Top 7 Grounding Sheets Made In Usa List and Guide: How To Solve S…

Introduction: Navigating the Global Market for grounding sheets made in usa

As international buyers seek to source high-quality grounding sheets made in the USA, a significant challenge arises: the current market is largely dominated by overseas manufacturing, particularly in regions like China and Vietnam. This guide addresses the complexities of sourcing these specialized products, which are often crafted from conductive materials like silver-threaded fabric. Here, we provide a comprehensive overview of the various types of grounding sheets available, their applications in wellness and health, and the critical aspects of supplier vetting to ensure quality and compliance with ethical manufacturing standards.

In this guide, B2B buyers from Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Brazil, will find valuable insights on navigating the intricate landscape of grounding products. We delve into cost considerations, production timelines, and the importance of supporting domestic manufacturing initiatives. By empowering buyers with actionable information, this resource aims to facilitate informed purchasing decisions, ultimately helping businesses invest in grounding sheets that enhance customer satisfaction and drive wellness trends in their respective markets.

Embrace the opportunity to connect with suppliers who prioritize quality and ethical practices, and discover how the future of grounding sheets can align with your business goals.

Top 10 Grounding Sheets Made In Usa Manufacturers & Suppliers List

1. GroundLuxe – Premium Grounding Sheets

Domain: groundluxe.com

Registered: 2019 (6 years)

Introduction: GroundLuxe is set to launch the first grounding sheets made in the USA in September 2025. These sheets will feature premium, American-made quality, ethically produced with fair labor standards, and sourced from high-quality, silver-threaded cotton. GroundLuxe aims to support domestic manufacturing and jobs.

2. Earthing Harmony – Grounding Sheets

Domain: earthingharmony.com

Registered: 2022 (3 years)

Introduction: Earthing Harmony offers #1 Grounding Sheets in the USA, made from a special blend of pure medical grade silver and skin-friendly cotton. Key benefits include improved sleep quality, enhanced recovery, reduced stress and anxiety, relief from chronic pain, improved mood and energy, and reduced inflammation. Available sizes include Flat – Single (35″ x 104″), Fitted – Twin XL (39″ x 80″), Fitted – Fu…

3. Grounding Well – Best Overall Grounding Sheet

Domain: globenewswire.com

Registered: 2007 (18 years)

Introduction: Consumer Reports Grounding Sheets 2025 Review highlights three top-rated grounding sheets made in the USA based on extensive testing. 1. Grounding Well Sheets (92/100): Best overall, featuring medical-grade silver fiber, 98% conductivity retention after 50 washes, 87% of users reported falling asleep 22 minutes faster, 300-thread-count organic cotton with 22% silver content, 3-year warranty. 2. Ma…

4. Earthing® – Grounding Products

Domain: earthing.com

Registered: 2001 (24 years)

Introduction: Earthing® & Grounding Products | The Original Grounding Innovators. Free shipping on domestic orders over $99. Various product categories including sleep accessories and clearance items. Information available on grounding and earthing, including a blog and FAQ section.

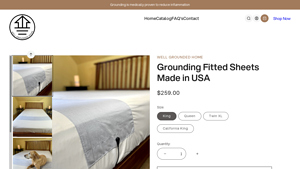

5. Well Grounded Home – Grounding Fitted Sheets

Domain: wellgroundedhome.com

Registered: 2024 (1 years)

Introduction: Grounding Fitted Sheets made in the USA, priced at $259. Available sizes: King, Queen, Twin XL, California King (currently sold out). Crafted from 100% natural cotton, designed for wellness and comfort. Features a grounding panel tailored to the sheet for consistent contact with feet and calves. Includes snap attachments for grounding cord on both sides, requiring only one side to be plugged in. C…

6. The Grounding Co – Grounding Sheets

Domain: thegrounding.co

Registered: 2023 (2 years)

Introduction: The Grounding Co offers a range of grounding products including:

1. **Grounding Sheets** – Available in various sizes:

– Fitted – Single (35 x 75 In)

– Fitted – Twin (39 x 75 In)

– Fitted – Twin XL (39 x 80 In)

– Fitted – Full (54 x 80 In)

– Fitted – Queen (60 x 80 In)

– Fitted – King (78 x 80 In)

– Fitted – California King (72 x 84 In)

