: Platforms like ThomasNet and Global Sources can help locate verified manufacturers.

- Check online reviews: Look for testimonials and feedback from other B2B clients to gauge supplier reliability.

Step 3: Verify Supplier Certifications

It’s crucial to ensure that your chosen suppliers have the necessary certifications. This may include ISO certifications, FDA compliance for food-grade products, and adherence to environmental standards.

- Request documentation: Ask suppliers to provide copies of their certifications and quality assurance processes.

- Evaluate compliance history: Investigate any past compliance issues that may affect your sourcing decisions.

Step 4: Evaluate Production Capabilities

Understanding a supplier’s production capabilities is vital to ensure they can meet your demand. Assess their manufacturing processes, technology, and capacity to handle your order volume.

- Inquire about lead times: Confirm how quickly they can fulfill your orders and whether they can accommodate rush requests.

- Assess flexibility: Check if they can adapt to changes in order size or specifications as your needs evolve.

Step 5: Request Samples

Before finalizing your supplier, request samples of the glass bottles you are interested in. This step allows you to evaluate the quality and suitability of the product for your needs.

- Inspect for quality: Look for any defects, such as bubbles or uneven surfaces, that could affect the product’s performance.

- Test usability: Consider how the bottles function with your intended contents, including closures and compatibility with your existing packaging.

Step 6: Discuss Pricing and Payment Terms

Once you have shortlisted potential suppliers, initiate discussions about pricing and payment terms. Transparency in these discussions can help avoid misunderstandings later in the process.

- Compare pricing: Evaluate quotes based on your specifications and ensure they include all costs, such as shipping and handling.

- Negotiate terms: Discuss payment options, including deposits and credit terms, to find a mutually beneficial arrangement.

Step 7: Finalize Your Order and Monitor Delivery

After selecting a supplier, finalize your order by confirming quantities, specifications, and delivery timelines. Establish a communication plan to monitor the order’s progress until delivery.

- Set expectations: Clearly communicate delivery dates and any penalties for late shipments.

- Stay engaged: Maintain regular contact with the supplier to address any issues that may arise during production or shipping.

By following this practical sourcing checklist, you can effectively navigate the complexities of procuring glass bottles made in the USA, ensuring that your business receives high-quality products that meet your operational needs.

Comprehensive Cost and Pricing Analysis for glass bottles made in usa Sourcing

What Are the Key Cost Components for Sourcing Glass Bottles Made in the USA?

When sourcing glass bottles manufactured in the USA, understanding the cost structure is crucial for international buyers. The primary cost components include:

-

Materials: High-quality glass is typically sourced domestically, which can drive up costs. Options vary from standard flint glass to colored glass, impacting the price based on the material’s characteristics and availability.

-

Labor: The USA generally has higher labor costs compared to other regions. Skilled labor is required for manufacturing glass bottles, which contributes significantly to the overall cost.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. Higher standards of quality and sustainability in US manufacturing can lead to increased overhead costs.

-

Tooling: Custom molds and tooling necessary for specific bottle designs can be a substantial upfront investment. This is particularly relevant for unique or specialized bottles.

-

Quality Control (QC): Stringent quality control measures are essential in the US market, ensuring compliance with safety and environmental regulations. This can add to the production costs but also enhances product reliability.

-

Logistics: Shipping costs can vary based on the distance to the buyer’s location, the size of the order, and the chosen shipping method. International logistics may involve additional fees, customs duties, and taxes.

-

Margin: Suppliers typically apply a markup to cover their costs and desired profit. This margin can fluctuate based on the supplier’s market position and the competitiveness of their offerings.

How Do Volume and Customization Impact Pricing for Glass Bottles?

Pricing for glass bottles is significantly influenced by order volume and customization.

-

Volume/MOQ (Minimum Order Quantity): Bulk orders usually come with discounted pricing. Suppliers often have tiered pricing structures, where higher quantities lead to lower per-unit costs. This is particularly beneficial for international buyers looking to maximize their investment.

