Top 4 Khs Usa Waukesha List and Guide: How To Solve Scenario 1: I…

Introduction: Navigating the Global Market for khs usa waukesha

In today’s competitive landscape, international B2B buyers face the significant challenge of sourcing reliable and innovative filling and packaging solutions that meet the diverse needs of their markets. KHS USA, based in Waukesha, stands out as a key player in this arena, offering advanced systems designed to optimize efficiency and sustainability in beverage production. This comprehensive guide aims to navigate the global market for KHS USA, providing insights into various product types, applications, and strategies for effective supplier vetting.

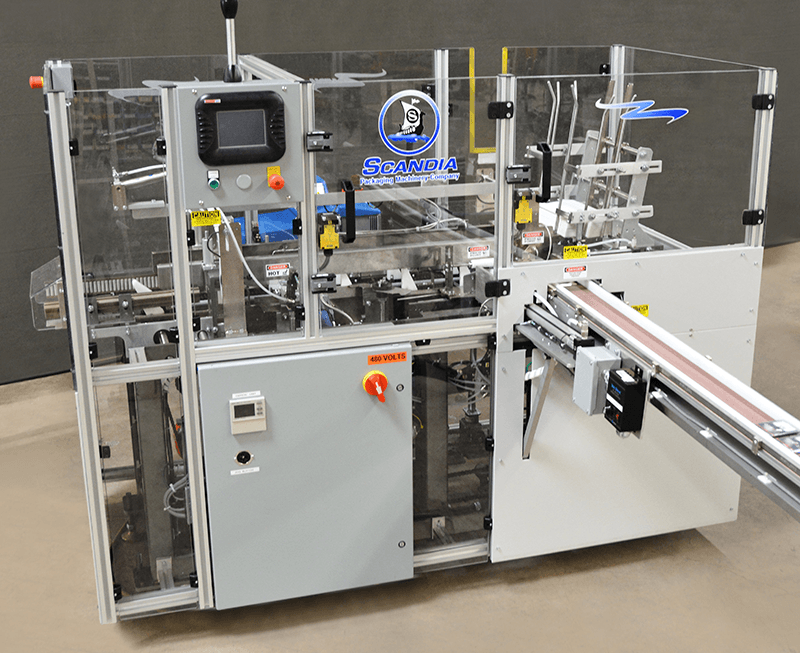

As you explore this guide, you will gain an in-depth understanding of KHS USA’s offerings, including their recent expansions into compact packaging through the acquisition of Scandia Packaging Machinery. We will delve into cost considerations, technology advancements, and sustainability initiatives that KHS is championing, helping you make informed purchasing decisions.

This resource is particularly tailored for B2B buyers from Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Germany, who are looking to enhance their operational capabilities. By leveraging the insights provided, you can confidently assess how KHS USA’s solutions can drive value creation in your production processes, ensuring that your investment aligns with your long-term strategic goals.

Top 10 Khs Usa Waukesha Manufacturers & Suppliers List

1. KHS – Beverage Processing Solutions

Domain: khs.com

Registered: 1995 (30 years)

Introduction: KHS offers a wide range of machines and equipment for various beverages including beer, still water, soft drinks, milk, juice, iced tea, sparkling wine, wine, and spirits. Their products include high-quality, technologically sophisticated single machines and process components, turnkey systems, and solutions for filling and packaging lines. Key features include: PET bottles, container design, recy…

2. KHS – Innovative Filling and Packaging Solutions

3. KHS USA – Filling and Capping Machinery

Domain: packworld.com

Registered: 1995 (30 years)

Introduction: KHS USA offers filling and capping machinery designed for liquid and viscous products. Their systems are tailored for various industries, ensuring high efficiency and precision in packaging processes.

4. ZipRecruiter – Job Opportunities in Waukesha, WI

Understanding khs usa waukesha Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Filling Systems | High precision, versatile for various beverage types | Soft drinks, beer, juices, and dairy products | Pros: High efficiency, customizable; Cons: Initial investment can be substantial. |

| Packaging Technology | Advanced solutions for primary and secondary packaging | Bottling and canning lines, ready-to-drink products | Pros: Reduces waste and enhances sustainability; Cons: May require specialized training for operation. |

| PET Bottle Technology | Focus on lightweight, recyclable PET bottle solutions | Beverage and liquid food industries | Pros: Eco-friendly, cost-effective; Cons: Limited to specific product types. |

| Automation Solutions | Integration of robotics and digital monitoring systems | High-volume production environments | Pros: Increases production speed and accuracy; Cons: High upfront costs and maintenance complexity. |

| Service & Maintenance | Comprehensive support including remote diagnostics | All KHS equipment users | Pros: Reduces downtime, enhances reliability; Cons: Ongoing service contracts can be costly. |

What Are the Key Characteristics of KHS USA Waukesha’s Filling Systems?

KHS USA Waukesha’s filling systems are designed for high efficiency and precision, accommodating a wide range of beverages, from carbonated drinks to sensitive dairy products. These systems are customizable, allowing businesses to tailor them to their specific production needs. When considering a filling system, buyers should evaluate factors such as production volume, beverage types, and the potential for future scalability.