– Price: $109.95 (regular price $23…

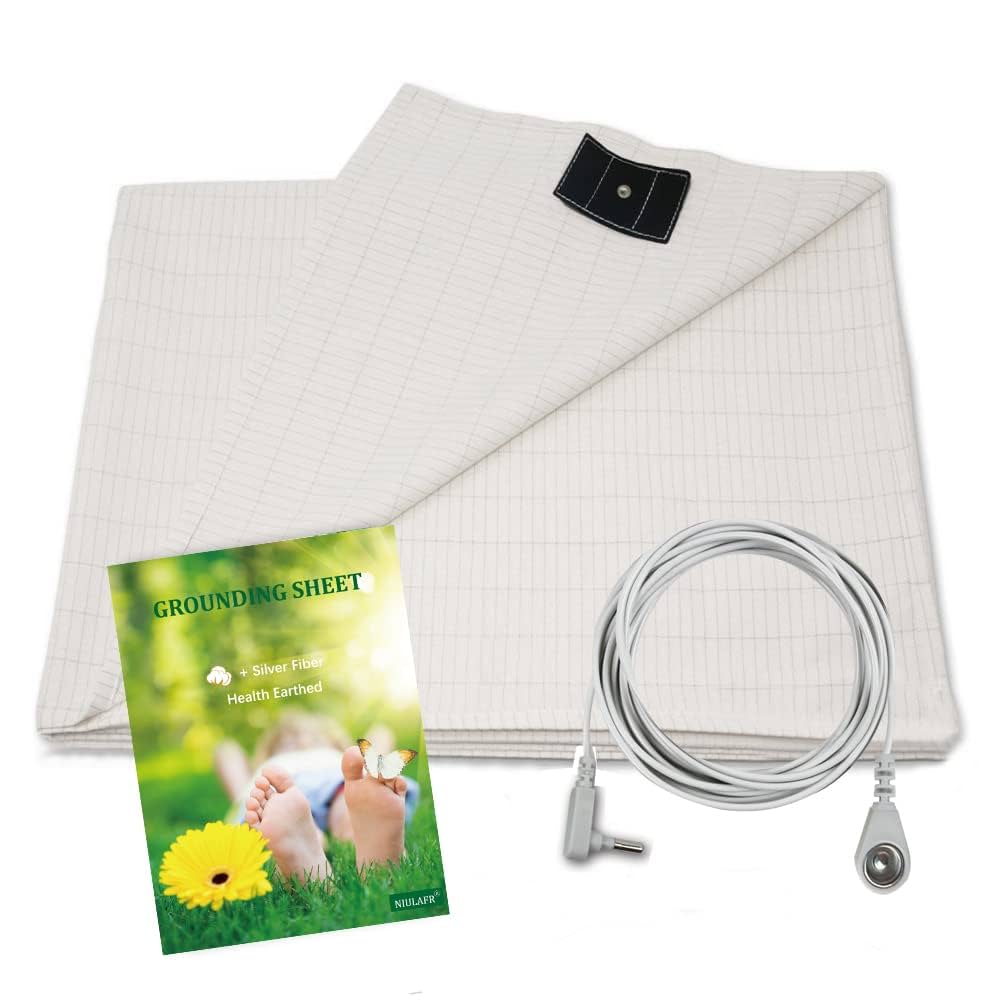

7. Orezon – Organic Grounding Bed Sheets

Domain: orezon.co

Registered: 2019 (6 years)

Introduction: Organic grounding bed sheets are specially designed with conductive materials like silver thread to connect with the earth while you sleep. They can be connected to a ground port of an electrical outlet, allowing beneficial electrons to flow into your body. These sheets are made from all-natural, organic materials and should have certifications such as USDA Certified Organic, GOTS Certified, or OE…

Understanding grounding sheets made in usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Silver-Threaded Cotton Sheets | Made with high-quality silver-threaded fabric | Health and wellness sectors | Pros: Effective grounding, improved sleep quality; Cons: Higher cost due to material sourcing. |

| Organic Cotton Sheets | Crafted from organic cotton with grounding properties | Eco-friendly product lines | Pros: Sustainable, appeals to health-conscious consumers; Cons: May lack conductivity compared to silver options. |

| Blended Fabric Sheets | Combination of cotton and synthetic grounding materials | Budget-friendly options | Pros: Cost-effective, versatile; Cons: May not provide the same grounding efficacy as pure silver or organic options. |

| Custom-Fit Grounding Sheets | Tailored to specific mattress sizes and designs | Luxury bedding retailers | Pros: Perfect fit for unique mattresses, enhances user experience; Cons: Longer lead times for production. |

| Travel Grounding Sheets | Lightweight and portable designs for on-the-go use | Hospitality and travel industries | Pros: Convenient for travelers, promotes wellness; Cons: Smaller surface area may limit effectiveness. |

What Are Silver-Threaded Cotton Sheets and Their Benefits for B2B Buyers?

Silver-threaded cotton sheets are the most recognized type of grounding sheets, offering a unique combination of conductivity and comfort. These sheets utilize high-quality silver fibers woven into the fabric, which allows for effective grounding by connecting the user to the Earth’s electrical energy. For B2B buyers, particularly in the health and wellness sectors, investing in these sheets can enhance product offerings aimed at improving sleep quality and reducing inflammation among consumers. However, their premium pricing due to the cost of silver sourcing can be a consideration for budget-conscious buyers.

How Do Organic Cotton Sheets Cater to Eco-Friendly Markets?

Organic cotton grounding sheets are crafted from sustainably sourced materials, appealing to businesses focused on eco-friendly products. These sheets provide a natural alternative to conventional bedding while still offering some grounding benefits. For B2B buyers, this type of sheet is ideal for companies looking to expand their product lines to include environmentally friendly options. While organic sheets can attract health-conscious consumers, their grounding efficacy may not be as high as that of silver-threaded varieties, which should be communicated transparently to potential customers.

What Makes Blended Fabric Sheets a Cost-Effective Choice?

Blended fabric grounding sheets incorporate a mix of cotton and synthetic materials to provide a more affordable alternative for buyers. These sheets are suitable for businesses targeting budget-conscious consumers or those entering the grounding market without significant investment. While they offer versatility and lower costs, buyers should note that the grounding efficacy might not match that of pure silver or organic options. This trade-off can be crucial when positioning products in a competitive market.

Why Are Custom-Fit Grounding Sheets Popular in Luxury Markets?

Custom-fit grounding sheets are designed to perfectly match specific mattress sizes and styles, making them a favored choice among luxury bedding retailers. This tailored approach not only enhances the user experience but also positions these products as premium offerings in the market. For B2B buyers, the ability to provide customized solutions can differentiate their brand and attract high-end clientele. However, the longer production times associated with custom orders may impact inventory management and delivery schedules.

How Do Travel Grounding Sheets Serve the Hospitality Industry?

Travel grounding sheets are lightweight and portable, making them ideal for the hospitality and travel industries. These sheets offer wellness benefits for travelers, promoting better sleep and relaxation during trips. For B2B buyers in these sectors, integrating travel grounding sheets into their offerings can enhance guest experiences and promote health-focused amenities. However, the smaller surface area of these sheets may limit their effectiveness, which should be considered when marketing to wellness-oriented consumers.

