Top 6 Brinkmann Pumps Usa List and Guide: How To Solve Scenario 1…

Introduction: Navigating the Global Market for brinkmann pumps usa

In today’s competitive landscape, sourcing reliable and efficient Brinkmann pumps in the USA poses a significant challenge for international B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, understanding the intricacies of pump technologies and their applications is crucial for optimizing your operations. This comprehensive guide delves into the various types of Brinkmann pumps available, their specific applications across industries, and the key factors to consider when vetting suppliers.

Buyers will find detailed insights into the cost structures associated with different pump models, ensuring that you can make informed purchasing decisions that align with your budget and operational needs. Additionally, we will explore the latest innovations in pump technology, including digital solutions that enhance efficiency and monitoring capabilities.

By equipping you with the knowledge needed to navigate the global market, this guide empowers B2B buyers to identify the right Brinkmann pump solutions tailored to their unique requirements. Whether you’re looking to improve coolant management in machine tools or seeking high-performance pumps for filtration applications, our guide serves as your essential resource for making confident, strategic investments.

Top 10 Brinkmann Pumps Usa Manufacturers & Suppliers List

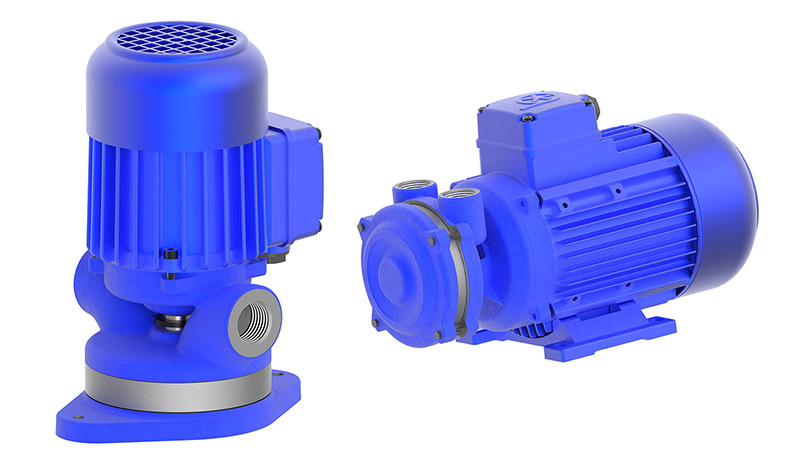

1. Brinkmann Pumps – Coolant and Centrifugal Solutions

Domain: brinkmannpumps.com

Registered: 2000 (25 years)

Introduction: Coolant pumps for machine tools, including Low Pressure Pumps, Medium and High Pressure Pumps, Chip handling, Lifting Pumps, Plastic and Miniature Centrifugal Pumps. Digital solutions for pump monitoring, control, and frequency converters. Stainless Steel Pumps (TVA and TVG) designed for corrosive fluids with high efficiency. Immersion Pumps (TB, (S)TA, (S)TE, TVG, TVA), Pressure Boosting Pumps (F…

2. BRINKMANN PUMPS – Intelligent Pump Solutions

3. Brinkmann – Stainless Steel Pumps

Domain: industrialsalesgroupllc.com

Registered: 2013 (12 years)

Introduction: Brinkmann Pumps – Stainless Steel Pumps, Screw-Spindle Pumps, Coolant Pump Catalog.

4. BRINKMANN PUMPS – High Tech Coolant Pumps

5. Brinkmann – 13.8 HP Pump Motor

6. Brinkmann Pumps – Centrifugal and Positive Displacement Pumps

Domain: us.metoree.com

Registered: 2020 (5 years)

Introduction: Brinkmann Pumps, Inc. offers a range of products including centrifugal pumps, positive displacement pumps, electric motors, servo motors, specialized motor designs, and digital control systems. They also provide automation solutions aimed at enhancing efficiency, reducing downtime, and improving machinery performance.

Understanding brinkmann pumps usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Centrifugal Pumps | High efficiency, designed for continuous operation | Industrial washing, coolant circulation | Pros: Reliable performance; Cons: Limited to low-viscosity fluids. |

| Screw-Spindle Pumps | Capable of handling viscous and abrasive fluids | Metalworking, machining processes | Pros: Excellent for challenging fluids; Cons: Higher initial investment. |

| Stainless Steel Pumps | Corrosion-resistant, suitable for harsh environments | Chemical processing, food and beverage | Pros: Durability and hygiene; Cons: Higher maintenance costs. |

| Digital Pump Systems | Integrated monitoring and control systems | Automated fluid transport and monitoring | Pros: Enhanced efficiency and data analytics; Cons: Requires technical expertise to operate. |

| Custom Pump Solutions | Tailored designs for specific applications | Specialized industrial processes | Pros: Optimized performance for unique needs; Cons: Longer lead times. |

What are the Key Characteristics of Centrifugal Pumps from Brinkmann?