How Does KHS USA Waukesha’s Packaging Technology Benefit Businesses?

KHS USA’s packaging technology offers innovative solutions that streamline both primary and secondary packaging processes. These systems are engineered to minimize waste while ensuring products are securely packaged for distribution. B2B buyers should consider the environmental impact of packaging choices and the potential for cost savings through efficiency improvements when selecting packaging technology.

Why Choose KHS USA Waukesha’s PET Bottle Technology?

KHS USA specializes in PET bottle technology that emphasizes lightweight and recyclable designs. This technology is particularly suitable for the beverage and liquid food industries, where sustainability is becoming increasingly crucial. Buyers should assess the compatibility of PET solutions with their product lines and consider the long-term cost benefits associated with using recyclable materials.

What Advantages Do Automation Solutions from KHS USA Waukesha Offer?

KHS USA’s automation solutions integrate advanced robotics and digital monitoring systems to enhance production speed and accuracy. These solutions are ideal for high-volume production environments, offering significant operational efficiencies. However, buyers should be prepared for higher initial costs and the complexity of maintenance associated with automated systems.

How Important Is Service & Maintenance for KHS USA Waukesha Equipment?

KHS USA provides comprehensive service and maintenance options, including remote diagnostics to ensure equipment reliability. This ongoing support is essential for minimizing downtime and maintaining high production standards. Businesses should factor in the costs of service contracts when evaluating their total investment in KHS equipment, as well as the potential return on investment through reduced operational disruptions.

Key Industrial Applications of khs usa waukesha

| Industry/Sector | Specific Application of khs usa waukesha | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Beverage Manufacturing | Complete filling and packaging systems | Enhanced efficiency and reduced downtime | Reliability of machinery, after-sales support |

| Food Processing | Aseptic filling technology for juices | Extended shelf-life and improved product safety | Compliance with international food safety standards |

| Brewery Equipment | Low-oxygen beer filling systems | Maintains flavor integrity and reduces CO2 consumption | Customization options for specific beer styles |

| Packaging Solutions | Compact cartoning and secondary packaging | Adaptability to market trends for single-serve products | Flexibility in design and scalability of operations |

| Digital Solutions | Remote diagnostics and maintenance services | Increased operational uptime and proactive problem-solving | Integration with existing systems and training needs |

How Does KHS USA Waukesha Address the Needs of the Beverage Manufacturing Sector?

In the beverage manufacturing industry, KHS USA Waukesha offers complete filling and packaging systems that enhance operational efficiency. These systems are designed to minimize downtime, ensuring that production lines run smoothly and consistently. For international buyers, particularly in regions like Africa and South America, the reliability of machinery is paramount. Additionally, KHS provides robust after-sales support, which is crucial for maintaining equipment in remote locations.

What Solutions Does KHS Provide for Food Processing Industries?

KHS USA specializes in aseptic filling technology tailored for juice production, allowing products to have an extended shelf-life while ensuring safety and quality. This technology is particularly valuable for companies looking to export their products to markets with stringent food safety regulations, such as in Europe and the Middle East. Buyers must consider compliance with international standards and the technological adaptability of KHS systems to meet local regulations.

How Does KHS Enhance Brewery Operations?

KHS USA’s low-oxygen beer filling systems are designed to maintain flavor integrity and reduce CO2 consumption, addressing a significant concern for breweries. This technology is essential for craft breweries aiming to differentiate their products in competitive markets, especially in Europe and North America. Buyers should evaluate customization options that cater to specific beer styles and production capacities to ensure optimal performance.

What Packaging Solutions Are Offered by KHS for Diverse Industries?

KHS USA has expanded its portfolio to include compact cartoning and secondary packaging solutions, catering to the growing demand for single-serve products. This adaptability helps businesses respond to market trends effectively. For B2B buyers, especially in emerging markets, flexibility in design and scalability of operations are key considerations when sourcing these packaging solutions.

How Does KHS USA Incorporate Digital Solutions for Operational Efficiency?

KHS USA offers remote diagnostics and maintenance services that enhance operational uptime, allowing businesses to address issues proactively. This feature is particularly beneficial for international buyers who may face challenges with on-site maintenance. When sourcing these digital solutions, companies should consider how well these services can integrate with their existing systems and the training requirements for their staff to ensure effective implementation.

3 Common User Pain Points for ‘khs usa waukesha’ & Their Solutions

Scenario 1: Inconsistent Product Quality during Scaling Up Production

The Problem: As beverage manufacturers expand their operations, maintaining consistent product quality becomes a pressing challenge. B2B buyers working with KHS USA in Waukesha often face issues related to the scaling of production lines. The introduction of new machines or technologies can lead to variations in product specifications, affecting taste, carbonation levels, and packaging integrity. This inconsistency can damage brand reputation and lead to costly recalls, making it imperative for buyers to address quality control proactively.