-

Specifications and Customization: Custom designs or specific bottle specifications (e.g., size, shape, neck finish) can lead to increased costs due to the need for bespoke tooling and design work. Buyers should weigh the necessity of customization against potential cost increases.

What Quality Factors and Certifications Should Buyers Consider?

Quality and certifications are paramount when sourcing glass bottles, especially for industries like food and beverage.

-

Material Quality: Ensure that the glass meets industry standards for safety and durability. Higher-quality glass may be more expensive but offers better protection for contents and enhances brand perception.

-

Certifications: Look for suppliers with certifications such as ISO, FDA compliance, and sustainability certifications. These credentials can add value and justify higher prices due to the assurance of quality.

What Are Effective Negotiation Tips for International Buyers?

Negotiating effectively can lead to significant cost savings. Here are some strategies:

-

Research and Leverage Market Prices: Familiarize yourself with current market prices and competitors to make informed offers. This knowledge can empower you during negotiations.

-

Build Relationships with Suppliers: Establishing a strong relationship with suppliers can lead to better terms, priority service, and potential discounts on future orders.

-

Discuss Incoterms: Clearly define shipping responsibilities and costs through Incoterms. This will prevent misunderstandings about who bears the cost and risk during transportation.

How Can Buyers Understand the Total Cost of Ownership?

Understanding the Total Cost of Ownership (TCO) is essential for making informed purchasing decisions. TCO includes:

- Initial Purchase Price: The upfront cost of buying the bottles.

- Logistics Costs: Shipping, customs, and handling fees.

- Storage and Handling: Costs associated with storing and managing inventory.

- End-of-Life Disposal: Consideration for recycling or disposal costs, especially in environmentally-conscious markets.

What Pricing Nuances Should International Buyers from Africa, South America, the Middle East, and Europe Keep in Mind?

International buyers should be aware of several pricing nuances:

-

Currency Fluctuations: Exchange rates can significantly impact the final cost. Budgeting for potential fluctuations is advisable.

-

Import Duties and Taxes: Research the applicable import duties and taxes in your country, as these can add to the total cost of acquisition.

-

Cultural Considerations: Understand cultural differences in negotiation styles and business practices to foster better relationships with suppliers.

In summary, a comprehensive understanding of the cost structure, price influencers, and effective negotiation strategies can empower international buyers to make informed decisions when sourcing glass bottles made in the USA.

Alternatives Analysis: Comparing glass bottles made in usa With Other Solutions

In the packaging industry, especially for beverages and food products, businesses often explore various container solutions to meet their specific needs. Glass bottles made in the USA have gained popularity due to their quality and safety standards. However, several alternatives exist that may suit different operational requirements or market conditions. This analysis compares glass bottles made in the USA with two viable alternatives: plastic bottles and aluminum cans.

| Comparison Aspect | Glass Bottles Made In USA | Plastic Bottles | Aluminum Cans |

|---|---|---|---|

| Performance | Excellent barrier against light and oxygen; preserves flavor and freshness. | Good for short-term storage; less effective against oxygen. | Great for carbonation and long shelf life; recyclable. |

| Cost | Higher initial costs; durable and reusable, leading to long-term savings. | Generally lower initial costs; may not be as durable. | Moderate cost; often cheaper than glass but can vary by market. |

| Ease of Implementation | Requires careful handling and storage; heavier than alternatives. | Lightweight and easy to transport; versatile in design. | Simple to stack and store; easy to fill and seal. |

| Maintenance | Requires cleaning and careful handling; can break if dropped. | Low maintenance; disposable or recyclable. | Low maintenance; recyclable but can be harder to reprocess than glass. |

| Best Use Case | Ideal for premium products, organic beverages, and items requiring a high-quality presentation. | Suitable for mass-market products, low-cost items, and on-the-go beverages. | Best for carbonated drinks, energy drinks, and products requiring long shelf life. |

What Are the Pros and Cons of Plastic Bottles as an Alternative?