Centrifugal pumps are a staple in the Brinkmann product line, known for their high efficiency and reliability in continuous operation. These pumps utilize centrifugal force to move fluids, making them ideal for applications like industrial washing and coolant circulation in machine tools. When purchasing centrifugal pumps, B2B buyers should consider factors such as flow rate, energy consumption, and compatibility with the fluids being handled. Their robust design generally allows for lower maintenance, but they are best suited for low-viscosity fluids.

How Do Screw-Spindle Pumps Stand Out in the Market?

Screw-spindle pumps are engineered to handle viscous and abrasive fluids, making them suitable for demanding industrial applications such as metalworking and machining processes. These pumps feature a unique design that allows for a smooth, continuous flow, minimizing shear and turbulence. B2B buyers should evaluate the pump’s material compatibility and pressure ratings when considering a screw-spindle pump. While they offer excellent performance for challenging fluids, the higher upfront cost can be a consideration for budget-conscious companies.

Why Choose Stainless Steel Pumps for Harsh Environments?

Brinkmann’s stainless steel pumps are specifically designed to resist corrosion, making them ideal for harsh environments, including chemical processing and the food and beverage industry. Their construction ensures durability and hygiene, which are critical in applications where contamination is a concern. Buyers should assess the pump’s specifications, such as flow rate and temperature limits, to ensure compatibility with their specific needs. While these pumps are highly durable, potential buyers should be aware of higher maintenance costs associated with stainless steel equipment.

What Advantages Do Digital Pump Systems Offer for B2B Buyers?

Digital pump systems from Brinkmann integrate advanced monitoring and control technologies, enhancing operational efficiency and providing real-time data analytics. These systems are particularly beneficial for automated fluid transport and monitoring applications. When considering digital pump systems, businesses should evaluate the ease of integration with existing systems and the level of technical expertise required for operation. While they offer significant advantages in efficiency, the complexity may necessitate additional training for staff.

How Can Custom Pump Solutions Meet Unique Industrial Needs?

Brinkmann also offers custom pump solutions tailored to meet specific industrial requirements. These pumps are designed based on the unique challenges of an application, ensuring optimized performance. B2B buyers should consider the specific needs of their processes, including flow rates and fluid characteristics, when opting for custom solutions. While these pumps can provide significant advantages in performance, buyers should be prepared for longer lead times and potentially higher costs associated with bespoke manufacturing.

Key Industrial Applications of brinkmann pumps usa

| Industry/Sector | Specific Application of Brinkmann Pumps USA | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Machine Tool Manufacturing | Coolant circulation in CNC machines | Enhances machining precision and tool lifespan | Ensure compatibility with existing machinery and fluid types |

| Food and Beverage | Liquid transport in processing plants | Maintains hygiene and efficiency in production | Verify compliance with food safety standards and corrosion resistance |

| Chemical Processing | Handling corrosive and viscous fluids | Reduces downtime and maintenance costs | Look for pumps with high durability and chemical resistance |

| HVAC Systems | Water circulation for cooling systems | Improves energy efficiency and system reliability | Assess pump capacity and energy consumption for specific applications |

| Automotive Industry | Fluid management in assembly lines | Optimizes production flow and reduces waste | Evaluate pump adaptability to various fluid types and pressures |

How Are Brinkmann Pumps Used in Machine Tool Manufacturing?

In machine tool manufacturing, Brinkmann pumps are integral for coolant circulation in CNC machines. These pumps ensure consistent delivery of coolant to the cutting tools, which is crucial for maintaining precision and extending tool life. International buyers, particularly from regions like Africa and South America, should consider the compatibility of these pumps with their existing equipment and the specific types of coolants used in their processes. This ensures optimal performance and minimizes operational disruptions.

What Role Do Brinkmann Pumps Play in the Food and Beverage Sector?

In the food and beverage industry, Brinkmann pumps are employed for liquid transport in processing plants, where hygiene and efficiency are paramount. These pumps facilitate the movement of ingredients and finished products while adhering to strict food safety regulations. Buyers from Europe and the Middle East must ensure that the selected pumps meet industry standards for cleanliness and material compatibility to prevent contamination and maintain quality.

How Are Brinkmann Pumps Applied in Chemical Processing?

Brinkmann pumps are designed to handle corrosive and viscous fluids in chemical processing applications, addressing the challenges of material degradation and downtime. Their robust construction and reliability help businesses reduce maintenance costs and improve operational efficiency. International buyers should focus on the pumps’ chemical resistance and durability, especially in harsh environments, to ensure longevity and performance in demanding applications.

Why Are Brinkmann Pumps Important for HVAC Systems?

In HVAC systems, Brinkmann pumps are crucial for water circulation, enhancing energy efficiency and system reliability. They help maintain optimal temperatures in commercial buildings and industrial facilities. Buyers, particularly from emerging markets, should assess the capacity and energy consumption of these pumps to ensure they meet the specific requirements of their cooling systems, thereby optimizing performance and reducing operational costs.

How Do Brinkmann Pumps Benefit the Automotive Industry?