The Solution: To tackle this problem, buyers should leverage KHS USA’s robust support systems, particularly their training and consultation services. Engaging with KHS’s expertise at the onset of scaling operations can ensure that production lines are optimized for consistent output. Buyers should specify their quality requirements clearly and ask for a comprehensive assessment of their existing processes. KHS can provide tailored solutions, including inspections and adjustments to machinery settings, to align with industry standards. Regular training sessions for operational staff on new equipment can also enhance their understanding of quality control measures. This proactive approach not only minimizes quality variations but also builds a sustainable production model.

Scenario 2: High Energy Costs and Environmental Compliance

The Problem: With increasing pressure to reduce operational costs and meet environmental regulations, beverage manufacturers are often caught in a bind. B2B buyers may find that traditional filling and packaging systems lead to excessive energy consumption and waste, impacting both profitability and compliance with sustainability initiatives. This concern is particularly relevant for international buyers who must navigate varying regulatory environments across regions like Africa and Europe.

The Solution: KHS USA offers innovative, energy-efficient solutions that can help buyers significantly reduce their carbon footprint. To address high energy costs, buyers should explore KHS’s advanced technologies, such as the InnoPET Blomax and the NRET PET line. These systems are designed to optimize resource usage while ensuring compliance with sustainability standards. By conducting a thorough energy audit in collaboration with KHS engineers, buyers can identify specific areas for improvement. Implementing KHS’s lightweight packaging solutions and investing in automation technologies can also enhance efficiency and reduce waste. Buyers should prioritize sustainable practices and align their operations with KHS’s offerings to achieve both cost savings and regulatory compliance.

Scenario 3: Complex Maintenance Needs and Downtime Risks

The Problem: Downtime due to equipment failure can be detrimental to beverage production, especially for businesses reliant on KHS machinery. B2B buyers may struggle with understanding maintenance schedules and the need for timely interventions, leading to unexpected halts in production and financial losses. The complexity of modern filling and packaging lines can also make it challenging for in-house teams to handle maintenance effectively.

The Solution: To mitigate downtime risks, B2B buyers should consider establishing a comprehensive service contract with KHS USA. This contract should encompass regular maintenance checks and diagnostics to ensure optimal machine performance. Buyers should also invest in KHS’s digital services, such as remote diagnostic tools and the ConnectApp, which provide real-time monitoring and troubleshooting capabilities. By setting up a proactive maintenance schedule and utilizing KHS’s expertise in equipment management, buyers can significantly reduce the likelihood of unexpected breakdowns. Furthermore, training sessions provided by KHS can equip in-house teams with the necessary skills to perform routine checks and minor repairs, thereby enhancing operational efficiency and minimizing downtime.

Strategic Material Selection Guide for khs usa waukesha

What Are the Key Materials Used in KHS USA Waukesha Products?

When selecting materials for beverage filling and packaging systems, KHS USA in Waukesha employs a variety of materials, each with distinct properties and applications. Understanding these materials is crucial for international B2B buyers to make informed decisions. Below, we analyze four common materials used in KHS products, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from diverse regions.

How Does Stainless Steel Benefit KHS Equipment?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It is particularly suitable for environments where hygiene is paramount, such as in the beverage industry.

Pros & Cons: The durability of stainless steel ensures a long lifespan, making it a cost-effective choice over time. However, its initial manufacturing cost can be high, and the complexity of fabrication may lead to longer lead times for custom parts.

Impact on Application: Stainless steel is compatible with a wide range of media, including acidic beverages and carbonated drinks, making it ideal for filling and packaging applications.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with relevant standards such as DIN and ASTM, which govern material specifications and safety.

What Role Does PET Play in KHS Packaging Solutions?

Key Properties: Polyethylene Terephthalate (PET) is lightweight, recyclable, and offers good barrier properties against moisture and gases. It is also resistant to impact, making it a popular choice for beverage containers.

Pros & Cons: PET’s lightweight nature reduces shipping costs and energy consumption during transport. However, its lower temperature resistance compared to metals can limit its use in certain high-temperature applications.

Impact on Application: PET is particularly suitable for soft drinks and water, providing a cost-effective solution for manufacturers looking to reduce packaging weight without compromising product integrity.

Considerations for International Buyers: In regions like Africa and South America, where recycling capabilities may vary, buyers should consider the local infrastructure for PET recycling to ensure sustainability goals are met.

Why Is Aluminum a Preferred Material for Beverage Cans?

Key Properties: Aluminum is lightweight, has excellent corrosion resistance, and is a good conductor of heat. It can be easily formed into various shapes, making it versatile for different packaging needs.

Pros & Cons: The recyclability of aluminum is a significant advantage, as it can be reused multiple times with minimal quality loss. However, the cost of aluminum can be higher than other materials, and its manufacturing process can be energy-intensive.

Impact on Application: Aluminum is ideal for carbonated beverages, as it maintains product freshness and prevents light exposure, which can degrade flavor.

Considerations for International Buyers: Buyers in regions such as Saudi Arabia and Germany should be aware of local recycling regulations and sustainability initiatives that may influence their material choices.