Plastic bottles are widely used due to their lightweight nature and lower production costs. They are suitable for a range of applications, particularly in high-volume markets where cost efficiency is critical. However, they can leach chemicals into contents over time, especially when exposed to heat, which raises safety concerns for certain products. Their environmental impact is also significant, as plastic bottles contribute to pollution and are often not biodegradable.

How Do Aluminum Cans Compare to Glass Bottles?

Aluminum cans provide a strong alternative to glass bottles, especially for beverages that require excellent barrier properties against light and oxygen. They are highly recyclable and often made from recycled materials, appealing to environmentally conscious consumers. However, while they offer convenience and are lightweight, they may not convey the same premium image as glass bottles. Additionally, they are typically used for carbonated beverages, limiting their application in non-carbonated products.

Conclusion: How Should B2B Buyers Choose the Right Packaging Solution?

When selecting a packaging solution, B2B buyers should consider several factors, including the nature of the product, target market, and brand positioning. Glass bottles made in the USA are ideal for high-end products that benefit from a premium presentation and need to maintain quality over time. In contrast, plastic bottles may be better suited for high-volume, budget-sensitive applications, while aluminum cans are optimal for beverages requiring carbonation and an eco-friendly appeal. Ultimately, the right choice will depend on balancing cost, functionality, and brand values to meet specific business goals.

Essential Technical Properties and Trade Terminology for glass bottles made in usa

What Are the Key Technical Properties of Glass Bottles Made in the USA?

Understanding the essential technical properties of glass bottles is crucial for B2B buyers looking to make informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

Glass bottles are typically made from soda-lime glass, which is standard for most beverage and food packaging. Higher-grade options, such as borosilicate glass, offer enhanced thermal resistance and durability. For international buyers, selecting the right material grade ensures product integrity during transport and storage.

2. Tolerance

Tolerance refers to the allowable deviation in the dimensions of the bottle, including diameter and height. For instance, a tolerance of ±0.5mm is common in glass manufacturing. Understanding these tolerances is vital for ensuring compatibility with closures and labels, which can affect production efficiency and reduce waste.

3. Neck Finish

The neck finish of a bottle is the design and measurement of the neck, which is critical for closure compatibility. Common neck finishes include 400, 410, and 450, indicating the diameter and threading style. Choosing the right neck finish is essential for ensuring that closures fit securely and maintain product freshness.

4. Capacity

The capacity of glass bottles varies widely, typically ranging from 4 oz to 64 oz or more. This specification is crucial for businesses in sectors such as food and beverage, as it dictates how much product can be contained, impacting shipping costs and shelf space.

5. Weight

The weight of a glass bottle can influence shipping costs and handling efficiency. Lighter bottles reduce shipping expenses but may compromise durability. Buyers should balance the need for lightweight designs with the necessity for robust packaging to ensure product safety.

6. Compliance Standards

Glass bottles manufactured in the USA must adhere to specific safety and quality standards, such as those set by the FDA for food contact materials. Compliance ensures that the products are safe for consumer use and can be critical for international trade, as different countries may have varying regulations.

What Are Common Trade Terms Related to Glass Bottles?

Familiarity with industry jargon can streamline communication and negotiations for B2B buyers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or products that are sold by another company under its brand name. In the context of glass bottles, an OEM might create custom designs based on a buyer’s specifications, offering unique branding opportunities.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand as it can impact inventory levels and cash flow. Lower MOQs may be beneficial for smaller businesses or startups.

3. RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to suppliers requesting a price quote for specific products or services. It allows buyers to compare offers from multiple suppliers and negotiate better terms. For glass bottles, including specifications such as size, material, and quantity in the RFQ can lead to more accurate pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps clarify who is responsible for shipping, insurance, and tariffs, which is particularly important for international buyers dealing with glass bottles.

5. Lead Time

Lead time refers to the time it takes from placing an order to the delivery of the product. For glass bottles, lead times can vary based on customization and production schedules. Knowing the lead time is essential for inventory planning and meeting market demands.

By grasping these technical properties and trade terms, B2B buyers can make strategic decisions that align with their business goals and enhance their supply chain efficiency.