In the automotive industry, Brinkmann pumps manage fluids in assembly lines, optimizing production flow and reducing waste. Their ability to handle various fluid types and pressures makes them essential for maintaining efficient operations. For international buyers, particularly in rapidly developing regions, evaluating the adaptability of these pumps to different manufacturing processes is key to enhancing productivity and ensuring smooth operations.

3 Common User Pain Points for ‘brinkmann pumps usa’ & Their Solutions

Scenario 1: Inefficient Pump Performance Leading to Increased Downtime

The Problem: Many B2B buyers experience issues with the performance efficiency of their coolant pumps, which can lead to unexpected downtime in their manufacturing processes. For instance, a machining facility may find that their Brinkmann pumps are not maintaining the required flow rates or pressure levels, resulting in overheating of machinery and reduced operational effectiveness. This not only affects production schedules but also incurs additional costs related to equipment repairs and lost labor hours.

The Solution: To combat performance inefficiencies, it is crucial for buyers to conduct a thorough assessment of their operational requirements before purchasing or upgrading their Brinkmann pumps. Buyers should engage in a detailed discussion with Brinkmann’s technical sales representatives to ensure they understand the specific demands of their applications, such as flow rates, pressure, and fluid characteristics. Utilizing Brinkmann’s pump selection menu can help identify the most suitable pump models tailored to specific processes. Furthermore, regular maintenance and monitoring using Brinkmann’s digital solutions can preemptively address performance issues, ensuring that pumps operate within optimal parameters and minimizing the risk of downtime.

Scenario 2: Difficulty in Sourcing Spare Parts for Prompt Repairs

The Problem: B2B buyers often face challenges in sourcing spare parts for their Brinkmann pumps, especially in regions where supply chains may be disrupted or delayed. For instance, a manufacturing plant in South America might experience a pump failure but struggle to find the required spare parts in a timely manner, resulting in prolonged operational halts and a backlog in production.

The Solution: To mitigate the impact of such scenarios, buyers should establish a proactive relationship with Brinkmann Pumps and their authorized distributors. It is advisable to maintain an inventory of critical spare parts that are prone to wear and tear, ensuring that replacements are readily available when needed. Utilizing Brinkmann’s online request system for spare parts can streamline the ordering process. Additionally, participating in training sessions on pump maintenance and troubleshooting provided by Brinkmann can empower staff to perform minor repairs and adjustments, reducing dependency on external suppliers for urgent needs.

Scenario 3: Inadequate Support and Understanding of Digital Integration

The Problem: As industries move towards digital solutions for enhanced efficiency, many B2B buyers may struggle with integrating digital monitoring and control systems into their existing Brinkmann pump setups. A factory in Europe might find that while they have invested in advanced digital technologies, the lack of understanding regarding how to effectively utilize Brinkmann’s digital offerings results in underperformance and missed opportunities for optimization.

The Solution: To address these integration challenges, buyers should leverage the comprehensive support services offered by Brinkmann. Engaging in workshops and training sessions focused on digital solutions—such as pump monitoring and control systems—can significantly enhance users’ understanding and ability to implement these technologies effectively. Buyers should also consider collaborating with Brinkmann’s technical support team to develop a tailored digital strategy that aligns with their operational goals. By actively using Brinkmann’s digital tools for pump performance monitoring, facilities can optimize their operations, ensuring real-time adjustments are made to enhance efficiency and reduce waste.

Strategic Material Selection Guide for brinkmann pumps usa

What Are the Key Materials Used in Brinkmann Pumps USA?

Brinkmann Pumps USA utilizes a variety of materials in the manufacturing of their pump systems, each selected for its unique properties that enhance performance and durability. Understanding these materials is crucial for international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe. Below is an analysis of three common materials used in Brinkmann pumps.

How Does Stainless Steel Benefit Pump Performance?

Stainless steel is a primary material used in Brinkmann pumps, particularly for the TVA and TVG series. Its key properties include excellent corrosion resistance, high strength, and the ability to withstand elevated temperatures and pressures. This makes stainless steel ideal for handling corrosive fluids and high-performance applications.

Pros: Stainless steel pumps are durable and have a long lifespan, which reduces maintenance costs. They are also easy to clean and maintain, making them suitable for industries requiring high hygiene standards.

Cons: The initial cost of stainless steel components is relatively high compared to other materials. Additionally, manufacturing complexities can arise due to the need for specialized welding techniques.

Impact on Application: Stainless steel is compatible with a wide range of media, including oils, coolants, and chemicals, making it a versatile choice for various industrial applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN for stainless steel grades. Additionally, awareness of local regulations regarding material specifications is essential for successful procurement.

What Role Does Cast Iron Play in Pump Design?

Cast iron is another material commonly used in the construction of Brinkmann pumps, particularly in components that require high strength and wear resistance. Its properties include good castability, vibration damping, and resistance to deformation under high loads.

Pros: Cast iron pumps are cost-effective and provide excellent durability for heavy-duty applications. They can withstand high pressures and are less prone to damage from physical impacts.