What Are the Advantages of Glass in KHS Beverage Packaging?

Key Properties: Glass is chemically inert, providing excellent protection against contamination. It can withstand high temperatures and offers superior barrier properties against oxygen and moisture.

Pros & Cons: Glass is highly durable and recyclable, but its weight can increase transportation costs. Additionally, glass is more prone to breakage, which can pose challenges in handling and storage.

Impact on Application: Glass is often used for premium beverages, such as craft beers and juices, where product quality and presentation are critical.

Considerations for International Buyers: Buyers should consider the logistics of glass transportation, especially in regions with less developed infrastructure, to mitigate the risk of breakage during shipping.

Summary Table of Material Selection for KHS USA Waukesha

| Material | Typical Use Case for khs usa waukesha | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Filling systems for various beverages | High durability and corrosion resistance | High initial cost and complexity | High |

| PET | Bottles for soft drinks and water | Lightweight and recyclable | Limited high-temperature resistance | Medium |

| Aluminum | Cans for carbonated beverages | Excellent recyclability | Higher cost and energy-intensive manufacturing | Medium |

| Glass | Premium beverage packaging | Superior barrier properties | Heavy and prone to breakage | High |

Understanding these materials and their implications can empower international B2B buyers to make strategic decisions that align with their operational needs and sustainability goals.

In-depth Look: Manufacturing Processes and Quality Assurance for khs usa waukesha

What Are the Main Stages of the Manufacturing Process at KHS USA in Waukesha?

At KHS USA in Waukesha, the manufacturing process for filling and packaging systems encompasses several critical stages: material preparation, forming, assembly, and finishing. Each stage is vital in ensuring that the equipment meets the high standards expected in the beverage industry.

-

Material Preparation: This initial stage involves sourcing high-quality materials that comply with industry specifications. KHS emphasizes the importance of using durable and sustainable materials, particularly in the production of components for filling and packaging systems. Suppliers are carefully selected based on their ability to meet KHS’s stringent quality and sustainability criteria.

-

Forming: In this stage, raw materials are transformed into components using advanced manufacturing techniques. For example, KHS employs precision machining and injection molding processes to create parts like bottle molds and filling heads. These methods ensure that the components are not only accurate but also capable of withstanding the rigors of high-volume production.

-

Assembly: After forming, the components undergo an intricate assembly process. KHS utilizes both automated and manual assembly techniques to ensure that every system is built to specification. This hybrid approach allows for flexibility and precision, ensuring that complex machinery functions seamlessly.

-

Finishing: The final stage involves testing and quality checks to ensure that the systems meet KHS’s high performance and aesthetic standards. This includes surface treatments and final inspections, which guarantee that the products are ready for deployment in the field.

What Key Techniques Are Employed in KHS USA’s Manufacturing?

KHS USA employs a range of advanced manufacturing techniques that enhance the efficiency and quality of its production processes. Notable techniques include:

-

Robotic Automation: The use of robotics in assembly lines not only speeds up the manufacturing process but also reduces human error. KHS has integrated robots for tasks such as palletizing and packaging, which increases throughput while maintaining precision.

-

Modular Design: The modular approach allows for the easy customization of systems based on client specifications. This flexibility is essential for addressing the diverse needs of B2B buyers, particularly those from varied international markets.

-

Digital Twin Technology: By utilizing digital twins, KHS can simulate manufacturing processes and equipment performance before actual production. This technology helps in identifying potential issues early in the design phase, thus saving time and resources.

How Does KHS USA Ensure Quality Control in Manufacturing?

Quality control is integral to KHS USA’s manufacturing process, ensuring that every piece of equipment meets rigorous standards. The company adheres to international standards such as ISO 9001, which focuses on quality management systems, and other industry-specific certifications like CE and API.

-

Quality Checkpoints: KHS implements multiple quality control checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet KHS’s specifications.

– In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor quality and performance. This proactive approach allows for immediate corrections if issues arise.

– Final Quality Control (FQC): Before equipment is shipped, final inspections are performed to ensure that all systems function correctly and meet customer requirements. -

Common Testing Methods: KHS employs a variety of testing methods, including:

– Functional Testing: Ensures that all systems operate according to specifications.

– Stress Testing: Assesses the durability and performance of equipment under extreme conditions.

– Compliance Testing: Verifies that products meet relevant industry standards and regulations.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, especially those from international markets like Africa, South America, the Middle East, and Europe, should take several steps to verify KHS USA’s quality control practices:

-

Audits: Conducting on-site audits can provide valuable insights into KHS’s manufacturing processes and quality assurance protocols. This allows buyers to assess compliance with industry standards and the effectiveness of quality control measures.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the results of various testing methods and inspections. This transparency can build trust and ensure that the supplier meets the buyer’s quality expectations.