Key Industrial Applications of grounding sheets made in usa

| Industry/Sector | Specific Application of grounding sheets made in usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Patient recovery in hospitals and rehabilitation centers | Enhances patient comfort and promotes faster recovery | Compliance with health regulations; materials should be hypoallergenic and durable |

| Wellness and Spa | Use in spas and wellness centers for therapeutic treatments | Supports relaxation and stress relief for clients | Sourcing high-quality, ethically produced materials; customizable options for branding |

| Hospitality | Integration into hotel bedding for enhanced guest experience | Increases guest satisfaction and loyalty | Availability of bulk orders; ability to meet specific aesthetic and quality standards |

| Sports and Fitness | Application in training facilities and gyms for recovery | Aids in muscle recovery and reduces inflammation | Need for durable, easy-to-clean materials; potential for co-branding with fitness organizations |

| Home Goods Retail | Retailing to consumers for home use | Expands product offerings and meets growing demand for wellness products | Ensuring competitive pricing; establishing reliable supply chain logistics |

How Are Grounding Sheets Made in the USA Used in Healthcare Settings?

In healthcare settings, grounding sheets made in the USA can play a pivotal role in patient recovery within hospitals and rehabilitation centers. These sheets are designed to enhance patient comfort and potentially promote faster healing by reducing inflammation and improving sleep quality. For international buyers, particularly from regions like Africa and the Middle East, it’s essential to ensure compliance with local health regulations and standards, while also confirming that the materials used are hypoallergenic and durable to withstand frequent laundering.

What Benefits Do Grounding Sheets Offer in Wellness and Spa Industries?

In the wellness and spa industry, grounding sheets serve as a valuable addition to therapeutic treatments. They are used to create a relaxing environment that supports stress relief and overall well-being for clients. For B2B buyers in South America or Europe, sourcing high-quality, ethically produced materials is crucial, as this aligns with consumer preferences for sustainable products. Customizable options for branding can also enhance the appeal of these sheets in spa settings.

How Can Hotels Enhance Guest Experience with Grounding Sheets?

Hotels can integrate grounding sheets into their bedding offerings to significantly enhance the guest experience. By providing a product that promotes relaxation and improves sleep quality, hotels can increase guest satisfaction and foster loyalty. For international buyers, considerations such as bulk ordering capabilities and the ability to meet specific aesthetic and quality standards are critical to ensure a seamless integration into existing bedding systems.

Why Are Grounding Sheets Important for Sports and Fitness Facilities?

In sports and fitness facilities, grounding sheets can be utilized in training areas and recovery rooms to aid athletes in muscle recovery and reduce post-exercise inflammation. This application is particularly beneficial for facilities looking to provide comprehensive wellness solutions. Buyers from regions like Brazil and Saudi Arabia should prioritize sourcing durable materials that are easy to clean, as well as explore potential co-branding opportunities with fitness organizations to enhance marketability.

What Role Do Grounding Sheets Play in the Home Goods Retail Sector?

In the home goods retail sector, grounding sheets made in the USA can cater to the rising consumer interest in wellness products. Retailers can expand their product offerings by including these sheets, which are marketed for their health benefits, such as improved sleep and reduced stress. For buyers, ensuring competitive pricing and establishing a reliable supply chain logistics are essential to meet the demand while maintaining profitability in a competitive market.

3 Common User Pain Points for ‘grounding sheets made in usa’ & Their Solutions

Scenario 1: Sourcing Quality Grounding Sheets Made in the USA

The Problem: B2B buyers often face the challenge of finding high-quality grounding sheets that are genuinely made in the USA. Many products marketed as American-made are actually produced overseas, leading to concerns about quality, ethical manufacturing, and compliance with local standards. For companies focused on sustainability and ethical sourcing, this can be a significant hurdle, especially when they want to promote their products as eco-friendly or locally sourced.

The Solution: To ensure that you are sourcing authentic grounding sheets made in the USA, begin by researching manufacturers that are committed to domestic production. Look for companies that provide transparency in their supply chain, including details about their sourcing of materials, such as silver-threaded fabric. Request samples to evaluate the quality firsthand and verify certifications that confirm compliance with U.S. manufacturing standards. Additionally, engage in direct communication with manufacturers to understand their production processes and labor practices. This proactive approach not only mitigates risks associated with sourcing but also aligns your business with suppliers who share your values in sustainability and ethical practices.

Scenario 2: Managing Price Sensitivity in Grounding Products

The Problem: Price sensitivity is a common issue for B2B buyers, particularly in regions where cost constraints are prevalent. Grounding sheets made in the USA may come with a higher price tag due to local labor costs and material sourcing, which can deter potential customers, especially in competitive markets such as South America or parts of Africa where cheaper alternatives are readily available. This can create a dilemma for businesses wanting to provide high-quality products while remaining price-competitive.

The Solution: To address price sensitivity, consider positioning the grounding sheets as a premium product that offers long-term value through their durability and health benefits. Educate your clients about the superior quality and manufacturing ethics associated with American-made products. Incorporate testimonials and case studies from satisfied customers to illustrate the tangible benefits of using grounding sheets, such as improved sleep quality and reduced inflammation. Additionally, explore bulk purchasing options or loyalty programs to incentivize larger orders, making the investment more palatable for budget-conscious buyers. By framing the higher price as an investment in quality and well-being, you can create a compelling narrative that resonates with your target audience.

Scenario 3: Addressing Misconceptions About Grounding Sheets

The Problem: Many potential buyers may have misconceptions about grounding sheets, particularly regarding their effectiveness and how they work. This lack of understanding can lead to skepticism, making it difficult for B2B buyers to convince their clients to invest in grounding products. For instance, some may view grounding as a fad or may not be aware of the scientific research backing its health benefits, thus hindering sales opportunities.

