Top Companies in Polynt Composites USA Inc Industry

Are you struggling to find the right manufacturer for your polynt composites needs? With so many options out there, choosing a supplier can feel overwhelming. But fear not—this guide is here to help you navigate the landscape of Polynt Composites USA Inc factories. Imagine partnering with a top-tier manufacturer that not only meets your quality standards but also enhances your production efficiency. The right choice can lead to superior products, reduced costs, and a smoother workflow.

Ready to discover the cream of the crop? Dive into our comparison of the top 30 Polynt composites manufacturers and unlock the potential for your business today!

Top 13 Polynt Composites Usa Inc Manufacturers

Polynt – Chemical Composites Solutions

Host2 – Composite Resins and Coating Solutions

Domain: host2.polyntusa.com

Registered: 2011 ( 14 years )

Introduction: The company offers a wide range of products including gel coats, composite resins, industrial cleaners, coating resins, and total composite design solutions.

Start – Industrial Organic Chemicals Solutions

Manta – Composite Materials and Resins Solutions

Domain: manta.com

Registered: 2004 ( 21 years )

Introduction: Polynt Composites USA Inc. primarily offers a range of composite materials including unsaturated polyester resins, vinyl ester resins, and gel coats.

Polynt Composites – Composite Materials Manufacturer

Domain: chamberofcommerce.com

Registered: 1997 ( 28 years )

Introduction: Polynt Composites USA Inc. specializes in manufacturing and supplying a wide range of composite materials, including unsaturated polyester resins, vinyl ester resins, and gel coats.

Polynt Composites – Advanced Composite Materials Solutions

Domain: business.dpchamber.org

Registered: 2001 ( 24 years )

Introduction: Polynt Composites USA Inc. primarily offers a range of composite materials, including resins and additives for various applications in industries such as automotive, construction, and marine.

The Blue Book – Construction Industry Networking Solutions

Incfact – In-Mold Gel Coatings and Resins

Domain: incfact.com

Registered: 2015 ( 10 years )

Introduction: Polynt Composites USA primarily offers in-mold gel coatings and synthetic resins used in the manufacturing of composite materials, including fiberglass products.

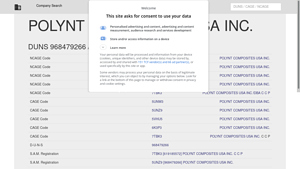

Panjiva – Organic and Inorganic Chemical Solutions

Domain: panjiva.com

Registered: 2006 ( 19 years )

Introduction: Polynt Composites USA Inc. primarily offers a range of organic and inorganic chemicals, including purified isophthalic acid, phthalic anhydride, and trimellitic anhydride.

Frs Public – Plastics and Synthetic Resins Solutions

Domain: frs-public.epa.gov

Registered: 1997 ( 28 years )

Introduction: Reichhold LLC 2 primarily offers products related to plastics materials, synthetic resins, and nonvulcanizable elastomers.

Cage – Composite Materials Solutions

Polynt – Specialty Chemicals Solutions

Govcb – Plastics Materials and Resins Manufacturer

Domain: govcb.com

Registered: 2004 ( 21 years )

Introduction: POLYNT COMPOSITES USA INC. specializes in the manufacturing of plastics materials and resins.

Category Information

Polynt Composites USA Inc. operates within the composites industry, which focuses on the development and manufacturing of composite materials. Composites are materials made from two or more constituent substances that, when combined, exhibit enhanced properties compared to their individual components. This category includes various materials such as fiberglass, carbon fiber, and resin systems, which are widely used in sectors like aerospace, automotive, construction, and marine.

The significance of the composites industry lies in its ability to produce lightweight, durable, and versatile materials that improve performance and efficiency in various applications. As industries increasingly prioritize sustainability and energy efficiency, composite materials play a critical role in reducing weight and enhancing fuel efficiency in transportation, while also providing robust solutions for infrastructure and construction. Companies like Polynt Composites USA Inc. are essential in driving innovation and meeting the growing demand for advanced materials in a competitive market.

Application Information

Polynt Composites USA Inc. specializes in the production of resins and composite materials, which find application across various industries. One key area is the automotive sector, where lightweight and durable composite materials are utilized to enhance fuel efficiency and reduce emissions in vehicle manufacturing. Another significant application is in the construction industry, where Polynt’s products are used in building materials, such as reinforced concrete and insulation, contributing to energy efficiency and structural integrity.

Additionally, the marine industry benefits from these composites, which are employed in boat manufacturing for their resistance to corrosion and lightweight properties. Furthermore, the aerospace sector uses these advanced materials for their high strength-to-weight ratio, essential for aircraft design and performance. Finally, consumer goods such as sporting equipment and electronics also incorporate Polynt’s composites for their durability and aesthetic appeal. These applications highlight the versatility and importance of Polynt’s products in enhancing performance and sustainability across multiple industries.

Production Process Information

Polynt Composites USA Inc. specializes in producing advanced composite materials used in various industries, such as automotive, aerospace, and construction. The production process typically involves several key stages. First, raw materials are sourced, including resins, additives, and reinforcements like fiberglass or carbon fiber. These materials are then mixed and formulated to create a composite material tailored for specific applications.

Next, the composite mixture is shaped using techniques like molding or extrusion, where it is formed into the desired parts or products. After shaping, the materials undergo curing, a process that hardens the composite, ensuring durability and strength. Finally, quality control checks are performed to ensure that the finished products meet industry standards before they are packaged and shipped to customers. This careful process ensures that Polynt’s products are reliable and high-performing in their respective applications.

Related Video

Frequently Asked Questions (FAQs)

What should I consider when looking for a polynt composites manufacturer?

When searching for a polynt composites manufacturer, consider factors such as their experience in the industry, production capabilities, and the range of products they offer. It’s also important to look into their quality control processes and certifications, as well as their ability to meet your specific requirements. Additionally, assess their customer service and communication practices to ensure a smooth working relationship.

How can I verify the reputation of a polynt composites supplier?

To verify the reputation of a polynt composites supplier, start by reading customer reviews and testimonials on their website and third-party platforms. You can also ask for references from other businesses that have worked with them. Networking within industry forums or attending trade shows can provide insights into their standing in the market. Don’t hesitate to reach out to past clients to get firsthand experiences.

What types of products can I expect from polynt composites manufacturers?

Polynt composites manufacturers typically offer a wide range of products, including resins, gel coats, and various composite materials for different applications. These can be used in industries like automotive, marine, construction, and aerospace. Make sure to inquire specifically about the types of composites they specialize in and whether they can customize products to suit your needs.

How do I assess the quality of products from a polynt composites factory?

Assessing the quality of products from a polynt composites factory involves requesting samples to evaluate their performance and durability. Look for manufacturers that adhere to industry standards and certifications, which can be a good indicator of quality. Additionally, ask about their testing processes and quality assurance practices to ensure that their products meet your specifications.

What is the typical lead time for orders from polynt composites suppliers?

The lead time for orders from polynt composites suppliers can vary based on factors like order size, product complexity, and the manufacturer’s current workload. Generally, it’s a good idea to discuss lead times upfront during your initial conversations. Most suppliers will provide estimated timelines, and it’s wise to factor in some extra time for any unforeseen delays to ensure your project stays on track.