Cons: Cast iron is heavier than other materials, which can complicate installation and transportation. It also has lower corrosion resistance compared to stainless steel, making it less suitable for aggressive media.

Impact on Application: Cast iron is often used in applications involving water and non-corrosive fluids, making it ideal for general industrial use.

Considerations for International Buyers: Buyers should be aware of regional preferences for materials, as some markets may favor lighter materials for ease of transport. Compliance with local standards is also crucial.

Why Choose Plastic for Specialized Applications?

Plastics, such as polypropylene and PVC, are increasingly used in specific applications within Brinkmann pumps. These materials are lightweight, resistant to corrosion, and can handle a range of chemical media.

Pros: Plastic pumps are generally less expensive than metal alternatives and are highly resistant to chemical attack, making them suitable for aggressive fluids. Their lightweight nature simplifies installation.

Cons: Plastics may not withstand high temperatures and pressures as effectively as metals, limiting their use in certain applications. They can also be less durable over the long term compared to metal options.

Impact on Application: Plastic pumps are ideal for applications involving harsh chemicals, such as in the chemical processing industry, where corrosion resistance is critical.

Considerations for International Buyers: Buyers should verify that the selected plastic materials comply with relevant standards, such as JIS or ASTM, particularly regarding chemical compatibility and safety.

Summary of Material Selection for Brinkmann Pumps USA

| Material | Typical Use Case for brinkmann pumps usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Corrosive fluid handling in industrial applications | Excellent corrosion resistance and durability | Higher initial cost and manufacturing complexity | High |

| Cast Iron | General industrial use with water and non-corrosive fluids | Cost-effective and durable for heavy-duty applications | Heavier and lower corrosion resistance | Medium |

| Plastic | Chemical processing and handling aggressive fluids | Lightweight and highly resistant to chemical attack | Limited temperature and pressure tolerance | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions when selecting Brinkmann pumps for various applications. Understanding the properties, advantages, and limitations of each material can significantly impact operational efficiency and cost-effectiveness in diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for brinkmann pumps usa

What Are the Main Stages of Manufacturing Brinkmann Pumps?

Brinkmann Pumps USA employs a sophisticated manufacturing process to produce high-quality pumps for various industrial applications. The main stages of manufacturing include material preparation, forming, assembly, and finishing.

Material Preparation

The manufacturing journey begins with the careful selection of raw materials. Brinkmann Pumps prioritizes high-grade stainless steel and other corrosion-resistant alloys to ensure durability and reliability. These materials are sourced from certified suppliers who meet stringent quality standards. Once the materials are received, they undergo a rigorous inspection process, known as Incoming Quality Control (IQC), to verify their compliance with specifications.

How Are Pumps Formed?

After material preparation, the forming stage involves advanced techniques such as precision machining, casting, and forging. Brinkmann utilizes Computer Numerical Control (CNC) machines for machining components to achieve high tolerances and repeatability. This stage is crucial, as even minor deviations can affect pump performance and longevity. Techniques like laser cutting and welding are also employed to ensure robust assembly of parts.

What Does the Assembly Process Entail?

The assembly of Brinkmann Pumps is carried out in a controlled environment to minimize contamination and ensure precision. Each pump is assembled by skilled technicians who follow detailed work instructions. During this stage, components are fitted together, and each assembly undergoes In-Process Quality Control (IPQC). This step includes visual inspections and functional tests to ensure that each pump meets the design specifications before proceeding to the next stage.

How Is the Finishing Process Conducted?

The finishing stage includes surface treatment processes such as polishing, anodizing, or coating, depending on the specific requirements of the pump. These treatments enhance corrosion resistance and aesthetic appeal. Final assembly checks are performed, and the pumps are prepared for testing and packaging. This stage is vital for ensuring that the product not only meets technical specifications but is also ready for customer delivery.

What Quality Assurance Standards Does Brinkmann Pumps Adhere To?

Brinkmann Pumps is committed to maintaining high standards of quality assurance throughout the manufacturing process. The company follows internationally recognized quality management standards, primarily ISO 9001. This certification ensures that the manufacturing processes consistently meet customer and regulatory requirements.

Are There Industry-Specific Certifications?

In addition to ISO 9001, Brinkmann Pumps also adheres to specific industry certifications such as CE marking for European markets and API standards for the oil and gas sector. These certifications are essential for B2B buyers who must comply with local regulations and industry standards.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control is integral to Brinkmann’s manufacturing process and is implemented at various checkpoints. The key stages include:

-

Incoming Quality Control (IQC): Ensures that raw materials meet specified quality standards before production begins.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process to monitor and verify that each stage adheres to quality standards.

-

Final Quality Control (FQC): Performed on completed pumps to ensure they meet all design and performance specifications before shipment.

What Common Testing Methods Are Used for Quality Assurance?

Brinkmann Pumps employs a variety of testing methods to ensure product quality. These include:

-

Hydraulic Testing: Verifying the pump’s performance under pressure to ensure it can operate efficiently in real-world conditions.