The Solution: To combat misconceptions, develop a robust educational strategy that includes informative content on the science of grounding and its benefits. Create detailed product guides, white papers, or webinars that explain how grounding sheets work and the physiological effects they have on the body. Collaborate with wellness experts or health professionals to validate your claims and enhance credibility. Utilize social media platforms and your website to share informative articles, infographics, and video testimonials from satisfied users. This educational approach not only builds trust with potential buyers but also positions your brand as a thought leader in the grounding space, ultimately leading to increased sales and customer loyalty.

Strategic Material Selection Guide for grounding sheets made in usa

What Materials Are Commonly Used in Grounding Sheets Made in the USA?

When selecting grounding sheets, the choice of materials significantly influences product performance, durability, and overall effectiveness. Here, we analyze four common materials used in grounding sheets, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Silver-Threaded Fabric

Key Properties: Silver-threaded fabric is known for its excellent conductivity, which is crucial for grounding applications. It typically has a high temperature tolerance and can withstand frequent washing without losing its conductive properties.

Pros & Cons: The primary advantage of silver-threaded fabric is its superior conductivity, leading to effective grounding. However, it is relatively expensive compared to other materials, which may affect the overall product pricing. Additionally, the manufacturing complexity increases due to the need for specialized weaving techniques.

Impact on Application: This fabric is highly suitable for grounding sheets as it ensures efficient electron transfer, enhancing the user’s experience. However, care must be taken to avoid exposure to harsh chemicals during washing, as these can degrade the silver threads.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with international standards such as ASTM for textile safety. The higher cost may be a consideration for markets with budget constraints.

2. Cotton

Key Properties: Cotton is a natural fiber known for its breathability, softness, and comfort. It typically has a moderate temperature rating and is resistant to wear and tear.

Pros & Cons: The main advantage of cotton is its comfort and hypoallergenic properties, making it suitable for sensitive skin. However, its conductivity is significantly lower than that of silver-threaded fabrics, which may limit its grounding effectiveness. Additionally, cotton sheets may require more frequent replacement due to wear.

Impact on Application: Cotton grounding sheets may be less effective in high-performance applications where maximum conductivity is required. They are better suited for general use, where comfort is prioritized over conductivity.

Considerations for International Buyers: Cotton is widely accepted and compliant with various international standards, making it a safer choice for buyers in Europe and South America. However, buyers should consider sourcing organic cotton to meet eco-conscious consumer demands.

3. Polyester

Key Properties: Polyester is a synthetic material known for its durability and resistance to shrinking and stretching. It has a moderate temperature tolerance and is often blended with other fibers for enhanced performance.

Pros & Cons: The durability of polyester makes it a cost-effective option for grounding sheets, as it can withstand extensive use. However, its conductivity is inferior to silver-threaded fabrics, which can limit its effectiveness in grounding applications. Additionally, polyester can trap heat, making it less comfortable in warmer climates.

Impact on Application: Polyester is suitable for grounding sheets intended for high-traffic use but may not provide the desired grounding benefits. Its compatibility with various cleaning processes also makes it a practical choice for commercial applications.

Considerations for International Buyers: Buyers should be aware of the environmental implications of polyester production, as it may not align with sustainability goals. Compliance with environmental standards is essential, especially in regions with strict regulations.

4. Conductive Carbon Fiber

Key Properties: Conductive carbon fiber combines strength and lightweight characteristics with good conductivity. It has a high-temperature resistance and is known for its durability.

Pros & Cons: The key advantage of carbon fiber is its excellent strength-to-weight ratio, making it ideal for applications requiring durability without added weight. However, the cost of carbon fiber can be high, and its manufacturing process is complex, which may limit its availability.

Impact on Application: Grounding sheets made from conductive carbon fiber can provide effective grounding while being lightweight and easy to handle. This makes them suitable for both residential and commercial applications.

Considerations for International Buyers: Buyers should ensure that the carbon fiber used meets international safety and quality standards. The higher cost may be a barrier in price-sensitive markets, but the long-term durability could justify the investment.

Summary Table of Material Selection for Grounding Sheets

| Material | Typical Use Case for grounding sheets made in usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silver-Threaded Fabric | High-performance grounding applications | Superior conductivity | High cost, complex manufacturing | High |

| Cotton | General comfort-focused use | Soft, breathable, hypoallergenic | Lower conductivity, shorter lifespan | Medium |

| Polyester | High-traffic commercial applications | Durable, cost-effective | Inferior conductivity, heat retention | Low |

| Conductive Carbon Fiber | Lightweight, durable grounding sheets | Excellent strength-to-weight ratio | High cost, complex manufacturing | High |

This strategic material selection guide provides insights into the various materials used in grounding sheets, helping international B2B buyers make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for grounding sheets made in usa

What Are the Key Stages in the Manufacturing Process of Grounding Sheets Made in the USA?

The manufacturing process for grounding sheets involves several crucial stages that ensure the final product meets quality and performance standards. Understanding these stages can help B2B buyers evaluate the production capabilities of suppliers.

Material Preparation: How Are Raw Materials Sourced and Processed?

The primary material used in grounding sheets is conductive fabric, often woven with silver threads. In the USA, sourcing high-quality silver-threaded cotton can be challenging due to limited domestic production. Suppliers must establish reliable partnerships with textile manufacturers who can provide this specialized material.

Once sourced, the materials undergo a thorough preparation process, including cleaning, cutting, and treating to ensure optimal conductivity. This step is critical as it directly impacts the performance of the grounding sheets. Buyers should inquire about the origin of these materials and the supplier’s supply chain management practices to ensure they align with ethical and quality standards.

Forming: What Techniques Are Used to Create the Fabric?