-

Third-Party Inspections: Engaging third-party inspectors to evaluate the manufacturing facility can provide an unbiased assessment of KHS’s quality control measures. This is particularly important for buyers from regions with specific regulatory requirements.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must be aware of several nuances when it comes to quality control in the context of KHS USA:

-

Regulatory Compliance: Different regions may have varying standards and regulations. For instance, European buyers might require CE marking, while buyers from the Middle East may focus on compliance with local standards. Understanding these differences is crucial for ensuring that the purchased equipment meets local regulations.

-

Cultural Considerations: Building a strong relationship with suppliers may require understanding cultural nuances. For example, communication styles and negotiation approaches can vary significantly between regions. KHS’s commitment to customer orientation helps bridge these gaps, fostering collaboration.

-

Logistical Challenges: International shipping and logistics can introduce risks to product quality. KHS USA’s robust packaging and handling procedures are designed to minimize these risks, but buyers should also consider local conditions that may affect equipment performance upon arrival.

In conclusion, KHS USA in Waukesha employs a sophisticated manufacturing process backed by stringent quality control measures. For international B2B buyers, understanding these processes and standards is vital for making informed procurement decisions. By leveraging KHS’s commitment to quality and sustainability, buyers can ensure they receive reliable and efficient filling and packaging systems tailored to their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘khs usa waukesha’

Introduction

This practical sourcing guide aims to assist international B2B buyers in effectively procuring equipment and services from KHS USA, located in Waukesha, Wisconsin. By following this step-by-step checklist, you can ensure a streamlined purchasing process that meets your operational needs while fostering a reliable partnership with KHS.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for your project. This includes the type of filling and packaging systems you need, such as PET bottle manufacturing or can filling lines. Defining these specifications helps in aligning your needs with KHS’s offerings, ensuring you select equipment that optimally fits your production goals.

Step 2: Conduct Market Research

Investigate the current market landscape for KHS products and services. Look for industry trends, competitor offerings, and customer feedback on KHS equipment. This information will help you gauge the company’s market position and innovation capabilities, ensuring you make an informed decision.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet KHS USA thoroughly. Request detailed company profiles, case studies, and references from other clients, particularly those in your industry or geographical area. Understanding previous projects will provide insights into their reliability and customer service.

Step 4: Verify Certifications and Compliance

Check that KHS USA holds all necessary certifications and complies with industry standards. This is essential for ensuring that the equipment meets safety, quality, and environmental regulations relevant to your region. Look for certifications such as ISO, CE, or others that apply to your specific requirements.

Step 5: Request Quotes and Proposals

Once you have a clear understanding of your needs and potential suppliers, request detailed quotes and proposals from KHS USA. Ensure these documents outline pricing, delivery timelines, and support services. Comparing multiple proposals can highlight the best value for your investment.

Step 6: Assess After-Sales Support and Training

Evaluate the after-sales support and training programs offered by KHS USA. Effective training is crucial for ensuring your team can operate the new systems efficiently. Look for options that include on-site training, remote diagnostics, and ongoing technical support to maximize operational uptime.

Step 7: Negotiate Terms and Conditions

Engage in discussions to negotiate favorable terms and conditions. This includes payment options, warranty details, and maintenance agreements. Clear communication during this phase will help establish a strong foundation for your business relationship with KHS USA, ultimately leading to smoother transactions in the future.

By following this checklist, you can effectively navigate the procurement process for KHS USA in Waukesha, ensuring that you select the right equipment and services for your business needs.

Comprehensive Cost and Pricing Analysis for khs usa waukesha Sourcing

What Are the Key Cost Components for Sourcing from KHS USA in Waukesha?

When evaluating the costs associated with sourcing from KHS USA in Waukesha, several key components need to be taken into account. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

-

Materials: The cost of raw materials plays a crucial role in the overall pricing structure. KHS USA utilizes high-quality, durable materials to ensure the longevity and efficiency of their filling and packaging systems. Buyers should inquire about material specifications and potential alternative options that could reduce costs without sacrificing quality.

-

Labor: Labor costs are influenced by the complexity of the machinery and the expertise required for assembly and maintenance. KHS USA prides itself on employing skilled technicians, which can impact labor costs. Understanding the labor component helps in forecasting total expenditures.

-

Manufacturing Overhead: Overhead costs include utilities, rent, and administrative expenses. KHS USA’s efficient production processes can help minimize these costs, which are often factored into the final pricing.

-

Tooling: Investment in specialized tooling can be significant, especially for custom machinery. Buyers should consider the potential for amortization of these costs over the lifespan of the equipment.

-

Quality Control (QC): KHS USA’s commitment to quality means that robust QC processes are in place. While this may increase initial costs, it can lead to long-term savings through reduced downtime and maintenance.

-

Logistics: Shipping and handling costs are vital to consider, particularly for international buyers. The logistics cost will vary based on distance, shipping method, and any import duties applicable to the destination country.

-

Margin: KHS USA aims to maintain a competitive margin while providing high-quality products. Understanding the margin expectations can help buyers negotiate better terms.

What Influences Pricing for KHS USA Products?

Several factors can influence the pricing of KHS USA products, which international buyers should be aware of:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs. Buyers should explore bulk purchasing options to maximize cost efficiency.