-

Performance Testing: Assessing flow rates, efficiency, and operational characteristics to meet customer specifications.

-

Material Testing: Conducting tests such as tensile strength and corrosion resistance to confirm the material’s suitability for intended applications.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, must ensure their suppliers maintain high-quality standards. Here are some actionable steps for verification:

-

Conduct Supplier Audits: Regular audits help assess compliance with quality standards and manufacturing processes. Buyers can request access to audit reports and certifications.

-

Request Quality Assurance Documentation: Suppliers should provide comprehensive documentation, including quality control plans, inspection reports, and test results.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. This is particularly beneficial for international buyers unfamiliar with local practices.

What Nuances Should International Buyers Consider for Quality Control?

International B2B buyers must navigate various challenges when it comes to quality control. Understanding the local regulatory environment is crucial. Each region may have unique standards and requirements that suppliers must meet. For instance, buyers in Europe may require CE certification, while those in Africa may prioritize compliance with local safety and performance standards.

Additionally, buyers should consider language barriers and cultural differences that may affect communication regarding quality expectations. Establishing clear lines of communication and having well-defined quality agreements can mitigate these issues.

Conclusion

Brinkmann Pumps USA exemplifies a commitment to quality through its meticulous manufacturing processes and stringent quality assurance practices. For B2B buyers, understanding these processes and standards is essential for ensuring that the products they source meet their operational needs and compliance requirements. By leveraging the insights provided, international buyers can confidently engage with Brinkmann Pumps, ensuring they receive reliable and high-performance pumping solutions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brinkmann pumps usa’

This guide aims to assist international B2B buyers in effectively sourcing Brinkmann Pumps from the USA. The following checklist provides a structured approach to ensure that you make informed decisions and procure the right pump solutions for your business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. Understanding the specific type of pump needed—such as centrifugal or screw-spindle pumps—and the application it will serve is crucial. This clarity will streamline the selection process and help suppliers provide the most suitable options for your operations.

Step 2: Research Supplier Backgrounds

Investigate the history and reputation of potential suppliers. Look for details such as years in business, manufacturing capabilities, and their experience with international shipping. A supplier with a solid track record is more likely to deliver quality products and reliable service.

Step 3: Verify Product Certifications and Standards

Ensure that the pumps meet relevant industry certifications and quality standards, such as ISO or ANSI. Compliance with these standards not only ensures product quality but also facilitates smoother imports and operational efficiency in your region. Request documentation that verifies these certifications.

Step 4: Assess After-Sales Support and Service

Evaluate the level of after-sales support offered by the supplier. Consider the availability of spare parts, technical assistance, and warranty policies. Strong after-sales support is essential for minimizing downtime and ensuring that your operations run smoothly after the purchase.

Step 5: Request and Analyze Quotes

Once you have shortlisted potential suppliers, request detailed quotations. Compare pricing, delivery terms, and payment options. Ensure that the quotes include all associated costs, such as shipping and customs duties, to avoid unexpected expenses down the line.

Step 6: Evaluate Supplier Communication and Responsiveness

Communication is vital in any business relationship. Assess how promptly and effectively potential suppliers respond to your inquiries. A supplier that prioritizes clear and timely communication is likely to be more reliable during the procurement process and beyond.

Step 7: Seek References and Client Testimonials

Before finalizing your supplier choice, request references or testimonials from other clients, particularly those in similar industries or regions. Speaking with past customers can provide insights into the supplier’s reliability, product quality, and overall service experience.

By following this checklist, B2B buyers can streamline their sourcing process for Brinkmann Pumps and ensure they make informed decisions that align with their operational needs and standards.

Comprehensive Cost and Pricing Analysis for brinkmann pumps usa Sourcing

What Are the Key Cost Components in Brinkmann Pumps USA Sourcing?

When analyzing the cost structure for sourcing Brinkmann pumps, several key components must be considered. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: Brinkmann pumps utilize high-quality materials, such as stainless steel and specialized alloys, particularly in models designed for corrosive fluids. The choice of materials significantly affects the overall cost, as higher quality often leads to increased durability and efficiency.

-

Labor: Labor costs are influenced by the region where the pumps are manufactured. Brinkmann, with its manufacturing base in Germany, may incur higher labor costs due to stringent labor laws and higher wage standards. However, assembly and service centers worldwide help mitigate costs for international buyers.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, depreciation, and factory maintenance. The efficiency of manufacturing processes and technology adoption (like automation) can reduce overheads, thus impacting pricing.

-

Tooling: The initial investment in tooling for custom or specialized pump designs can be substantial. This cost is amortized over the production volume; hence, higher order volumes can lead to lower per-unit costs.

-

Quality Control: Brinkmann’s commitment to quality necessitates rigorous QC processes. These processes ensure that each pump meets international quality standards, which can add to the cost but is essential for reliability, especially in industrial applications.