The next stage is forming, where the prepared materials are woven or knitted into fabric. Advanced weaving techniques are employed to ensure that the conductive threads are evenly distributed throughout the fabric, maximizing its grounding capabilities.

This process often requires specialized machinery and skilled technicians familiar with textile engineering. Buyers should look for manufacturers that utilize modern technology and techniques to enhance fabric durability and conductivity. This can include methods such as warp knitting or jacquard weaving, which can produce a fabric that is both functional and aesthetically pleasing.

Assembly: How Are Grounding Sheets Constructed?

Once the fabric is formed, the assembly stage begins. This involves cutting the fabric into appropriate sizes and stitching it to create the final product, including features like fitted edges or pillowcases. Manufacturers may also integrate additional layers or treatments to enhance comfort and usability, such as breathable or hypoallergenic materials.

Quality assurance during assembly is vital. Buyers should verify that suppliers have established protocols to ensure that all seams are strong, and that the grounding sheets are free from defects. This can include visual inspections and functional tests to ensure that the grounding properties remain intact throughout the manufacturing process.

Finishing: What Final Touches Are Added to Ensure Quality?

The finishing stage involves several processes aimed at enhancing the appearance and performance of the grounding sheets. This may include washing, drying, and pressing the sheets to ensure they maintain their shape and feel. Treatments such as anti-static or moisture-wicking finishes may also be applied, which can further improve the product’s usability.

Quality control during this stage is essential. Manufacturers should adhere to strict guidelines to ensure that all sheets are consistent in quality and performance. B2B buyers should ask about the specific finishing processes used and any certifications that the final products may carry.

What Quality Control Measures Are Essential for Grounding Sheets Made in the USA?

Quality control (QC) is a critical aspect of the manufacturing process for grounding sheets. It ensures that the products not only meet customer expectations but also comply with international standards.

Which International Standards Should Grounding Sheet Manufacturers Adhere To?

Manufacturers of grounding sheets should comply with various international standards, such as ISO 9001, which focuses on quality management systems. This standard ensures that organizations consistently provide products that meet customer and regulatory requirements.

In addition to ISO certifications, compliance with industry-specific standards such as CE marking (for European markets) can be crucial. This certification indicates that the product meets health, safety, and environmental protection standards, which can be a significant selling point for international buyers.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control typically includes several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This is the initial inspection of raw materials to ensure they meet specified standards before production begins. Suppliers should have clear criteria for assessing the quality of incoming materials.

-

In-Process Quality Control (IPQC): During manufacturing, various checks are performed to monitor the production process. This may include testing for conductivity, fabric strength, and other relevant properties.

-

Final Quality Control (FQC): After assembly, the finished grounding sheets undergo comprehensive testing to ensure they meet all quality standards. This includes checking for defects, verifying dimensions, and ensuring that grounding capabilities are intact.

B2B buyers should request information about these QC checkpoints from potential suppliers to understand their commitment to quality assurance.

What Common Testing Methods Are Used to Ensure Product Quality?

Various testing methods are employed to verify the performance and safety of grounding sheets. Common tests include:

-

Conductivity Testing: This ensures that the fabric can effectively conduct electrical charges, which is crucial for grounding effectiveness.

-

Durability Testing: This assesses how well the sheets withstand washing, stretching, and general wear and tear.

-

Comfort Testing: Some manufacturers may conduct tests to evaluate the feel and breathability of the fabric, which can be important for user satisfaction.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying the quality control practices of potential suppliers is essential for B2B buyers, especially when sourcing products internationally.

What Steps Should Buyers Take to Ensure Supplier Compliance?

-

Conduct Audits: Buyers should consider performing onsite audits of their suppliers to assess their manufacturing processes and quality control measures firsthand.

-

Request Documentation: Suppliers should provide documentation of their quality management systems, including certifications and test reports. This transparency is crucial for establishing trust.

-

Engage Third-Party Inspectors: Employing third-party inspection services can provide an unbiased assessment of the supplier’s adherence to quality standards. This can be particularly beneficial for buyers from regions like Africa and South America, where establishing direct oversight may be more challenging.

-

Understand Certification Nuances: International buyers should be aware of the specific certifications required in their markets. For instance, grounding sheets exported to Europe must comply with CE regulations, while those sold in the Middle East may need to meet different standards.

By following these steps, B2B buyers can ensure they are partnering with reputable suppliers who prioritize quality in the manufacturing of grounding sheets made in the USA.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘grounding sheets made in usa’

To successfully procure grounding sheets made in the USA, international B2B buyers must navigate a complex landscape of sourcing, supplier verification, and quality assurance. This guide provides a structured approach to ensure you find a reliable supplier that meets your business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to clearly outline what you need. This includes the type of materials (e.g., silver-threaded fabric), dimensions, and any specific certifications or standards you require. Precise specifications help streamline the sourcing process and ensure that potential suppliers can meet your expectations.

Step 2: Research Market Availability

Investigate the current market for grounding sheets made in the USA. Since many products are manufactured overseas, identifying suppliers who are committed to domestic production is crucial. Utilize industry directories, trade shows, and online resources to compile a list of potential suppliers who align with your quality and ethical standards.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Key factors to consider include:

– Production Capacity: Ensure the supplier can meet your volume requirements.

– Quality Control Measures: Understand their processes for maintaining product quality.

Step 4: Verify Supplier Certifications

Confirm that suppliers possess relevant certifications, such as ISO or organic certifications for materials. This step is vital for ensuring that the grounding sheets meet quality and safety standards, particularly if they will be marketed to health-conscious consumers. Additionally, inquire about their labor practices to ensure ethical manufacturing.

Step 5: Request Samples for Evaluation

Once you’ve narrowed down your list of potential suppliers, request samples of their grounding sheets. This allows you to assess the product quality firsthand. Evaluate the sheets for:

– Material Quality: Check for the softness, breathability, and durability of the fabric.