-

Specifications and Customization: Tailored solutions may come with additional costs. It is essential to balance the need for customization with budget constraints.

-

Materials and Quality Certifications: The choice of materials and any associated certifications can impact pricing. Buyers should assess the importance of certifications in their markets to justify any additional costs.

-

Supplier Factors: The reliability and reputation of KHS USA as a supplier can influence pricing. Established suppliers may offer better terms based on their market position.

-

Incoterms: Understanding the chosen Incoterms (International Commercial Terms) is crucial for international transactions, as they define the responsibilities of buyers and sellers concerning shipping costs, risks, and insurance.

What Are the Best Negotiation Tips for International Buyers?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant savings:

-

Leverage Total Cost of Ownership (TCO): Focus on the long-term value rather than just the upfront costs. Highlighting the benefits of KHS USA’s efficient machinery can justify a higher initial investment.

-

Be Informed About Market Prices: Researching comparable products and pricing can provide leverage during negotiations.

-

Build Relationships: Establishing a good rapport with KHS USA can lead to better terms and conditions.

-

Explore Payment Terms: Discussing flexible payment options can help manage cash flow effectively.

-

Stay Open to Alternative Solutions: Be willing to consider alternative products or configurations that could meet your needs at a lower cost.

Disclaimer on Pricing

Prices for KHS USA products can vary significantly based on the factors mentioned above. It is advisable for buyers to contact KHS USA directly to obtain a tailored quote that reflects their specific requirements and circumstances.

Alternatives Analysis: Comparing khs usa waukesha With Other Solutions

When considering the right filling and packaging solutions, it’s crucial to evaluate various alternatives to ensure that the chosen technology aligns with business objectives and operational requirements. KHS USA Waukesha is a prominent player in the beverage industry, known for its innovative filling and packaging systems. However, other solutions may offer distinct advantages depending on specific needs, such as cost, ease of integration, and maintenance requirements.

Comparison Table

| Comparison Aspect | KHS USA Waukesha | Alternative 1: SIG Combibloc | Alternative 2: Tetra Pak |

|---|---|---|---|

| Performance | High efficiency and reliability in filling and packaging processes. | Excellent for aseptic filling and packaging with a focus on sustainability. | Strong in liquid food packaging, with a wide range of formats. |

| Cost | Premium pricing, justified by high quality and advanced technology. | Competitive pricing with a focus on cost-effective solutions. | Premium pricing, but offers long-term savings through durability and efficiency. |

| Ease of Implementation | Requires significant setup time and training for staff. | Moderate setup with user-friendly systems, shorter training times. | Moderate to high setup time, but robust support and training available. |

| Maintenance | Comprehensive service contracts available, but can be complex. | Low maintenance with readily available parts and support. | Requires regular maintenance; however, Tetra Pak offers extensive service support. |

| Best Use Case | Ideal for large-scale beverage producers requiring high output. | Best for companies focusing on sustainability in packaging. | Suitable for diverse industries, including dairy and juice producers, needing versatile packaging solutions. |

What Are the Advantages and Disadvantages of SIG Combibloc?

SIG Combibloc is recognized for its innovative aseptic packaging technology, which is particularly advantageous for companies focused on sustainability and reducing waste. Its systems allow for long shelf-life products without refrigeration, which can be a game-changer in regions with limited cold chain logistics. However, while the initial investment can be lower than KHS USA, the complexity of some systems may require additional training and support, which could offset initial savings.

How Does Tetra Pak Compare in Terms of Versatility?

Tetra Pak is a leader in the liquid food packaging sector, providing a wide array of packaging formats tailored to specific needs. Its solutions are particularly effective for products that require extended shelf life and have stringent hygiene requirements, making it a strong choice for dairy and juice producers. The downside is that Tetra Pak often comes with a premium price tag and may require more frequent maintenance to ensure optimal performance.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting a filling and packaging solution, B2B buyers should carefully assess their operational needs and strategic objectives. Factors such as production scale, budget constraints, and the desired sustainability impact should guide decision-making. KHS USA Waukesha excels in high-efficiency systems for large-scale operations, while alternatives like SIG Combibloc and Tetra Pak may provide more cost-effective and versatile solutions for specific markets. Ultimately, the right choice will depend on aligning the technology’s strengths with the buyer’s unique requirements and long-term goals.

Essential Technical Properties and Trade Terminology for khs usa waukesha

What Are the Key Technical Properties of KHS USA Waukesha Products?

When considering KHS USA Waukesha’s offerings, several critical technical properties are essential for B2B buyers to understand. These specifications not only dictate the performance of the equipment but also influence operational efficiency and cost-effectiveness in production.

-

Material Grade

– Definition: Material grade refers to the type of materials used in manufacturing KHS equipment, including stainless steel, aluminum, and specialized plastics.

– Importance: The choice of material affects durability, resistance to corrosion, and maintenance needs. High-grade materials ensure longer equipment life and lower replacement costs, which are crucial for maintaining production lines in the beverage industry. -

Tolerance Levels

– Definition: Tolerance levels indicate the acceptable limits of variation in the dimensions of components.