-

Logistics: Transporting pumps from manufacturing facilities to international markets involves significant logistics costs. These include freight charges, customs duties, and insurance. The choice of Incoterms can also influence the final price, affecting who bears the cost of logistics.

-

Margin: The profit margin set by Brinkmann for its pumps typically reflects the brand’s reputation for quality and innovation. Buyers should consider how this margin aligns with their own pricing strategies in their respective markets.

What Factors Influence Pricing for Brinkmann Pumps?

Several factors play a crucial role in determining the final pricing for Brinkmann pumps:

-

Volume and Minimum Order Quantity (MOQ): Larger orders can lead to bulk pricing discounts, making it more cost-effective for buyers. Understanding the MOQ for various models can help in negotiating better deals.

-

Specifications and Customization: Custom pumps tailored to specific applications can incur additional costs. Buyers should clearly communicate their requirements upfront to avoid unexpected price increases.

-

Material Quality and Certifications: Pumps manufactured with higher quality materials or specific certifications (like ISO or CE) may come at a premium. Buyers should evaluate whether these certifications are necessary for their applications.

-

Supplier Factors: The relationship with suppliers can influence pricing. Long-term partnerships often lead to better pricing terms and conditions. Additionally, suppliers’ operational efficiencies can affect the price.

-

Incoterms: The choice of Incoterms dictates the responsibilities between buyers and sellers in terms of shipping, insurance, and logistics. Understanding these terms can help buyers minimize costs and avoid misunderstandings.

How Can International B2B Buyers Optimize Costs When Sourcing Brinkmann Pumps?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several strategies to optimize costs when sourcing Brinkmann pumps:

-

Negotiate Terms: Engaging in negotiations regarding price, payment terms, and delivery schedules can lead to significant savings. It’s advisable to approach discussions with a clear understanding of market prices.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the upfront costs, buyers should consider the TCO, which includes maintenance, operational efficiency, and potential downtime costs. This holistic view can reveal the true value of investing in high-quality pumps.

-

Understand Pricing Nuances: Different markets may have unique pricing structures influenced by local demand, competition, and economic factors. Conducting thorough market research can help buyers make informed decisions.

-

Leverage Supplier Relationships: Building strong relationships with suppliers can lead to preferential pricing and access to new products or technologies. Regular communication and feedback can foster trust and collaboration.

Disclaimer on Indicative Prices

Prices for Brinkmann pumps can vary significantly based on the factors discussed above. It’s advisable for buyers to request quotes tailored to their specific requirements to ensure accurate pricing information.

Alternatives Analysis: Comparing brinkmann pumps usa With Other Solutions

Understanding Alternatives in Pump Solutions

In the competitive landscape of industrial fluid handling, selecting the right pump solution is crucial for operational efficiency and cost-effectiveness. While Brinkmann Pumps USA offers advanced technologies and customization options, it’s essential to compare these with viable alternatives that can meet similar needs. This analysis will examine two alternative pump solutions: the Vertiflo Pump and the Goulds Pumps.

Comparison Table

| Comparison Aspect | Brinkmann Pumps USA | Vertiflo Pump | Goulds Pumps |

|---|---|---|---|

| Performance | High efficiency, tailored for coolant applications | Good for general industrial use, moderate efficiency | Robust performance in diverse applications |

| Cost | Premium pricing | Competitive pricing | Variable, depending on model |

| Ease of Implementation | Requires specialized installation | Easy to install, versatile | Moderate; some models complex |

| Maintenance | Low maintenance, high reliability | Moderate maintenance needs | Varies by model; some high maintenance |

| Best Use Case | Machine tools, coolant systems | General industrial processes, water treatment | Mining, agricultural, and chemical applications |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Vertiflo Pumps?

Vertiflo Pumps are recognized for their competitive pricing and versatility in various industrial applications. They offer a solid performance for general fluid handling, making them suitable for water treatment and other non-specialized tasks. However, while they are easy to install, their efficiency may not match the high standards set by Brinkmann Pumps, especially in specialized coolant applications. This makes them less ideal for industries that require precise fluid temperature control and handling of specific materials.

How Do Goulds Pumps Compare in Terms of Performance?

Goulds Pumps are known for their robustness and are widely used across various sectors, including mining and agriculture. They provide reliable performance and can handle a diverse range of fluids, making them a flexible choice for companies needing varied solutions. However, their pricing can be variable, and some models may require more maintenance than Brinkmann Pumps. This could lead to higher long-term operational costs, especially in industries where downtime is costly.

Conclusion: Choosing the Right Pump Solution for Your Needs

When evaluating pump solutions, B2B buyers should consider their specific operational requirements, including the nature of the fluids being handled, installation complexity, and long-term maintenance needs. While Brinkmann Pumps USA excels in high-efficiency coolant systems with low maintenance, alternatives like Vertiflo and Goulds Pumps may offer cost-effective solutions for less specialized applications. Buyers should conduct a thorough analysis of their operational needs and budget constraints to select the most suitable pump solution, ensuring that they achieve optimal performance and reliability in their processes.