– Conductivity: Ensure the grounding functionality is effective, as this is a key selling point for the product.

Step 6: Negotiate Terms and Pricing

Engage in discussions regarding pricing, payment terms, and delivery schedules. Ensure that all terms are clearly outlined in a contract to avoid misunderstandings later. Look for opportunities to negotiate bulk purchase discounts or favorable payment terms, especially if you plan to place large orders.

Step 7: Establish a Long-Term Relationship

After selecting a supplier, focus on building a strong business relationship. Regular communication can help address any issues quickly and foster collaboration for future orders. Consider setting up periodic reviews to evaluate product performance and supplier reliability, ensuring that your sourcing needs continue to be met effectively.

By following this structured approach, B2B buyers can confidently source grounding sheets made in the USA, ensuring high quality and ethical standards while meeting their business needs.

Comprehensive Cost and Pricing Analysis for grounding sheets made in usa Sourcing

What Are the Key Cost Components for Grounding Sheets Made in the USA?

When sourcing grounding sheets made in the USA, understanding the cost structure is crucial for international B2B buyers. The main components influencing the overall cost include:

-

Materials: The primary material for grounding sheets is silver-threaded fabric, which is expensive and difficult to source domestically. This high-quality material is essential for effective grounding and contributes significantly to the total cost.

-

Labor: Labor costs in the U.S. are typically higher than in countries where grounding sheets are commonly manufactured, such as China and Vietnam. Skilled labor is necessary for the intricate process of sewing and quality control, thus impacting the final pricing.

-

Manufacturing Overhead: This includes costs associated with maintaining production facilities, utilities, and administrative expenses. Since domestic manufacturing often involves higher operational costs, this can further elevate the price point.

-

Tooling and Equipment: Specialized machinery for producing conductive fabrics and sheets can be costly. The investment in state-of-the-art equipment to ensure high quality adds to the overall expense.

-

Quality Control (QC): Ensuring that each batch meets rigorous quality standards incurs additional costs. U.S. manufacturers often implement stringent QC processes to maintain product integrity, which can influence pricing.

-

Logistics: Domestic logistics costs, including shipping and warehousing, are often higher than overseas logistics. However, sourcing locally can reduce lead times and import duties.

-

Margin: Manufacturers typically add a margin to cover risks and ensure profitability. This margin can vary widely depending on the brand’s positioning, market strategy, and competition.

How Do Price Influencers Affect Grounding Sheets Sourcing?

Several factors can influence the pricing of grounding sheets for international buyers:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often qualify for bulk discounts, reducing the per-unit cost. Buyers should assess their needs to optimize order sizes.

-

Specifications and Customization: Customization requests, such as specific dimensions or additional features, can lead to increased costs. Standard specifications are generally more cost-effective.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., organic, fair trade) typically lead to higher prices. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a history of quality may charge a premium, while new entrants may offer competitive rates to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. They dictate the responsibility for shipping, insurance, and tariffs, which can affect total costs.

What Are Essential Buyer Tips for Cost Efficiency in Grounding Sheets?

To navigate the complexities of sourcing grounding sheets made in the USA, international buyers should consider the following strategies:

-

Negotiation: Engage in negotiations with suppliers to explore flexible pricing structures or payment terms. Many manufacturers are open to discussions, especially for larger orders.

-

Cost-Efficiency Analysis: Conduct a Total Cost of Ownership (TCO) analysis, which includes not just the purchase price but also shipping, handling, and potential tariffs. This comprehensive view can reveal hidden costs.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should consider currency fluctuations and local market conditions. Familiarizing themselves with local import regulations can also prevent unexpected expenses.

-

Establishing Long-term Relationships: Building a strong relationship with suppliers can lead to better pricing and priority service in future orders. Consistent business can often result in loyalty discounts.

Disclaimer on Indicative Prices

Prices for grounding sheets made in the USA can vary widely based on the factors discussed above. It is essential for buyers to conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing grounding sheets made in usa With Other Solutions

Exploring Alternatives to Grounding Sheets Made in the USA

In the quest for health benefits associated with grounding, various products and methods are available. Grounding sheets made in the USA promise premium quality and ethical production, but it’s essential for B2B buyers to consider alternative solutions that might offer similar benefits. Below, we compare grounding sheets with two viable alternatives: grounding mats and earthing pads.

| Comparison Aspect | Grounding Sheets Made In USA | Grounding Mats | Earthing Pads |

|---|---|---|---|

| Performance | High-quality silver-threaded fabric ensures effective grounding. | Moderate grounding effectiveness depending on surface area covered. | Good for localized grounding; effective when in direct contact with skin. |

| Cost | Premium pricing expected due to U.S. manufacturing. | Generally lower cost; varies by brand and material. | Usually affordable; prices vary based on size and brand. |

| Ease of Implementation | Requires full bedding setup; easy to install on existing mattresses. | Easy to use; can be placed on the floor or under furniture. | Highly portable; can be used on the go or in specific locations. |

| Maintenance | Machine washable but requires care to preserve conductive properties. | Low maintenance; typically needs occasional cleaning. | Minimal upkeep; can be wiped clean as needed. |

| Best Use Case | Ideal for individuals seeking a comprehensive grounding experience while sleeping. | Suitable for users needing grounding while working or relaxing at home. | Best for targeted grounding during travel or short periods. |

What Are the Pros and Cons of Grounding Mats?

Grounding mats serve as an alternative to grounding sheets by allowing users to connect with the earth’s energy while sitting or standing. They are generally more affordable and can be easily placed under desks or used while lounging. However, their effectiveness may be limited compared to full bedding solutions, as they only cover a smaller area. This makes them less suitable for those looking for a comprehensive grounding experience during sleep.