– Importance: Precise tolerances are vital for ensuring that machinery parts fit together seamlessly, reducing wear and tear and minimizing downtime. In high-speed production environments, even small deviations can lead to inefficiencies and increased costs. -

Production Capacity

– Definition: This refers to the maximum output that KHS systems can achieve, typically measured in bottles or cans per minute.

– Importance: Understanding production capacity helps buyers assess whether the equipment can meet their operational demands. Higher capacity often translates to better economies of scale and reduced per-unit production costs. -

Energy Efficiency Ratings

– Definition: Energy efficiency ratings measure the energy consumption of KHS machinery compared to industry standards.

– Importance: Efficient equipment reduces operational costs and aligns with sustainability goals, which are increasingly important in global markets. Buyers can leverage energy savings as a competitive advantage in their respective industries. -

Automation Features

– Definition: Automation features encompass the use of advanced technologies such as robotics and digital interfaces in KHS systems.

– Importance: Automation enhances productivity, consistency, and safety in production processes. It also allows for remote diagnostics and maintenance, reducing the need for on-site interventions and enhancing overall efficiency.

What Are Common Trade Terms Relevant to KHS USA Waukesha?

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B landscape. Here are several key terms relevant to KHS USA Waukesha:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: KHS USA often operates as an OEM, providing machinery that other brands utilize under their name. Understanding this term helps buyers recognize the quality and reliability associated with KHS products. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ is critical for budget planning and inventory management. Buyers must ensure that their order aligns with these requirements to avoid extra costs. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document issued by a buyer to request pricing and terms from suppliers.

– Relevance: Submitting an RFQ to KHS USA allows buyers to obtain detailed quotes for specific machinery or services, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law.

– Relevance: Understanding Incoterms is essential for buyers involved in international transactions, as these terms define responsibilities regarding shipping, insurance, and tariffs. -

Lead Time

– Definition: Lead time is the period between the initiation of an order and its completion.

– Relevance: Knowing the lead time for KHS equipment helps buyers plan their production schedules effectively and avoid disruptions in their supply chain.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when engaging with KHS USA Waukesha, ultimately leading to more successful partnerships and optimized operational performance.

Navigating Market Dynamics and Sourcing Trends in the khs usa waukesha Sector

What Are the Current Market Dynamics and Key Trends Affecting KHS USA Waukesha?

The global beverage industry is experiencing transformative changes driven by consumer preferences, technological advancements, and sustainability imperatives. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. The trend towards smaller, single-serve products is reshaping packaging strategies, as evidenced by KHS USA’s recent acquisition of Scandia Packaging Machinery. This move enhances their capacity to deliver compact cartoning solutions, catering to the rising demand for convenient packaging.

Digitalization is another key trend, with manufacturers increasingly adopting smart technologies to enhance operational efficiency. KHS USA’s innovations, such as remote diagnostic services and digital service platforms, enable clients to optimize production lines while reducing downtime. Additionally, the shift towards automation in manufacturing processes is gaining traction, allowing companies to improve productivity and reduce labor costs.

Emerging markets are also becoming significant players in the beverage sector. As consumption patterns evolve, buyers in regions like Africa and South America are looking for adaptable and scalable solutions that can cater to diverse market needs. KHS USA’s commitment to providing flexible and future-proof filling and packaging systems positions them as a strategic partner for businesses aiming to navigate these market shifts effectively.

How Is Sustainability Influencing Sourcing Trends at KHS USA Waukesha?

Sustainability is no longer just a buzzword; it is a fundamental aspect of the beverage industry’s sourcing strategies. For B2B buyers, the environmental impact of packaging and production processes is becoming increasingly important. KHS USA emphasizes sustainable practices, focusing on reducing carbon footprints through innovations like the Nature MultiPack, which significantly lowers CO2 emissions.

Ethical sourcing is also gaining traction, with businesses seeking suppliers who adhere to environmentally responsible practices. KHS USA’s commitment to using recyclable materials and developing lightweight packaging solutions exemplifies a proactive approach to sustainability. Certifications such as EcoVadis gold rating further bolster their credibility, assuring international buyers that they are partnering with a responsible manufacturer.

Moreover, the emphasis on circular economy principles is reshaping sourcing decisions. KHS USA’s initiatives to utilize recycled PET and develop refillable packaging options align with global sustainability goals, making them an appealing choice for businesses prioritizing eco-friendly practices. For buyers in regions like Europe and the Middle East, where regulatory frameworks increasingly favor sustainable solutions, KHS USA’s offerings provide a competitive edge.

What Is the Evolution of KHS USA Waukesha in the Beverage Industry?

KHS USA, part of the globally recognized KHS Group, has established a strong foothold in the beverage industry since its inception. Founded in Waukesha, Wisconsin, the company has evolved from a regional manufacturer to a leader in filling and packaging systems on an international scale. This growth trajectory has been marked by continuous innovation and strategic acquisitions, including the recent purchase of Scandia Packaging Machinery, which enhances their portfolio in compact packaging solutions.