Navigating Market Dynamics and Sourcing Trends in the glass bottles made in usa Sector

What Are the Current Market Dynamics Influencing the Glass Bottles Made in USA Sector?

The global glass bottles market is witnessing significant growth, driven by increasing consumer preferences for sustainable packaging solutions. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are shifting towards glass due to its recyclability and perceived safety compared to plastic. Notably, markets in Brazil and Germany are increasingly emphasizing eco-friendly products, which aligns with the broader global sustainability movement.

Emerging technologies in the glass manufacturing sector are also reshaping sourcing strategies. Innovations in production techniques, such as automated glass molding and energy-efficient furnaces, have led to cost reductions and improved product quality. Additionally, digital platforms are enhancing supply chain transparency, enabling buyers to track the origin and environmental impact of their sourced products. These technological advancements are crucial for international buyers aiming to streamline procurement processes and optimize inventory management.

Moreover, the post-pandemic recovery phase has heightened demand for domestically produced goods. The “Made in USA” label is gaining traction as buyers prioritize local sourcing to mitigate supply chain disruptions and support local economies. This trend is particularly relevant for European buyers, who are increasingly scrutinizing supply chains for reliability and ethical practices.

How Is Sustainability Shaping the Sourcing of Glass Bottles Made in USA?

Sustainability is at the forefront of the glass bottles sector, influencing both production methods and purchasing decisions among international B2B buyers. The environmental impact of packaging materials is a growing concern, prompting companies to adopt greener practices. Glass is inherently sustainable due to its recyclability; it can be recycled indefinitely without losing quality, making it a preferred choice for brands committed to reducing their carbon footprint.

Ethical sourcing is equally important, as buyers seek suppliers who adhere to sustainable practices throughout their supply chains. Certifications such as ISO 14001 (Environmental Management) and the Forest Stewardship Council (FSC) can help buyers identify environmentally responsible manufacturers. Additionally, many glass bottle producers are now using recycled materials in their products, further reducing environmental impact and promoting a circular economy.

For international buyers, especially those in emerging markets, understanding the sustainability credentials of suppliers is critical. This not only enhances brand reputation but also aligns with the growing consumer demand for ethical and sustainable products. By prioritizing suppliers with strong sustainability practices, businesses can leverage their commitment to environmental responsibility as a competitive advantage in the marketplace.

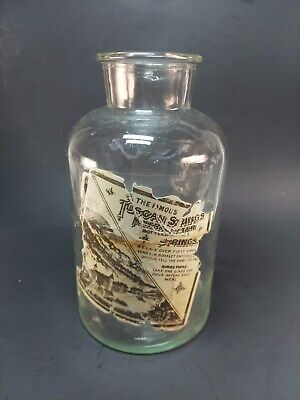

What Is the Historical Context of Glass Bottle Production in the USA?

The history of glass bottle production in the USA dates back to the early 19th century, when glassblowing techniques were first adapted from Europe. Over the decades, advancements in technology and manufacturing processes led to increased production efficiency and a broader variety of glass products. The introduction of automated bottle-making machines in the early 20th century revolutionized the industry, allowing for mass production and lower costs.

Throughout the years, American glass manufacturers have adapted to changing consumer preferences, transitioning from traditional glass containers to innovative designs that cater to modern needs. The focus on sustainability has also evolved, with many companies now prioritizing eco-friendly practices in their operations. This historical context is essential for B2B buyers, as it highlights the longstanding expertise and reliability of American glass manufacturers, reinforcing their position as leaders in sustainable packaging solutions.

By understanding these market dynamics, sustainability trends, and historical developments, international B2B buyers can make informed sourcing decisions in the glass bottles sector, ensuring they partner with manufacturers that align with their values and business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of glass bottles made in usa

-

How do I ensure the quality of glass bottles made in the USA?

To guarantee the quality of glass bottles, it’s essential to conduct thorough supplier vetting. Request samples to evaluate the glass clarity, weight, and durability. Additionally, inquire about their manufacturing processes, quality assurance protocols, and compliance with industry standards. Certifications such as ISO or ASTM can indicate adherence to quality norms. Regular visits to the manufacturing facility can also provide insights into their operations and quality control measures, ensuring that you partner with a reliable supplier. -

What is the minimum order quantity (MOQ) for glass bottles made in the USA?