How Do Earthing Pads Compare to Grounding Sheets?

Earthing pads are another option that provides localized grounding benefits. They are typically small, portable, and can be used on various surfaces, making them ideal for targeted grounding during travel or at work. While they are easy to use and maintain, their effectiveness is contingent on direct skin contact. This could limit their appeal for users who prefer a full-body grounding experience that sheets provide during sleep.

How Can B2B Buyers Choose the Right Grounding Solution?

When selecting between grounding sheets made in the USA and alternative solutions, B2B buyers should assess their specific needs. Consider factors such as the desired level of grounding, budget constraints, and the intended use case (e.g., sleeping, working, or traveling). Grounding sheets offer a premium experience, particularly for those focused on quality and ethical manufacturing. However, for businesses seeking more flexible or budget-friendly options, grounding mats and earthing pads may be suitable alternatives that still provide grounding benefits. Ultimately, understanding the unique advantages and limitations of each solution will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for grounding sheets made in usa

What Are the Essential Technical Properties of Grounding Sheets Made in the USA?

When considering grounding sheets for B2B procurement, understanding the technical specifications is crucial for ensuring product quality and performance. Here are some key properties to consider:

1. Material Composition

Grounding sheets are primarily made from conductive materials, often featuring silver-threaded fabric. The silver content plays a vital role in conductivity, allowing the sheet to effectively transfer the Earth’s electrical energy. For B2B buyers, ensuring high-quality materials can enhance product efficacy and durability, leading to increased customer satisfaction and reduced return rates.

2. Thread Count

The thread count of grounding sheets refers to the number of threads woven into a square inch of fabric. A higher thread count typically indicates a denser and more durable fabric, which can improve the sheet’s lifespan and comfort. Buyers should assess thread count to ensure they are investing in sheets that will withstand regular use while providing a comfortable sleeping experience.

3. Conductivity Level

This specification measures how well the fabric can conduct electrical charges. Conductivity is typically measured in ohms per square meter (Ω/m²). For grounding sheets, a lower resistance indicates better conductivity, which is essential for achieving the desired health benefits associated with grounding. B2B buyers should prioritize products with optimal conductivity levels to maximize effectiveness.

4. Certification Standards

Products made in the USA may adhere to specific certification standards, such as Oeko-Tex Standard 100, which ensures textiles are free from harmful substances. Certification is crucial for B2B buyers who prioritize safety and compliance, as it can significantly impact their brand reputation and customer trust.

5. Size and Fit

Grounding sheets come in various sizes, including twin, full, queen, and king. Ensuring the correct fit for mattresses is essential for functionality and customer satisfaction. B2B buyers should verify that their suppliers offer a range of sizes to accommodate different mattress dimensions in the market.

6. Care Instructions

Understanding the care requirements for grounding sheets is vital for maintaining product integrity. This includes washing and drying recommendations that preserve the conductive properties of the fabric. Buyers should ensure that care instructions are clearly communicated to end-users to prevent product damage and maintain performance.

What Are Common Trade Terms Related to Grounding Sheets Made in the USA?

Familiarity with industry terminology can streamline the purchasing process and enhance communication between buyers and suppliers. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products that are sold under another company’s brand name. For grounding sheets, knowing if a supplier operates as an OEM can help buyers understand the supply chain and quality control processes involved in production.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is critical for B2B buyers to ensure they can meet their inventory needs without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For grounding sheets, submitting an RFQ can help buyers compare pricing, terms, and product specifications across different suppliers to make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms is crucial for B2B buyers to understand their obligations and risks associated with shipping grounding sheets across borders.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For grounding sheets, understanding lead times is essential for inventory management and meeting customer demand.

6. Warranty

A warranty is a guarantee that a product will meet certain performance standards over a specified period. For grounding sheets, knowing the warranty terms can protect B2B buyers against defects and ensure product reliability.

By understanding these essential properties and trade terms, international B2B buyers can make informed decisions when sourcing grounding sheets made in the USA, ultimately leading to better business outcomes.

Navigating Market Dynamics and Sourcing Trends in the grounding sheets made in usa Sector

What Are the Key Market Dynamics and Trends Affecting Grounding Sheets Made in the USA?

The grounding sheets market is experiencing a notable shift driven by increased consumer awareness of health and wellness, particularly in the wake of the global pandemic. This heightened focus on physical well-being has led to a surge in demand for grounding products, including sheets that claim to promote better sleep and reduce inflammation. For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, this represents a unique opportunity to capitalize on a growing market segment.

One of the primary challenges in sourcing grounding sheets is the historical reliance on overseas manufacturing, mainly in countries like China and Vietnam. However, a new trend is emerging as brands like Groundluxe are looking to bring production back to the USA, starting in late 2025. This transition is expected to provide American-made products that meet higher quality and ethical manufacturing standards, appealing to buyers who prioritize sustainability and local sourcing.

Additionally, technological advancements in textile manufacturing are opening avenues for more efficient and cost-effective production of conductive fabrics. B2B buyers should keep an eye on innovations in sourcing strategies, including partnerships with domestic suppliers and manufacturers that can meet the evolving demand for high-quality grounding products.

How Is Sustainability and Ethical Sourcing Shaping the Grounding Sheets Market?

Sustainability and ethical sourcing are becoming increasingly important in the B2B landscape, particularly for products like grounding sheets made in the USA. Environmental concerns regarding the textile industry, which has a significant carbon footprint due to overseas shipping and manufacturing processes, are pushing businesses to seek out greener alternatives.

Brands that commit to ethical sourcing and manufacturing practices are likely to gain a competitive edge. This includes utilizing organic cotton and silver-threaded fabrics sourced from sustainable suppliers. Moreover, certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX can help verify the environmental impact and safety of these products, making them more attractive to discerning buyers.