Essential Technical Properties and Trade Terminology for brinkmann pumps usa

What are the Essential Technical Properties of Brinkmann Pumps?

When considering the acquisition of Brinkmann Pumps, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some key properties that international B2B buyers should be aware of:

1. Material Grade

Brinkmann Pumps are typically constructed from high-grade stainless steel, which enhances durability and corrosion resistance. The choice of material is significant in industrial applications where pumps are exposed to harsh environments or aggressive fluids. Using high-quality materials ensures longevity and reduces the need for frequent replacements, ultimately leading to lower total cost of ownership.

2. Flow Rate

The flow rate is a critical specification that indicates the volume of fluid a pump can move within a specific time frame, usually measured in liters per minute (LPM). For businesses, understanding flow rates helps in selecting a pump that meets the demands of their operational processes, whether for cooling, tempering, or filtration. An adequate flow rate ensures efficient production cycles and minimizes downtime.

3. Head Pressure

Head pressure refers to the height of fluid that a pump can effectively move against gravity. This specification is vital for applications requiring the transportation of fluids over distances or to elevated locations. Selecting a pump with suitable head pressure is essential to maintain system efficiency and avoid operational failures.

4. Tolerance Levels

Tolerance levels denote the permissible limits of variation in the dimensions of pump components. High tolerance levels are essential for ensuring proper fit and function, particularly in precision applications. For B2B buyers, this means investing in pumps that will integrate seamlessly into existing systems, minimizing the risk of leaks or failures.

5. Energy Efficiency Rating

Energy efficiency is becoming increasingly important for businesses aiming to reduce operational costs and environmental impact. Brinkmann Pumps often feature energy-efficient designs that help minimize power consumption while maintaining performance. Understanding the energy efficiency rating can lead to significant savings on energy bills over time.

6. Operating Temperature Range

The operating temperature range specifies the conditions under which a pump can function effectively. Knowing this range is crucial for applications involving extreme temperatures, ensuring that the pump will operate reliably without risk of failure.

Which Trade Terminology Should B2B Buyers Know When Dealing with Brinkmann Pumps?

Familiarity with industry terminology is essential for effective communication and negotiation. Here are some common trade terms relevant to Brinkmann Pumps:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help in assessing the quality and compatibility of the pumps with existing machinery.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for buyers looking to manage inventory costs, as it can dictate how much product they must purchase at once.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a quote on specific products or services. For B2B buyers, issuing an RFQ can streamline the procurement process by clearly outlining their needs and enabling suppliers to provide competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC). They are crucial for international shipping agreements, clarifying the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk. Understanding Incoterms helps buyers manage logistics more effectively.

5. Lead Time

Lead time refers to the time it takes from placing an order to its delivery. This term is critical for B2B buyers to ensure that they can meet production schedules and avoid delays in their operations.

6. Warranty Period

The warranty period is the time frame during which the manufacturer guarantees the pump’s performance and covers repairs or replacements. Knowing the warranty terms can provide peace of mind and protect against unforeseen costs, making it a vital consideration for B2B buyers.

In summary, grasping these essential technical properties and trade terminologies enables international buyers to make informed decisions when investing in Brinkmann Pumps, fostering successful procurement strategies.

Navigating Market Dynamics and Sourcing Trends in the brinkmann pumps usa Sector

What Are the Key Market Dynamics and Trends Influencing Brinkmann Pumps in the USA?

The global market for fluid handling solutions, particularly in the B2B sector, is influenced by several dynamic factors. One of the most significant drivers is the increasing demand for efficient coolant and filtration systems in manufacturing processes. Industries in Africa, South America, the Middle East, and Europe are seeking reliable pump solutions to enhance operational efficiency and reduce downtime. As manufacturers strive for automation, the integration of digital technologies—such as pump monitoring and control systems—has become a crucial trend. This shift not only improves efficiency but also allows for predictive maintenance, reducing operational costs.

Emerging trends also highlight the importance of customization in pump solutions. International buyers are increasingly looking for tailored products that can meet specific industrial requirements. For instance, Brinkmann Pumps’ ability to offer stainless steel pumps designed for corrosive fluids demonstrates a commitment to meeting diverse customer needs. Moreover, the rise of Industry 4.0 is driving the demand for smart pumps that can be seamlessly integrated into existing systems, further enhancing the appeal of Brinkmann’s product offerings.

How Is Sustainability Shaping the Sourcing of Brinkmann Pumps?

Sustainability is becoming a central focus for B2B buyers, particularly in sectors with significant environmental impacts. The pump manufacturing industry is no exception, as companies are increasingly held accountable for their environmental footprint. International buyers are prioritizing suppliers who demonstrate a commitment to sustainability through ethical sourcing practices and environmentally friendly materials.

Brinkmann Pumps is well-positioned to meet these demands by focusing on sustainable manufacturing processes. The company’s use of high-quality stainless steel not only enhances product durability but also reduces the need for frequent replacements, contributing to lower resource consumption over time. Additionally, certifications related to environmental standards can serve as a key differentiator for buyers. By ensuring that their products meet ‘green’ certifications, Brinkmann Pumps can attract environmentally conscious customers looking for sustainable solutions.