Minimum order quantities can vary significantly among manufacturers. Typically, MOQs for glass bottles range from 1,000 to 10,000 units, depending on the bottle type, customization, and supplier capabilities. It’s advisable to discuss your specific requirements with potential suppliers to understand their MOQ policies. Some manufacturers may offer flexibility for smaller orders or provide options for stock items, which can be beneficial for new businesses or those testing the market. -

What customization options are available for glass bottles made in the USA?

Many manufacturers offer a range of customization options, including bottle shapes, sizes, colors, and closures. You can also explore options for custom labeling, printing, or embossing to enhance brand visibility. Discuss your vision with potential suppliers, as they may provide design assistance or templates to facilitate the process. Keep in mind that customization may impact lead times and costs, so factor these into your planning. -

What payment terms should I expect when sourcing glass bottles made in the USA?

Payment terms can vary based on the supplier and your relationship with them. Common options include net 30, net 60, or upfront payment for new customers. Some suppliers may offer discounts for early payments or larger orders. It’s important to clarify these terms before placing an order to avoid misunderstandings. Establishing a good relationship with your supplier can also lead to more favorable terms over time. -

How can I ensure timely delivery of glass bottles from the USA to my location?

To ensure timely delivery, discuss logistics with your supplier during the negotiation phase. Confirm their shipping methods and estimated lead times, as well as any potential customs delays. It’s advisable to work with freight forwarders experienced in international shipping to manage the complexities of customs clearance and import regulations. Additionally, consider placing orders well in advance of your need to buffer against unforeseen delays. -

What are the advantages of sourcing glass bottles made in the USA?

Sourcing glass bottles made in the USA offers several benefits, including shorter lead times, reduced shipping costs, and better communication due to time zone alignment. Furthermore, American-made products often adhere to stricter quality standards, providing assurance of durability and safety. Supporting local manufacturers can also enhance your brand image, appealing to consumers who value sustainability and domestic production. -

How do I vet suppliers for glass bottles made in the USA?

Vetting suppliers involves researching their reputation, production capabilities, and compliance with industry standards. Start by checking online reviews, testimonials, and case studies. Request references from other clients, and assess their responsiveness and willingness to provide information. A visit to their facility can also help gauge their operations and quality control practices. Additionally, ensure they have the necessary certifications and are transparent about their sourcing and manufacturing processes. -

What are common challenges in international trade for glass bottles made in the USA?

Challenges in international trade can include customs regulations, tariffs, and varying quality standards across countries. Understanding the import regulations in your country is crucial to avoid delays and additional costs. Additionally, fluctuating currency exchange rates can impact overall costs. To mitigate these issues, work closely with your supplier and logistics partners to develop a comprehensive shipping plan, and consider consulting with a trade expert to navigate complex regulations effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for glass bottles made in usa

As international B2B buyers explore the advantages of sourcing glass bottles made in the USA, several key insights emerge. First, prioritizing American-made products enhances brand integrity, as these bottles often reflect higher quality standards and sustainability practices. By choosing suppliers that emphasize local production, businesses can also benefit from shorter lead times and reduced shipping costs, making the supply chain more efficient.

Furthermore, the growing global demand for eco-friendly packaging aligns perfectly with glass bottles, which are recyclable and contribute to a sustainable brand image. This trend is particularly relevant for markets in Africa, South America, the Middle East, and Europe, where consumers increasingly prefer environmentally responsible products.

Looking ahead, the glass bottle market in the USA is poised for growth, driven by innovations in design and functionality. International buyers should leverage this momentum by forging partnerships with reliable manufacturers committed to quality and sustainability. By aligning sourcing strategies with market trends, businesses can not only meet customer expectations but also enhance their competitive advantage. Now is the time to explore the diverse offerings of American-made glass bottles to elevate your product line and support sustainable practices in your supply chain.