Throughout its history, KHS USA has remained committed to quality and customer-centric service, ensuring that it meets the evolving needs of its clients across diverse markets. The company’s emphasis on technological advancements, sustainability, and ethical sourcing positions it well for future growth, particularly as global demands for more efficient and environmentally responsible beverage solutions continue to rise.

Frequently Asked Questions (FAQs) for B2B Buyers of khs usa waukesha

-

1. How do I ensure reliable supply when sourcing from KHS USA in Waukesha?

To ensure a reliable supply from KHS USA, it’s crucial to establish clear communication and define your expectations upfront. Engage in discussions regarding production timelines, lead times, and inventory levels. Consider setting up a service-level agreement (SLA) that outlines delivery schedules and quality standards. Regular check-ins and updates on order status can help mitigate any potential disruptions. Additionally, leveraging KHS’s extensive experience in the beverage industry can provide insights into best practices for managing supply chain efficiency. -

2. What is the best packaging solution for my beverage product from KHS USA?

The best packaging solution for your beverage product depends on various factors, including the type of beverage, target market, and sustainability goals. KHS USA offers a wide range of innovative filling and packaging systems tailored to different beverage types, such as soft drinks, beer, and juices. Consider solutions like the InnoPET TriBlock for PET bottles or Nature MultiPack for environmentally friendly packaging. Engaging with KHS’s experts can help you identify the most suitable options that align with your product’s requirements and market trends. -

3. What customization options are available for KHS machinery?

KHS USA provides extensive customization options to meet the specific needs of your production line. This includes tailored machinery configurations, specialized features, and adjustments to fit unique production volumes or packaging types. During the initial consultation, you can discuss your operational requirements, and KHS will collaborate with you to develop a customized solution. Additionally, KHS offers retrofit systems, allowing you to upgrade existing equipment for enhanced performance and flexibility. -

4. What are the minimum order quantities (MOQ) for KHS equipment?

Minimum order quantities (MOQ) for KHS equipment can vary depending on the type of machinery and specific configurations required. For large-scale production lines, MOQs may be higher due to the complexity and customization involved. It’s advisable to discuss your production needs directly with KHS representatives to understand the MOQ applicable to your order. They can provide insights into bulk purchasing benefits and potential cost savings for larger orders. -

5. What payment terms can I expect when working with KHS USA?

Payment terms with KHS USA may vary based on the size of the order and the nature of the agreement. Generally, payment structures can include a combination of upfront deposits, milestone payments during the production process, and final payment upon delivery. For international buyers, options like letters of credit or bank guarantees may be available. It’s recommended to clarify payment terms during negotiations to align expectations and ensure a smooth transaction. -

6. How does KHS ensure quality assurance for their equipment?

KHS employs rigorous quality assurance processes to ensure that all equipment meets industry standards and client specifications. This includes comprehensive testing at various stages of manufacturing, including performance testing and adherence to safety regulations. Additionally, KHS offers maintenance services and support contracts to help clients maintain equipment performance over time. Engaging in quality assurance discussions during the procurement process can provide further confidence in the machinery’s reliability and longevity. -

7. What logistics support does KHS offer for international shipping?

KHS provides comprehensive logistics support to facilitate international shipping of their equipment. This includes assistance with customs documentation, freight forwarding, and delivery coordination to your facility. They work with established logistics partners to ensure timely and efficient delivery of machinery. It is advisable to discuss your shipping requirements during the order placement phase to ensure all logistical considerations are addressed, including any specific import regulations for your country. -

8. How can I access training and support for KHS equipment?

KHS offers extensive training and support services for clients to ensure optimal use of their equipment. This includes on-site training sessions, virtual training programs via KHS Campus, and access to technical support for troubleshooting. Clients can schedule training sessions tailored to their operational needs, which can be particularly beneficial for staff onboarding or when introducing new machinery. Establishing a relationship with KHS support teams will enhance your operational efficiency and ensure best practices in equipment usage.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for khs usa waukesha

In the dynamic landscape of beverage manufacturing, KHS USA Waukesha stands out as a beacon of innovation and reliability. By strategically sourcing state-of-the-art filling and packaging technologies, businesses can not only enhance operational efficiency but also significantly reduce their carbon footprint. KHS’s commitment to sustainability, as exemplified by their energy-efficient systems and recyclable packaging solutions, positions them as a valuable partner for companies aiming to meet increasing consumer demands for eco-friendly practices.

International buyers from Africa, South America, the Middle East, and Europe should consider KHS USA not just for its advanced machinery but for its holistic approach to customer collaboration. The recent acquisition of Scandia Packaging Machinery underscores KHS’s dedication to expanding its portfolio, allowing clients to tap into the growing market for compact and sustainable packaging solutions.

As you explore opportunities with KHS USA Waukesha, remember that strategic sourcing is not merely a procurement function; it is a pathway to long-term value creation. Engage with KHS to discover tailored solutions that can elevate your operational capabilities and market presence. The future of beverage production is here—take the next step towards innovation and sustainability.