What Is the Historical Context of Brinkmann Pumps in the B2B Market?

Established over 75 years ago, Brinkmann Pumps has evolved from a small manufacturing entity into a recognized leader in the fluid handling sector. Initially focused on basic pumping solutions, the company has consistently embraced innovation and technological advancements, positioning itself at the forefront of the industry. The company’s commitment to quality “Made in Germany” products has earned it a strong reputation among international buyers.

As the market landscape has transformed, Brinkmann Pumps has adapted by expanding its product line to include advanced digital solutions and customized pump systems. This evolution is not just about keeping pace with market demands but also reflects a proactive approach to addressing the challenges faced by B2B buyers today. The company’s ability to integrate cutting-edge technology with traditional craftsmanship continues to set it apart in a competitive market, making it a preferred choice for international buyers seeking reliable and innovative pumping solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of brinkmann pumps usa

-

How do I select the right Brinkmann pump for my application?

Choosing the right Brinkmann pump involves assessing your specific application needs, such as the type of fluid, flow rate, pressure requirements, and environmental conditions. Brinkmann offers a range of pumps, including centrifugal and screw-spindle models, each designed for different uses. Utilize the pump selection tools available on their website or consult with a Brinkmann sales representative to ensure you select a pump that meets your operational criteria effectively. -

What are the customization options available for Brinkmann pumps?

Brinkmann pumps can be tailored to meet specific industry requirements. Customization options may include variations in pump size, materials (such as stainless steel for corrosive fluids), and integration with digital monitoring systems. To explore customization possibilities, it is advisable to submit a special request through Brinkmann’s dedicated channels, allowing their engineering team to assess your needs and provide a suitable solution. -

What are the minimum order quantities (MOQs) for Brinkmann pumps?

The minimum order quantity for Brinkmann pumps varies based on the specific product line and customization requests. Generally, standard products may have lower MOQs, while custom solutions could require higher quantities. It is best to contact Brinkmann’s sales team directly to discuss your project requirements, as they can provide detailed information on MOQs and bulk purchasing options. -

What payment terms does Brinkmann Pumps offer for international orders?

Brinkmann Pumps typically offers various payment terms depending on the buyer’s location, order size, and relationship history. For international buyers, options may include bank transfers, letters of credit, or payment upon delivery. It’s essential to clarify payment terms upfront during negotiations to avoid any misunderstandings and ensure a smooth transaction process. -

How does Brinkmann ensure quality assurance for its pumps?

Quality assurance at Brinkmann Pumps is achieved through rigorous testing and adherence to international manufacturing standards. Each pump undergoes a series of inspections and performance tests before it is shipped to ensure reliability and efficiency. Clients can request detailed quality control documentation and certifications to verify compliance with industry standards for their specific markets. -

What logistics and shipping options are available for international buyers?

Brinkmann Pumps offers various logistics solutions for international shipping, including air and sea freight. The choice of shipping method may depend on factors like delivery time, cost, and the nature of the products. It is recommended to discuss your logistics needs with Brinkmann’s sales representatives, who can assist in coordinating shipping arrangements and providing estimated delivery timelines. -

Can I obtain spare parts for Brinkmann pumps easily?

Yes, spare parts for Brinkmann pumps are readily available through their official website and authorized distributors. The company provides an online request system for spare parts sets, ensuring that you can maintain your equipment with genuine components. For urgent needs, contacting their customer service can expedite the process, ensuring minimal downtime for your operations. -

What support does Brinkmann offer for installation and maintenance?

Brinkmann Pumps provides comprehensive support for installation and maintenance through user manuals, installation guides, and technical assistance from their team of experts. For complex installations or ongoing maintenance, customers can request on-site support or training sessions to ensure proper handling and optimal performance of their pumps. This proactive approach helps maximize the efficiency and longevity of the equipment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for brinkmann pumps usa

In today’s competitive landscape, strategic sourcing of high-quality pumps like those offered by Brinkmann Pumps USA is critical for optimizing operations and ensuring efficiency. Their extensive product range, including stainless steel and screw-spindle pumps, is designed to meet the diverse needs of industries worldwide. With over 75 years of expertise and a commitment to innovation, Brinkmann Pumps stands out as a reliable partner for businesses looking to enhance fluid handling processes.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, the value of engaging with Brinkmann Pumps cannot be overstated. Their solutions not only promise durability and efficiency but also align with sustainability goals, essential in today’s market. By leveraging Brinkmann’s advanced technology and digital solutions, companies can significantly improve their operational capabilities and reduce costs.

As we look ahead, now is the time to explore partnerships that drive growth and innovation. Reach out to Brinkmann Pumps USA to discuss tailored solutions that can elevate your business operations and meet the demands of a rapidly changing industrial environment. Together, we can pave the way for a successful and sustainable future.