For international buyers, emphasizing sustainability in procurement processes not only aligns with global trends but also meets the growing demand from consumers who are increasingly aware of the importance of ethical products. Engaging with suppliers who prioritize eco-friendly materials and practices can enhance brand reputation and foster customer loyalty.

What Is the Evolution of Grounding Sheets and Their Market?

The concept of grounding, or earthing, has its roots in ancient practices but has gained modern traction as a health and wellness trend. Grounding sheets are designed to connect individuals to the Earth’s natural electric charge, purportedly offering various health benefits such as improved sleep, reduced inflammation, and enhanced energy levels.

Historically, grounding products were primarily manufactured overseas, leading to a perception of lower quality among international buyers. However, as consumer preferences evolve, there is a growing demand for American-made grounding sheets that assure quality, ethical production, and sustainability. The anticipated launch of domestically produced grounding sheets in late 2025 signifies a pivotal moment in the market’s evolution, providing new opportunities for B2B buyers looking to source high-quality products that resonate with contemporary values of health and sustainability.

In summary, the grounding sheets market is poised for growth driven by consumer demand for wellness products, sustainability, and ethical sourcing practices. International buyers should stay informed on these trends to leverage the emerging opportunities within this sector.

Frequently Asked Questions (FAQs) for B2B Buyers of grounding sheets made in usa

-

1. How do I ensure the quality of grounding sheets sourced from the USA?

To ensure the quality of grounding sheets, request samples from potential suppliers. Look for certifications that demonstrate adherence to industry standards, such as OEKO-TEX or GOTS for organic textiles. Additionally, inquire about the materials used, specifically the type and quality of silver-threaded fabric. Establishing a clear quality assurance process, including regular audits and inspections, will also help maintain high standards throughout production. -

2. What are the benefits of sourcing grounding sheets made in the USA?

Sourcing grounding sheets made in the USA provides several advantages, including higher quality control, ethical manufacturing practices, and support for local economies. American-made products often adhere to stricter labor and environmental regulations, ensuring that your supply chain is responsible. Furthermore, products manufactured domestically can offer quicker turnaround times and reduced shipping costs, which are critical factors for timely inventory replenishment. -

3. What customization options are available for grounding sheets?

Many manufacturers offer customization options for grounding sheets, including variations in size, fabric type, and thread count. You can also request specific designs, colors, or branding features to align the product with your company’s identity. Discuss your requirements with potential suppliers early in the negotiation process to understand their capabilities and lead times for custom orders. -

4. What is the minimum order quantity (MOQ) for grounding sheets?

The minimum order quantity for grounding sheets can vary significantly between suppliers. Generally, MOQs may range from 100 to 1,000 units, depending on the manufacturer’s production capabilities and inventory management. It’s important to communicate your needs upfront, as some suppliers may offer flexibility in MOQs for first-time buyers or larger orders, facilitating a partnership that suits your business model. -

5. How should I evaluate potential suppliers of grounding sheets?

When evaluating suppliers, consider factors such as their manufacturing capabilities, industry experience, and customer reviews. Request references and case studies to assess their reliability and quality. Additionally, examine their adherence to ethical and sustainability standards. Conducting a site visit or virtual audit can provide further insights into their operations and help build trust before entering a contract. -

6. What payment terms are typical for international B2B transactions?

Payment terms for international B2B transactions typically involve a combination of upfront deposits and balance payments upon delivery. Common practices include a 30% deposit upon order confirmation and the remaining 70% before shipping or upon receipt of goods. It’s crucial to negotiate terms that safeguard both parties, potentially including letters of credit or escrow services to ensure compliance with the agreement. -

7. What logistics considerations should I keep in mind when importing grounding sheets?

Logistics considerations include shipping methods, customs clearance, and potential tariffs or duties. Choose a reliable freight forwarder experienced in handling textile imports to navigate these complexities. Ensure that all necessary documentation, such as bills of lading and customs declarations, is accurately prepared to avoid delays. Additionally, factor in lead times for production and shipping to align with your inventory needs. -

8. How can I address potential supply chain disruptions when sourcing grounding sheets?

To address potential supply chain disruptions, diversify your supplier base by identifying multiple manufacturers in different regions. Establishing strong relationships with suppliers can also lead to better communication and quicker problem resolution. Implementing a robust risk management strategy, including contingency planning for inventory shortages and alternative logistics options, will help ensure continuity in your supply chain.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for grounding sheets made in usa

As the demand for grounding sheets continues to grow, international B2B buyers must navigate the complexities of sourcing quality products. The current landscape reveals that most grounding sheets are manufactured overseas, primarily in China and Vietnam, due to cost and supply chain limitations. However, the anticipated introduction of domestically manufactured grounding sheets in the USA signals a pivotal shift towards premium quality and ethical production.

Why Should You Consider Sourcing Grounding Sheets Made in the USA?

Investing in American-made grounding sheets offers several advantages: superior craftsmanship, compliance with rigorous labor standards, and the potential for enhanced brand reputation among consumers who prioritize sustainability and ethical sourcing. This emerging market presents a unique opportunity for B2B buyers from regions like Africa, South America, the Middle East, and Europe to differentiate their offerings by aligning with a growing trend towards quality and local production.

What’s Next for International B2B Buyers?

As Groundluxe prepares to launch its American-made grounding sheets in late 2025, now is the time to strategize your sourcing plans. By engaging with suppliers early, you can position your business to meet the rising consumer demand for high-quality, ethically produced bedding. Embrace this opportunity to enhance your product lineup and cater to a market increasingly focused on health and wellness. Connect with us to stay informed about product launches and explore how you can be part of this transformative shift in the grounding sheet industry.